Abstract

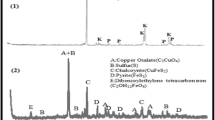

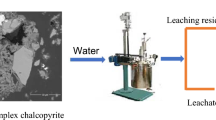

As the first part of a novel process proposed for copper extraction, selective dissolution of iron from chalcopyrite in oxalic acid solutions with hydrogen peroxide was studied. Despite the fact that both iron and copper are readily soluble in acidic conditions, it was found that oxalic acid provides altered solubility behaviors for these metals. It should be used to form iron (II) oxalate which has a higher solubility (0.008 g/100 g H2O at 293 K) than copper oxalate (2.16 × 10–10 g/100 g H2O at 293 K), while hydrogen peroxide was used to provide an oxidative leaching environment to break the chalcopyrite structure. Under the examined leaching conditions where 100 g/L of H2C2O4, 3 M of H2O2, 318 K of leaching temperature, 120 min of leaching time, 25 mL/g of liquid–solid ratio, and 400 rpm of stirring speed were applied, extraction rates of copper and iron from the chalcopyrite concentrate were almost 1.5% and 70%, respectively. Copper was found as a solid oxalate form in the residue obtained after the leaching process in these conditions.

Graphical Abstract

Similar content being viewed by others

References

Free ML (2013) Hydrometallurgy: fundamentals and applications. Wiley, Hoboken

Koleini SMJ, Aghazadah V, Sandström A (2011) Acidic sulphate leaching of chalcopyrite concentrates in presence of pyrite. Miner Eng 24:381–386

Turan MD, Altundoğan HS (2013) Leaching of copper from chalcopyrite concentrate by using ammonium persulphate in an autoclave: Determination of most suitable impeller type by using response surface methodology. J Cent South Univ 20:622–628

Solis-Marcial OJ, Lapidus GT (2014) Chalcopyrite leaching in alcoholic acid media. Hydrometallurgy 147:54–58

Ağacayak T, Aras A, Aydogan S, Erdemoglu M (2014) Leaching of chalcopyrite concentrate in hydrogen peroxide solution. Physicochem Problems Miner Process 50:657–666

Sokic MD, Markovic B, Zirkovic D (2009) Kinetics of chalcopyrite leaching by sodium nitrate in sulphuric acid. Hydrometallurgy 95:273–279

Yoo K, Kim SK, Lee JC, Ito M, Tsunekawa M, Hiroyoshi N (2010) Effect of chloride ions on leaching rate of chalcopyrite. Miner Eng 23:471–477

Padilla R, Vega D, Ruiz MC (2007) Pressure leaching of sulfidized chalcopyrite in sulfuric acid-oxygen media. Hydrometallurgy 86:80–88

Turan MD, Boyrazlı M, Altundoğan HS (2018) Improving of copper extraction from chalcopyrite by using NaCl. J Cent South Univ 25:21–28

Gok O, Anderson CG (2013) Dissolution of low-grade chalcopyrite concentrate in acidified nitrite electrolyte. Hydrometallurgy 135:40–46

Ruiz MC, Montes KS, Padilla R (2011) Chalcopyrite leaching in sulfate–chloride media at ambient pressure. Hydrometallurgy 109:37–42

Turan MD, Altundoğan HS (2014) Leaching of a copper flotation concentrate with ammonium persulfate in an autoclave system. Int J Miner Metallurgy Mater 21:862–870

Kamali AR, Khaki JV (2008) Copper leaching from nanoparticles of chalcopyrite concentrate. Miner Process Non-Ferrous Metals 49:138–143

Cordoba EM, Munoz JA, Blazquez M, Gonzalez F, Ballester A (2008) Leaching of chalcopyrite with ferric ion. Part I: general aspects. Hydrometallurgy 93:81–87

Lu ZY, Jeffrey MI, Lawson F (2000) The effect of chloride ions on the dissolution of chalcopyrite in acidic solutions. Hydrometallurgy 56:189–202

Antonijevic MM, Jankovic ZD, Dimitrijevic MD (2004) Kinetics of chalcopyrite dissolution by hydrogen peroxide in sulphuric acid. Hydrometallurgy 71:329–334

Turan MD, Sarı ZA, Mıller JD (2017) Leaching of blended copper slag in microwave oven. Trans Nonferrous Met Soc China 27:1404–1410

Cordoba EM, Munoz JA, Blazquez ML, Gonzalez F, Ballester A (2008) Leaching of chalcopyrite with ferric ion. Part III: effect of redox potential on the silver-catalyzed process. Hydrometallurgy 93:97–105

Carranza F, Iglesias N, Mazuelos A, Palencia I, Romero R (2004) Treatment of copper concentrates containing chalcopyrite and non-ferrous sulphides by the BRISA process. Hydrometallurgy 71:413–420

Aydogan S, Ucar G, Canbazoglu M (2006) Dissolution kinetics of chalcopyrite in acidic potassium dichromate solution. Hydrometallurgy 81:45–51

Turan MD (2014) Direct selective leaching of chalcopyrite concentrate. Can Metall Q 53:444–449

Turan MD, Arslanoğlu H, Altundoğan HS (2015) Optimization of the leaching conditions of chalcopyrite concentrate using ammonium persulfate in an autoclave system. J Taiwan Inst Chem Eng 50:49–55

Kanari N, Gaballah I, Allain E, Menad N (1999) Chlorination of chalcopyrite concentrates. Metall Mater Trans B 30B:567–576

Antonijevic MM, Dimitrijevic M, Jankovic Z (1997) Leaching of pyrite with hydrogen peroxide in sulphuric acid. Hydrometallurgy 46:71–83

Turan MD, Altundoğan HS (2013) Leaching of chalcopyrite concentrate with hydrogen peroxide and sulfuric acid in an autoclave system. Metall Mater Trans B 44:809–819

Pecina T, Franco T, Castillo P, Orrantia E (2008) Leaching of a zinc concentrate in H2SO4 solutions containing H2O2 and complexing agents. Miner Eng 21:23–30

Salmimies R, Vehmaanpera P, Hakkien A (2016) Acidic dissolution of magnetite in mixtures of oxalic and sulfuric acid. Hydrometallurgy 163:91–98

Lee SO, Tran T, Jung BH, Kim SJ, Kim MJ (2007) Dissolution of iron oxide using oxalic acid. Hydrometallurgy 87:91–99

Ambikadevi VR, Lalithambika M (2000) Effect of organic acids on ferric iron removal from iron-stained kaolinite. Appl Clay Sci 16:133–145

Taxiarchou M, Panias D, Douni I, Paspaliaris I, Kontopoulos A (1997) Dissolution of hematite in acidic oxalate solutions. Hydrometallurgy 44:287–299

Truong QD, Kakihana M (2012) Hydrothermal growth of cross-linked hyperbranched copper dendrites using copper oxalate complex. J Cryst Growth 348:65–70

Turan MD (2018) The two-stage selective leaching of copper from chalcopyrite concentrates. Final report for TÜBİTAK under project no 315M006

Taxiarchou M, Panias D, Douni I, Paspaliaris I, Kontopoulos A (1997) Removal of iron from silica sand by leaching with oxalic acid. Hydrometallurgy 46:215–227

Acknowledgements

The authors would like to acknowledge TÜBİTAK (The Scientific and Technological Research Council of Turkey) under project no 315M006, and Research Foundation of Fırat University under project no FUBAP-MF.15.25 for supporting the study.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

The contributing editor for this article was D. Panias.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Turan, M.D., Sarı, Z.A. & Erdemoğlu, M. Copper Enrichment in Solid with Selective Reverse Leaching with Oxalic Acid. J. Sustain. Metall. 6, 428–436 (2020). https://doi.org/10.1007/s40831-020-00286-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40831-020-00286-3