Abstract

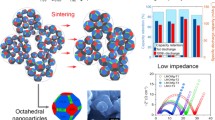

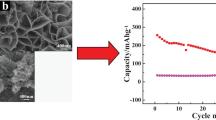

These days, innovative ideas in converting wastes to value-added materials are a solution for the fast-growing environment hazards of lithium-ion batteries (LIBs). The present paper introduces a novel method for synthesizing Co3S4 nano-powders from the pregnant leach solution (PLS) after acidic leaching of LIBs. For the first time, the cobalt along with nickel ions was selectively extracted from the PLS by a xanthate complex at room temperature. Then, the complex was washed with ammonia solution to obtain a pure cobalt complex. Finally, the complex was converted to uniform and pure nano-spheres of Co3S4 through a comparatively mild heat treatment (250 °C for 1 h). Characterization techniques (X-ray diffraction (XRD) and energy dispersive spectroscopy (EDS) analyses) revealed high purity of the nano-architectures. Thermal analysis (TG-DSC) also confirmed the single phase of pure Co3S4 nano-articles, while the mean particle sizes were obtained 48 nm and 40 ± 2 nm using XRD and transmission electron microscopy (TEM) analyses, respectively. Plus, the presence of high specific surface area (36.42 m2/g) using BET analysis for this nano-powder is in complete agreement with the electrochemical studies in which a relatively high insertion peaks (1.14 V) were observed for the first cycle of cyclic voltammetry and (1.00 V) for the seventh cycle (equilibrium cycle). Finally, we believe that the presented approach and its results can open up new avenues to the recycling industry of LIBs.

Graphical Abstract

Similar content being viewed by others

References

Granata G, Moscardini E, Pagnanelli F, Trabucco F, Toro L (2012) Product recovery from Li-ion battery wastes coming from an industrial pre-treatment plant: lab scale tests and process simulations. J Power Sources 206:393–401

Pavón S, Kaiser D, Mende R, Bertau M (2021) The COOL-process—a selective approach for recycling lithium batteries. Metals 11(2):259

Chagnes A, Pospiech B (2013) A brief review on hydrometallurgical technologies for recycling spent lithium-ion batteries. J Chem Technol Biotechnol 88(7):1191–1199

Miao Y, Hynan P, von Jouanne A, Yokochi A (2019) Current Li-ion battery technologies in electric vehicles and opportunities for advancements. Energies 12(6):1074

Scrosati B, Garche J (2010) Lithium batteries: status, prospects and future. J Power Sources 195(9):2419–2430

Zeng X, Li J, Ren Y (2012) Prediction of various discarded lithium batteries in China. In: 2012 IEEE International Symposium on Sustainable Systems and Technology (ISSST), 2012. IEEE, pp 1–4

Meshram P, Pandey B (2019) Perspective of availability and sustainable recycling prospects of metals in rechargeable batteries—a resource overview. Resour Policy 60:9–22

Winslow KM, Laux SJ, Townsend TG (2018) A review on the growing concern and potential management strategies of waste lithium-ion batteries. Resour Conserv Recycl 129:263–277

Shi H, Zhang Y, Dong P, Huang X, He J, Duan J, Wang D, Zhang Y (2020) A facile strategy for recovering spent LiFePO4 and LiMn2O4 cathode materials to produce high performance LiMnxFe1−xPO4/C cathode materials. Ceram Int 46(8, Part B):11698–11704

Xu J, Thomas H, Francis RW, Lum KR, Wang J, Liang B (2008) A review of processes and technologies for the recycling of lithium-ion secondary batteries. J Power Sources 177(2):512–527

Zhang W, Xu C, He W, Li G, Huang J (2018) A review on management of spent lithium ion batteries and strategy for resource recycling of all components from them. Waste Manage Res 36(2):99–112

Pinegar H, Smith YR (2019) Recycling of end-of-life lithium ion batteries, Part I: commercial processes. J Sustain Metall 5:402–416. https://doi.org/10.1007/s40831-019-00235-9

Pinegar H, Smith YR (2020) Recycling of end-of-life lithium-ion batteries, Part II: laboratory-scale research developments in mechanical, thermal, and leaching treatments. J Sustain Metall 6:142–160

Porvali A, Ojanen S, Wilson BP, Serna-Guerrero R, Lundström M (2020) Nickel metal hydride battery waste: mechano-hydrometallurgical experimental study on recycling aspects. J Sustain Metall 6(1):78–90

Yang Y, Xu S, He Y (2017) Lithium recycling and cathode material regeneration from acid leach liquor of spent lithium-ion battery via facile co-extraction and co-precipitation processes. Waste Manage 64:219–227

Lv W, Wang Z, Cao H, Sun Y, Zhang Y, Sun Z (2018) A critical review and analysis on the recycling of spent lithium-ion batteries. ACS Sustain Chem Eng 6(2):1504–1521

Sun L, Qiu K (2011) Vacuum pyrolysis and hydrometallurgical process for the recovery of valuable metals from spent lithium-ion batteries. J Hazard Mater 194:378–384

Nan J, Han D, Zuo X (2005) Recovery of metal values from spent lithium-ion batteries with chemical deposition and solvent extraction. J Power Sources 152:278–284

Nayaka G, Zhang Y, Dong P, Wang D, Zhou Z, Duan J, Li X, Lin Y, Meng Q, Pai K (2019) An environmental friendly attempt to recycle the spent Li-ion battery cathode through organic acid leaching. J Environ Chem Eng 7(1):

Zhang B, Xie H, Lu B, Chen X, Xing P, Qu J, Song Q, Yin H (2019) A green electrochemical process to recover Co and Li from spent LiCoO2-based batteries in molten salts. ACS Sustain Chem Eng 7(15):13391–13399

Diaz LA, Strauss ML, Adhikari B, Klaehn JR, McNally JS, Lister TE (2020) Electrochemical-assisted leaching of active materials from lithium ion batteries. Resour Conserv Recycl 161:

Pegoretti V, Dixini P, Magnago L, Rocha A, Lelis M, Freitas M (2019) High-temperature (HT) LiCoO2 recycled from spent lithium ion batteries as catalyst for oxygen evolution reaction. Mater Res Bull 110:97–101

Zhang P, Yokoyama T, Itabashi O, Suzuki TM, Inoue K (1998) Hydrometallurgical process for recovery of metal values from spent lithium-ion secondary batteries. Hydrometallurgy 47(2–3):259–271

Zhang P, Yokoyama T, Itabashi O, Wakui Y, Suzuki TM, Inoue K (1998) Hydrometallurgical process for recovery of metal values from spent nickel-metal hydride secondary batteries. Hydrometallurgy 50(1):61–75

Nan J, Han D, Yang M, Cui M, Hou X (2006) Recovery of metal values from a mixture of spent lithium-ion batteries and nickel-metal hydride batteries. Hydrometallurgy 84(1–2):75–80

Swain B, Jeong J, Lee J-c, Lee G-H, Sohn J-S (2007) Hydrometallurgical process for recovery of cobalt from waste cathodic active material generated during manufacturing of lithium ion batteries. J Power Sources 167(2):536–544

Mantuano DP, Dorella G, Elias RCA, Mansur MB (2006) Analysis of a hydrometallurgical route to recover base metals from spent rechargeable batteries by liquid–liquid extraction with Cyanex 272. J Power Sources 159(2):1510–1518

Dorella G, Mansur MB (2007) A study of the separation of cobalt from spent Li-ion battery residues. J Power Sources 170(1):210–215

Pranolo Y, Zhang W, Cheng C (2010) Recovery of metals from spent lithium-ion battery leach solutions with a mixed solvent extractant system. Hydrometallurgy 102(1–4):37–42

Chen L, Tang X, Zhang Y, Li L, Zeng Z, Zhang Y (2011) Process for the recovery of cobalt oxalate from spent lithium-ion batteries. Hydrometallurgy 108(1–2):80–86

Suzuki T, Nakamura T, Inoue Y, Niinae M, Shibata J (2012) A hydrometallurgical process for the separation of aluminum, cobalt, copper and lithium in acidic sulfate media. Sep Purif Technol 98:396–401

Xunbing L, Ouyang J, Xijuan L (2019) Method for preparing nickel/manganese/lithium/cobalt sulfate and tricobalt tetraoxide from battery wastes. Google Patents

Zhu S-g, He W-Z, Li G-M, Xu Z, X-j ZHANG, Huang J-W (2012) Recovery of Co and Li from spent lithium-ion batteries by combination method of acid leaching and chemical precipitation. Trans Nonferrous Met Soc China 22(9):2274–2281

Wang Y, Gratz E, Sa Q, Zheng Z, Heelan J (2019) Method and apparatus for recycling lithium-ion batteries. Google Patents

Joulié M, Laucournet R, Billy E (2014) Hydrometallurgical process for the recovery of high value metals from spent lithium nickel cobalt aluminum oxide based lithium-ion batteries. J Power Sources 247:551–555

Sun L, Qiu K (2012) Organic oxalate as leachant and precipitant for the recovery of valuable metals from spent lithium-ion batteries. Waste Manage 32(8):1575–1582

Chen X, Fan B, Xu L, Zhou T, Kong J (2016) An atom-economic process for the recovery of high value-added metals from spent lithium-ion batteries. J Clean Prod 112:3562–3570

Huang Y, Han G, Liu J, Chai W, Wang W, Yang S, Su S (2016) A stepwise recovery of metals from hybrid cathodes of spent Li-ion batteries with leaching-flotation-precipitation process. J Power Sources 325:555–564

Vieceli N, Reinhardt N, Ekberg C, Petranikova M (2021) Optimization of manganese recovery from a solution based on lithium-ion batteries by solvent extraction with D2EHPA. Metals 11(1):54

Xu P, Liu C, Zhang X, Zheng X, Lv W, Rao F, Yao P, Wang J, Sun Z (2021) Synergic mechanisms on carbon and sulfur during the selective recovery of valuable metals from spent lithium-ion batteries. ACS Sustain Chem Eng 9(5):2271–2279

Zhao Y, Fang L-Z, Kang Y-Q, Wang L, Zhou Y-N, Liu X-Y, Li T, Li Y-X, Liang Z, Zhang Z-X (2021) A novel three-step approach to separate cathode components for lithium-ion battery recycling. Rare Met 40(6):1431–1436

Bai Y, Muralidharan N, Li J, Essehli R, Belharouak I (2020) Sustainable direct recycling of lithium-ion batteries via solvent recovery of electrode materials. Chemsuschem 13(21):5664–5670

Wang J, Ng S, Wang G, Chen J, Zhao L, Chen Y, Liu H (2006) Synthesis and characterization of nanosize cobalt sulfide for rechargeable lithium batteries. J Power Sources 159(1):287–290

Jiang T, Yang S, Dai P, Yu X, Bai Z, Wu M, Li G, Tu C (2018) Economic synthesis of Co3S4 ultrathin nanosheet/reduced graphene oxide composites and their application as an efficient counter electrode for dye-sensitized solar cells. Electrochim Acta 261:143–150

Fei L, Williams BP, Yoo SH, Carlin JM, Joo YL (2016) A general approach to fabricate free-standing metal sulfide@ carbon nanofiber networks as lithium ion battery anodes. Chem Commun 52(7):1501–1504

Rui X, Tan H, Yan Q (2014) Nanostructured metal sulfides for energy storage. Nanoscale 6(17):9889–9924

Li H, Yang H, Sun Z, Shi Y, Cheng H-M, Li F (2019) A highly reversible Co3S4 microsphere cathode material for aluminum-ion batteries. Nano Energy 56:100–108

Mahmood N, Zhang C, Jiang J, Liu F, Hou Y (2013) Multifunctional Co3S4/graphene composites for lithium ion batteries and oxygen reduction reaction. Chemistry 19(16):5183–5190

Pu J, Shen Z, Zheng J, Wu W, Zhu C, Zhou Q, Zhang H, Pan F (2017) Multifunctional Co3S4@ sulfur nanotubes for enhanced lithium-sulfur battery performance. Nano Energy 37:7–14

Liu Y, Xiao C, Lyu M, Lin Y, Cai W, Huang P, Tong W, Zou Y, Xie Y (2015) Ultrathin Co3S4 nanosheets that synergistically engineer spin states and exposed polyhedra that promote water oxidation under neutral conditions. Angew Chem Int Ed 54(38):11231–11235

Tian R, Zhou Y, Duan H, Guo Y, Li H, Chen K, Xue D, Liu H (2018) MOF-derived hollow Co3S4 quasi-polyhedron/MWCNT nanocomposites as electrodes for advanced lithium ion batteries and supercapacitors. ACS Appl Energy Mater 1(2):402–410

Shi J, Liu G, Weng W, Cai L, Zhang Q, Wu J, Xu X, Yao X (2020) Co3S4@Li7P3S11 hexagonal platelets as cathodes with superior interfacial contact for all-solid-state lithium batteries. ACS Appl Mater Interfaces 12(12):14079–14086

Tang S, Wang X, Zhang Y, Courté M, Fan HJ, Fichou D (2019) Combining Co3S4 and Ni:Co3S4 nanowires as efficient catalysts for overall water splitting: an experimental and theoretical study. Nanoscale 11(5):2202–2210

Li Y, Jiang T, Yang H, Lei D, Deng X, Hao C, Zhang F, Guo J (2020) A heterostuctured Co3S4/MnS nanotube array as a catalytic sulfur host for lithium–sulfur batteries. Electrochim Acta 330:

Park YS, Lee JH, Jang MJ, Jeong J, Park SM, Choi W-S, Kim Y, Yang J, Choi SM (2020) Co3S4 nanosheets on Ni foam via electrodeposition with sulfurization as highly active electrocatalysts for anion exchange membrane electrolyzer. Int J Hydrogen Energy 45(1):36–45

Zhu X, Dai J, Li L, Zhao D, Wu Z, Tang Z, Ma L-J, Chen S (2020) Hierarchical carbon microflowers supported defect-rich Co3S4 nanoparticles: an efficient electrocatalyst for overall water splitting. Carbon 160:133–144

Yan Y, Li K, Chen X, Yang Y, Lee JM (2017) Heterojunction-assisted Co3S4@Co3O4 core-shell octahedrons for supercapacitors and both oxygen and carbon dioxide reduction reactions. Small 13(47):1701724

Dai J, Li J, Zhang Q, Liao M, Duan T, Yao W (2019) Co3S4@C@MoS2 microstructures fabricated from MOF template as advanced lithium-ion battery anode. Mater Lett 236:483–486

Zhang Z, Huang Y, Liu X, Chen C, Xu Z, Liu P (2020) Zeolitic imidazolate frameworks derived ZnS/Co3S4 composite nanoparticles doping on polyhedral carbon framework for efficient lithium/sodium storage anode materials. Carbon 157:244–254

Qiu J, Zheng W, Yuan R, Yue C, Li D, Liu F, Zhu J (2020) A novel 3D nanofibrous aerogel-based MoS2@Co3S4 heterojunction photocatalyst for water remediation and hydrogen evolution under simulated solar irradiation. Appl Catal B 264:

Muthurasu A, Ojha GP, Lee M, Kim HY (2020) Zeolitic imidazolate framework derived Co3S4 hybridized MoS2–Ni3S2 heterointerface for electrochemical overall water splitting reactions. Electrochim Acta 334:

Gao Z, Chen C, Chang J, Chen L, Wang P, Wu D, Xu F, Jiang K (2018) Porous Co3S4@Ni3S4 heterostructure arrays electrode with vertical electrons and ions channels for efficient hybrid supercapacitor. Chem Eng J 343:572–582

Grace AN, Ramachandran R, Vinoba M, Choi SY, Chu DH, Yoon Y, Nam SC, Jeong SK (2014) Facile Synthesis and Electrochemical Properties of Co3S4-Nitrogen-Doped Graphene Nanocomposites for Supercapacitor Applications. Electroanalysis 26(1):199–208

Ghosh D, Das CK (2015) Hydrothermal growth of hierarchical Ni3S2 and Co3S4 on a reduced graphene oxide hydrogel@ Ni foam: a high-energy-density aqueous asymmetric supercapacitor. ACS Appl Mater Interfaces 7(2):1122–1131

Liu Y, Wen S, Shi W (2018) Co3S4 nanoneedles decorated on NiCo2O4 nanosheets for high-performance asymmetric supercapacitors. Mater Lett 214:194–197

Xu B, Pan L, Zhu Q (2016) Synthesis of Co3S4 nanosheets and their superior supercapacitor property. J Mater Eng Perform 25(3):1117–1121

Tabrizi AG, Arsalani N, Naghshbandi Z, Ghadimi LS, Mohammadi A (2018) Growth of polyaniline on rGO-Co3S4 nanocomposite for high-performance supercapacitor energy storage. Int J Hydrog Energy 43(27):12200–12210

Wang H, Li Z, Li G, Peng F, Yu H (2015) Co3S4/NCNTs: a catalyst for oxygen evolution reaction. Catal Today 245:74–78

Xu Y, Lv X-J, Chen Y, Fu W-F (2017) Highly selective reduction of nitroarenes to anilines catalyzed using MOF-derived hollow Co3S4 in water under ambient conditions. Catal Commun 101:31–35

Xu M, Niu H, Huang J, Song J, Mao C, Zhang S, Zhu C, Chen C (2015) Facile synthesis of graphene-like Co3S4 nanosheet/Ag2S nanocomposite with enhanced performance in visible-light photocatalysis. Appl Surf Sci 351:374–381

Zhang Y-H, Wu L-M, Huang P-P, Shen Q, Sun Z-X (2018) Determination and application of the solubility product of metal xanthate in mineral flotation and heavy metal removal in wastewater treatment. Miner Eng 127:67–73

Otero-Calvis A, Ramírez-Serrano B, Coello-Velazquez A (2020) Selectivity in the flotation of copper with xanthate over other ions present in wastewater: an experimental and computational study. J Mol Graph Model 98:

Chen Y, Liu X, Chen J (2021) Steric hindrance effect on adsorption of xanthate on sphalerite surface: a DFT study. Miner Eng 165:

Zhang Q, Wen S, Feng Q, Liu J (2021) Surface modification of azurite with lead ions and its effects on the adsorption of sulfide ions and xanthate species. Appl Surf Sci 543:

Ge P, Zhang C, Hou H, Wu B, Zhou L, Li S, Wu T, Hu J, Mai L, Ji X (2018) Anions induced evolution of Co3X4 (X = O, S, Se) as sodium-ion anodes: the influences of electronic structure, morphology, electrochemical property. Nano Energy 48:617–629

Zhu J, Wei Y, Zhou Y, Yang J (2018) Triethylenediamine-assisted one-step hydrothermal synthesis of polyhedron-shaped Co3S4 for high performance supercapacitor. Ceram Int 44(2):1836–1842

Yang H, Yin L, Liang J, Sun Z, Wang Y, Li H, He K, Ma L, Peng Z, Qiu S (2018) An aluminum–sulfur battery with a fast kinetic response. Angew Chem 130(7):1916–1920

Zhang Q, Xu C, Lu B (2014) Super-long life supercapacitors based on the construction of Ni foam/graphene/Co3S4 composite film hybrid electrodes. Electrochim Acta 132:180–185

Ghanbari H, Cousins BG, Seifalian AM (2011) A nanocage for nanomedicine: polyhedral oligomeric silsesquioxane (POSS). Macromol Rapid Commun 32(14):1032–1046

Duhovic S, Dincă M (2015) Synthesis and electrical properties of covalent organic frameworks with heavy chalcogens. Chem Mater 27(16):5487–5490

Xu M, Guo H, Zhang T, Zhang J, Wang X, Yang W (2021) High-performance zeolitic imidazolate frameworks derived three-dimensional Co3S4/polyaniline nanocomposite for supercapacitors. J Energy Storage 35:

Manjunatha C, Lakshmikant S, Shreenivasa L, Srinivasa N, Ashoka S, Shivraj B, Selvaraj M, Meda US, Babu GS, Pollet BG (2021) Development of non-stoichiometric hybrid Co3S4/Co0.85Se nanocomposites for an evaluation of synergistic effect on the OER performance. Surf Interfaces 25:

Zhao Q, Wang R, Zhang Y, Huang G, Jiang B, Xu C, Pan F (2021) The design of Co3S4@MXene heterostructure as sulfur host to promote the electrochemical kinetics for reversible magnesium-sulfur batteries. J Magnes Alloys 9(1):78–89

Zhu X, Dai J, Li L, Zhao D, Wu Z, Tang Z, Ma L-J, Chen S (2020) Hierarchical carbon microflowers supported defect-rich Co3S4 nanoparticles: an efficient electrocatalyst for water splitting. Carbon 160:133–144

Peng C, Liu F, Wang Z, Wilson BP, Lundström M (2019) Selective extraction of lithium (Li) and preparation of battery grade lithium carbonate (Li2CO3) from spent Li-ion batteries in nitrate system. J Power Sources 415:179–188

Chen X, Kang D, Cao L, Li J, Zhou T, Ma H (2019) Separation and recovery of valuable metals from spent lithium ion batteries: simultaneous recovery of Li and Co in a single step. Sep Purif Technol 210:690–697

Shen Y, Nagaraj D, Farinato R, Somasundaran P (2016) Study of xanthate decomposition in aqueous solutions. Miner Eng 93:10–15

Elizondo-Álvarez MA, Uribe-Salas A, Bello-Teodoro S (2021) Chemical stability of xanthates, dithiophosphinates and hydroxamic acids in aqueous solutions and their environmental implications. Ecotoxicol Environ Saf 207:

Shen Y, Nagaraj D, Farinato R, Somasundaran P, Tong S (2019) Decomposition of flotation reagents in solutions containing metal ions. Part I: gaseous compounds from xanthate decomposition. Miner Eng 139:

Shen Y, Nagaraj D, Farinato R, Somasundaran P, Tong S (2019) Xanthate decomposition in ore pulp under flotation conditions: method development and effects of minerals on decomposition. Miner Eng 131:198–205

Mensah MB, Awudza JA, Revaprasadu N, O’Brien P (2021) Synthesis of CdS and PbS nanoparticles by the thermal decomposition of ethyl xanthate complexes in castor oil using the heat-up technique. Mater Sci Semicond Process 122:

Darezereshki E, Vakylabad AB, Hassanzadeh A, Niedoba T, Surowiak A, Koohestani B (2021) Hydrometallurgical synthesis of nickel nano-sulfides from spent lithium-ion batteries. Minerals 11(4):419

Wang H, Bai Y, Chen S, Luo X, Wu C, Wu F, Lu J, Amine K (2015) Binder-free V2O5 cathode for greener rechargeable aluminum battery. ACS Appl Mater Interfaces 7(1):80–84

Ferreira DA, Prados LMZ, Majuste D, Mansur MB (2009) Hydrometallurgical separation of aluminium, cobalt, copper and lithium from spent Li-ion batteries. J Power Sources 187(1):238–246

Wu C, Li B, Yuan C, Ni S, Li L (2019) Recycling valuable metals from spent lithium-ion batteries by ammonium sulfite-reduction ammonia leaching. Waste Manage 93:153–161

Gao G, Luo X, Lou X, Guo Y, Su R, Guan J, Li Y, Yuan H, Dai J, Jiao Z (2019) Efficient sulfuric acid-vitamin C leaching system: towards enhanced extraction of cobalt from spent lithium-ion batteries. J Mater Cycles Waste Manage 21(4):942–949

Sasaki Y (1982) Extraction—spectrophotometric determination of manganese (II) with xanthates. Anal Chim Acta 138:419–424

Pilipenko A, Ul’ko N (1955) Analytical properties of xanthates (III). Zh Anal Khim 10:299–304

Pradhan N, Katz B, Efrima S (2003) Synthesis of high-quality metal sulfide nanoparticles from alkyl xanthate single precursors in alkylamine solvents. J Phys Chem B 107(50):13843–13854

Efrima S, Pradhan N (2003) Xanthates and related compounds as versatile agents in colloid science. C R Chim 6(8–10):1035–1045

Darezereshki E, Bakhtiari F, Alizadeh M, Ranjbar M (2012) Direct thermal decomposition synthesis and characterization of hematite (α-Fe2O3) nanoparticles. Mater Sci Semicond Process 15(1):91–97

Fronzi M, Assadi MHN, Ford MJ (2018) Ab initio investigation of water adsorption and hydrogen evolution on Co9S8 and Co3S4 low-index surfaces. ACS Omega 3(9):12215–12228

Vakylabad AB, Schaffie M, Naseri A, Ranjbar M, Manafi Z (2016) A procedure for processing of pregnant leach solution (PLS) produced from a chalcopyrite-ore bio-heap: CuO nano-powder fabrication. Hydrometallurgy 163:24–32

Sahoo MK, Rao GR (2018) Fabrication of NiCo2S4 nanoball embedded nitrogen doped mesoporous carbon on nickel foam as an advanced charge storage material. Electrochim Acta 268:139–149

Tang Y, Chen T, Yu S, Qiao Y, Mu S, Zhang S, Zhao Y, Hou L, Huang W, Gao F (2015) A highly electronic conductive cobalt nickel sulphide dendrite/quasi-spherical nanocomposite for a supercapacitor electrode with ultrahigh areal specific capacitance. J Power Sources 295:314–322

Borthakur P, Darabdhara G, Das MR, Boukherroub R, Szunerits S (2017) Solvothermal synthesis of CoS/reduced porous graphene oxide nanocomposite for selective colorimetric detection of Hg (II) ion in aqueous medium. Sensors Actuators B 244:684–692

Hotze EM, Phenrat T, Lowry GV (2010) Nanoparticle aggregation: challenges to understanding transport and reactivity in the environment. J Environ Qual 39(6):1909–1924

Yasui K, Kato K (2012) Dipole–dipole interaction model for oriented attachment of BaTiO3 nanocrystals: a route to mesocrystal formation. J Phys Chem C 116(1):319–324

Xing B, Vecitis CD, Senesi N (2016) Engineered nanoparticles and the environment: biophysicochemical processes and toxicity, vol 4. Wiley, Somerset

Fernández-Baldo MA, Berni E, Raba J, Sanz MI, Durán N (2013) Applications of nanoparticles synthesized by yeasts: a green and eco-friendly method. In: Green biosynthesis of nanoparticles. CABI, Oxford Shire, p 216

Thanh NT, Green LA (2010) Functionalisation of nanoparticles for biomedical applications. Nano Today 5(3):213–230

Ezhov AA, Shandryuk GA, Bondarenko GN, Merekalov AS, Abramchuk SS, Shatalova AM, Manna P, Zubarev ER, Talroze RV (2011) Liquid-crystalline polymer composites with CdS nanorods: structure and optical properties. Langmuir 27(21):13353–13360

Guozhong C (2004) Nanostructures and nanomaterials: synthesis, properties and applications. World Scientific, Singapore

Wang S, Jiao S, Wang J, Chen H-S, Tian D, Lei H, Fang D-N (2017) High-performance aluminum-ion battery with CuS@C microsphere composite cathode. ACS Nano 11(1):469–477

Acknowledgements

This research has been supported by Institute of Science and High Technology and Environmental Sciences, Graduate University of Advanced Technology (Kemran-Iran) under grant number of 7/S/98/1621. Also, some part of this research was funded by the Iran National Science Foundation (INSF) under the grant number of 98/S/8700. Additionally, we would like to thank the anonymous reviewers for their insightful remarks, constructive comments, and fruitful criticisms.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The present study has no competing financial interest.

Additional information

The contributing editor for this article was Gabrielle Gaustad.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Behrad Vakylabad, A., Darezereshki, E. & Hassanzadeh, A. Selective Recovery of Cobalt and Fabrication of Nano-Co3S4 from Pregnant Leach Solution of Spent Lithium-Ion Batteries. J. Sustain. Metall. 7, 1027–1044 (2021). https://doi.org/10.1007/s40831-021-00393-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40831-021-00393-9