Abstract

To develop an efficient recycling process for the selective recovery of rare earth elements (REEs) from neodymium (Nd)-iron (Fe)-boron (B) magnets, a selective chlorination process using zinc chloride (ZnCl2) was investigated. A mixture of Nd-Fe-B magnet powder and ZnCl2 was set in a gas-tight quartz tube, and the tube was placed in a vertical furnace preheated to 1000 K. During the experiment, the magnet powder reacted with ZnCl2 for 1.5 – 5 h to selectively chlorinate the REEs in the magnet. The influence of the particle size of the magnet powder, reaction time, and premelting of ZnCl2 on the chlorination efficiency of REEs was investigated. Under certain conditions, the chlorination efficiencies of Nd, dysprosium (Dy), and praseodymium (Pr) were 96.5%, 57.2%, and 97.6%, respectively. In addition, Fe and neodymium chloride (NdCl3) were found to have been generated after the selective chlorination reactions. The results of this study demonstrate that the selective recovery of REEs, such as Nd, Dy, and Pr, from Nd-Fe-B magnets is feasible by utilizing the selective chlorination process using ZnCl2.

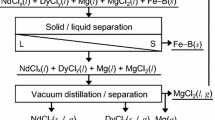

Graphical Abstract

Similar content being viewed by others

References

Haider SK, Lee J-Y, Kim D, Kang YS (2020) Eco-friendly facile three-step recycling method of (Nd-RE)2Fe14B magnet sludge and enhancement of (BH)max by ball milling in ethanol. ACS Sustainable Chem Eng 8:8156–8163

Future Market Insights (2015) Rare earth metals market: global industry analysis and opportunity assessment, 2016–2026. Future Market Insights, London

Takeda O, Okabe TH (2014) Current status on resource and recycling technology for rare earths. Metall Mater Trans E 1:160–173

Nakamura T (2016) NEDO report: review of rare metals. New Energy and Industrial Technology Development Organization, Japan (in Japanese)

Kang J (2020) Current status of rare earth industry in Japan. Ceramic Korea 3:72–79 (in Korean)

Akahori T, Miyamoto Y, Saeki T, Okamoto M, Okabe TH (2017) Optimum conditions for extracting rare earth metals from waste magnets by using molten magnesium. J Alloys Compd 703:337–343

Okabe TH, Takeda O, Fukuda K, Umetsu Y (2003) Direct extraction and recovery of neodymium metal from magnet scrap. Mater Trans 44:798–801

Takeda O, Okabe TH, Umetsu Y (2005) Phase equilibria of the system Fe-Mg-Nd at 1076 K. J Alloys Compd 392:206–213

Takeda O, Okabe TH, Umetsu Y (2006) Recovery of neodymium from a mixture of magnet scrap and other scrap. J Alloys Compd 408–412:387–390

Chae HJ, Kim YD, Kim BS, Kim JG, Kim T-S (2014) Experimental investigation of diffusion behavior between molten Mg and Nd-Fe-B magnets. J Alloys Compd 586:S143–S149

Nam S-W, Park S-M, Kim D-H, Kim T-S (2020) Thermodynamic calculations and parameter variations for improving the extraction efficiency of Dy in ternary alloy system. Met Mater Int 27(3):538–544

Takeda O, Okabe TH, Umetsu Y (2004) Phase equilibrium of the system Ag-Fe-Nd, and Nd extraction from magnet scraps using molten silver. J Alloys Compd 379:305–313

Nohira T, Kobayashi S, Kobayashi K, Hagiwara R, Oishi T, Konishi H (2010) Electrochemical formation of Nd-Ni alloys in molten LiF-CaF2-NdF3. ECS Trans 33:205–212

Kobayashi S, Kobayashi K, Nohira T, Hagiwara R, Oishi T, Konishi H (2011) Electrochemical formation of Nd-Ni alloys in molten LiF-CaF2-NdF3. J Electrochem Soc 158:E142–E146

Saito T, Sato H, Ozawa S, Yu J, Motegi T (2003) The extraction of Nd from waste Nd-Fe-B alloys by the glass slag method. J Alloys Compd 353:189–193

Saito T, Motegi T (2004) Extraction of Tb from Tb-Fe alloys by the glass slag method. Scripta Mater 51:1069–1073

Saito T, Sato H, Motegi T (2005) Extraction of Sm from Sm-Fe alloys by the glass slag method. J Alloys Compd 387:274–278

Saito T, Sato H, Motegi T, Kobayashi K (2005) Extraction of Sm from Sm-Fe-N magnets by the glass slag method. J Alloys Compd 403:341–344

Saito T, Sato H, Motegi T (2006) Recovery of rare earths from sludges containing rare-earth elements. J Alloys Compd 425:145–147

Shirayama S, Okabe TH (2018) Selective extraction and recovery of Nd and Dy from Nd-Fe-B magnet scrap by utilizing molten MgCl2. Metall Mater Trans B 49:1067–1077

Uda T (2002) Recovery of rare earths from magnet sludge by FeCl2. Mater Trans 43:55–62

Itoh M, Miura K, Machida K (2009) Novel rare earth recovery process on Nd-Fe-B magnet scrap by selective chlorination using NH4Cl. J Alloys Compd 477:484–487

Hua Z, Wang J, Wang L, Zhao Z, Li X, Xiao Y, Yang Y (2014) Selective extraction of rare earth elements from NdFeB scrap by molten chlorides. ACS Sustainable Chem Eng 2:2536–2543

Barin I (1995) Thermochemical data of pure substances. VCH Verlagsgesellschaft mbH, Weinheim

Hatada N (2014) Chesta: Software for Creating Chemical Potential Diagram, version 3.2.6.9, http://www.aqua.mtl.kyoto-u.ac.jp/wordpress/chestaEng.html

Jacob KT, Dixit A, Rajput A (2016) Stability field diagrams for Ln-O-Cl systems. Bull Mater Sci 39:603–611

Windholz M, Budavari S, Blumetti RF, Otterbein E.S (1983) The merch index – An encyclopedia of chemicals, drugs, and biologicals, 3rd ed. Rahway N.J., pp. 9932

Acknowledgements

The authors are grateful to Ms. Jieun Ahn and all the members of the Geoanalysis Department of KIGAM for their technical assistance. This research was supported by the Korea Evaluation Institute of Industrial Technology funded by the Korean Ministry of Industry in Korea (Project No.: 20000970, 20-9805).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflicts of interest.

Additional information

The contributing editor for this article was Hojong Kim.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Lim, KH., Choi, C.U., Moon, G. et al. Selective Chlorination of Rare Earth Elements from a Nd-Fe-B Magnet Using Zinc Chloride. J. Sustain. Metall. 7, 794–805 (2021). https://doi.org/10.1007/s40831-021-00380-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40831-021-00380-0