Abstract

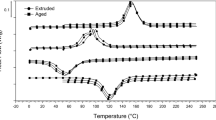

NiTiHf High Temperature Shape Memory Alloys (HTSMAs) with high Hf content are promising candidates for very high temperature actuation applications. However, high operating temperatures at which HTSMAs are used are detrimental to their actuation capabilities since they lose their actuation fatigue performances with the increase of plastic deformation via number of thermal cycles. Therefore, stable actuation behavior at high temperatures is vital to achieve long actuation fatigue lives. In this work, the stability of the shape memory characteristics was investigated by conducting thermo-mechanical deformation studies on ternary Ni50Ti25Hf25 (at. %) HTSMA. Cold rolling and warm rolling operations at 500 and 600 °C with 5% thickness reduction were applied to improve the stability of the shape memory properties of the alloy. DSC studies were done to determine the transformation temperatures. Furthermore, thermo-mechanically treated samples were subjected to actuation fatigue experiments under 200 MPa. Actuation strain, transformation temperatures, thermal hysteresis and austenite strains were determined from the experiments. Although the thermal cycles were run at very high temperatures it was observed that actuation stability of the ternary Ni50Ti25Hf25 (at. %) HTSMA was enhanced and plasticity due to phase transformation at high temperatures and under constant load was mitigated after rolling operations.

Similar content being viewed by others

References

Otsuka K, Ren X (2005) Physical metallurgy of Ti-Ni-based shape memory alloys. Prog Mater Sci 50:511–678

Ma J, Karaman I, Noebe RD (2010) High temperature shape memory alloys. Int Mater Rev 55:257–315

Gall K, Sehitoglu H, Chumlyakov YI, Zuev YL, Karaman I (1998) The role of coherent precipitates in martensitic transformations in single crystal and polycrystalline Ti-508 at. % Ni. Scr Mater 39:699–705

Gall K, Maier HJ (2002) Cyclic deformation mechanisms in precipitated NiTi shape memory alloys. Acta Mater 50:4643–4657

Panchenko EY, Chumlyakov YI, Kireeva IV, Ovsyannikov AV, Sehitoglu H, Karaman I, Maier YHJ (2008) Effect of disperse Ti3N4 particles on the martensitic transformations in titanium nickelide single crystals. Phys Met Metall 106:577–589

Patriarca L, Sehitoglu H (2015) High-temperature superelasticity of Ni50.6Ti24.4Hf25.0 shape memory alloy. Scr Mater 101:12–15

Umale T, Salas D, Tomes B, Arroyave R, Karaman I (2019) The effects of wide range of compositional changes on the martensitic transformation characteristics of NiTiHf shape memory alloys. Scr Mater 161:78–83

Saghaian SM, Karaca HE, Tobe H, Pons J, Santamarta R, Chumlyakov YI, Noebe RD (2016) Effects of Ni content on the shape memory properties and microstructure of Ni-rich NiTi-20Hf alloys. Smart Mater Struct. https://doi.org/10.1088/0964-1726/25/9/095029

Hayrettin C, Karakoc O, Karaman I, Mabe JH, Santamarta R, Pons J (2019) Two way shape memory effect in NiTiHf high temperature shape memory alloy tubes. Acta Mater 163:1–13

Evirgen A, Basner F, Karaman I, Noebe RD, Pons J, Santamarta R (2012) Effect of aging on the martensitic transformation characteristics of a Ni-Rich NiTiHf high temperature shape memory alloy. Funct Mater Lett. https://doi.org/10.1142/S1793604712500385

Santamarta R, Arróyave R, Pons J, Evirgen A, Karaman I, Karaca HE, Noebe RD (2013) TEM study of structural and microstructural characteristics of a precipitate phase in Ni-rich Ni–Ti–Hf and Ni–Ti–Zr shape memory alloys. Acta Mater 61:6191–6206

Patriarca L, Wu Y, Sehitoglu H, Chumlyakov YI (2016) High temperature shape memory behavior of Ni50.3Ti25Hf24.7 single crystals. Scr Mater 115:133–136

Benafan O, Bigelow GS, Garg A, Noebe RD (2019) Viable low temperature shape memory alloys based on Ni-Ti-Hf formulations. Scr Mater 164:115–120

Saghaian SM, Karaca HE, Tobe H, Turabi AS, Saedi S, Saghaian SE, Chumlyakov YI, Noebe RD (2017) High strength NiTiHf shape memory alloys with tailorable properties. Acta Mater 134:211–220

Angst DR, Thoma PE, Kao MY (1995) The effect of hafnium content on the transformation temperatures of Ni49 Ti51–x Hfx shape memory alloys. J de Phys. https://doi.org/10.1051/jp4/199558747

Yang F, Coughlin DR, Phillips PJ, Yang L, Devaraj A, Kovarik L, Noebe RD, Mills MJ (2013) Structure analysis of a precipitate phase in an Ni-rich high-temperature NiTiHf shape memory alloy. Acta Mater 61:3335–3346

Karakoc O, Atli KC, Benafan O, Noebe RD, Karaman I (2022) Actuation fatigue performance of NiTiZr and comparison to NiTiHf high temperature shape memory alloys. Mater Sci Eng, A 829:142154

Karaca HE, Saghaian SM, Ded G, Tobe H, Basaran B, Maier HJ, Noebe RD, Chumlyakov YI (2013) Effects of nanoprecipitation on the shape memory and material properties of an Ni-rich NiTiHf high temperature shape memory alloy. Acta Mater 61:7422–7431

Karakoc O, Hayrettin C, Bass M, Wang SJ, Canadinc D, Mabe JH, Lagoudas DC, Karaman I (2017) Effects of upper cycle temperature on the actuation fatigue response of NiTiHf high temperature shape memory alloys. Acta Mater 138:185–197

Karakoc O, Hayrettin C, Canadinc D, Karaman I (2018) Role of applied stress level on the actuation fatigue behavior of NiTiHf high temperature shape memory alloys. Acta Mater 153:156–168

Akin E, Akgul O, Tugrul HO, Dugan G, Kockar B (2021) Investigating the effect of hot extrusion and annealing to the functional fatigue behavior of Ni50Ti30Hf20 high temperature shape memory alloy. Smart Mater Struct 30:105017

Ekiciler M, Kockar B (2022) Crack growth behavior during actuation cycling of hot extruded and annealed Ni50Ti30Hf20 high temperature shape memory alloys. Smart Mater Struct. https://doi.org/10.1088/1361-665X/ac798f

Ye YF, Wang Q, Zhao YL, He QF, Lu J, Yang Y (2016) Elemental segregation in solid-solution high-entropy alloys: experiments and modeling. J Alloys Compd 681:167–174

Hinte C, Barienti K, Steinbrücker J, Gerstein G, Swider MA, Herbst S, Eggeler G, Maier HJ (2020) Pattern-forming nanoprecipitates in NiTi-related high entropy shape memory alloys. Scr Mater 186:132–135

McAlpine SW, Logan JV, Short MP (2021) Predicting single phase stability and segregation in the NbMoTaTi–(W, V) high entropy alloy system with the vacancy exchange potential. Scr Mater 191:29–33

Coughlin DR, Phillips PJ, Bigelow GS, Garg A, Noebe RD, Mills MJ (2012) Characterization of the microstructure and mechanical properties of a 50.3Ni–29.7Ti–20Hf shape memory alloy. Scr Mater 67:112–115

Evirgen A, Karaman I, Santamarta R, Pons J, Noebe RD (2015) Microstructural characterization and shape memory characteristics of the Ni50.3Ti34.7Hf15 shape memory alloy. Acta Mater 83:48–60

Kockar B, Karaman I, Kim JI, Chumlyakov Y (2006) A method to enhance cyclic reversibility of NiTiHf high temperature shape memory alloys. Scr Mater 54:2203–2208

Belbasi M, Salehi MT (2014) Influence of chemical composition and melting process on hot rolling of NiTiHf shape memory alloy. J Mater Eng Perform 23:2368–2372

Belbasi M, Salehi MT, Mousavi SAAA, Ebrahimi SM (2013) A study on the mechanical behavior and microstructure of NiTiHf shape memory alloy under hot deformation. Mater Sci Eng, A 560:96–102

Young AW, Wheeler RW, Ley NA, Benafan O, Young ML (2019) Microstructural and thermomechanical comparison of Ni-rich and Ni-lean NiTi-20 at. % Hf high temperature shape memory alloy wires. Shape Mem Superelasticity 5:397–406

Babacan N, Bilal M, Hayrettin C, Liu J, Benafan O, Karaman I (2018) Effects of cold and warm rolling on the shape memory response of Ni50Ti30Hf20 high-temperature shape memory alloy. Acta Mater 157:228–244

Baradari S, Resnina N, Belyaev S, Prokofiev E, Valiev RZ, Nili-Ahmadabadi M (2022) Significant improvement in the thermal cycling stability of Ni44.8Ti45.8Hf5Cu5 shape memory alloy by high pressure torsion and post-deformation annealing. J Mater Res Technol 19:2215–2224

Atli KC, Karaman I, Noebe RD (2011) Work output of the two-way shape memory effect in Ti50.5Ni 24.5Pd25 high-temperature shape memory alloy. Scr Mater 65:903–906

Sehitoglu H, Patriarca L, Wu Y (2017) Shape memory strains and temperatures in the extreme. Curr Opin Solid State Mater Sci 21:113–120

F2004-17 Standard Test Method for Transformation Temperature of Nickel-Titanium Alloys by Thermal Analysis. ASTM International. (2017)

Lin HC, Wu SK, Chou TS, Kao HP (1991) The effects of cold rolling on the martensitic transformation of an equiatomic TiNi alloy. Acta Metall, Mater 39:2069–2080

Liu Y, Favier D (2000) Stabilisation of martensite due to shear deformation via variant reorientation in polycrystalline NiTi. Acta Mater 48:3489–3499

Acknowledgements

This study was supported by the Air Force Office of Scientific Research (award number: FA9550-20-1-0261).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This article is an invited submission to Shape Memory and Superelasticity selected from presentations at the 12th European Symposium on Martensitic Transformations (ESOMAT 2022) held September 5–9, 2022 at Hacettepe University, Beytepe Campus, Ankara, Turkey, and has been expanded from the original presentation. The issue was organized by Prof. Dr. Benat Koҫkar, Hacettepe University.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Akgul, O., Kockar, B. The Effect of Rolling Process on the Actuation Fatigue Behavior of Ni50Ti25Hf25 High Temperature Shape Memory Alloy. Shap. Mem. Superelasticity 9, 460–472 (2023). https://doi.org/10.1007/s40830-023-00455-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40830-023-00455-9