Abstract

A steelmaking slag–dredged soil mixture has been applied to develop or recover the sea coast. In recent years, the side effect of its utilization has been reported, in which the coastal environment has been rehabilitated from sea desertification. It is considered that the mixture can provide various nutrient elements essential for the growth of seaweeds which are lacking in the natural seawater. In the present research, the dissolution behaviors of steelmaking slag–dredged soil mixture into seawater were investigated at laboratory-scale experiments, and the mechanisms were discussed. Variation of pH and the dissolution of Ca were significantly dependent on the CaO/SiO2 ratio of the slag, and simultaneously, a slight buffering action on the pH of seawater was provided by the dredged soil. When the pH of seawater increased to a certain extent, Mg contained in seawater precipitated and hindered the further increase of the pH. After the complete precipitation of Mg, pH started to increase again. Dissolution of Si and P greatly depended on the CaO/SiO2 ratio of the slag and also slightly depended on the ratio of steelmaking slag to dredged soil. According to the CaO/SiO2 ratio of the slag, the existing forms of Si were considered to change, while those of P were considered to be the HPO4 2− ion in the whole range. A reasonable dissolution mechanism of Fe from steelmaking slag–dredged soil mixture was estimated based on the variation of ORP value, dissolved Fe concentration and its solubility diagram in seawater condition.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The sea desertification, called as “Isoyake” in Japanese, extends along the Japanese coast with the gradual destruction of the coastal ecological system year by year. Among various causes, such as the elevation of seawater temperature or the ingestion by herbivorous animals such as sea urchin, the lack of nutrient elements in seawater, especially iron, is considered as one of the most important factors of barren ground [1]; iron is indispensable for the chlorophyll synthesis and the respiration of various seaweeds as a micronutrient. Considering various oxides such as FeO, SiO2 and CaO as constituents, steelmaking slag as a major by-product of the steel manufacturing process is one of the prominent candidates as a source of iron [2, 3]. It has been confirmed that steelmaking slag buried in the coast exhibits the significant enhancement effect on the growth of marine photoplankton or the recovery of the disappeared seaweed beds [4]. However, the solubility of iron in oxic seawater is extremely small at the normal pH range [5] and the dissolution of iron from steelmaking slag is significantly little. Some previous works clarified that organic acids such as gluconic acid acted as a sequestering agent for metal ions in alkaline solution and enhanced the dissolution of iron to keep the soluble iron stable in seawater [6–9]. However, the liquid organic acids are difficult to be used directly at the sea coast in a practical application, and thus, an appropriate substitute is required. Dredged soil containing organic acids such as humic acid and fulvic acid may be applicable to be mixed with steelmaking slag for supplying soluble iron into seawater for the multiplication of phytoplankton [1, 10]. The national research project for the environmental improvement by the maritime use of steelmaking slag, conducted by the Japan Iron and Steel Federation from 2004 to 2007, demonstrated not only the supply of nutrient elements, especially iron, but also the improvement of the soil strength as well as the buffering action on the pH increase by steelmaking slag, [11, 12]. Previous research also confirmed that the mixture of steelmaking slag and humus soil or dredged soil effectively provides Fe for the growth of seaweeds [13–16]. Furthermore, the reuse of the soil dredged from the seabed together with steelmaking slag as the dissolution unit is believed to have a lower impact on the ecological system [11]. As introduced above, the previous research has shown obvious evidence that the addition of dredged soil to steelmaking slag can enhance the growth of photoplankton, while the dissolution behaviors and mechanisms of nutrient elements from the steelmaking slag–dredged soil mixture still need to be clarified for more efficient application.

In the current research, the variation of pH and dissolution behaviors of nutrient elements from steelmaking slag–dredged soil mixture were investigated at laboratory-scale shaking experiments by changing the CaO/SiO2 ratio and amount of slag. The dissolution mechanisms were discussed by using the solubility diagram of elements. Furthermore, the dissolution trend of iron was also discussed.

Experimental

Materials

Two kinds of synthesized slags with a particle size under 150 μm were used for the shaking experiments. The compositions of slags are given in Table 1. The synthesis process was explained in detail in our previous work [2]. The slag S-A with the CaO/SiO2 ratio of 1.0 is composed of crystalline CaO·FeO·SiO2 and amorphous phases, while the slag S-B with the CaO/SiO2 ratio of 2 is composed of crystalline 2CaO·SiO2 and FeO, and amorphous phases. Though the dissolution of the amorphous phase is one of the important points in the present study, and thus the quantitative analysis should be conducted, the quantitative XRD analysis could not be performed because the laboratory-scale XRD analyzer was employed for the sample phase detection and thus the X-ray was not strong enough.

The artificial seawater is the same type as that used in our previous work [9]. The compositions are given in Table 2, and have a pH value of about 8.20 and concentrations of Ca and Mg are 418 and 1328 mg/L, respectively.

The dredged soil used in the present shaking experiments was collected from an inner harbor in west Japan, and the ratio of water to dried soil is 3:4. Figure 1 shows the XRD pattern of the dredged soil after being dried in ambient conditions. The dried dredged soil is mainly composed of crystalline SiO2 and NaCl phases.

Shaking Procedure

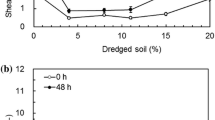

A quantity ranging from 0 to 3 g of slag was mixed with 8 g of dredged soil in a 250-mL polyethylene bottle, and then was cured for 24 h inside a fume cupboard. The prepared mixture of steelmaking slag and dredged soil was put into 100 mL seawater, mixed well and then shaken by a shaking machine with the oscillation speed of 160 cycles/min and the amplitude of 20 ± 5 mm at room temperature. The shaking time varied from 1 to 96 h. At the same time, the shaking experiment of 100 mL seawater without any solid sample was also conducted as a reference.

After shaking, the solution was filtrated by a membrane filter with 0.45-μm pore diameter, and then, the pH and oxidation–reduction potential (ORP) were measured immediately by a pH/ORP meter (TOA Electronics Ltd. HM-25R with the GST-5731C probe for pH and the PS-5111C probe for ORP). The concentrations of Ca, Mg and Si in the shaking solution were measured by an inductively coupled plasma optical emission spectrometry (ICP-OES, Seiko Instruments Inc., SPS7800 Plasma Spectrometer), and the concentrations of P and Fe were measured by the molybdenum blue spectrophotometric method and the 1,10-phenanthroline spectrometric method, respectively.

Results and Discussion

Variation of pH

The S-A Slag and Dredged Soil Mixture

Variation of pH with shaking time for the mixture of S-A slag and dredged soil is shown in Fig. 2. The pH values showed the incubation period before 12 h and then gradually decreased until stabilized between 24 h and 96 h. The pH values of the slag–dredged soil mixture changed between those of seawater only and those of seawater shaken with dredged soil. After 96 h, the pH value was 8.26 for seawater, 7.80, 7.72, 7.72 or 7.53 for the mixture of 3, 2, 1 or 0.5 g slag with 8 g dredged soil or 6.62 for dredged soil, respectively. The values decreased with decreasing the amount of slag in the mixture.

It is well known that the dissolution of Ca from slag into seawater results in the increase of the pH value [17, 18]. Figure 3 shows the dissolution behavior of Ca from the S-A slag–dredged soil mixture. The dissolution of Ca occurred in two stages. An incubation period was observed at the first stage until 12 h, with increasing the Ca concentration by about 50 mg/L for the S-A slag–dredged soil mixture. After 24 h, it increased suddenly by about 180 mg/L in the case of the slag–dredged soil mixture or about 70 mg/L in the case of dredged soil. The slag amount in the mixture did not show the obvious effect on the dissolution behavior of Ca. Even though Ca dissolution from the slag–dredged soil mixture was observed, the pH values of the seawater after shaking were still smaller than those of the original seawater. This is attributed to the buffering effect of the dredged soil on the pH change of seawater, which has also been confirmed by other researchers [12].

The S-B Slag and Dredged Soil Mixture

Figure 4 shows the variation of pH with shaking time for the S-B slag–dredged soil mixture. The pH values increased immediately after starting the shaking of seawater with the mixture. According to the amount of slag, the variation of pH is slightly different. In the case of 0.5 or 1 g slag mixed to 8 g dredged soil, the pH value reached the maximum at around 10 h and then decreased gradually, with extending the shaking time. In the case of 2 or 3 g slag mixed to 8 g dredged soil, the pH value increased monotonically with shaking time. After 96 h, the pH value was 10.4, 10.0, 9.4 or 9.1 for the mixture of 3, 2, 1 or 0.5 g slag with 8 g dredged soil, respectively, which decreased with decreasing the amount of slag.

Figure 5 shows the dissolution behavior of Ca from the S-B slag–dredged soil mixture. The Ca concentration increased greatly with increasing the shaking time and also the amount of slag in the mixture. After 96 h, the Ca concentration was 911, 1415, 2365 or 2437 mg/L for the mixture of 0.5, 1, 2 or 3 g slag with 8 g dredged soil, respectively. The significant dissolution of Ca from the S-B slag–dredged soil mixture is not only due to its larger CaO/SiO2 ratio than S-A slag, but also due to the possible complexation reactions with organic acids contained in the dredged soil.

The concentration change of Mg with shaking time and the relationship between the concentrations of Ca and Mg are shown in Fig. 6. The Mg concentration increased during shaking with dredged soil only by about 50 mg/L compared with seawater. Using the S-B slag–dredged soil mixture, the Mg concentration decreased quickly with shaking time and also with increasing the amount of slag. Because soluble Mg was completely substituted by soluble Ca dissolved from the S-B slag–dredged soil mixture, the Mg concentration could not be quantitatively measured after 48 or 24 h for the case of 2 or 3 g S-B slag mixed with 8 g dredged soil, respectively.

As shown in Fig. 6b, the Mg concentration in mmol/L decreased linearly with increasing the Ca concentration with a slope of −1.00. The variation mechanisms for the concentrations of Ca and Mg as well as the pH values are explicated as follows. With the dissolution of Ca from the slag–dredged soil mixture, the pH value increases as expressed by reaction (1),

When the pH value reaches a certain extent, the Mg ion begins to precipitate instead of the concentration increase of OH−, namely the pH value, by substitution reaction (2) and thus the pH value of the solution is maintained [2, 17, 18],

The slope of −1.00 in Fig. 6b is consistent with the molar relationship between Ca2+ and Mg2+ expressed as reaction (2). After the complete precipitation of Mg ion as Mg(OH)2 such as the 3 g slag–8 g dredged soil mixture after 24 h, the pH value starts to increase again with the further dissolution of Ca from the slag–soil mixture by reaction (1).

Solubility Diagram of Ca and Mg

Figure 7 shows the solubility diagram of Ca and Mg in seawater together with the shaking results. The calculation method of the solubility diagram has been explained in detail in our previous work [2]. Change of Ca and Mg concentrations with pH was dependent on the CaO/SiO2 ratio of the used slag. The concentrations of Ca and Mg were in the constant range regardless of the pH change in the case of the S-A slag–dredged soil mixture or only the dredged soil. On the contrary, the concentration of Ca increased with increasing pH, while that of Mg decreased. Based on the Mg concentration in the original seawater, it is estimated that the soluble Mg begins to precipitate at pH of about 9.1, which is slightly lower than the observed initial constant pH values as shown in Fig. 4. As shown in Fig. 7, Mg(OH)2 would be oversaturated in seawater for a while after the initiation of precipitation. The Ca concentration monotonically increased, while the Mg concentration gradually decreased and finally reached the solubility line of Mg(OH)2 with increasing the pH up to about 10. Beyond that critical pH value, pH increased with further increase of Ca concentration. The variations of pH value, and Ca and Mg concentrations are explained from those solubility diagrams consistently.

Dissolution of Si from the Slag–Dredged Soil Mixture into Seawater

Figure 8 shows the dissolution behavior of Si from the mixture of the S-A or S-B slag and dredged soil. The concentration of Si in seawater with dredged soil is a little larger than that of the original seawater. In the case of the S-A slag–dredged soil mixture, the dissolution of Si showed an incubation period of 12 h followed by the significant increase in Si concentration from 24 to 96 h regardless of the amount of slag. In the case of the S-B slag–dredged soil mixture, the concentration of Si was relatively large in the beginning and then it decreased to a minimum: 1.38 mg/L (slag: 3 g) or 1.98 mg/L (slag: 2 g) after 8 h and 3.95 mg/L (slag: 1 g) or 6.99 mg/L (slag: 0.5 g) after 24 h. Subsequently, the Si concentration gradually increased with the shaking time. Though the influence of the slag amount on it was obscure, the Si concentration in the seawater with the mixture was generally larger than that with dredged soil only or that in the original seawater.

The solubility diagram of Si together with the shaking results is shown in Fig. 9, in which the concentration of Si and pH are the variables while concentrations of other elements are the same as those of seawater [2]. The soluble Si from dredged soil only is generally equilibrated with H4SiO4 phase, and its form is H4SiO 04 . The soluble Si from the S-A slag–dredged soil mixture was in the concentration range similar to that from dredged soil, while that concentration was observed along the solubility line of 2CaO·SiO2. However, it is hard to expect that 2CaO·SiO2 phase is formed in the slag or the slag–dredged soil mixture from its composition. Therefore, it is considered that the dissolution of the S-A slag–dredged soil mixture may result in the formation of H2SiO3 and H4SiO4, and thus, the Si concentration is in the range between two solubility lines. The soluble Si from the S-B slag–dredged soil mixture was mainly in equilibrium with H4SiO4 phase, and its forms are H4SiO 04 or H3SiO4 −. From the above discussion, the dissolution reactions would be explained as follows. For the dredged soil, reaction (3) is most likely to occur,

For the S-A slag–dredged soil mixture, reactions (3) and (4) are possible,

For the S-B slag–dredged soil mixture, reaction (5) or (6) is most probable because 2CaO·SiO2 phase is the main solid phase in the S-B slag,

The above explanation is also supported by the solubility diagram of Ca in Fig. 7 where the seawater after shaking is significantly far from the saturation of Ca(OH)2.

Dissolution of P from the Slag–Dredged Soil Mixture into Seawater

The dissolution behavior of P from the mixture of the S-A or S-B slag and dredged soil is shown in Fig. 10. The concentration of P in seawater with dredged soil is a little larger than that in the original seawater. In the case of the S-A slag–dredged soil mixture, the concentration of P showed the general tendency to increase with shaking time and the amount of slag, which varied from 0.03 to 0.34 mg/L. In the case of the S-B slag–dredged soil mixture, the concentration of P was very small which was similar to that of the original seawater and the case with dredged soil only, except 0.5 g slag/8 g dredged soil case. The reason for the irregular P concentration change for the exceptional case has not been clarified yet. Since the detection limit of P concentration analysis method (spectrophotometry) employed in the present study is close to P concentration of the present experiments, the results may be largely affected by such reason. Dissolution behavior of P from slag–dredged soil mixture must be studied further in detail.

The solubility diagram of P with the shaking results is shown in Fig. 11. In this diagram, the concentration of P and pH are the variables while concentrations of other elements are the same as those of seawater [2]. All of the results are located below the solubility line of 2CaO·P2O5 phase with the form of HPO4 2−. Hence, the dissolution reaction of P from the slag–dredged soil mixture is expressed as reaction (7) [2],

The lower P concentration in the case of the S-B slag–dredged soil mixture can be explained by the Ca concentration in the solution significantly larger than that in the case of the S-A slag–dredged soil mixture, which may result in the promotion of 2CaO·P2O5 precipitation as expressed by reaction (7).

The dissolution ratio of Ca, Si and P from slag–dredged soil mixture was approximately 800:120:1 (S-1: CaO/SiO2 ratio is 1.0) and 80,000:500:1 (S-2: CaO/SiO2 ratio is 2.0) in weight after shaking for 96 h in seawater.

Dissolution of Fe from the Slag–Dredged Soil Mixture into Seawater

The variation of ORP with shaking time is shown in Fig. 12. The ORP during shaking with the slag–dredged soil mixture was lower than that with seawater. The effect of the slag amount on the variation of ORP was not clearly observed for the S-A slag–dredged soil mixture. On the contrary, the ORP fluctuated at the first 12 h and then reached stability with further increase of the shaking time for the S-B slag–dredged soil mixture. After reaching the stable period, the ORP decreased with increasing the amount of slag.

All of the ORP were in the stable condition of solid Fe2O3 phase on the potential–pH diagram for the iron–water system as shown in Fig. 13. It forecasts that the soluble Fe in the shaking solution is in equilibrium with the solid Fe2O3 phase, which is very low as explained below.

It has been confirmed that the low ORP for the dredged soil case can promote the dissolution of Fe [11]. The dissolution behavior of Fe from the mixture of the S-A or S-B slag and dredged soil is shown in Fig. 14. The soluble Fe in the original artificial seawater and in some shaking solutions was not detected. During shaking, the concentration of Fe showed maximum at 12 h for the S-A slag–dredged soil mixture and at 24 h for the S-B slag–dredged soil mixture and varied from several to 132 μg/L. Furthermore, the influence of the slag amount on the Fe concentration was ambiguous.

The solubility diagram of Fe with the shaking results is shown in Fig. 15. The soluble Fe in the case of the S-A slag–dredged soil mixture or dredged soil only was close to the solubility of the Fe(OH)3 phase, and thus its form is Fe(OH) 03 , while that in the case of the S-B slag–dredged soil mixture was close to that of the FeO, Fe(OH)2 or Fe(OH)3 phase with the form of Fe2+ or Fe(OH) 03 .

According to the present study, the dissolution mechanisms of Fe from the mixture of the steelmaking slag and dredged soil mixture into seawater can be estimated as follows.

Firstly, solid complexes between ferric ion and organic acids (OAs) contained in the dredged soil are formed after mixing the slag and dredged soil as given in reaction (8). During the shaking experiment, solid complexes dissolve into seawater and photoreduction reactions under the illumination in the day time induce these solid ferric–organic acid complexes to form ferrous organic acid complexes as given in reaction (9). Due to the smaller equilibrium constants for the formation reaction of the ferrous organic acid complexes, free Fe2+ ions are released, which are readily reoxidized by the dissolved oxygen to the ferric ions. Some portion of the reproduced Fe3+ ion may react with OH− ion to form colloidal ferric hydroxides, and the other part may form the soluble ferric organic acid complexes again. In the initial stage, the dissolution of soluble ferric organic acid complexes is much more significant compared with the degradation of complexes, and thus, the Fe concentration in the solution increases in the initial shaking period. The hydrolytic precipitation reaction and the complexation reaction occur continuously and simultaneously under the illumination, while the dissolution rate of complexes contained in the mixture gradually decreases. Therefore, the Fe concentration declines continuously in the shaking period that follows, after its maximum in the initial period [1, 4–7, 10, 19–23].

Conclusions

The dissolutions of elements from mixtures of steelmaking slag and dredged soil into seawater were investigated by changing the CaO/SiO2 ratio of the synthesized slag and the slag to dredged soil ratio. Dissolution of Ca from the mixture resulted in the variation of pH whereas Mg concentration greatly depended on the CaO/SiO2 ratio of the slag by following the relationship between concentrations of Ca and Mg in the seawater. Dredged soil provided a buffering action on the pH variation. The dissolution of Si was largely influenced by the dissolution behavior of Ca due to the change in pH as well as the equilibrating phase. The P concentration that dissolved from the slag–dredged soil mixture was very low, varying from 0.03 to 0.47 mg/L. The soluble Fe in the shaking solution was extremely low up to 130 μg/L and largely fluctuated. It increased in the initial shaking period and then decreased with the following shaking time. Based on the present research, the dissolution mechanisms of Fe from the mixture of the steelmaking slag and dredged soil into seawater were proposed, which was reasonable to explain the dissolution behavior of Fe. The dissolution ratio of Ca, Si and P from slag–dredged soil mixture was approximately 800:120:1 (S-1:CaO/SiO2 ratio is 1.0) and 80,000:500:1 (S-2:CaO/SiO2 ratio is 2.0) in weight after shaking for 96 h in seawater, while the dissolution of Fe was significantly less and its concentration was mostly in the range below 50 μg/L.

References

Yamamoto M, Hamasuna N, Fukushima M, Okata S, Horiya S, Kiso E, Shibuya M, Sadakata M (2006) Recovery from barren ground by supplying slug and humic substances. J Jpn Inst Energy 85(12):971–978

Zhang X, Matsuura H, Tsukihashi F (2012) Dissolution mechanism of various elements into seawater for recycling of steelmaking slag. ISIJ Int 52(5):928–933

Futatsuka T, Shitogiden K, Miki T, Nagasaka T, Hino M (2004) Dissolution behavior of nutrition elements from steelmaking slag into seawater. ISIJ Int 44(4):753–761

Sugie K, Taniguchi A (2011) Continuous supply of bioavailable iron for marine diatoms from steelmaking slag. ISIJ Int 51(3):513–520

Kuma K, Nakabayashi S, Suzuki Y, Kudo I, Matsunaga K (1992) Photo-reduction of Fe(III) by dissolved organic substances and existence of Fe(II) in seawater during spring blooms. Mar Chem 37(1–2):15–27

Sawyer DT (1964) Metal-gluconate complexes. Chem Rev 64(6):633–643

Mehltretter CL, Alexander BH, Rist CE (1953) Sequestration by sugar acids. Ind Eng Chem 45(12):2782–2784

Zhang X, Atsumi H, Matsuura H, Tsukihashi F (2013) Influence of gluconic acid on dissolution of Si, P and Fe from steelmaking slag with different composition into seawater. ISIJ Int 54(6):1443–1449

Zhang X, Matsuura H, Tsukihashi F (2015) Enhancement of the dissolution of nutrient elements from steelmaking slag into seawater by gluconic acid. J Sustain Metall 1(2):134–143

Yamamoto M, Fukushima M, Liu D (2011) Effect of humic substances on iron elusion in the method of restoration of seaweed beds with steelmaking slag. Tetsu-to-Hagané 97(3):159–164

Hayashi A, Tozawa H, Shimada K, Takahashi K, Kaneko R, Tsukihashi F, Inoue R, Ariyama T (2011) Effects of the seaweed bed construction using the mixture of steelmaking slag and dredged soil on the growth of seaweeds. ISIJ Int 51(11):1919–1928

(2008) The Japan Iron and Steel Federation: guideline for the utilization of converter-type steelmaking slag in coastal area, p 52

Kiso E, Tsutsumi N, Shibuya M, Nakagawa M (2008) At-sea experiment of influence of marine fertilizing on growth of Laminaria religiosa.; development for recovery from barren ground using steelmaking-slag et al.-. In: 20th ocean engineering symposium, JFOES, JASNAOE, Tokyo

Kato T, Aimoto M, Miki O, Nakagawa M (2008) Analysis of iron concentration in the Fe-fertilizing experimental sea area; development for recovery from barren ground using steelmaking-slag et.al.-2. In: 20th ocean engineering symposium, JFOES, JASNAOE, Tokyo

Tsutsumi N, Kato T, Motomura T, Nakagawa M (2008) Influence of marine fertilizing components on growth of Laminaria religiosa.; development for recovery from barren ground using steelmaking-slag et al.-3. In: 20th ocean engineering symposium, JFOES, JASNAOE, Tokyo

Yamamoto M, Fukushima M, Kiso E, Kato T, Shibuya M, Horiya S, Nishisa A, Otsuki K, Komai T (2010) Application of iron humates to barren ground in a coastal area for restoring seaweed beds. J Chem Eng Jpn 43(7):627–634

Miki T, Shitogiden K, Samada Y, Nagasaka T, Hino M (2003) Consideration of dissolution behaviour of elements in steelmaking slag based on their stability diagram in seawater. Tetsu-to-Hagané 89(4):388–392

Miki T, Futatsuka T, Shitogiden K, Nagasaka T, Hino M (2004) Dissolution behavior of environmentally regulated elements from steelmaking slag into seawater. ISIJ Int 44(4):762–769

Kuma K, Nakabayashi S, Matsunaga K (1995) Photoreduction of Fe(III) by hydroxycarboxylic acids in seawater. Water Res 29(6):1559–1569

Pecsok RL, Sandera J (1955) The gluconate complexes. II. The ferric-gluconate system. J Am Chem Soc 77(6):1489–1494

Prescott FJ, Shaw JK, Bilello JP, Cragwall GO (1953) Gluconic acid and its derivatives. Ind Eng Chem 45(2):338–342

Rose AL, Waite TD (2002) Kinetic model for Fe(II) oxidation in seawater in the absence and presence of natural organic matter. Environ Sci Technol 36(3):433–444

Matsumoto K, Yamamoto M, Sadakata M (2006) Supplying Fe from molten coal ash to revive kelp community. J Chem Eng Jpn 39(2):229–236

Author information

Authors and Affiliations

Corresponding author

Additional information

The contributing editor for this article was S. Kitamura.

Rights and permissions

About this article

Cite this article

Zhang, X., Matsuura, H. & Tsukihashi, F. Dissolution Mechanisms of Steelmaking Slag–Dredged Soil Mixture into Seawater. J. Sustain. Metall. 2, 123–132 (2016). https://doi.org/10.1007/s40831-015-0040-6

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40831-015-0040-6