Abstract

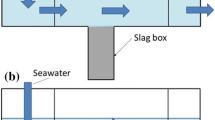

The mutual effect of steelmaking slag layer depth and diameter on alkali elution rate was investigated using two kinds of open channel vessels with straightened seawater. Seawater velocity, slag layer depth, and diameter were changed from 0.2 × 10−2 to 4.2 × 10−2 m/s, from 3.3 × 10−2 to 5.0 × 10−1 m, and from 0.10 × 10−2 to 2.18 × 10−2 m, respectively. The alkali elution rate increased with an increase in seawater velocity. The effective mass transfer coefficient, which was smaller than the true mass transfer coefficient, was calculated using the total slag surface area including the slag layer irrelevant to the alkali elution. It approached the true mass transfer coefficient when the slag diameter was larger and the slag layer was thinner. Moreover, the ratio of the effective mass transfer coefficient to the true one approached unity when the pH change in the slag layer was decreased. The slag layer height, H (m), involved in the alkali elution rate was calculated using H/d = 2.98 × 10−2 Re − 1.24 × 10−5 Re 2 when the total slag layer height, h s (m), was larger than H (m). Here, d is the slag diameter (m) and Re is the Reynolds number.

Similar content being viewed by others

Change history

16 December 2016

An erratum to this article has been published.

References

Horii K, Tsutsumi N, Kitano Y, Kato T (2013) Processing and reusing technologies for steelmaking slag. Nippon Steel Tech Rep 104:123–129

The Japan Iron and Steel Federation (2008) Tenrokei Steelmaking Slag Kaiikiriyono Tebiki (Steelmaking Slag; a Guide for Usage in the Ocean Area). JISF, Tokyo

The Japan Iron and Steel Federation (2008) Tenrokei Steelmaking Slag Kaiikiriyono Tebiki, Bessatsu, Tenrokei Steelmaking Slag to Syunsetsudo tono Kongokairyokoho (Steelmaking Slag; a Guide for Usage in the Ocean Area, Supplementary volume, Mixing Method of Steelmaking Slag and dredged soil). JISF, Tokyo

Nakamura Y, Taniguchi A, Okada S, Tokuda M (1998) Positive growth of phytoplankton under conditions enriched with steel-making slag solution. ISIJ Int 38(4):390–398

Futatsuka T, Shitogiden K, Miki T, Nagasaka T, Hino M (2004) Dissolution behavior of nutrition elements from steelmaking slag into seawater. ISIJ Int 44(4):753–761

Tanaka M, Hirata J, Nakamoto D, Terada I, Ryumae I, Takahashi M, Oikawa T, Takahashi K, Aimoto M (2014) Dissolution behavior of silicic acid from steelmaking slag to seawater. Tetsu-to-Hagané 100(7):919–923

Liu D, Yamamoto M (2014) Influence of seawater temperature and organic matter on iron elution from a mixture of steelmaking slag and composts. Tetsu-to-Hagané 100(8):1043

Yamamoto M, Fukushima M, Liu D (2011) Effect of humic substances on iron elution in the method of restoration of seaweed beds with steelmaking slag. Tetsu-to-Hagané 97(3):159–164

Zhang X, Matsuura H, Tsukihashi F (2012) Dissolution mechanism of various elements into seawater for recycling of steelmaking slag. ISIJ Int 52(5):928–933

Zhang X, Matsuura H, Tsukihashi F (2014) Influence of gluconic acid on dissolution of Si, P and Fe from steelmaking slag with different composition into seawater. ISIJ Int 54(6):1443–1449

Zhang X, Matsuura H, Tsukihashi F (2015) Enhancement of the dissolution of nutrient elements from steelmaking slag into seawater by gluconic acid. J Sustain Metall 1(2):134–143

Zhang X, Matsuura H, Tsukihashi F (2016) Dissolution mechanism of steelmaking slag-dredged soil mixture into seawater. J Sustain Metall 2(2):123–132

Kato T, Kosugi C, Kiso E, Torii K (2015) Application of steelmaking slag to marine forest restoration. Nippon Steel Sumitomo Metal Techn Rep 109:79–84

Hayashi A, Watanabe T, Kaneko R, Takano A, Takahashi K, Miyata Y, Matsuo S, Yamamoto T, Inoue R, Ariyama T (2012) Decrease of sulfide in enclosed coastal sea by using steelmaking slag. Tetsuto-Hagané 98(5):207–214

Hayashi A, Asaoka S, Watanabe T, Kaneko R, Takano A, Takahashi K, Miyata Y, Matsuo S, Kim K, Inoue R, Ariyama T (2012) Mechanism of suppression of sulfide ion seawater using steelmaking slag. Tetsu-to-Hagané 98(11):618–625

Miyata Y, Hayashi A, Kuwayama M, Yamamoto T, Urabe N (2014) Reduction test of hydrogen sulfide in the silty sediment of the Fukuyama inner harbor using steelmaking slag. Tetsu-to-Hagané 100(3):421–428

Miyata Y, Hayashi A, Kuwayama M, Yamamoto T, Tanishiki K, Urabe N (2014) A field experiment of sulfide reduction in silty sediment using steelmaking slag. Tetsu-to-Hagané 100(11):1426–1432

Kiso E, Tsujii M, Ito K, Nakagawa M, Gomyo M, Nagatome K (2008) Method of dredged soil improvement by mixing with converter steel-making slag. J Civil Eng Ocean 24(7):327–332

Takeda M, Gomyo M, Nagatome T, Tsujii M, Kiso E, Nakagawa M (2008) Field experiments on dreged soil improvement by continuously mixing with converter steelmaking slag. J Civil Eng Ocean 24(7):351–356

Miki T, Shitogiden K, Samada Y, Hino M (2004) Elution mechanism of fluorine from steelmaking slag into seawater. ISIJ Int 44(5):935–939

Mizukami H, Ishikawa M, Hirata T, Kamiyama T, Ichikawa K (2004) Dissolution mechanism of fluorine in aqueous solution from fluorine containing synthetic slag. ISIJ Int 44(3):623–629

Miki T, Futatsuka T, Shitogiden K, Nagasaka T, Hino M (2004) Dissolution behavior of environmentally regulated elements from steelmaking slag into seawater. ISIJ Int 44(4):762–769

Kanayama S, Souma A, Tanaka Y, Tsujii M, Kiso E, Nakagawa M (2008) Prediction of influence on pH by utilization of mixture of dredged soil and converter steel-making slag for coastal environment improvement works. J Civil Eng Ocean 24(7):333–338

Kanayama S, Sakanakura H, Mizutani S, Kato Y, Takahashi K, Kiso E, Hirai N, Miyazaki T (2013) Study on the elution of alkalinity from steel-making slag piled in seawater. J Civil Eng B3(Ocean) 70(2):I_1152–I_1157

Miyazaki T, Sakanakura H, Mizutani S, Takahashi K, Kiso E, Hirai N, Takeda M, Kurahara Y (2013) Experimental study on alkali diffusion behavior from steel slag products in steady seawater flow. J Civil Eng B3(Ocean) 69(2):I_1142–I_1147

Tamaki H, Uddin MA, Kato Y, Takahashi K (2013) Alkali elution behavior of steelmaking slag into seawater by batch test. Tetsu-to-Hagané 99(11):676–682

Takeuchi G, Uddin MA, Kato Y, Takahashi K (2015) Alkali elution behavior of steelmaking slag into seawater by continuous stirred tank reactor. ISIJ Int 55(10):2252–2257

Chow VT (1959) Open-channel hydraulics. International student edn. McGraw-Hill, New York

Miki T, Shitogiden K, Samada Y, Nagasaka T, Hino M (2003) Consideration of dissolution behavior of elements in steelmaking slag based on their stability diagram in seawater. Tetsu-to-Hagane 89(4):388

Chemical Society of Japan (1975) Handbook of chemistry, basic edition reviews, 2nd edn. Maruzen, Tokyo

Hoffert M, Wey YC, Callegari AJ, Broecker WS (1979) Atmospheric response to deep-sea injections of fossil-fuel carbon dioxide. Clim Change 2(1):53–68

Sohma S, Kakio T, Sekiguchi Y (2005) Introduction of the global ocean ecosystem model “DONGURI” and its implementation to investigate the biochemical effects on global warming. In: Proceedings 7th international conference on greenhouse gas control technologies, IEA (International Energy Agency), Paris, pp 2389–2393

Acknowledgements

This study was carried out under collaboration with Nippon Slag Association.

Author information

Authors and Affiliations

Corresponding author

Additional information

The contributing editor for this article was D. Panias.

An erratum to this article is available at https://doi.org/10.1007/s40831-016-0113-1.

Rights and permissions

About this article

Cite this article

Takeuchi, G., Tamaki, H., Uddin, M.A. et al. Mutual Effect of Steelmaking Slag Layer Depth and Diameter on Alkali Elution Rate in Open Channel Vessels with Straightened Seawater Flow. J. Sustain. Metall. 3, 459–468 (2017). https://doi.org/10.1007/s40831-016-0107-z

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40831-016-0107-z