Abstract

At present, reducing carbon emissions and energy consumption have become the most crucial ironmaking development objectives. Hot metallurgical off-gas (MOG) is one of the most valuable by-product resources containing great underutilized heat and recyclable gas. A sustainable strategy of reinjecting hot MOG as one of the raw materials into the Cr-bearing vanadiferous titanomagnetite ore (CVTO) blast furnace (BF) to achieve its recovery and reuse was proposed and investigated in this study. It is considered feasible according to the obtained results of heat-carbon balance calculations and softening–melting–dripping experiments. First, hot MOG reinjection was beneficial to ameliorate the industrial smelting index and reduce carbon emission and consumption. With the CO2 in the hot MOG increased from 0 to 30 vol%, the softening zone increased from 11 to 135 °C, the dripping temperature increased from 1486 to 1534 °C, and the melting–dripping zone increased from 150 to 198 °C, and it could reduce a considerable carbon rate of 17.2 kg-C/t-Fe. Besides, it could suppress the generation of titanium carbonitride in Ti compounds with a remarkable decrease from 14.4 to 11.9 wt%. Besides, it also improved the high-temperature properties of the titania slag. The melting temperature of the titania slag decreased from 1348.2 to 1331.2 °C, and its surface tension increased from 0.302 to 0.551 N/m. Moreover, the corrected viscosity of TiN-bearing slag was calculated, and it showed a profitable decrease from 0.433 to 0.414 Pa·s at 1500 °C. In addition, the high-basicity pellet was used to replace the conventional sinter in the above experiments, which was conducive to achieve energy saving and emission reduction in practical applications.

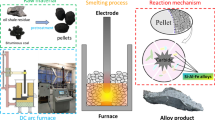

Graphical Abstract

Similar content being viewed by others

References

Chen QQ, Gu Y, Tang ZY, Wei W, Sun YH (2018) Assessment of low-carbon iron and steel production with CO2 recycling and utilization technologies: a case study in China. Appl Energy 220:192–207. https://doi.org/10.1016/j.apenergy.2018.03.043

Chen W, Yin X, Ma D (2014) A bottom-up analysis of China’s iron and steel industrial energy consumption and CO2 emissions. Appl Energy 136:1174–1183. https://doi.org/10.1016/j.apenergy.2014.06.002

Wen Z, Meng F, Chen M (2014) Estimates of the potential for energy conservation and CO2 emissions mitigation based on Asian-Pacific Integrated Model (AIM): the case of the iron and steel industry in China. J Clean Prod 65:120–130. https://doi.org/10.1016/j.jclepro.2013.09.008

Zhang W, Stern D, Liu X, Cai W, Wang C (2017) An analysis of the costs of energy saving and CO2 mitigation in rural households in China. J Clean Prod 165:734–745. https://doi.org/10.1016/j.jclepro.2017.07.172

Zhang Q, Li Y, Xu J, Jia GY (2018) Carbon element flow analysis and CO2 emission reduction in iron and steel works. J Clean Prod 172:709–723. doi;https://doi.org/10.1016/j.jclepro.2017.10.211

Rammer B, Millner R, Boehm C (2017) Comparing the CO2 emissions of different steelmaking routes. BHM 162:7–13. https://doi.org/10.1007/s00501-016-0561-8

Zhang Z, Wang T, Blunt MJ, Anthony EJ, Park A-HA, Hughes RW, Webley PA, Yan J (2020) Advances in carbon capture, utilization and storage. Appl Energy 278:115627. https://doi.org/10.1016/j.apenergy.2020.115627

Nocito F, Dibenedetto A (2020) Atmospheric CO2 mitigation technologies: carbon capture utilization and storage. Curr Opin Green Sust 21:34–43. https://doi.org/10.1016/j.cogsc.2019.10.002

Bae J, Chung Y, Lee J, Seo H (2020) Knowledge spillover efficiency of carbon capture, utilization, and storage technology: a comparison among countries. J Clean Prod 246:119003. https://doi.org/10.1016/j.jclepro.2019.119003

Khoo Z-Y, Ho EHZ, Li Y, Yeo Z, Low JSC, Bu J, Chia LSO (2021) Life cycle assessment of a CO2 mineralisation technology for carbon capture and utilisation in Singapore. J CO2 Util 44:101378. doi:https://doi.org/10.1016/j.jcou.2020.101378

Wilberforce T, Olabi AG, Sayed ET, Elsaid K, Abdelkareem MA (2021) Progress in carbon capture technologies. Sci Total Environ 761:143203. https://doi.org/10.1016/j.scitotenv.2020.143203

Neeraj YS (2020) Carbon storage by mineral carbonation and industrial applications of CO2. Mater Sci Energy Technol 3:494–500. https://doi.org/10.1016/j.mset.2020.03.005

Gutknecht V, Snæbjörnsdóttir SÓ, Sigfússon B, Aradóttir ES, Charles L (2018) Creating a carbon dioxide removal solution by combining rapid mineralization of CO2 with direct air capture. Energy Procedia 146:129–134. https://doi.org/10.1016/j.egypro.2018.07.017

Chung W, Roh K, Lee JH (2018) Design and evaluation of CO2 capture plants for the steelmaking industry by means of amine scrubbing and membrane separation. Int J Greenh Gas Con 74:259–270. https://doi.org/10.1016/j.ijggc.2018.05.009

Zhang S, Zhuang Y, Liu L, Zhang L, Du J (2020) Optimization-based approach for CO2 utilization in carbon capture, utilization and storage supply chain. Comput Chem Eng 139:106885. https://doi.org/10.1016/j.compchemeng.2020.106885

Yang Y, Zhang Q, Yu H, Feng X (2021) Tech-economic and environmental analysis of energy-efficient shale gas and flue gas coupling system for chemicals manufacture and carbon capture storage and utilization. Energy 217:119348. https://doi.org/10.1016/j.energy.2020.119348

Zhu R (2019) Theory and practice of carbon dioxide steelmaking. Science Press, Beijing

Wang H, Zhu R, Wang X, Li Z (2017) Utilization of CO2 in metallurgical processes in China. Min Proc Ext Met 126:47–53. https://doi.org/10.1080/03719553.2016.1255401

Xue XX, Yang ST, Zhang Y (2020) Blast furnace process smelting chromium-containing vanadia-titania magnetite: theory and practice. Science Press, Beijing

Song HL, Zhang JP, Cheng GJ, Yang ST, Xue XX (2021) CO2 injection improves the high-temperature performances of Cr-bearing vanadia-titania magnetite smelting in blast furnace. J CO2 Util 43:23. doi:https://doi.org/10.1016/j.jcou.2020.101363

Song HL, Zhang JP, Cheng GJ, Yang ST, Xue XX (2020) The Effect of Abandoned Basic Oxygen Furnace Gas Blowing on the Softening-Melting-Dripping Performance of Full High Cr-Bearing Vanadia-Titania Magnetite Pellets. Steel Res Int. doi:https://doi.org/10.1002/srin.201900501

Song HL, Zhang JP, Cheng GJ, Yang ST, Xue XX (2020) Study on the high-temperature properties of high-titania slags produced with Cr-bearing vanadia-titania magnetite smelting in blast furnace. Surf Interfaces. doi:https://doi.org/10.1016/j.surfin.2020.100767

Cheng GJ, Xue XX, Jiang T, Duan PN (2016) Effect of TiO2 on the crushing strength and smelting mechanism of high-chromium vanadium-titanium magnetite pellets. Metall Mater Trans B 47:1713–1726. https://doi.org/10.1007/s11663-016-0628-7

Du HG (1996) Principle of smelting vanadium-titanium magnetite. Science Press, Beijing

Zhao W, Chu MS, Wang HT, Liu ZG, Tang YT (2016) Novel blast furnace operation process involving charging with low-titanium vanadium-titanium magnetite carbon composite hot briquette. Int J Min Met Mater 23:501–510. doi:https://doi.org/10.1007/s12613-016-1261-9

Sunahara K, Natsui T, Shizawa K, Ujisawa Y (2011) Effect of coke reactivity on sinter softening-melting property by simultaneous evaluation method of carbonaceous and ferrous burdens in blast furnace. Isij Int 51:1322–1332. doi:https://doi.org/10.2355/isijinternational.51.1322

Nandy B, Chandra S, Bhattacharjee D, Ghosh D (2006) Assessment of blast furnace behaviour through softening-melting test. Ironmak Steelmak 33:111–119. doi:https://doi.org/10.1179/174328106X94744

Qie YN, Lyu Q, Liu XJ, Li JP, Lan CC, Zhang SH, Yan CJ (2018) Effect of hydrogen addition on softening and melting reduction behaviors of ferrous burden in gas-injection blast furnace. Metall Mater Trans B 49:2622–2632. doi:https://doi.org/10.1007/s11663-018-1299-3

Ueda S, Kon T, Miki T, Kim SJ, Nogami H (2016) Effects of Al2O3 and MgO on softening, melting, and permeation properties of CaO-FeO-SiO2 on a coke bed. Metall Mater Trans B 47:2371–2377. https://doi.org/10.1007/s11663-016-0683-0

An XW, Wang JS, Lan RZ, Han YH, Xue QG (2013) Softening and melting behavior of mixed burden for oxygen blast furnace. J Iron Steel Res Int 20:11–16. doi;https://doi.org/10.1016/S1006-706X(13)60090-4

Liu JX, Cheng GJ, Liu ZG, Chu MS, Xue XX (2015) Softening and melting properties of different burden structures containing high chromic vanadium titano-magnetite. Int J Miner Process 142:113-118. doi;https://doi.org/10.1016/j.minpro.2015.04.020

Chen DS, Song B, Wang LN, Qi T, Wang Y, Wang WJ (2011) Solid state reduction of Panzhihua titanomagnetite concentrates with pulverized coal. Miner Eng 24:864–869. https://doi.org/10.1016/j.mineng.2011.03.018

Liu ZG, Chu MS, Wang HT, Zhao W, Xue XX (2016) Effect of MgO content in sinter on the softening-melting behavior of mixed burden made from chromium-bearing vanadium-titanium magnetite. Int J Min Met Mater 23:25–32. https://doi.org/10.1007/s12613-016-1207-2

Li TL, Sun CY, Lan D, Song J, Song S, Wang Q (2019) Effect of mineral elements migration on softening-melting properties of Ti-bearing high basicity sinter. Isij Int 59:245–252. https://doi.org/10.2355/isijinternational.ISIJINT-2018-498

Zhou Y, Liu J, Cheng G, Xue X, Yang H (2021) Carbothermal reduction followed by sulfuric acid leaching of Bayan Obo tailings for selective concentration of iron and rare earth metals. Separ Purif Technol 271:118742. https://doi.org/10.1016/j.seppur.2021.118742

Xiang JY, Wang J, Li QJ, Shan C, Qiu GB, Yu WZ, Lv XW (2020) Slag-foaming phenomenon originating from reaction of titanium-bearing blast furnace slag: effects of TiO2 content and basicity. Can Metall Quart 59:151–158. https://doi.org/10.1080/00084433.2020.1715696

Li QH, Yang SF, Zhang YL, An ZQ, Guo ZC (2017) Effects of MgO, Na2O, and B2O3 on the viscosity and structure of Cr2O3-bearing CaO-SiO2-Al2O3 slags. Isij Int 57:689–696. https://doi.org/10.2355/isijinternational.ISIJINT-2016-569

Yue HR, He ZW, Jiang T, Duan PN, Xue XX (2018) Rheological evolution of Ti-bearing slag with different volume fractions of TiN. Metall Mater Trans B 49:2118–2127. https://doi.org/10.1007/s11663-018-1280-1

Acknowledgements

The research was financially supported by the National Natural Science Foundation of China (Grant No. 51674084, No. ZX20200031, and No. 2017YFB0304304), and special thanks are due to the instrumental or data analysis from Analytical and Testing Center, Northeastern University.

Author information

Authors and Affiliations

Contributions

HS: Data curation, Formal analysis, Visualization, Writing—original draft, Writing—review & editing. JZ: Data curation, Software, Writing—review & editing. GC & ZG: Writing—review & editing, Supervision. XX: Conceptualization, Funding acquisition, Investigation, Project administration, Resources, Supervision.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

The contributing editor for this article was Hiromichi Takebe.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Song, H., Zhang, J., Cheng, G. et al. Novel CO2 Recycling and Reuse Strategy: Reinjection of Hot Metallurgical Off-Gas Into A Vanadiferous Titanomagnetite Ore Blast Furnace. J. Sustain. Metall. 7, 1128–1142 (2021). https://doi.org/10.1007/s40831-021-00405-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40831-021-00405-8