Abstract

This position paper introduces the reader to the concept of solvometallurgy, the term used to describe the extraction of metals from ores, industrial process residues, production scrap, and urban waste using non-aqueous solutions. Here, non-aqueous is not used to imply anhydrous, but rather a low water content. The unit operations are as follows: solvent leaching; separation of the residue; purification of the leach solution by non-aqueous solvent extraction or non-aqueous ion exchange; and metal recovery by precipitation or electrolysis in non-aqueous electrolytes. Solvometallurgy is similar to hydrometallurgy in that both the branches of extractive metallurgy use low-temperature processes, but with solvometallurgy, there is no discrete water phase. Both branches use organic or inorganic solvents (excluding water in the case of solvometallurgy). However, for solvometallurgical processes to be sustainable, they must be based on green solvents, which means that all toxic or environmentally harmful solvents must be avoided. Solvometallurgy is complementary to pyrometallurgy and hydrometallurgy, but this new approach offers several advantages. First, the consumption of water is very limited, and so the generation of wastewater can be avoided. Second, the leaching and solvent extraction can be combined to form a single step, resulting in more simplified process flow sheets. Third, solvent leaching is often more selective than leaching with acidic aqueous solutions, leading to reduced acid consumption and fewer purification steps. Fourth, solvometallurgy is useful for the treatment of ores rich in soluble silica (e.g., eudialyte) because no silica gel is formed. In short, solvometallurgy is in a position to help develop the near-zero-waste metallurgical processes, and with levels of energy consumption that are much lower than those with the high-temperature processes. The Technology Readiness Level (TRL) of this emerging branch of extractive metallurgy is still low (TRL = 3–4), which is a disadvantage for short-term implementation, but offers a great opportunity for further research, development, and innovation.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Until a few centuries ago, mankind made use of only seven metals—copper, tin, iron, gold, silver, lead, and mercury—in pure form or in the form of alloys (e.g., bronze) [1]. In the early nineteenth century, metallic zinc began to be produced, although this metal had been used for centuries as a component of brass. All these metals were produced from high-grade ores by the high-temperature, pyrometallurgical processes. However, once the rich ore deposits began to run out, there was no alternative but to start mining lower-grade ores, which could not be processed into a concentrate using the beneficiation methods that were employed at that time. This became a serious problem at the turn of the twentieth century and led to the development of mineral processing (e.g., froth flotation) and hydrometallurgical processing (e.g., leaching, ion exchange, and solvent extraction) [2]. Hydrometallurgy makes use of water as a solvent, and operates at much lower temperatures (20–200 °C) than pyrometallurgy (>300 °C) [3]. Hydrometallurgical processes were originally developed for the extraction of copper and gold, but the extraction of uranium from low-grade ores after World War II gave a boost to the development of hydrometallurgy.

Hydrometallurgical flow sheets are now important for the extractive metallurgy of the rare-earth elements (REEs), zirconium, niobium, tantalum, gallium, indium, platinum-group metals (PGMs) zinc, and copper. The aluminum industry has also contributed to the development of hydrometallurgy; for example, the Bayer process, used to prepare pure alumina from bauxite ore, is the oldest example of a commercialized, high-pressure hydrometallurgical process. For the production of iron, pyrometallurgy is the dominant technique, whereas the flow sheets for the extraction of many other metals are based on a combination of pyrometallurgical and hydrometallurgical process steps. For instance, after sintering and roasting the ore concentrate (i.e., a pyrometallurgical process), the calcine can be leached by an acid (i.e., a hydrometallurgical process). Hydrometallurgy is used only in the first parts of the flow sheet, and metal production is finalized quite often by pyrometallurgy.

As the demand for metals increases, the metallurgical industry has to rely increasingly on low-grade ores. In fact, industry is currently considering whether to recover metals from industrial process residues (e.g., bauxite residue, goethite, jarosite, phosphogypsum) or mine tailings, which were considered as waste until recently. Pyrometallurgical methods are often incapable of treating these residues in an economic way, because the metal concentrations are too low. Likewise, most hydrometallurgical processes are not very suitable for the recovery of metals from low-grade ores, tailings, or industrial residues with low concentrations of valuable metals, because leaching with aqueous solutions of acids suffers from a poor selectivity. This means that not only are the metals of interest dissolved, but also large parts of the matrix or gangue minerals go into solution, which leads to unnecessary acid consumption and generation of impure leachates. Alkaline leaching is more selective, but not all metals of interest can be solubilized by alkaline lixiviants. Furthermore, alkaline leaching causes the dissolution of large amounts of silica. The processing of urban waste (e.g., waste electric and electronic equipment, WEEE) by hydrometallurgical processes has some specific issues. For instance, the dissolution of metals and alloys from scrap through the use of acids will form large volumes of flammable hydrogen gas, while the dissolution of semiconductor materials such as gallium arsenide can generate highly toxic arsine gas. The recovery of metals from mine tailings, industrial process residues, and urban waste helps to close the materials loop and to establish a circular economy. Figure 1 shows the different materials’ streams in the zero-waste approach to metal-containing waste streams: (1) direct (pre-consumer) recycling of metal scrap and swarf generated during the production of metal-based (intermediate) products; (2) (post-consumer) recycling and/or urban mining of, respectively, flows and stocks of complex, multimaterial, metal-containing products (for example, a hybrid electric vehicle); (3) landfill mining of historic urban solid waste; (4) metal recovery from flows of industrial process residues from primary and secondary metal productions; and, finally, (5) metal recovery from stocks of landfilled mining waste and industrial process residues. The zero-waste vision implies that for (4) and (5), the residual mineral matrixes are valorized in building or engineered materials. In combination with the extraction of metals from low-grade ores, an optimized material’s flow also helps to slow the depletion of our natural resources.

In cases where pyrometallurgical or hydrometallurgical processes fail to efficiently extract metal values from low-grade ores, mine tailings, industrial process residues, or urban waste, we could turn to solvometallurgy, which constitutes a branch of extractive metallurgy that is complementary to both pyrometallurgy and hydrometallurgy. Solvometallurgy makes use of processes involving the non-aqueous solvents. These non-aqueous solvents can be molecular organic solvents, ionic liquids, deep-eutectic solvents (DESs), but also the inorganic solvents such as liquefied ammonia, concentrated sulfuric acid, or supercritical carbon dioxide. High-temperature molten salts and liquid metals are excluded if they require temperatures above 300 °C. Non-aqueous solvents do not imply anhydrous conditions, but rather a low water content. Some solvometallurgical processes must take place in the absence of water, while for other processes, a low water content is required. Strictly speaking, conventional solvent extraction, which is based on the preferential distribution of metal ions between an aqueous phase and a water-immiscible organic phase, is not a solvometallurgical process because of the presence of an aqueous phase.

The original concept of solvometallurgy dates from the late 1940s and early 1950s when researchers in the United States were developing processes to recover uranium from the uranium ores through leaching with organic mixtures such as acetone-HCl or alkylphosphoric acids in kerosene [4,5,6,7,8,9]. At that time, the term “lyometallurgy” was introduced to describe solvent-based leaching processes, derived from the Greek word lyein, meaning to loosen or to dissolve. Other suggested terms included “anhydrometallurgy” and the contradictory “non-aqueous hydrometallurgy.” Later, solvometallurgical methods were used for the recovery of copper from chrysocolla, a largely amorphous copper silicate [10,11,12]. It was also realized that solvometallurgy could be useful for the reprocessing of spent nuclear fuel [13]. Sastri reviewed the possibility of using organic solvents and chelating agents for the processing of ores [14]. In 1985, in his book on ion solvation, Marcus used the term “solvometallurgy” to describe the extension of hydrometallurgy to solvents other than water [15]. Russian researchers also applied the solvometallurgical methods to recover metals from complex silica-rich ores (e.g., eudialyte), urban waste, and pellets of nuclear fuel [16,17,18,19]. In recent years, there has been progress in the use of ionic liquids and deep-eutectic solvents in metallurgical processes, ranging from leaching, to solvent extraction, and the electrodeposition of metals [20,21,22,23]. The term “ionometallurgy” was coined for metallurgical processes involving the ionic solvents [24], but ionic-liquid processes are solvometallurgical as well. Although we could consider hydrometallurgy to be part of solvometallurgy (since water is a solvent), we want to make a clear distinction between hydrometallurgy (based on water as solvent) and solvometallurgy (based on non-aqueous solvents).

In this paper, we describe the concept of solvometallurgy and its potential applications in extractive metallurgy. An overview of solvometallurgical unit processes is provided, and ten reasons are presented to highlight why solvometallurgy is a useful complement to hydrometallurgy and pyrometallurgy. Because we realize that several hurdles must be overcome before solvometallurgy will become commonplace in extractive metallurgy, the main challenges facing this new approach are discussed. Selected examples of solvometallurgical processes reported in the scientific literature and the patent literature are described. Attention is paid to the selection and disposal of the solvents, because the use of green solvents is a must for the development of sustainable solvometallurgical processes.

Solvometallurgical Unit Processes

Most of the unit processes in solvometallurgy are very similar to those in hydrometallurgy, with the main difference being that the water is replaced by a non-aqueous solvent. Table 1 shows a comparison of the hydrometallurgical and solvometallurgical processes. Some solvometallurgical processes make use of solvent–water mixtures, but the solvent concentration is assumed to be at least 50 vol%, because otherwise the phase should be considered as an aqueous phase with added solvent, rather than as a non-aqueous phase. It is important to note that the word solvent can have different meanings in solvometallurgy, and therefore the intended meaning must be derived from the context. The most general meaning of solvent is that of an organic phase, as opposed to an aqueous phase in hydrometallurgy. A solvent can contain different components, such as the extractant, the diluent, and dissolved acids. The diluent is an organic solvent, the main purpose of which is to obtain an organic phase with a reasonably low viscosity, if the extractant is a viscous liquid. According to the more strict definition, the term solvent is used to indicate the diluent.

Solvent Leaching

In hydrometallurgy, leaching (solid–liquid extraction) mainly involves: (1) mineral acids such as H2SO4, HNO3, or HCl, (2) bases such as NH3 or NaOH, or (3) chelating agents such as EDTA or citric acid. These lixiviants are used in diluted or concentrated forms. In solvometallurgy, one approach to carrying out leaching is with solutions of mineral acids in water-miscible (polar) organic solvents, such as acetone, methanol, ethanol, isopropanol or ethylene glycol [4, 25,26,27,28]. HCl is often selected as the acid. Anhydrous solutions of HCl in an organic solvent can be prepared by saturating the solvent with HCl gas and diluting with solvent until the appropriate HCl concentration. It is also possible to use organic acids such as formic acid or acetic acid in undiluted form or diluted with small amounts of water. Other lixiviants are deep-eutectic solvents (DESs) [29].

Another approach to solvent leaching is the use of water-immiscible (nonpolar) organic solvents with dissolved extractants. Here, the lixiviant is very similar to the organic phase used in solvent-extraction processes [6, 9, 10,11,12]. If an acidic extractant is used, such as a dialkylphosphoric acid (e.g., D2EHPA) or a carboxylic acid (e.g., Versatic acid), the organic phase can be applied directly for the solvent leaching of a solid material, without the need to add a mineral acid. Higher selectivities for leaching can be achieved by using solutions of chelating extractants as lixiviants. Some examples include α-hydroxyoximes (e.g. LIX® 63), β-hydroxyaryloximes (e.g. LIX® 65 N), β-diketones (e.g. LIX® 54), and 8-hydroxyquinolines (e.g. Kelex® 100). In Fig. 2, the structures of some commonly used extractants are shown.

Structures of extractants: bis(2-ethylhexyl)phosphoric acid, D2EHPA (1), (2-ethylhexyl)phosphonic acid, mono(2-ethylhexyl) ester (2), bis(2,4,4-trimethylpentyl)phosphinic acid, Cyanex® 272 (3), Versatic acid (4), naphthenic acid (5), β-diketone (6), 5,8-diethyl-7-hydroxydodecane-6-oxime, LIX63 (7), β-hydroxyaryloxime (8), Kelex® 100 (9) tri-n-butylphosphate, TBP (10), Aliquat® 336 (11)

If a neutral extractant such as tri-n-butyl phosphate (TBP) is used, in general the solvent cannot be used directly for the solvent leaching of a solid material, because the neutral extractants are poor lixiviants. However, very powerful lixiviants can be obtained by bringing an organic phase containing TBP into contact with a concentrated aqueous solution of a mineral acid (H2SO4, HNO3, HCl) [13, 30, 31]. During this conditioning step, TBP will extract the acid molecules as well as a certain amount of water. Whereas the extraction of acids by TBP is often an unwanted phenomenon in solvent extraction (because this process competes with the extraction of metal ions), the affinity of TBP for strong acids is an asset during solvent leaching, because a highly acidic organic phase can be obtained. TBP–H2SO4, TBP–HNO3 and TBP–HCl are useful lixiviants in solvometallurgy. TBP can be used in undiluted form or it can be diluted in an organic solvent to reduce its viscosity. The strength of the TBP-based lixiviant can be tuned by varying the acid concentration in the conditioning step. TBP can be replaced by other neutral extractants such as Cyanex® 923, which is a commercial mixture of trialkylphosphine oxides [32]. We could also consider using the 8-hydroxyquinoline derivative Kelex® 100 saturated with mineral acids as a lixiviant [33]. The nitrogen atom in the quinoline ring is relatively basic and has a strong tendency to bind acids. The strong tendency to extract acids is a disadvantage when using Kelex® 100 for conventional solvent extraction, but it is an advantage when using this extractant for solvent leaching.

Basic extractants are anion exchangers, and they are not very suitable for solvent leaching, unless they are combined with mineral acids. In undiluted form, they can be considered as ionic liquids. The ionic liquid trihexyl(tetradecyl)phosphonium chloride (Cyphos® IL 101), saturated with concentrated HCl [34] as well as the ionic liquid betainium bis(trifluoromethylsulfonyl)imide, [Hbet][Tf2N] have been used to dissolve different metal oxides [35]. Instead of Cyphos® IL 101, a quaternary ammonium chloride such as Aliquat® 336 could also be used.

A promising system for solvent leaching is n-octanol/HCl; this was originally developed by Russian researchers to chemically attack resistant ores such as titanomagnetite [36]. n-Octanol is a cheap solvent and has a very low solubility in water (<0.1%). This system has a low density, resulting in good hydrodynamics and a rapid phase separation from water. The lixiviant is stable over time and is reasonably stable toward concentrated mineral acids. The maximum concentration of HCl in n-octanol is 5.2 mol/L at 20 °C [36].

In some cases, the dissolution of metal oxides is enhanced by a change in the oxidation state. For instance, MnO2 is much easier to dissolve in an acid solution when a reducing agent is present. An example of a reducing lixiviant for use in solvometallurgy is methanol-HCl [27, 37]. For the dissolution of metals in their elemental state, an oxidative dissolution process is required. This can be achieved with solutions of chlorine, bromine or iodine in organic solvents (vide infra).

Solvent leaching has a number of routes (Fig. 3) [6]. The organic extractant phase can be brought into direct contact with the solid material; this approach is called “direct solid leaching.” The solid can be a crushed and grinded ore, but it can also be a fine-grained industrial process residue, or even a solid that is obtained by the dehydration of aqueous leachates or by precipitation from aqueous leachates. After the solvent leaching, the liquid organic phase and the solid residue can be separated by filtration, decantation, or centrifugation, followed by washing of the solid residue with the diluent or with another organic solvent to reduce the amount of solvent retained by the solid particles. Alternatively, the solid material can be brought into contact with both a concentrated mineral acid (typically concentrated H2SO4) and the organic phase. The mineral acid acts as a solubilizing agent. It is also possible to digest the ore first with the mineral acid (i.e., an acid cure), before the damp solid is brought into contact with the organic phase. This approach, with the addition of a concentrated acid and an organic extracting phase to the solid material, is called “non-aqueous-slurry leaching,” because the acid and the solid form a slurry with a low water content. After leaching, the liquid organic phase and the solid residue can be separated by filtration, decantation, or centrifugation, followed by washing of the solid residue with a solvent, just as in the case of direct solid leaching. “Non-aqueous-slurry leaching” should not be confused with “aqueous-slurry solvent extraction,” which is also known as “solvent-in-pulp extraction” [38]. In the latter approach, an organic extraction phase is brought into contact with a slurry of the solid material and an aqueous phase. After leaching, the organic phase can be separated from the aqueous phase and the solid residue after phase disengagement by simple decantation. However, an aqueous raffinate is also obtained, which then needs to be treated further. “Aqueous-slurry solvent extraction” is not considered as a solvometallurgical method, because of the presence of a discrete aqueous phase. It is important to note that in the three approaches, i.e., direct solid leaching, non-aqueous-slurry leaching, and aqueous-slurry solvent extraction, the metallurgical unit operations of leaching and solvent extraction are combined into a single step. This is a form of process intensification, compared with the traditional approach, where leaching and solvent extraction are carried out as two separate steps. After solvent leaching, both direct solid leaching and non-aqueous-slurry leaching give an organic-pregnant leach solution in which the metals of interest are dissolved. The metals can then be recovered from this organic phase using different approaches, depending on the polarity of the organic phase. If the organic phase contains a solvent with low polarity, the organic phase can be treated in the same way as a loaded organic phase in solvent extraction, using a scrubbing step with an aqueous solution to remove the co-dissolved impurities and a stripping step to recover the valuable metals. The stripping step can be carried out with an aqueous stripping solution or with a stripping reagent (for precipitation stripping). In principle, the aqueous phase can be replaced by a polar organic phase, which is immiscible with the less-polar phase. If the solvent leaching is performed using a polar organic phase, the metals can be recovered by precipitation, non-aqueous ion exchange, the use of a solid adsorbent (e.g., activated charcoal), or by non-aqueous solvent extraction with an immiscible organic phase.

Comparison of different approaches to solvent leaching involving hydrometallurgical leaching/extraction methods. Direct solid leaching and non-aqueous-slurry solvent leaching are solvometallurgical processes, while aqueous-slurry solvent leaching is not. Figure adapted from Ref. [6] (Color figure online)

Non-Aqueous Solvent Extraction

Solvent extraction (SX) is a very important technique in hydrometallurgy for the separation and purification of metals such as cobalt, nickel, copper, zinc, uranium, REEs, and PGMs [39]. In conventional solvent extraction, the metal ions are distributed between an aqueous phase and a water-immiscible organic phase, in general with the aid of an extractant (also called the extracting agent). Because the various metal ions distribute differently between the aqueous and organic phases, mixtures of metal ions can be separated by solvent extraction. It is clear that an aqueous phase is present in all the hydrometallurgical solvent-extraction processes. This could give the impression that all the solvent-extraction systems must involve an aqueous phase. However, this is not correct: all that is required are two mutually immiscible liquid phases. Solvent-extraction systems can also consist of (1) two mutually immiscible molten salts, (2) a molten salt and a molten metal, (3) a molten salt and an organic solvent, or (4) two mutually immiscible organic solvents.

An important point with respect to solvometallurgy is the possibility to perform solvent extraction with two immiscible molecular organic solvents, two immiscible ionic liquids, or combinations thereof (Fig. 4). It is obvious that we cannot speak about the aqueous phase and the organic phase, as is the case with conventional solvent extraction. It is better to use the terms more-polar phase and less-polar phase. The solvent pairs for non-aqueous solvent extraction need to fulfill the following requirements: (1) ability to form two immiscible phases and have low mutual solubility of the two solvents; (2) exhibition of rapid phase separation after mixing; (3) demonstration of good solubility of the extractant in the less-polar phase and poor solubility of the extractant in the more-polar phase; and (4) demonstration of good solubility of the to-be-extracted metal salts in the more-polar phase and good solubility of the extracted metal complexes in the less-polar phase. The first condition is the most difficult to fulfill because most organic solvents are mutually miscible. However, several guidelines are available for the initial selection of solvent pairs, such as reported miscibility data [40, 41], the Hildebrand solubility parameter δ for solvents [42], and the mixotropic series [43, 44]. The mixotropic series is a useful tool: the further the two solvents are apart in the series, the lower is their mutual solubility [43, 44]: concentrated aqueous salt solutions > mineral acids > water > lactic acid > formamide > morpholine > formic acid > nitromethane > acetonitrile > acetic acid > methanol > glycolmonoethylether > ethanol > propanol > phenol > aniline > acetone > dioxane > tetrahydrofuran > pyridine > ethyl acetate > methyl ethyl ketone > diethyl ether > dichloromethane > tetrachloroethylene > chloroform > dichloroethane > trichloroethane > benzene > toluene > carbon tetrachloride > carbon disulfide > cyclopentane > cyclohexane > 2,2,4-trimethylpentane > heptane > hexane > paraffin oil.

The solvents at the beginning of the series have a very high polarity, whereas the solvents at the end of the series have a low polarity. Although the miscibility can be tested by simple test-tube experiments, the mutual solubility must be quantitatively measured using Fourier transform infrared (FTIR) spectroscopy, gas chromatography (GC) or nuclear magnetic resonance (NMR) spectroscopy. The mutual solubility is a function of the temperature and the concentration of dissolved salts. Two solvents that are totally miscible in the pure state can phase-separate after the addition of metal salts. For instance, ethanol is miscible with all conventional organic solvents. However, the phase separation of a mixture of ethanol and n-dodecane occurs upon the addition of 1 M LiCl. Higher LiCl concentrations result in the phase separation of mixtures of ethanol and aromatic solvents. Examples of immiscible solvent pairs are methanol–dodecane, formamide–dodecane, acetonitrile–dodecane, and ethylene glycol–dodecane. The ionic liquids 1-ethyl-3-methylimidazolium chloride and trihexyl(tetradecyl)phosphonium bis(2,4,4-trimethylpentyl)phosphinate form a pair of immiscible non-aqueous solvents as well [45]. Another immiscible pair of ionic liquids are betainium bis(trifluoromethylsulfonyl)imide and trihexyl(tetradecyl)phosphonium bis(trifluoromethylsulfonyl)imide [46]. It is important to realize that the extractant dissolved in the less-polar phase can have an influence on the mutual miscibility of the two organic solvents; two solvents that are mutually immiscible can become partly miscible after dissolving an extractant in the less-polar phase. Moreover, some extractants can also extract solvent molecules from the more-polar phase.

Although non-aqueous solvent extraction has not received much attention so far, it offers several advantages over conventional aqueous solvent-extraction systems. First of all, the approach is applicable to the separation of covalent metal compounds such as halide complexes of p-block elements (SiCl4, GeCl4, SbCl3) and early d-block elements (ZrCl4, HfCl4, NbCl5, TaCl5), as well as organometallic compounds. These compounds hydrolyze in water, and the hydrolysis reaction can be vigorous. Second, there is the opportunity to carry out separations that are not efficient in an aqueous solution because of the differences in the extraction mechanism.

Non-Aqueous Ion Exchange

Ion exchange (IX) is an often-used method for the removal of metal ions or metal salts from aqueous solutions. Typically, ion exchanges are carried out using functionalized, crosslinked, polystyrene-derived resins. The strongly acidic cation-exchange resins have sulfonic acid functional groups, whereas the strongly basic cation-exchange resins have quaternary ammonium groups. Whereas solvent extraction is more often used to recover metals from concentrated solutions, ion exchange is typically used for the recovery of metals from dilute aqueous solutions. Many studies have been devoted to the effect of adding polar organic solvents to the aqueous phase, because the presence of an organic solvent can lead to a stronger adsorption of metal ions by the ion-exchange resin and to higher selectivities in separation processes [47]. On the other hand, there are relatively few studies on ion exchange in non-aqueous solvents. Ion-exchange resins must swell in the solvent used in order to adsorb and exchange the ions at a sufficiently rapid rate. In general, ion-exchange resins swell well in water, even if the resin has a relatively high degree of crosslinking. However, commonly used ion-exchange resins might not swell sufficiently in a non-aqueous solvent, leading to a slowing down or inhibition of the ion-exchange reaction. Another reason is that the compounds must exhibit some ionic dissociation, which means that a polar solvent with a relatively high dielectric constant ε r must be used. An exception is anion exchangers with relatively basic anions, which can bind neutral metal complexes through adduct formation. For instance, an anion exchanger in the chloride form can bind nondissociated CoCl2 dissolved in an organic solvent by the formation of a complex anion [48].

Solvents that can be used instead of water in ion-exchange processes include the lower alcohols (methanol, ethanol, propanol, isobutanol, and n-butanol), polyalcohols (ethylene glycol, propylene glycol, glycerine), ethers (diethyl ether, dioxane, tetrahydrofuran), ketones (acetone, methyl ethyl ketone), organic acids (formic acid, acetic acid), pyridine, DMF and DMSO [47]. To these solvents, mineral acids can be added, for example, H2SO4, HNO3, HCl or HBr. Often, mixtures of these solvents with water are used instead of non-aqueous solvents. However, as mentioned above, the liquid phase must consist of at least 50 vol% of organic solvent if we are to consider the ion-exchange process as a solvometallurgical process. An example of an exotic solvent for ion exchange is molten urea [49].

A major advantage of non-aqueous ion exchange is that more metal ions form anionic complexes with chloride or nitrate ions in organic solvents than in water, which means that more metals can be recovered using an anion exchanger from an organic solution than from an aqueous solution. A typical example is the trivalent rare-earth ions. These do not form anionic complexes with chloride ions in aqueous solutions and form only anionic complexes with nitrate ions in the presence of very high nitrate concentrations. However, the rare-earth ions readily form anionic complexes with chloride or nitrate ions in organic solvents such as methanol. Other metal ions that only form anionic complexes with chloride ions in organic solvents are thorium(IV), nickel(II), calcium(II) and chromium(III).

Cation exchangers in the protonated (H+) form can be used to recover metal ions from the leachate after direct solid leaching with a solution of a mineral acid in a polar organic solvent, such as HCl in acetone. Anion exchangers in the chloride form can be used to recover metal chloride salts from organic solvents, even from those with a lower polarity, as long as the swelling of the resin is sufficient. Another approach to removing salts from organic solvents is to use dual or mixed beds of cation and anion exchangers [50].

Precipitation or Crystallization

An alternative approach in hydrometallurgy to the recovery of dissolved metals from the leachate—in addition to solvent extraction, ion exchange or adsorption by activated charcoal—is crystallization or precipitation. Crystallization results from evaporation of the aqueous phase until the aqueous solution becomes saturated and the metal salts start to form crystals. Precipitation can be achieved by increasing the pH to form insoluble hydroxides, or by adding a precipitation agent such as sodium carbonate to precipitate insoluble metal carbonates. Metals can be recovered in metallic form by cementation (for instance by adding iron scrap to a CuSO4 solution) or by reduction with hydrogen gas [1]. In principle, most of these methods can be applied to recover metal salts dissolved in organic solvents, although it is important to realize that water must be present for the precipitation of metal hydroxides. An alternative approach to crystallize or precipitate metal compounds from organic solutions is through the addition of an anti-solvent that is miscible with the solubilizing solvent. It is important to keep in mind that metals must be reduced to the metallic state. Precipitation is needed only if purification or further separation from contaminants is required.

Electrolysis in Non-Aqueous Electrolytes

The electrowinning of metals can be achieved from aqueous electrolytes or from molten salts. It is often used to recover copper, nickel, and zinc from aqueous solutions. A typical example of an electrowinning process based on molten-salt electrolytes is the Hall–Héroult process for producing aluminum metal. Electrolysis can also be used for the electrorefining of metals, by anodic dissolution of the metal and electroreduction of the metal at the cathode. Another use of electroreduction is covering metallic objects with a thin protective or decorative layer of another metal (i.e., electroplating). An example is the coating of a steel plate with a layer of zinc for corrosion protection. Many fundamental studies have been devoted to the electrodeposition of metals from non-aqueous electrolytes, but very few of them have been applied on an industrial scale. There are several reasons for this lack of industrial interest. First of all, non-aqueous electrolytes with dissolved conducting salts have a much lower conductivity with respect to aqueous electrolytes, so that the electrodeposition rates are much slower. Second, there are serious safety issues associated with many organic electrolytes, especially if they are based on volatile solvents such as diethyl ether. Third, sacrificial anodes have to be used, because otherwise the organic solvents in the electrolyte bath will decompose. Most of the technologies developed for the electrodeposition of metals from non-aqueous solvents are about the electrorefining or electrodeposition of metal coatings, not about electrowinning. One of the few examples of the electrowinning of metals from non-aqueous solvents is the electrowinning of zinc and lead from deep-eutectic solvents after the leaching of these metals from electric-arc-furnace (EAF) dust [51]. These deep-eutectic solvents also make it possible to deposit hard chrome layers from chromium(III) salts, which is only possible from carcinogenic chromium(VI) salts when using aqueous electrolytes [52]. The electrodeposition of aluminum layers from non-aqueous electrolytes containing organo-aluminum compounds is applied on an industrial scale by companies such as AlumiPlate Inc. in Minneapolis, MN (www.alumiplate.com) and Rasant–Alcotec in Overath, Germany (www.rasant-alcotec.de). The electrodeposition or electrorefining of metals from non-aqueous electrolytes is interesting for metals that cannot be deposited from aqueous electrolytes, e.g., aluminum, or which can only be deposited with low current efficiencies from aqueous solutions, e.g., germanium. There is a large body of literature on the electrodeposition of metals from ionic liquids, but most of this research is fundamental studies [23, 53, 54].

Organic Solvents for Solvometallurgy

Green Solvents

It is clear that the solvent plays a crucial role in solvometallurgy and that careful solvent selection is essential. However, the selection of the best solvent for a solvometallurgical process is not only based on performance. Stability, the possibility to recycle the solvent, and economics, because environmental impact, safety, and toxicity must also be considered. The sustainability of a solvometallurgical process is closely related to the solvent on which the process is based. A sustainable solvometallurgical process cannot make use of harmful and dangerous solvents. Such solvents must be avoided, even if they would perform well in a specific leaching or extraction process. A large number of organic solvents are commercially available at a reasonable cost, but not all of these solvents are useful in solvometallurgical processes. Table 2 lists the most relevant organic solvents for solvometallurgy, divided into three classes: (1) preferred, (2) usable and (3) undesirable, according to the Pfizer “traffic light” solvent-selection guide [55]. If possible, the solvents listed in the first column of Table 2 should be used (= preferred solvents). If no suitable solvent is found in the first column, a solvent listed in the second column can be tried (= usable solvents). However, solvents listed in the third column of Table 2 (= undesirable solvents) must be strictly avoided for the development of sustainable solvometallurgical processes. These solvents either have a very low flash point, easily form explosive peroxides, are ozone-depleting substances, have other environmental issues, they are toxic or they are carcinogenic. There is little ambiguity about the list of solvents in the third column, in the sense that all these solvents are problematic. The division of solvents among the first two columns is, however, more arbitrary, because the sustainable character of a solvent is determined by several criteria, including workers’ safety, process safety, and environmental concerns. For more information on solvent-selection guides, the reader is referred to the literature [55,56,57,58,59]. It is important to realize that these solvent-selection guides were drawn up for the chemical and pharmaceutical industries and not for extractive metallurgy. Nevertheless, many conclusions have general validity.

Ionic liquids and deep-eutectic solvents are not listed in Table 2 because the properties of these solvents are very much dependent on the composition. The compositional range here is too wide to draw any general conclusions. However, these solvents are often considered as green solvents because of their nonvolatility, low flammability, and, in general, low toxicity.

Volatile solvents might appear to be very useful because they can be recycled by distillation. However, they contribute a great deal to smog formation and present health risks through inhalation. Many volatile solvents have a low flash point, are flammable, and can even form explosive mixtures with air. If possible, distillation should be avoided as a recycling method for organic solvents because this technique is energy intensive and requires the use of volatile solvents. It is, therefore, recommended to explore nonthermal techniques for solvent recuperation rather than distillation. An example of such a technique is organic solvent nanofiltration (OSN), also known as solvent-resistant nanofiltration (SRNF), which is a pressure-driven membrane technique [60].

The environmental impact of a solvent requires more attention when the solvent is used in a system that is open to the environment, rather than a fully closed system. A solvent used in an open system should be nonvolatile and have a low toxicity. In the case of solvents used for leaching in open systems (e.g., for heap leaching), the biodegradability, i.e., the breakdown of chemical compounds by microorganisms, of the solvent is an asset. Water-soluble esters, ketones, alcohols, and glycol ethers are readily biodegradable, while hydrocarbon solvents often have a much slower biodegradability due to their poor solubility in water, but there are differences in the degradation rate for the different classes of hydrocarbons. The order of susceptibility to biodegradation is: n-alkanes > branched alkanes > low-molecular-weight aromatics > cyclic alkanes. Chlorinated and fluorinated solvents are, in general, poorly degradable. Several ionic liquids have a poor biodegradability, although other types of ionic liquids have been specifically designed to be biodegradable [61]. On the other hand, biodiesel is an easily biodegradable and nontoxic solvent. Biodiesel is a mixture of mono-alkyl esters of long-chain fatty acids derived from vegetable oils or animal fats [62, 63]. It has been successfully tested as a diluent in solvent-extraction studies [64,65,66,67]. Soybean oil methyl esters have also been investigated as a diluent for solvent-extraction systems [68]. Soybean oil consists of a mixture of fatty acids, with the vast majority of the fatty-acid component being linoleic acid, an 18-carbon, long-chain fatty acid with double bonds at carbon atoms 9 and 12. Glycerol is a side product formed during the production of biodiesel, and it is a good solvent for many metal salts [69]. It can also be used as a starting product for the production of other green solvents such as alkyl glycerol ethers [70].

Methanesulfonic acid (MSA) is an example of a strongly acidic organic solvent that can be considered as a green solvent [71]. Methanesulfonic acid has a low toxicity, is readily biodegradable, and is part of the natural sulfur cycle. In general, metal methanesulfonate salts have a very high solubility in water so that they are often considered as a metal source in the preparation of aqueous electrolytes for metal deposition.

A new class of solvents that shows great promise for applications in solvometallurgy is solvents prepared by gas-to-liquids (GTL) technology [72]. GTL solvents are prepared from natural gas using the Fischer–Tropsch process. The GTL process consists of three stages. In the first stage (syngas reforming), the natural gas is partially oxidized to create synthesis gas (syngas), a mixture of hydrogen and carbon monoxide, which is then purified. In the second stage (the Fischer–Tropsch reaction), the syngas is converted by a catalyst to a long-chain, heavy paraffinic liquid, the Fischer–Tropsch wax, which consists of a mixture of many compounds. In the third stage (product upgrading), the oxygen-containing products and alkenes are hydrogenated to alkanes. Through hydrocracking and isomerization, the paraffins are converted into smaller alkanes with a very characteristic branching pattern. Using distillation, fractions with a different distillation range are obtained. The GTL solvents consist mostly of iso-paraffins and normal paraffins, with only very small amounts of cyclic paraffins. They contain small amounts of impurities such as sulfur, olefins, and polycyclic aromatics. They are almost odorless, due to their low aromatic and naphthenic content. Shell offers a range of commercial GTL solvents with different distillation ranges (GS190, GS215, GS250, GS270, GS310). The solvents with the higher distillation ranges have the lowest volatility, but they also have a higher viscosity (although it must still be considered as a relatively low viscosity). A very interesting property of these solvents is their good biodegradability [73, 74]. GTL solvents were found to exhibit more than 60% biodegradation over the required 28-day test period, with the degradation continuing after the 28 days toward complete degradation. Therefore, they are considered to be readily biodegradable according to the OECD 301F guideline. GTL solvents have better biodegradation scores than comparable petroleum-derived solvents because of the lower proportions of aromatics and/or naphthenics in the GTL solvents.

Organic solvents tend to degrade over time. In general, this is a disadvantage compared with water. In many cases, organic impurities can be removed by a washing step with water or with an organic solvent. In other cases, solvents can be purified by distillation, even though this is an energy-intensive process. This purification process cannot be repeated endlessly, and at any given moment, the solvent has to be replaced by a fresh batch of solvent. At the end of the lifetime of the solvent, safe disposal is required. The best approach is to burn the spent solvent, with heat recuperation. The disposal by incineration is one of the reasons why halogenated solvents must be avoided. Halogenated solvents cannot readily be handled in most incinerators.

Although inorganic solvents (with the exclusion of water, of course) can in principle be used for solvometallurgical processes, inorganic solvents are generally of little use in this context because they are too reactive, too dangerous, too toxic or too difficult to handle. Examples include liquid ammonia, liquid sulfur dioxide, anhydrous hydrogen fluoride, thionyl chloride, sulfuryl chloride, phosphoryl chloride, dinitrogen tetroxide, and antimony trichloride. Concentrated sulfuric acid is an inorganic solvent, but it is not used in solvometallurgy as a solvent, but rather for ore acidification (acid curing of ores). Supercritical CO2 could find applications in the field of non-aqueous solvent extraction and solvent leaching [75,76,77,78]. Of particular interest are the promising combinations of supercritical CO2 with TBP-HNO3 and supercritical CO2 with fluorinated β-diketones as solvents for direct solid leaching [79,80,81,82,83]. CO2 becomes a supercritical fluid at its critical temperature (31.10 °C) and critical pressure (72.8 atm) [84]. Any supercritical fluid expands to fill a container, but it has a density that is similar to that of a liquid.

Ionic Liquids (ILs) and Deep-Eutectic Solvents (DESs)

Ionic liquids (ILs) are a special class of solvents that consist entirely of ions [85, 86]. This differentiates ionic liquids from both conventional organic solvents, which consist of neutral molecules, and from salt solutions, which consist of a mixture of neutral molecules and ions. Many researchers define ionic liquids as organic salts with a melting point below 100 °C, but this definition is too restrictive, and the threshold of 100 °C (the normal boiling point of water) is arbitrary. There are many examples of ionic liquids with melting points above 100 °C that have properties very similar to those of low-melting ionic liquids. Of course, low melting points are an advantage, and the room-temperature ionic liquids (RTILs) are preferred. The typical cations in ionic liquids are organic cations with one or more alkyl chains. Examples include 1-alkyl-3-methylimidazolium, N-alkylpyridinium, N-alkyl-N-methylpyrrolidinium, tetraalkylammonium, and tetraalkylphosphonium cations. Anions can be inorganic, such as chloride, bromide, iodide, thiocyanate, tetrafluoroborate, hexafluorophosphate, bis(trifluoromethylsulfonyl)imide (=bistriflimide), or organic, such as acetate or benzoate. By combining these cations and anions, a wide range of ionic liquids can be obtained (Fig. 5). A special type of ionic liquids is the “liquid metal salts” that have a metal-containing cation. Molten-salt hydrates also belong to this class of ionic liquids [87]. In molten-salt hydrates, all the water molecules are strongly coordinated to the metal ions so that there are no free water molecules in the melt. Examples include CaCl2·6H2O, or Mn(NO3)2·6H2O. Also worth mentioning are the functionalized ionic liquids in which a functional group is covalently attached to the ionic liquid cation. In the past, these ionic liquids were often called “task-specific ionic liquids” [88]. However, “functionalized ionic liquids” is nowadays the preferred term. A well-known example of a functionalized ionic liquid is betainium bis(trifluoromethylsulfonyl)imide, [Hbet][Tf2N], which contains a carboxylic acid functional group (Fig. 6) [35].

Although the physicochemical properties of ionic liquids are very dependent on the chemical composition of the ionic liquid, we can also make some generalizations. First of all, many ionic liquids have a nonmeasurable vapor pressure at room temperature, although some ionic liquids can be distilled in a high vacuum at high temperatures. Ionic liquids often have a very wide liquidus range; it is not uncommon to have ionic liquids that are fluid over a range of more than 250 °C, which is much wider than the 100 °C range of water. Ionic liquids are intrinsic electrical conductors, and they can have an electrochemical window of more than 4 V (the electrochemical window of water is just 1.23 V). Ionic liquids are good solvents for many classes of inorganic and organic compounds. Compared with molecular organic solvents, ionic liquids have a much higher viscosity, which can hamper mass transport and slow down the rate of chemical processes. However, the viscosity of ionic liquids reduces dramatically upon heating or the addition of a small amount of a molecular co-solvent.

A drawback of many ionic liquids is their high price, and this has hindered the development of ionic-liquid processes on an industrial scale. A cheap alternative to ionic liquids are the deep-eutectic solvents (DESs) [22, 29, 89, 90], of which there are many different types. Most of them are mixtures of choline chloride and a hydrogen-bond donor (urea, ethylene glycol, malonic acid) or mixtures of choline chloride with a hydrated metal salt. A typical feature of a DES is that it has a much lower melting point than each of its individual components. Popular DESs are those obtained by mixing chloride and urea in a 1:2 molar ratio, or choline chloride and ethylene glycol in a 1:2 molar ratio. These solvents are liquid at room temperature. Choline chloride is produced on a large scale and is used as chicken feed. Due to the low cost of DESs, it is much easier to use them on a large scale than ionic liquids. Although DESs often have a significant water content, their properties are generally different from those of aqueous solutions. As mentioned before, hard chrome layers can only be electrodeposited from aqueous electrolytes using toxic chromium(VI) salts, whereas the metal can be deposited from DESs containing the much-less-toxic chromium(III) salt. In fact, a DES electrolyte for chromium deposition can be prepared by simply mixing CrCl3·6H2O and choline chloride [91], or by mixing CrCl3·6H2O and urea [92]. Although deep-eutectic solvents cannot be considered as ionic liquids, as they are mixtures of ions and smaller or larger amounts of neutral molecules, their properties are very similar to those of conventional ionic liquids. For this reason, they are often described as ionic-liquid-like solvents, or just as ionic liquids. Due to their water content, the electrochemical window of DESs is smaller than that of conventional ionic liquids.

The most obvious applications for ionic liquids and deep-eutectic solvents in solvometallurgy are in the electrodeposition of metals from non-aqueous electrolytes. Commonly used ionic liquids for electrodeposition are 1-butyl-3-methylimidazolium bis(trifluoromethylsulfonyl)imide, [C4mim][Tf2N], or N-butyl-N-methylpyrrolidinium bis(trifluoromethylsulfonyl)imide, [BMP][Tf2N], as well as several deep-eutectic solvents [23]. Other applications of these ionic solvents in solvometallurgy are as solvents for solvent leaching and in non-aqueous solvent extraction. As mentioned in the introduction, the term “ionometallurgy” is used for solvometallurgical processes based on ionic liquids or deep-eutectic solvents [24].

Ten Good Reasons to Use Solvometallurgy

We recommend considering solvometallurgy for those cases where the application of traditional methods of extractive metallurgy is difficult or problematic. If existing processes are working well, there might be no need to consider alternative processes based on the use of non-aqueous solvents. However, there are many cases where solvometallurgy could make a difference. We have identified ten reasons to use solvometallurgy (Table 3), and these are discussed in more detail below.

Reason 1. Very Limited Water Consumption

Because no bulk aqueous phase is present in a solvometallurgical process, the consumption of water can be limited to a strict minimum. In some solvometallurgical processes, a small amount of water is essential, but the water volumes are always small compared to the volumes of organic solvents, and in most cases no discrete aqueous phase is present. If no water is consumed in a solvometallurgical process, it also implies that no wastewater is generated, and that there are no issues with wastewater treatment. Solvometallurgical processes have the potential to recover metals from ore deposits in arid areas, where it is difficult to guarantee a sufficient supply of process water. This is very relevant for exploiting copper mines in the Atacama Desert in Chile. Likewise, solvometallurgical processes can also be operated in (mobile) stand-alone units that can be used to recover metals from small ore deposits at remote locations.

Reason 2. Reduced Energy Consumption

Solvometallurgical processes offer the opportunity to treat, at ambient temperatures, ores that otherwise have to be heated to high temperatures to convert them to oxides before they can be further processed. A good example is the calcination of carbonate ores. By means of chlorine gas dissolved in an organic solvent, it is possible to chlorinate ores at ambient temperatures, instead of using chlorination or carbochlorination at high temperatures. The possibility to work at room temperature or at slightly elevated temperatures results in a considerably reduced energy consumption compared with pyrometallurgical processes, which are typically carried out at temperatures above 300 °C. In general, organic solvents have a lower heat of vaporization than water, so that less energy is required to distil the organic solvent (for solvent recycling) than to distil the same volume of water. However, as mentioned elsewhere in this paper, the use of volatile organic solvents and distillation must be avoided, whenever possible.

Reason 3. Process Intensification

Solvometallurgy allows for process intensification, because different unit operations (e.g., leaching and solvent extraction) can be combined, and this reduces the number of process steps. A combination of mechanical activation (e.g., by ball milling) and solvometallurgy allows the treatment of resistant ores such as columbite, tantalite, and pyrochlore under much milder conditions (ambient temperatures, no HF) with respect to traditional metallurgical methods [18].

Reason 4. Reduced Consumption of Acids

Even if acid curing of the ore is used as a pretreatment step prior to solvent leaching, the total acid consumption can be much lower than that in the case of conventional leaching. This is because a larger excess of acid is often used in conventional acid leaching and because protons can be provided by the extractant in the case of solvent leaching with acidic extractants. Hydrometallurgical processes with acid leaching are not very compatible with carbonate-rich ores and especially not with those rich in calcite or dolomite, because the dissolution of the carbonate gangue material consumes large amounts of acids. This is relevant if the minerals in a carbonate matrix cannot be separated from the gangue by flotation, e.g., in the case of the uranium ore carnotite. By solvent leaching the ore minerals, the carbonate gangue materials can be left largely untouched. Because solvent leaching is more selective than leaching with aqueous solutions of mineral acids, it is possible to avoid the co-dissolution of unwanted metals such as iron, which also leads to a reduction in the consumption of acids (see also Reason 5).

Reason 5. Higher Selectivity for Leaching

In general, leaching with aqueous solutions of mineral acids (H2SO4, HNO3, HCl) suffers from low selectivity. Besides the targeted metals, many unwanted metals are co-dissolved. This poor selectivity leads not only to a higher consumption of acids (see Reason 4), but also to extra process steps for the removal of impurities from the leachate. Solvent leaching can, in principle, offer a higher selectivity than leaching with aqueous solutions of acids, especially if chelating extractants are used, such as the LIX® family of extractants.

Reason 6. Fewer Problems with Silica Gel Formation

For the recovery of technological metals such as rare earths, zirconium, tantalum, or niobium, we are forced to rely more and more on ores with a complex composition and a high content of soluble silica, because of the depletion of ores with a simpler chemical composition. A good example is eudialyte, Na15Ca6(Fe,Mn)3Zr3(Si,Nb,REE)Si25O73(OH,Cl,H2O)5. The leaching of such minerals with mineral acids dissolves the silica as silicic acid. This dissolved silica is gradually transformed by polymerization into colloidal silica, and these colloids can aggregate to form a gel. Gel formation in a leachate makes the filtration for solid–liquid separation impossible. Dissolved silica can also interfere with solvent extraction, because it causes the formation of extremely stable emulsions during the mixing of the aqueous and the organic phases. These emulsions can be stable for weeks or even months. Silica colloids can also block the pores in ion-exchange resins. Dissolved silica is not only a problem in the case of acidic leaching; it is even more so in the case of alkaline leaching, because silica has a higher solubility in alkaline solutions. Because water is required for the formation of silicic acid, it is evident that the leaching of silica-rich ores with non-aqueous solvents leads to much lower solubilization of the silica and hence to fewer problems with silica gel formation.

Reason 7. Suitable for the Treatment of Low-Grade Ores, Mine Tailings, and Industrial Process Residues

As mentioned in the introduction, the depletion of high-grade ores with a simple composition necessitates the shift to low-grade ores, mine tailings, and industrial process residues that contain only low concentrations of valuable metals and often have a complex composition with several mineral phases. Conventional leaching with aqueous solutions of mineral acids lacks selectivity, leading to the consumption of large amounts of acid and the co-dissolution of unwanted impurities. In particular, the co-dissolution of the matrix is a major problem. Solvometallurgical processes are suitable for the recovery of metals from low-grade ores (e.g., nickel laterites), tailings from primary mining, or industrial process residues (e.g., bauxite residue, goethite, or jarosite) because of their intrinsic higher selectivity (see also Reasons 4 and 5).

Reason 8. Useful for the Treatment of Urban Waste

In ore deposits, the metals typically occur in complex polymetallic sulfide or oxide ores, whereas the metals of the urban mine are typically present in the form of alloys. Examples are the rare-earth permanent magnets, which consist of neodymium-iron-boron or samarium-cobalt alloys. The direct reuse of these alloys is often not possible, and the mixture of constituting metals needs to be separated into the individual elements. In hydrometallurgical recycling methods, the alloys are dissolved in aqueous solutions of strong mineral acids (H2SO4, HCl, HNO3). This step can be unsafe because of the formation of flammable hydrogen gas during the metal dissolution. In the case of arsenic-containing alloys (e.g., GaAs), there is a danger of formation of highly toxic arsine gas (AsH3). The acidic attack dissolves the whole mass of the alloy, so that selective leaching is impossible, and large volumes of acid are consumed. This is a problem with the recovery of rare earths from neodymium-iron-boron magnets, since 70 wt% of the magnet alloy consists of iron. The pyrometallurgical recycling of metals often involves a high-temperature chlorination step to transform the metals into the corresponding chlorides, followed by fractional distillation or sublimation, or by further hydrometallurgical processing (e.g., solvent extraction) after the dissolution of the chlorides in water. This approach is not energy efficient, and it is difficult to obtain high-purity compounds by distillation or sublimation. The hydrometallurgical process steps make the flow sheet more complicated, and they can be carried out only in very acidic solutions to avoid hydrolysis and the precipitation of the metals. After purification by solvent extraction, the dissolved metals have to be converted into anhydrous chlorides, fluorides, or oxides before they can be further processed to the metal, for instance, by electrolysis in molten salts. The flow sheets for the recycling of valuable metals from production scrap and end-of-life consumer goods (Fig. 1) can be shortened and made to be more energy efficient by using solvometallurgy if (1) the chlorination is carried out with chlorine gas dissolved in an organic solvent rather than in a chlorine gas stream at high temperatures, (2) the water in the hydrometallurgical process steps is replaced by organic solvents, and (3) the electrolysis is carried out in organic electrolytes instead of molten salts.

Reason 9. Compatibility with Bioleaching

Although the aim is to recover 100% of the organic solvent after the solvent leaching, complete recovery of the solvent is impossible and some traces of solvent will always remain adhered to the particles of the solid residue, even after a washing step with another organic solvent. However, the solid residue obtained after the solvent leaching can be treated in a subsequent step with bioleaching. This bioleaching step can further enhance the recovery of metals from the residue. Based on differences in the reactivity between the solvent leaching and the bioleaching steps, metals other than those solubilized in the solvent-leaching step can be solubilized in the bioleaching step. More importantly, the solvent traces left after solvent leaching are rich in carbon and could serve as a nutrient for heterotrophic microorganisms (bacteria and fungi), which need organic supplements for growth and energy supply. In this way, the solid residue can be cleared from any solvent traces left behind after the solvent leaching. It is of course necessary that the solvents used for the solvent leaching are not toxic to microorganisms. Of course, it is preferable for the solvents to be biodegradable. Nonpolar solvents with a good biodegradability include some gas-to-liquid solvents (GTL solvents) prepared using the Fischer–Tropsch synthesis from natural gas, such as the GS series of solvents produced by Shell (e.g., GS250). In addition, biodiesel could be used as a biodegradable nonpolar solvent in solvometallurgical processes.

Reason 10. New Separation Processes

Some separation processes can only be carried out in the absence of water. An example is the electrowinning of reactive metals in non-aqueous electrolytes (electrodeposition of aluminum or very pure indium), which is possible in high-temperature molten salts, but not in aqueous solutions. Another example is the purification of LiCl [19, 93], which is very soluble in many organic solvents, in contrast to the other alkali-metal chlorides. Alcohols are particularly good solvents for LiCl, due to the formation of stable solvates such as LiCl·3CH3OH in methanol or LiCl·4C2H5OH in ethanol. By treating mixtures of alkali-metal chlorides with absolute ethanol, LiCl goes into solution, whereas NaCl and KCl do not.

Examples of Solvometallurgical Processes

Solvent Leaching of Low-Grade Uranium Ores

The concept of solvometallurgy originates from research activities in the United States shortly after World War II, aimed at recovering uranium from domestic uranium ores. These were typically low-grade uranium ores with a U3O8 content of less than 1%, such as low-lime sandstone ores containing carnotite, autunite, torbernite, and uranophane or high-lime carnotite ores containing high concentrations of calcite (CaCO3) gangue material. Carnotite is a secondary uranium-vanadium ore with the chemical formula K2(UO2)2(VO4)2·3H2O that occurs extensively on the Colorado Plateau. The recovery of uranium from high-lime carnotite ores is very challenging because conventional hydrometallurgical processes based on acid leaching are often not economic due to the large quantities of acid consumed, resulting from the co-dissolution of the calcite gangue material. Three different solvometallurgical processes for uranium recovery from low-grade ores have been disclosed [9] (Fig. 7): (1) the TBP process; (2) the acetone-HCl process, and (3) the alkyl phosphoric acid process. Of these three processes, the alkyl phosphoric acid process is the only one that consumes less than the stoichiometric amount of acid with respect to the lime content, and it is thus the most suitable process for the recovery of uranium from high-lime carnotite ores. However, all three processes consume much lower amounts of water than hydrometallurgical processes.

Flow diagrams for the solvent leaching of uranium from ores. Adapted from Ref. [9] (Color figure online)

The TBP process uses tri-n-butylphosphate (TBP) to extract uranyl nitrate and gives a high-grade uranium concentrate [7]. The uranium ore is crushed to a particle size of less than 10 mesh, mixed with concentrated H2SO4 and a small amount of water, and cured for about 1 h to dissolve the uranium in the form of uranyl sulfate and to neutralize any of the lime that the ore might contain. The amount of acid used in this step is equivalent to that required for a conventional acidic leaching step, but the water requirements are much lower. The ore-acidification step produces a damp, friable mass into which all of the acid solution is absorbed. No liquid phase remains or separates from the ore over time. This acid-curing step is carried out with about 80% of solids present. After the pretreatment, the ore is wetted with an NH4NO3 solution to convert the uranyl sulfate into uranyl nitrate (nitrate-conditioning step) and the damp mass is leached with a 5 vol% solution of TBP in kerosene or hexone (methyl isobutyl ketone). Kerosene or hexone is used as a diluent to obtain a solvent with a sufficiently low viscosity. By adding NH4NO3 to the acid-cured ore, a nearly complete recovery of uranium from the ores is possible. The solvent can be brought into contact with the ore by agitation in a mixing tank, by percolation through a column or by spraying it on the ore, while the ore travels on a moving belt (Fig. 8). About 4000–11,000 L of solvent are required per ton of ore. The leach residue is washed with a volatile organic solvent to recover the entrained TBP and kerosene. The uranium can be easily stripped from the loaded organic phase by water to give a uranyl nitrate solution. Precipitation with an ammonia solution gives ammonium diuranate, which can be calcined to drive off the ammonia and to yield high-purity U3O8. The advantages of the process are that (1) a small volume of water is used, (2) the uranium stripping from the solvent is straightforward and (3) a minimum number of steps is required to produce a high-grade U3O8 concentrate from a low-grade uranium ore. The disadvantages are that (1) the ore-acidification step consumes the same amount of acid as required for a conventional hydrometallurgical leaching step, (2) the pretreatment is not effective for uranium ores requiring an oxidizing agent for good uranium dissolution, and (3) the economic recovery of TBP and kerosene is difficult.

Solvent leaching with a moving belt contactor. Adapted from Ref. [9] (Color figure online)

The acetone-HCl process is based on the high solubility of uranyl chloride in acetone [4, 94, 95]. The ore is crushed to 10 mesh and first treated with concentrated HCl or with a mixture of concentrated HCl and H2SO4 to solubilize uranium. The cured ore is fed into a pool of acetone in an enclosed extractor. Uranium, iron, vanadium, and calcium are dissolved in acetone as chloride complexes. Anhydrous ammonia gas is bubbled through the loaded acetone phase, and the dissolved metals precipitate as hydroxides. The hydroxide precipitate is removed by filtration, and the regenerated acetone is returned to the extractor. The final concentrate is of a low grade and contains about 10–15% U3O8. Since acetone is not selective for uranyl chloride dissolution, the process is used primarily for upgrading low-grade ores. The advantage of the process is the small volume of water required. Therefore, the process could be useful for upgrading ores using relatively small installations in remote areas. The disadvantages are that a gas-tight system is needed to minimize the acetone losses and that HCl is required. HCl is more expensive than H2SO4 and it causes more corrosion problems. The precipitated hydroxides are bulky and of low grade.

The alkyl phosphoric acid process uses alkyl phosphoric acids and H2SO4 for the extraction of uranyl ions from the ores [5, 9]. This process is well suited to the recovery of uranium from high-lime carnotite ores. The process was optimized for OPA, a mixture of mono- and dialkylphosphoric acids, but other alkyl phosphoric acids such as bis(2-ethylhexyl)phosphoric acid (D2EHPA) can be used as well. The ground ore is passed on a moving belt, and a solvent is sprayed on it. The solvent is an acidified solution of an alkyl phosphoric acid in a diluent. The solvent percolates through the ore bed and dissolves the uranium. The solvent entrained by the solid residue is washed with fresh diluent at the discharge end of the moving belt. This solvent-leaching strategy is highly dependent on several process parameters. The most important parameters are the type and concentration of the solvent, the amount and type of the acid, the type of diluent, the phase ratio of solvent to ore, and the contact time during the leaching. The contact time can be short, i.e. 10–20 min. The preferred acid is H2SO4, and concentrated H2SO4 (96%) is used to reduce the amount of water. Upon reacting the H2SO4 with the ore, a coating of CaSO4·2H2O (gypsum) is formed around the calcite particles. This isolates the calcite particles and prevents any further consumption of H2SO4. On the other hand, the coating of uranyl sulfate formed on the surface of the uranium minerals can be dissolved by the organic solvent. The freshly exposed surface of the uranium mineral particles further reacts with H2SO4 and the process continues until the entire uranium mineral particle is dissolved. Only about one-tenth of the stoichiometric amount of H2SO4 that would be required to dissolve all of the uranium minerals and calcite is needed. For this reason, the alkyl phosphoric acid process is very suitable for the recovery of uranium from high-lime carnotite ore. The amount of H2SO4 that is used also affects the loss of alkyl phosphoric acid to the solid residue. When no H2SO4 is used, a considerable amount of alkyl phosphoric acid is deposited on the ore, and this cannot be recovered by washing the residue with a diluent. The best efficiencies are observed by adding H2SO4 to the solvent before or during the contact of the solvent with the ore. Acid curing of the ore before contact with the solvent causes local neutralizations and the consumption of larger amounts of acid. The best uranium recoveries are obtained with methyl ethyl ketone (MEK) as the diluent, but isopropyl ether (IPE) has a lower solubility in water. Although kerosene would be a desirable solvent because of its low solubility in water and its relatively high flash point, the use of kerosene results in slow slurry-settling rates, higher alkyl phosphoric acid losses, and more difficult solvent recovery from the solid residue. In the final step, uranium can be stripped from the loaded solvent using a 10 M HCl solution.

Solvent Leaching of Copper Ores

One of the principal oxidized copper ores is chrysocolla, which is a poorly defined hydrated copper(II) silicate with varying composition, often represented by the formula CuSiO3·2H2O. The recovery of copper from chrysocolla by direct acid leaching is challenging because of the formation of silica gel. Raghavan and Fuerstenau developed a solvometallurgical process for the recovery of copper from chrysocolla by leaching it with the extractant LIX® 63 dissolved in kerosene, in the presence of a small amount of aqueous ammonia solution [10,11,12]. LIX® 63 is a selective extractant for the extraction of copper from ammoniacal solutions and its active component is 5,8-diethyl-7-hydroxy-6-dodecanone oxime. The authors were able to leach 70–75% of the copper from the ore using an ammonia content that is only about one-quarter of the stoichiometrically required amount for leaching with ammoniacal solutions. The facts that chrysocolla is a porous solid and that the pores are filled with capillary condensed water are crucial to the success of the method. Removal of the water from the pores by heating led to much lower leaching efficiencies. The nonporous synthetic CuO gave poor results as well. Ammonia is believed to enter the pores and react with the copper(II) to form the [Cu(NH3)4]2+ complex, which diffuses to the entrance of the pores on the surface of the ore particles where it reacts with LIX® 63 dissolved in kerosene. Ammonia is regenerated during this reaction and returns to the aqueous phase within the pores. This process was also applied to ocean-floor manganese nodules to recover copper, nickel and cobalt, but the leaching efficiencies were poor unless a reductive treatment at 600 °C was first applied. In that case, a recovery of 71% for nickel, 69% for copper, and 44% for cobalt could be achieved.

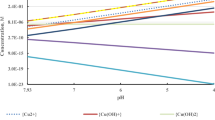

The copper(I) ion is more strongly solvated by organic nitriles such as acetonitrile (CH3CN) than by water, whereas most other cations, including copper(II) ions and protons, are more strongly solvated by water than by acetonitrile. As a consequence, copper(II) is a strong oxidizing ion in acetonitrile or in acetonitrile–water solutions, because it has a strong tendency to be transformed into the copper(I) ion. This observation was used by Parker to develop a process to recover copper from copper(I) sulfides, such as the ore minerals chalcocite, digenite, or bornite, without the need to transform the sulfides beforehand into oxides by roasting [96]. CuSO4 oxidizes Cu2S to sulfur in the presence of acetonitrile, and the acetonitrile can be recycled by distilling the acetonitrile–water mixture. When the volume ratio of cetonitrile to water becomes too low, copper(I) is no longer stable and is disproportionate to copper metal and copper(II). The reactions are

The advantage of using CuSO4 as the oxidizing agent is that no other metals are introduced in the pregnant leach solution, as in the case of leaching with Fe2(SO4)3 as an oxidizing agent. Because acetonitrile and CuSO4 can, in principle, be recycled, it would be possible to develop a closed-loop leaching process based on this technology. One drawback of the process is that a high liquid-to-solid ratio is needed: about 40 g of acetonitrile is required to recover 1 g of copper. The liquid-to-solid ratio can be reduced, but this leads to the formation of CuS instead of sulfur. This reaction can also be carried out in an acetonitrile–water solution, with the acetonitrile being removed by distillation. In water, copper(I) is unstable and undergoes a rapid disproportionation. The relevant reactions are

CuS* is activated copper(II) sulfide that can be leached, for instance, by air in the presence of H2SO4, with CuSO4 and acetonitrile acting as catalysts:

Cu2S can be dissolved in an acetonitrile solution, not only by oxidative dissolution with CuSO4, but also by H2SO4 in anhydrous acetonitrile [97]:

The solubility product of Cu2S in acetonitrile is a factor of about 1040 higher than the corresponding value in water (about 10−25 in a 1-M H2SO4 at 25 °C). The driving forces are the strong solvation of the Cu+ ion in acetonitrile and the poor solvation of the H+ ion in acetonitrile. After the dissolution the copper can be recovered from the solution by the addition of water so that Cu+ disproportionates into Cu2+ and Cu. The H2S can be oxidized to H2SO4, which can then be used in the leaching process. Not only Cu2S, but also NiS and AgS are soluble in acidified acetonitrile, but these processes have not yet been investigated in detail.

The ores containing cuprite (Cu2O) can be dissolved by H2SO4 in the presence of acetonitrile [96]:

Copper can be recovered from the oxidized copper ores by solutions of SO2 in water, in the presence of acetonitrile [96]:

Acetonitrile is recovered by distillation, and this leads to the disproportionation of copper(I). The advantage of this method is that the SO2 can be converted into sulfate, which means that the method can be coupled with the roasting of sulfidic ores. In general, a roasting plant has to be coupled to a sulfuric acid plant to avoid the release of SO2 to the atmosphere. In this case, the SO2 can be used for the reductive dissolution of metal oxides, such as CuO. Parker and coworkers have investigated the metallurgical applications of copper(I) in acetonitrile–water solutions in detail (cuprous metallurgy) [98,99,100].

A process has been proposed to recover copper, silver, and lead from copper-lead-silver dross from a blast furnace [97]. CuSO4 in 50% acetonitrile–water in the presence of H2SO4 can oxidize copper and silver. However, lead is not attacked by this reagent because of the formation of a protective layer of PbSO4. Silver can be cemented from the solution by the addition of copper powder, while copper is precipitated by distilling the acetonitrile. A process flow sheet has been developed for the refining of copper from scrap copper, cement copper, and reduced copper from the roasted chalcopyrite (Fig. 9) [98]. This flow sheet is also applicable to the refining of silver and to the recovery of copper from copper sulfides (CuS and Cu2S).

Flow sheet of a continuous process to refine copper and silver, or to recover copper from copper sulfides by leaching with CuSO4 in acetonitrile–water (An:H2O) mixtures. Adapted from Ref. [98] (Color figure online)

A remark has to be made about acetonitrile and other organic nitriles. Although these compounds contain the cyano group (−CN), they do not behave like ionic cyanides such as NaCN or KCN, which release the highly toxic hydrogen cyanide (HCN) gas when in contact with acid. Organic nitriles are relatively stable compounds, but they can be metabolized to hydrogen cyanide. However, the metabolism of acetonitrile is much slower than that of other aliphatic nitriles (propionitrile, butyronitrile, acrylonitrile) so that acetonitrile has a relatively low toxicity [101, 102].

The dissolution of chalcopyrite (CuFeS2) in acidic aqueous solutions at near-ambient temperatures and at atmospheric pressure proves to be a challenge because of the surface passivation. For this reason, the leaching of chalcopyrite is typically performed under oxidizing conditions or at high temperatures and pressures. Solis-Marcial and Lapidus found that the formation of a passivation layer could be limited by leaching with H2SO4/H2O2 in the presence of acetone or ethylene glycol in the aqueous phase [103]. The enhanced recovery of copper was attributed to the greater stability of the copper(I) ion in organic solvents. In a follow-up study, those authors investigated the leaching of chalcopyrite by H2SO4 in the presence of alcohols (methanol, isopropanol) using different oxidants (H2O2, CuSO4, O3) [104]. Also, the addition of acetic acid instead of an alcohol resulted in good copper extraction, but the addition of formic acid did not [105]. This negative result can be explained by the oxidative degradation of formic acid by the oxidizing agents.

Recovery of Zinc From Industrial Process Residues