Abstract

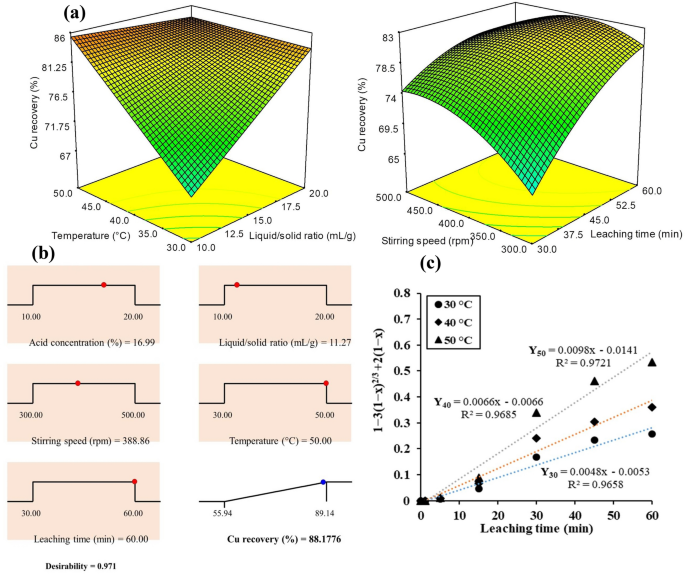

In the present work, the leaching behavior of copper from an oxide/sulfide ore was assessed in two work phases including process optimization and kinetics modeling. In the first phase, the individual and synergistic impacts of the influential parameters such as sulfuric acid concentration, liquid/solid ratio, pulp mixing rate, temperature, and contact time were investigated on the dissolution rate of copper using response surface modeling. The findings demonstrated that the linear effects of dissolution time and temperature and the quadratic impact of acid concentration had the largest influence on the recovery and the linear impact of stirring speed had the least degree of importance. Process optimization was also performed utilizing the desirability function approach and more than 88.17% copper was recovered at the optimum conditions: ~ 17% acid concentration, ~ 11.3 mL/g liquid/solid ratio, ~ 390 rpm stirring speed, 50 °C temperature, and 60 min leaching time. In the second phase, the leaching kinetics was examined by heterogeneous shrinking core models and it was realized that diffusion through product layer was the dissolution rate controlling step with the activation energy of 28.92 kJ/mol and frequency factor of 6.155 min−1. Ultimately, a mathematical kinetics model was developed and suggested to understand the leaching process.

Graphical Abstract

a 3D response surface graphs displaying the synergistic effects between “temperature and liquid/solid ratio” and “stirring speed and leaching time” on the leaching recovery of copper; b the optimum conditions of influential factors; c plot of diffusion through product layer versus leaching time for temperature effect.

Similar content being viewed by others

References

Bai X, Wen S, Liu J, Lin Y (2018) Response surface methodology for optimization of copper leaching from refractory flotation tailings. Minerals 8:165. https://doi.org/10.3390/min8040165

Shishkin A, Mironovs V, Vu H, Novak P, Baronins J, Polyakov A, Ozolins J (2018) Cavitation-dispersion method for copper cementation from wastewater by iron powder. Metals 8:920. https://doi.org/10.3390/met8110920

Bayati B, Azizi A, Karamoozian M (2018) A comprehensive study of the leaching behavior and dissolution kinetics of copper oxide ore in sulfuric acid lixiviant. Sci Iran 25:1412–1422. https://doi.org/10.24200/SCI.2018.5226.1154

Antonijević MM, Dimitrijević MD, Stevanović ZO, Serbula SM, Bogdanovic GD (2008) Investigation of the possibility of copper recovery from the flotation tailings by acid leaching. J Hazard Mater 158:23–34. https://doi.org/10.1016/j.jhazmat.2008.01.063

Liu ZX, Yin ZL, Hu HP, Chen QY (2012) Leaching kinetics of low-grade copper ore with high-alkality gangues in ammonia-ammonium sulphate solution. J Cent South Univ 19:77–84. https://doi.org/10.1007/s11771-012-0975-8

Chen T, Lei C, Yan B, Xiao X (2014) Metal recovery from the copper sulfide tailing with leaching and fractional precipitation technology. Hydrometallurgy 147–148:178–182. https://doi.org/10.1016/j.hydromet.2014.05.018

Ahmed IM, Nayl AA, Daoud JA (2016) Leaching and recovery of zinc and copper from brass slag by sulfuric acid. J Saudi Chem Soc 20:S280–S285. https://doi.org/10.1016/j.jscs.2012.11.003

Han B, Altansukh B, Haga K, Stevanović Z, Jonović R, Avramović L, Urosević D, Takasaki Y, Masuda N, Ishiyama D, Shibayama A (2018) Development of copper recovery process from flotation tailings by a combined method of high-pressure leaching-solvent extraction. J Hazard Mater 352:192–203. https://doi.org/10.1016/j.jhazmat.2018.03.014

Khalid MK, Hamuyuni J, Agarwal V, Pihlasalo J, Haapalainen M, Lundström M (2019) Sulfuric acid leaching for capturing value from copper rich converter slag. J Clean Prod 215:1005–1013. https://doi.org/10.1016/j.jclepro.2019.01.083

Gargul K, Boryczko B, Bukowska A, Jarosz P, Małecki S (2019) Leaching of lead and copper from flash smelting slag by citric acid. Arch Civ Mech Eng 19:648–656. https://doi.org/10.1016/j.acme.2019.02.001

Nozhati RA, Azizi A (2020) Leaching of copper and zinc from the tailings sample obtained from a porcelain stone mine: feasibility, modeling, and optimization. Environ Sci Pollut Res 27:6239–6252. https://doi.org/10.1007/s11356-019-07199-z

Haghighi HK, Moradkhani D, Sedaghat B, Rajaie Najafabadi M, Behnamfard A (2013) Production of copper cathode from oxidized copper ores by acidic leaching and two-step precipitation followed by electrowinning. Hydrometallurgy 133:111–117. https://doi.org/10.1016/j.hydromet.2012.12.004

Crundwell FK (2014) The mechanism of dissolution of minerals in acidic and alkaline solutions: Part III. Application to oxide, hydroxide and sulfide minerals. Hydrometallurgy 149:71–81. https://doi.org/10.1016/j.hydromet.2014.06.008

Ata ON, Colak S, Ekinci Z, Copur M (2001) Determination of the optimum conditions for leaching of malachite ore in H2SO4 solutions. Chem Eng Technol 24:409–413. https://doi.org/10.1002/1521-4125(200104)24:4<409:AID-CEAT409>3.0.CO;2-0

Bingol D, Canbazoğlu M (2004) Dissolution kinetics of malachite in sulphuric acid. Hydrometallurgy 72:159–165. https://doi.org/10.1016/j.hydromet.2003.10.002

Sun X, Chen B, Yang X, Liu Y (2009) Technological conditions and kinetics of leaching copper from complex copper oxide ore. J Cent South Univ Technol 16:936–941. https://doi.org/10.1007/s11771-009-0156-6

Habbache N, Alane N, Djerad S, Tifouti L (2009) Leaching of copper oxide with different acid solutions. Chem Eng J 152:503–508. https://doi.org/10.1016/j.cej.2009.05.020

Liu W, Tang M-T, Tang C-B, He J, Yang S-H, Yang J-G (2010) Dissolution kinetics of low grade complex copper ore in ammonia-ammonium chloride solution. Trans Nonferrous Metals Soc China 20:910–917. https://doi.org/10.1016/S1003-6326(09)60235-1

Ekmekyapar A, Aktaş E, Künkül A, Demirkiran N (2012) Investigation of leaching kinetics of copper from malachite ore in ammonium nitrate solutions. Metall Mater Trans B 43:764–772. https://doi.org/10.1007/s11663-012-9670-2

Ekmekyapar A, Demirkıran N, Künkül A, Aktaş E (2015) Leaching of malachite ore in ammonium sulfate solutions and production of copper oxide. Braz J Chem Eng 32:155–165. https://doi.org/10.1590/0104-6632.20150321s00003211

Liu M, Wen J, Tan G, Liu G, Wu B (2016) Experimental studies and pilot plant tests for acid leaching of low-grade copper oxide ores at the Tuwu copper mine. Hydrometallurgy 165:227–232. https://doi.org/10.1016/j.hydromet.2016.04.009

Mohagheghi M, Askari M (2016) Copper recovery from reverberatory furnace flue dust. Int J Miner Process 157:205–209. https://doi.org/10.1016/j.minpro.2016.11.010

Tanda BC, Eksteen JJ, Oraby EA (2017) An investigation into the leaching behaviour of copper oxide minerals in aqueous alkaline glycine solutions. Hydrometallurgy 167:153–162. https://doi.org/10.1016/j.hydromet.2016.11.011

Hossain MS, Yahaya ANA, Yacob LS, Abdul Rahim MZ, Yusof NNM, Bachmann RT (2018) Selective recovery of copper from waste mobile phone printed circuit boards using sulphuric acid leaching. Mater Today Proc 5:21698–21702. https://doi.org/10.1016/j.matpr.2018.07.021

Nicol MJ (2018) The kinetics of the dissolution of malachite in acid solutions. Hydrometallurgy 177:214–217. https://doi.org/10.1016/j.hydromet.2018.03.017

Li B, Wang X, Wei Y, Wang H, Barati M (2018) Extraction of copper from copper and cadmium residues of zinc hydrometallurgy by oxidation acid leaching and cyclone electrowinning. Miner Eng 128:247–253. https://doi.org/10.1016/j.mineng.2018.09.007

Stanković V, Milošević V, Milićević D, Gorgievski M, Bogdanović G (2018) Reprocessing of the old flotation tailings deposited on the RTB BOR tailings pond—a case study. Chem Ind Chem Eng Q 24:333–344. https://doi.org/10.2298/CICEQ170817005S

Bai S, Fu X, Li C, Wen S (2018) Process improvement and kinetic study on copper leaching from low-grade cuprite ores. Physicochem Probl Miner Process 54:300–310. https://doi.org/10.5277/ppmp1818

Wang G, Liu Y, Tong L, Jin Z, Chen G, Yang H (2019) Effect of temperature on leaching behavior of copper minerals with different occurrence states in complex copper oxide ores. Trans Nonferr Metals Soc China 29:2192–2201. https://doi.org/10.1016/S1003-6326(19)65125-3

Li H, Oraby E, Eksteen J (2020) Extraction of copper and the co-leaching behaviour of other metals from waste printed circuit boards using alkaline glycine solutions. Resour Conserv Recycl 154:104624. https://doi.org/10.1016/j.resconrec.2019.104624

Conejeros V, Pérez K, Ricardo IJ, Castillo J, Hernández P, Toro N (2020) Novel treatment for mixed copper ores: leaching ammonia–precipitation–flotation (L.A.P.F.). Miner Eng 149:106242. https://doi.org/10.1016/j.mineng.2020.106242

Oluokun OO, Otunniyi IO (2020) Kinetic analysis of Cu and Zn dissolution from printed circuit board physical processing dust under oxidative ammonia leaching. Hydrometallurgy 193:105320. https://doi.org/10.1016/j.hydromet.2020.105320

Shi G, Liao Y, Su B, Zhang Y, Wang W, Xi J (2020) Kinetics of copper extraction from copper smelting slag by pressure oxidative leaching with sulfuric acid. Sep Purif Technol 241:116699. https://doi.org/10.1016/j.seppur.2020.116699

Zakrzewska-Koltuniewicz G, Herdzik-Konieckoa I, Cojocarub C, Chajduk E (2014) Experimental design and optimization of leaching process for recovery of valuable chemical elements (U, La, V, Mo, Yb and Th) from low-grade uranium ore. J Hazard Mater 275:136–145. https://doi.org/10.1016/j.jhazmat.2014.04.066

Montgomery DC (2001) Design and analysis of experiments. Wiley, New York

Myers RH, Montgomery DC (2002) Response surface methodology: process and product optimization using designed experiments, 2nd edn. Wiley, New York

Zhang Z, Peng J, Srinivasakannanc C, Zhang Z, Zhang L, Fernández Y, Menéndez JA (2010) Leaching zinc from spent catalyst: process optimization using response surface methodology. J Hazard Mater 176:1113–1117. https://doi.org/10.1016/j.jhazmat.2009.11.125

Javed U, Farooq R, Shehzad F, Khan Z (2018) Optimization of HNO3 leaching of copper from old AMD Athlon processors using response surface methodology. J Environ Manage 211:22–27. https://doi.org/10.1016/j.jenvman.2018.01.026

Bezera MA, Santelli RE, Oliveira EP, Villar LS, Escaleira LA (2008) Review response surface methodology (RSM) as a tool for optimization in analytical chemistry. Talanta 76:965–977. https://doi.org/10.1016/j.talanta.2008.05.019

Maran JP, Nivetha CV, Priya B, Al-Dhabi NA, Ponmurugan K, Blessing Manoj JJ (2016) Modeling of polysaccharide extraction from Gossypium arboreum L. seed using central composite rotatable design. Int J Biol Macromol 86:857–864. https://doi.org/10.1016/j.ijbiomac.2016.01.094

Rao S, Yang T, Zhang D, Liu WF, Chen L, Hao Z, Xiao Q, Wen JF (2015) Leaching of low grade zinc oxide ores in NH4Cl–NH3 solutions with nitrilotriacetic acid as complexing agents. Hydrometallurgy 158:101–106. https://doi.org/10.1016/j.hydromet.2015.10.013

Habashi F (1968) Extractive metallurgy. General principle, vol 1. Gordon & Breach, Science Publishers Inc., New York

Espiari S, Rashchi F, Sadrnezhaad SK (2006) Hydrometallurgical treatment of tailings with high zinc content. Hydrometallurgy 82:54–62. https://doi.org/10.1016/j.hydromet.2006.01.005

Oediyani S, Ariyanto U, Febriana E (2019) Effect of concentration, agitation, and temperature of Pomalaa limonitic nickel ore leaching using hydrochloric acid. IOP Conf Ser Mater Sci Eng 478:012013. https://doi.org/10.1088/1757-899X/478/1/012013

Levenspiel O (1999) Chemical reaction engineering, 3rd edn. Wiley, New York

Adebayo AO, Olasehinde EF (2015) Leaching kinetics of lead from galena with acidified hydrogen peroxide and sodium chloride solution. Trans Inst Min Metall Sect C 124:137–142. https://doi.org/10.1179/1743285515Y.0000000001

Tanda BC, Eksteen JJ, Oraby EA, O'Connor GM (2019) The kinetics of chalcopyrite leaching in alkaline glycine/glycinate solutions. Miner Eng 135:118–128. https://doi.org/10.1016/j.mineng.2019.02.035

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

The contributing editor for this article was T. Hirato.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Nozari, I., Azizi, A. Experimental and Kinetic Modeling Investigation of Copper Dissolution Process from an Iranian Mixed Oxide/Sulfide Copper Ore. J. Sustain. Metall. 6, 437–450 (2020). https://doi.org/10.1007/s40831-020-00291-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40831-020-00291-6