Abstract

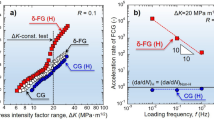

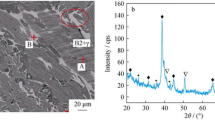

Characterization of hydrogen thermal desorption behavior and enhancement of hydrogen embrittlement in Ni–Ti superelastic alloy have been investigated in terms of the type of cathodic charging in easy-to-handle 0.15 M NaCl, KCl, Na2SO4, and NaHCO3 solutions. Immediately after hydrogen charging at approximately 200 mass ppm, the amounts of hydrogen desorbed in the low-temperature region (150–400 °C) for specimens charged in NaCl and KCl solutions are larger than those charged in Na2SO4 and NaHCO3 solutions. Even upon aging at room temperature after hydrogen charging, the shoulder in the low-temperature side (400–500 °C) of the desorption peak remains for specimens charged in NaCl and KCl solutions. In cyclic tensile deformation in the stress plateau region caused by stress-induced martensite and reverse transformations, fracture occurs after 50–60 cycles irrespective of the type of solution immediately after hydrogen charging. Upon aging, the cycle numbers to fracture of specimens charged in NaCl and KCl solutions (800–900 cycles) are smaller than those charged in Na2SO4 and NaHCO3 solutions (approximately 1000 cycles). The present results suggest that hydrogen states, which strongly interact with martensite transformation, are charged to a greater degree in the presence of chloride ions, thereby enhancing hydrogen embrittlement.

Similar content being viewed by others

Data availability

The dataset used in this study is available upon reasonable request.

References

Yokoyama K, Hamada K, Moriyama K, Asaoka K (2001) Degradation and fracture of Ni–Ti superelastic wire in an oral cavity. Biomaterials 22(16):2257–2262

Asaoka K, Yokoyama K, Nagumo M (2002) Hydrogen embrittlement of nickel-titanium alloy in biological environment. Metall Mater Trans A: Phys Metall Mater Sci 33(3):495–501

Yokoyama K, Ogawa T, Takashima K, Asaoka K, Sakai J (2007) Hydrogen embrittlement of Ni–Ti superelastic alloy aged at room temperature after hydrogen charging. Mater Sci Eng A 466(1–2):106–113

Tomita M, Yokoyama K, Asaoka K, Sakai J (2008) Hydrogen thermal desorption behavior of Ni–Ti superelastic alloy subjected to tensile deformation after hydrogen charging. Mater Sci Eng A 476(1–2):308–315

Gamaoun F, Ltaief M, Bouraoui T, Ben Zineb T (2011) Effect of hydrogen on the tensile strength of aged Ni–Ti superelastic alloy. J Intell Mater Syst Struct 22(17):2053–2059

Letaief WE, Hassine T, Gamaoun F (2016) Rate dependency during relaxation of superelastic orthodontic NiTi alloys after hydrogen charging. Shap Mem Superelasticity 2:121–127

Yokoyama K, Tomita M, Sakai J (2009) Hydrogen embrittlement behavior induced by dynamic martensite transformation of Ni–Ti superelastic alloy. Acta Mater 57(6):1875–1885

Yokoyama K, Hirata Y, Inaba T, Mutoh K, Sakai J (2017) Strong interactions between hydrogen in solid solution and stress-induced Martensite transformation of Ni–Ti superelastic alloy. Philos Mag Lett 97(1):11–18

Sarraj R, Hassine T, Gamaoun F (2018) Mechanical behavior of NiTi arc wires under pseudoelastic cycling and cathodically hydrogen charging. Mater Res Exp 5:015704

Zhenxing L, Fei X, Xiao L, Hong C, Zhu L, Xuejun J, Takashi F (2019) Effect of hydrogen doping on stress-induced martensitic transformation in a Ti–Ni shape memory alloy. Metall Mater Trans A: Phys Metall Mater Sci 50(7):3033–3037

Baturin A, Lotkov A, Grishkov V, Rodionov I, Kabdylkakov Y, Kudiiarov V (2019) The effect of hydrogen on martensite transformations and the state of hydrogen atoms in binary TiNi-based alloy with different grain sizes. Materials 12(23):3956

Grishkov V, Lotkov A, Zhapova D, Mironov Y, Timkin V, Barmina E, Kashina O (2021) Structure and phase state of Ti49.4Ni50.6 (at%) hydrogenated in normal saline. Materials 14(22):7046. https://doi.org/10.3390/ma14227046

Yokoyama K, Kaneko K, Moriyama K, Asaoka K, Sakai J, Nagumo M (2003) Hydrogen embrittlement of Ni–Ti superelastic alloy in fluoride solution. J Biomed Mater Res A 65(2):182–187

Yokoyama K, Kaneko K, Ogawa T, Moriyama K, Asaoka K, Sakai J (2005) Hydrogen embrittlement of work-hardened Ni–Ti alloy in fluoride solutions. Biomaterials 26(1):101–108

Yokoyama K, Ogawa T, Asaoka K, Sakai J, Nagumo M (2003) Degradation of tensile strength of Ni–Ti superelastic alloy due to hydrogen absorption in methanol solution containing hydrochloric acid. Mater Sci Eng A 360(1–2):153–159

Ogawa T, Yokoyama K, Asaoka K, Sakai J (2005) Hydrogen embrittlement of Ni–Ti superelastic alloy in ethanol solution containing hydrochloric acid. Mater Sci Eng A 393(1–2):239–246

Ogawa T, Yokoyama K, Asaoka K, Sakai J (2006) Effects of moisture and dissolved oxygen in methanol and ethanol solutions containing hydrochloric acid on hydrogen absorption and desorption behaviors of Ni–Ti superelastic alloy. Mater Sci Eng A 422(1–2):218–226

Nagaoka A, Yokoyama K, Sakai J (2010) Evaluation of hydrogen absorption behaviour during acid etching for surface modification of commercial pure Ti, Ti–6Al–4V and Ni–Ti superelastic alloys. Corros Sci 52(4):1130–1138

Yokoyama K, Nagaoka A, Sakai J (2012) Effects of the hydrogen absorption conditions on the hydrogen embrittlement behavior of Ni–Ti superelastic alloy. ISIJ Int 52(2):255–262

Tomita M, Yokoyama K, Sakai J (2008) Effects of potential, temperature and pH on hydrogen absorption and thermal desorption behaviors of Ni–Ti superelastic alloy in 0.9% NaCl solution. Corros Sci 50(7):2061–2069

Ota A, Yazaki Y, Yokoyama K, Sakai J (2009) Hydrogen absorption and thermal desorption behavior of Ni–Ti superelastic alloy immersed in neutral NaCl and NaF solutions under applied potential. Mater Trans 50(7):1843–1849

Schiff N, Grosgogeat B, Lissac M, Dalard F (2002) Influence of fluoride content and pH on the corrosion resistance of titanium and its alloys. Biomaterials 23(9):1995–2002

Yokoyama K, Ogawa T, Asaoka K, Sakai J (2006) Hydrogen absorption of titanium and Nickel-Titanium alloys during long-term immersion in neutral fluoride solution. J Biomed Mater Res Part B Appl Biomater 78(1):204–210

Xiaoji L, Jianqiu W, En-hou H, Wei K (2007) Influence of fluoride and chloride on corrosion behavior of NiTi orthodontic wires. Acta Biomater 3(5):807–815

Adachi Y, Wade N, Hosoi Y (1990) Effect of hydrogen on the shape memory effect and transformation behavior of Ti–Ni alloy. J Japan Inst Metals 54(5):525–531

Wade N, Adachi Y, Hosoi Y (1990) A role of hydrogen in shape memory effect of Ti–Ni alloys. Scripta Metall Mater 24:1051–1055

Asaoka T, Yamashita H, Saito H, Ishida Y (1993) Effect of a small amount of hydrogen on the pseudo-elastic properties of Ti–Ni alloy. J Japan Inst Metals 57(10):1123–1129

Haruna T, Fujita Y, Morihashi D, Hirohata Y (2016) Role of the electrochemical potential and solution pH to environment-assisted cracking of super-elastic TiNi alloy. Mater Trans 57(12):2026–2032

Yamaguchi N, Yokoyama K (2022) Degradation caused by self-multiplication of damage induced by an interplay between hydrogen and the martensite transformation in a Ni–Ti superelastic alloy. Philos Mag Lett 102(2):60–70

Yokoyama K, Hirata Y, Sakai J (2017) After-effects induced by interactions between hydrogen and the martensite transformation in Ni–Ti superelastic alloy. Philos Mag Lett 97(9):350–358

Noréus D, Werner P-E, Alasafi K, Schmidtihn E (1985) Structural studies of TiNiH. Int J Hydrogen Eng 10(7–8):547–550

Soubeyroux JL, Fruchart D, Lorthioir G, Ochin P, Colin D (1993) Structural study of the hydrides NiTiHx (X = 1.0 and 1.4). J Alloys Compd 196(1–2):127–132

Yokoyama K, Watabe S, Hamada K, Sakai J, Asaoka K, Nagumo M (2003) Susceptibility to delayed fracture of Ni–Ti superelastic alloy. Mater Sci Eng A 341(1–2):91–97

Gamaoun F (2021) Strain rate effect upon mechanical behaviour of hydrogen-charged cycled NiTi shape memory alloy. Materials 14(16):4772

Ono K, Meshii M (1992) Hydrogen detrapping from grain boundaries and dislocations in high purity iron. Acta Metall Mater 40(6):1357–1364

Suzuki N, Ishii N, Tuchida Y (1994) Diffusible hydrogen behavior in pre-strained high strength steel. Tetsu-to-Hagané 80(11):855–859

Takai K, Watanuki R (2003) Hydrogen in trapping states innocuous to environmental degradation of high-strength steels. ISIJ Int 43(4):520–526

Wang M, Akiyama E, Tsuzaki K (2007) Effect of hydrogen on the fracture behavior of high strength steel during slow strain rate test. Corros Sci 49(11):4081–4097

Schmidt R, Schlereth M, Wipf H, Assmus W, Müllner M (1989) Hydrogen solubility and diffusion in the shape-memory alloy NiTi. J Phys Condens Matter 1(14):2473–2482

Duerig T, Shelley O, Madamba D, Vien L (2019) A practitioner’s perspective of hydrogen in Ni–Ti alloys. Shap Mem Superelasticity 5:235–248

Yokoyama K, Hirata Y, Inaba T, Mutoh K, Sakai J (2015) Inhibition of localized corrosion of Ni–Ti superelastic alloy in NaCl solution by hydrogen charging. J Alloys Compd 639:365–372

Carpenter GJC, Watters JF (1978) An in-situ study of the dissolution of γ-zirconium hydride in zirconium. J Nucl Mater 73(2):190–197

Hitonari S, Ohmori Y, Terasaki F (1985) Effect of Nickel on hydride formation and hydrogen embrittlement in Ni–Cr–Fe alloys. Mater Sci Eng 74:119–131

Rozenak P, Eliezer D (1987) Phase changes related to hydrogen-induced cracking in austenitic stainless steel. Acta Metall 35(9):2329–2340

Kon K, Tsujikawa S, Hisamatsu Y (1992) Embrittlement and its recovery process of hydrogen-charged alloy 800. Zairyo-to-Kankyo 41(5):308–315

Gamaoun F, Hassine T (2014) Ageing effect and rate dependency of a NiTi shape memory alloy after hydrogen charging. J Alloys Compd 615(1):5680–5683

Sun F, Jordan L, da Silva A, Martin F, Prima F (2021) Revisiting the effects of low-concentration hydrogen in NiTi self-expandable stents. Mater Sci Eng C 118:111405

Nicolas U, Céline B, Amani L, Tarak B, Tarak BZ (2019) Modeling of hydrogen effects on the thermomechanical behavior of NiTi-based shape memory alloys. Shap Mem Superelasticity 5:206–217

Miyazaki S, Mizukoshi K, Ueki T, Sakuma T, Liu Y (1999) Fatigue life of Ti–50 at.% Ni and Ti–40Ni–10Cu (at.%) shape memory alloy wires. Mater Sci Eng A 273–275:658–663

Zinelis S, Eliades T, Pandis N, Eliades G, Bourauel C (2007) Why do nickel-titanium archwires fracture intraorally? Fractographic analysis and failure mechanism of in-vivo fractured wires. Am J Orthod, Dentofacial Orthop 132(1):84–89

Acknowledgements

This study was supported in part by JSPS KAKENHI Grant Number 18K04780.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Hayashi, R., Yokoyama, K. Characterization of Hydrogen Thermal Desorption Behavior and Enhancement of Hydrogen Embrittlement in Ni–Ti Superelastic Alloy Induced by Cathodic Hydrogen Charging in the Presence of Chloride Ions. Shap. Mem. Superelasticity 9, 520–530 (2023). https://doi.org/10.1007/s40830-023-00441-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40830-023-00441-1