Abstract

The UK national atmospheric emissions inventory estimates of construction industry emissions use a top-down approach, based on fuel consumption and employment. It estimates that the sector is the 2nd largest emitter of PM2.5 (14%) and 4th largest emitter of NOX (7%). In this study, we have adopted a bottom-up approach to assess emissions of NOX from the sector and show that emissions are 39% higher than the existing estimates. By developing a novel fleet turnover model to predict the population and emission standard of construction machinery up to 2025, we demonstrate a significant shift in the quantity and types of machines used. The overall uncertainty of the model was calculated to be 55%. Applying the estimated uncertainties to the model, in 2018, the non-road mobile machinery fleet in the UK emitted 36.6 ± 10.0 kilo-tonnes of NOX, whilst the NAEI estimated 33.2 kilo-tonnes for the same sector. For the subsequent years 2019 and 2020, the NAEI estimate was within the model’s uncertainty prediction—28.0 kilo-tonnes compared with 32.7 ± 8.9 kilo-tonnes for 2019 and 23.2 kilo-tonnes compared with 29.5 ± 8.1 kilo-tonnes for 2020. Overall, the size of the non-road mobile machinery fleet in the UK is predicted to reduce by 4% in 2025 compared to 2018. Furthermore, the introduction of Stages IV and V emission regulations for new machines will lead to a 58% reduction in fleet NOX emissions over the same period. These emission regulations are targeted at the larger, more polluting machines, with smaller machines not required to meet tighter emissions standards under Stage V. As a result, mini-excavators are the most common machines and consequently become the dominant source of NOX emissions from the fleet, contributing 55% in 2025. Therefore, tighter emissions regulations, or the uptake of battery power in the form of electrification, for these small machines would yield significant emissions reductions.

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

In the UK, the Department of Health and Social Care has identified air pollution as one of the biggest health risks across the UK [1]. The World Health Organisation (WHO) estimates that air pollution is the biggest environmental risk to health, implicated in about one in every nine deaths annually [2]. In London, the major sources of nitrogen oxides (NOX) and particulate matter (PM) emissions are road transport, domestic and commercial gas, industry, non-road mobile machinery (NRMM), aviation, and resuspension [3]. NRMM is defined as any mobile machine, transportable equipment or vehicle, with or without bodywork or wheels, not intended for the transport of passengers or goods on roads, and includes machinery installed on the chassis of vehicles intended for the transport of passengers on roads [4]. Emissions from engines in these machines are regulated under Regulation (EU) 2016/1628 in Europe[4] and under different engine classifications in the USA [5]. The relative contribution from NRMM is expected to increase in the future due to the decrease in emissions from road transport caused by the implementation of more stringent emissions standards for on-road vehicles when compared to NRMM [6].

For certification purposes, laboratory studies are carried out to quantify engine emissions on dynamometers to provide baseline emission factors. The in-use emission factors for NRMM are difficult to characterise, due to complex duty cycles and various activities carried out by different types of NRMM. Consequently, real-world emissions studies have been carried out on various types of NRMM using portable emissions measurement systems (PEMS) [7,8,9,10,11,12,13,14,15,16,17,18,19,20]. Notable amongst these, Johnson et al. [13] in 2016 evaluated the in-use emission factors from 27 different pieces of construction equipment; Frey et al. [9] in 2008 reported on the real-world duty cycles for construction equipment. More recently, through the continuous development of PEMS [21] and the European standards for in-use service compliance and monitoring testing for Stage V non-road engines [22], it has become easier to characterise emissions from NRMM [23]. Since most NRMM engines have relatively longer life spans than on-road vehicles [13], it is not uncommon to find machinery with older engines being used in the construction industry; these do not adhere to the current emission standards.

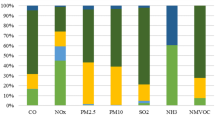

An emissions inventory lists, by source, the amount of air pollutants discharged into the atmosphere during a year or other time period [24]. It is used to determine significant sources of air pollutants, confirm compliance with regulations [25], and provide input data for atmospheric models [26]. In the UK, the National Atmospheric Emissions Inventory (NAEI) provides spatially (1 km) disaggregated annual estimates for a wide range of important pollutants [27]. It estimates that NRMM exhaust emissions contributed 14% of PM2.5 (2nd largest source) and 7% of the total NOX (4th largest source) in 2017. Emissions from industrial off-road mobile machinery (category 1A2gvii) [28] which use gas oil (red diesel) were included for the construction sector. NRMM emissions are included in the NAEI from a range of machines (e.g., agricultural tractors and combine harvesters, industrial generators and forklifts, construction excavators and cranes, domestic lawnmowers, and aircraft support machines). Activity statistics are obtained from government statistical sources [29, 30], trade associations, and research institutes. These emissions are mapped across the UK based on employment in the individual sectors. This provides a good first approximation; however, it is difficult to estimate tail-pipe NOX emissions based on fuel consumption alone. NOX emissions are dependent on engine load factors, engine idling, engine size, payload, type of work, and other parameters which influence emissions. A further limitation of this approach is the reliance on employment data, which disproportionately allocates emissions to city centres where company headquarters are based. This study aims to develop a more robust and accurate spatial and fleet disaggregated emissions inventory than is currently available in the UK by combining calculated fleet composition using sales data with measured NRMM real-world emission factors [6].

2 Methodology

Improved estimates for the UK NRMM population were derived using a novel fleet turnover model (FTM), which was then coupled with measured emission factors and measured activity data to calculate the NOX emissions from the construction sector in the UK.

2.1 Fleet Turnover Model (FTM)

The machine fleet turnover model (FTM) used recorded and predicted manufacturer and machine-specific sales data from all suppliers in the UK, coupled with machine-specific estimated lifetime, shown in Eq. 1. This approach provided a more realistic assessment of NRMM emissions and an opportunity to identify the machines and emission technologies which contribute most to the emissions from the diverse range of machines, thereby enabling more targeted emission-reduction policies. The FTM used the latest available industry sales data between 2004 and 2018, as well as projected sales data to 2025, to predict the current and future fleet populations. For this study, the most common (‘core 9’) machines—backhoe loaders, compaction equipment, mini-excavators, rough terrain forklifts, skid-steer loaders, telescopic handlers, tracked excavators, wheeled excavators, and wheeled loading shovels were considered, similar to previous studies [31]. Reduction in fleet numbers each year due to scrappage from the fleet was applied monotonically using individual machines’ useful lifetime factor (L).

where isales = machines sold in the year i and L = machine-specific useful lifetime.

The useful lifetime factors for a range of different machines in the NRMM fleet up to 2004 (L2004) were estimated in previous studies [31]; however, this has a large degree of uncertainty as it is not quantified using independent data, neither is it up to date or able to account for changes in fleet use over time. Nevertheless, it does provide estimates of the different lifetimes for the ‘core 9’ machines, for example, compaction equipment was estimated to last 3.9 years, whilst wheeled loaders had an estimated lifetime of 8.4 years. To improve these estimates for each machine type, a machine disaggregated FTM was developed using a subset of the sales data focusing on a single manufacturer where complementary telematic data was available. This provided an independent assessment of the machine population for that manufacturer in 2018. This was assumed to be representative of all manufacturers due to the lack of available data from other representative original engine manufacturer’s (OEM) sales data.

The NRMM fleet was disaggregated further by EU emission standards, using the year (date) of introduction for each of the EU emission standards [6, 22]. The introduction of newer machines into the fleet was determined by data received from the construction industry, which indicated an 80–30–15–0% sale over a 4-year period. For example, the sale of Stage III-B engines during the introduction year of Stage IV engines declined from 100 to 80%, in year two it was 30%, etc. Thus, the model predicts that 100% of all machines sold in the UK 4 years after the date of introduction of the emission standard were the newest machines.

Machine telematic data provided the geographical location and whether the machine was active or not. This had the advantage of accounting for all exported and scrapped machines. The UK NRMM fleet was distributed geographically based on the location of the single manufacturer NRMM fleet telemetry data, again assuming that this was representative of all suppliers, since there is a combination of various OEM’s NRMM on construction sites.

2.2 Emissions Inventory Development

The EMEP/EEA tier 3 methodology for equipment-specific and technology-stratified approach was adopted. This method is more detailed than the tier 1 or tier 2 approaches, which only utilise fuel consumption and base emission factors. The basic algorithm used is shown below [32].

where \(E\) = mass of emissions of pollutant during inventory period, \(N\) = number of engines (units), \({\text{HRS}}\) = annual hours of use, \(P\) = engine size (kW), \({\text{DFA}}\) = deterioration factor adjustment, \({\text{LFA}}\) = load factor adjustment, and \({{\text{EF}}}_{{\text{Base}}}\) = base emission factor (g/kWh).

The population of the fleet (N) used in the construction sector in the UK was derived from the FTM described in the previous section. The annual hours of operation for each type of NRMM were derived from OEMs’ engine control module (ECM) data. The proprietary sales data provided by the original engine manufacturers does not include specific engine net rated power (kW), and thus, calculations were made based on the engine size category for individual machines from registered machines in London, as an accurate reflection of NRMM within a zone. Hence, the size of the engine was assumed to be 75 kW on average, which was the median value noted for NRMM registered on the London database, apart from mini-excavators, which are defined as machines up to 40 kW. For this study, mini-excavators were assumed to be 37 kW—the most common engine size. The deterioration factor adjustment (DFA) and load factor adjustment (LFA) for each individual engine size and emission standard were calculated using the European Monitoring and Evaluation Programme/European Environment Agency (EMEP/EEA) emissions inventory guidebook [32]. DFAs and LFAs are calculated according to the machine category, i.e., emission standards, as per guidelines provided in the EMEP/EEA emissions inventory guidebook and hence vary by individual category and not net rated power (kW). All machines < 37 kW were assumed to be Stage III-B, the latest emission standards for engines in this net-rated power range, hence DFA and LFA were assigned accordingly. For the rest of the machines, the date of introduction of the emission standards was input into the fleet turnover model to account for the variability in the emission standards. Emission factors (EF) were utilised in the following order of priority:

-

1.

Emission factors measured in a previous study [6] conducted in the UK were applied, where NRMM type and emissions category were a direct match.

-

2.

For the remaining unmatched machinery, emission factors measured from two international studies on construction machines [9, 13] were utilised, where the NRMM type and emission category were direct matches.

-

3.

Emission standard limit values for machines in each emission category were utilised, where measured emission factors, either from this study or previous studies, were unavailable. When machines were not matched by emission category, an average emission factor for each emission standard was applied.

2.3 Uncertainty Estimations

With our current approach to calculating the emissions from the construction sector, and in the absence of a national register similar to a Driver and Vehicle Licensing Agency (DVLA) database for road vehicles, the following equation was used to estimate the overall uncertainty of the model, as defined by the EMEP/EEA emissions inventory guidebook [32]:

where \({\text{uE}}\) = uncertainty of mass of emissions of pollutant during inventory period, \({\text{uN}}\) = uncertainty of the number of engines, \({\text{uHRS}}\) = uncertainty of annual hours of use, \({\text{uP}}\) = uncertainty of engine size, \({\text{uDFA}}\) = uncertainty of deterioration factor adjustment, \({\text{uLFA}}\) = uncertainty of load factor adjustment, and \({{\text{uEF}}}\) = uncertainty of emission factor.

Uncertainties identified (Table 1) within the FTM were calculated for each individual input parameter where data was available. NRMM population was calculated from confidential data, as such, assumptions had to be made to the uncertainty of sales of various NRMM by machine type. The hours of operation for various types of machines were derived from machine telemetry, which greatly reduces the uncertainty for this parameter of the equation. The current NAEI methodology does not consider the hours of use of various NRMMs. The size of the engine (P) for various NRMM was derived from the most common engine size of various NRMM registered on the London database, which was the only available and most accurately reliable source of information for NRMM registered in the UK. The proprietary sales data provided by the OEMs does not include specific engine net-rated power (kW). Both deterioration and load factors used were derived from the EMEP/EEA emissions inventory guidebook [32] and have low uncertainties. The DFAs and LFAs vary by individual engine category and not by net-rated power (kW). The emission factors utilised were measured from various NRMM [6, 9, 13], which mitigates the uncertainties as compared to emission factors derived from fuel consumption—the methodology used for the NAEI. The overall uncertainty of the model along with the individual uncertainties and related calculations for each input parameter in the model are shown in SI.

3 Results and Discussion

3.1 Useful Lifetime Factor

As described, the fleet turnover model was used to calculate the population from the sales data of a specific manufacturer using a range of useful lifetime factors. The useful lifetime was adjusted in 10% increments until an approximate agreement was reached between the population and the known population for that manufacturer, which was recorded from machine telemetry data. This is shown in Figure SI1 and Table SI1 supplementary information (SI). A 20% increase was required, and this factor was used as a multiplier for all the machines irrespective of type; to provide new estimates of useful lifetime, these are shown in Table SI2 (SI). This indicates that all machines have a longer useful life in 2018, as compared to the previous estimate in 2004, and likely reflects the improved efficiency and robustness of current machines. We have assumed that all machines have increased useful lifetime by an equal proportion and accept that some residual uncertainty remains. These new useful lifetime factors were used in the calculation of the total UK NRMM population (2018–2025).

3.2 NRMM Population in the UK

Using the methods described above, the UK NRMM fleet composition was calculated using the adjusted machinery lifetimes, national sales data between 2004 and 2018, and the NRMM population estimates from 2004 [31] the results are shown in Table SI4 in SI. Future estimates of the NRMM fleet population between 2018 and 2025, which were calculated using the fleet lifetime and mean sales figures from the previous 3 years, are also shown in Table SI4 (SI). The current (2018) calculated population and future (2019–2025) estimated projection of the total fleet are shown in Table SI4 (SI) and Fig. 1, disaggregated by the type of machinery (‘core 9’ only, excludes site dumpers, piling rigs, generators, etc.). In 2018, the total NRMM population was calculated at 147,832 machines.

NRMM fleet population in the UK, disaggregated by machine type, for each year from 2018 and projected up to 2025. Core 9 type of machine includes backhoe loader, compaction, crawler excavator, mini excavator, rough terrain forklift, skid steer loader, telehandler, wheeled excavator, and wheeled loader

Mini-excavators are defined as machines classified up to 6 tonnes, with a typical engine size of up to 40 kW net-rated power. In this study, all mini-excavators were assumed to be < 37 kW machines. This machinery type was the single largest population, contributing to 38% of the total fleet in 2018. A similar trend is noted for the fleet projected up to 2025, with mini-excavators still contributing 38% of the total fleet and remaining the most common machine. All other machines were assumed to be > 37 kW. Telehandlers were the second largest population in 2018, contributing to 27% of the total fleet. The population of backhoe loaders, rough terrain forklifts, and wheeled excavators is expected to decrease by 2025 when compared with 2018, as shown in Fig. 1.

The NRMM population disaggregated by emission standards is shown in Table 2 and Fig. 2 In 2018, Stages III-B and IV machines contributed to the majority of the population (> 80%) for all types of NRMM. Future projections (2020 to 2025) indicate Stages IV and V machines contributing to the majority of all NRMM types, as shown in Table 2 (and Table SI3 in SI)

3.3 UK NRMM Fleet Activity

The average number of hours each machine worked per day was calculated using ECM data. Real-world data from the machine suppliers indicate that the snapshot of a dataset containing 3.1 million data points over ~ 10,000 machine hours of activity was analysed (shown in Table SI5 in SI). This real-world data from the machine suppliers is a highly accurate source of machine telemetry information which is logged and received from the engine telematics on the machine. Backhoe loaders worked for 3.03 h (± 0.62) per day, compaction equipment worked for 1.04 h (± 0.63) per day, crawler excavators worked for 4.45 h (± 1.07) per day, mini-excavators worked for 2.85 h (± 0.51) per day, rough terrain forklifts worked for 2.17 h (± 0.41) per day, skid-steer loaders worked for 2.94 h (± 0.53) per day, telehandlers worked for 2.84 h (± 0.66) per day, wheeled excavators worked for 4.21 h (± 1.02) per day, and wheeled loaders worked for 4.08 h (± 0.91) per day. All machines were assumed to work for 300 days per calendar year, accounting for non-working days in the UK including public and bank holidays. Deterioration factors and load factors were adjusted per machine type, engine size, and engine age.

3.4 Emissions from NRMM in the UK

The EMEP/EEA tier 3 methodology for equipment-specific and technology-stratified approach was used to calculate the tonnes of NOX emissions for 2018–2025 and a breakdown is shown in Table SI6 (in SI). Using this approach, NRMM in the UK emitted 36.6 kilo-tonnes of NOX in 2018, in comparison, the NAEI methodology estimated 27 kilo-tonnes of NOX (expressed as NO2) for industrial off-road mobile machinery (NFR, 1A2gvii) for 2018. The difference in emissions is due to the high-level detail included in our calculations of fleet composition, machinery useful life, disaggregated emission standards, work activity, and emission factors, which have lower uncertainties compared to the NAEI’s approach of assumed emission factors from the sale of red diesel. Examining the trends in fleet emissions in this data, there is a 58% decrease in NOX projected for 2025 from 2018 despite there being only a predicted 4% decrease in fleet population. This is primarily due to the increased uptake of cleaner Stage V machines and the subsequent scrapping of high-emitting Stages III-A and III-B machines.

Figure 3 shows that tracked mini-excavators contribute to the highest NOX emissions mainly due to the large population and the older engine emission standards (Stage III-A with no exhaust gas after-treatment). Mini-excavators are defined as machines classified up to 6 tonnes, with a typical engine size of up to 40 kW net-rated power, which fall under the category of engines < 56 kW. For this category of machines, there is no change in the NOX emission standards for EU Stage V standards, when compared to the previous EU emission standards [22]. Hence, these machines (mini-excavators) would be subject to the same NOX emissions for Stage V standards. Their relative contribution to NOX emissions is expected to increase, despite the introduction and uptake of Stage V machines in the coming years. Quantitatively, mini-excavators made up 38% of the total fleet in 2018, and continue with this share up to 2025 (Table SI4 in SI); however, the calculated contribution to overall NOX emissions was increased from 24% in 2018 to 55% in 2025 (Table SI6 in SI).

Figure 4 shows the calculated tonnes of NOX emissions from the core 9 types of machines, further disaggregated by the respective emission standard contributions. All machines with the exception of mini-excavators show a decreasing trend in emissions. The population of mini-excavators is expected to decrease by 4% from 2018 to 2025, with the NOX emissions expected to decrease by 4%. There is little decreasing trend in the emissions from mini-excavators as they are subject to similar NOX limit values for Stage V when compared to Stage III-A or Stage III-B. Hence, the change in emissions would be driven solely by the machine population. For other machines, the decrease in NOX emissions is attributed to the introduction of Stage V machines, which are required to meet lower emission limits, and the reducing number of machines in some categories.

Tonnes of NOX emissions disaggregated by the type of machine and respective emission standards, for each year from 2018 and projected up to 2025. Core 9 type of machine includes backhoe loader, compaction, crawler excavator, mini excavator, rough terrain forklift, skid steer loader, telehandler, wheeled excavator, and wheeled loader

Backhoe loaders show a 91% reduction in population alongside an improved emission abatement technology and a corresponding 96% decrease in NOX emissions. There is a 4% increase in compaction equipment and a corresponding 77% decrease in NOX emissions. Crawler excavators are estimated to increase by 1% with a corresponding 74% decrease in NOX emissions. Rough terrain forklifts show a 57% decrease in population and a corresponding 87% decrease in NOX emissions. The population of skid steer loaders is calculated to decrease by 18% with an 82% decrease in NOX emissions. Telehandlers show a 3% increase in population but a 73% decrease in NOX emissions. Wheeled excavators show a 56% reduction in population and an 86% reduction in NOX emissions. Wheeled loaders are expected to increase by 6% with a 71% reduction in NOX emissions.

Uncertainties were estimated for all individual parameters of the fleet turnover model—fleet population at 10% was assumed from the emissions inventory guidebook due to a lack of available data, hours of operation at 18% was calculated for the fleet, machine power at 11%, load factor at 7%, and emission factor at 13%. The overall uncertainty of the model was calculated to be 55%, utilising the guidance from the EMEP/EEA emissions inventory guidebook. Applying the estimated uncertainties to the model, in 2018, the NRMM fleet in the UK emitted 36.6 ± 10.0 kilo-tonnes of NOX, whilst the NAEI estimated 33.2 kilo-tonnes for the same sector. For the subsequent years 2019 and 2020, the NAEI estimate was within the model’s uncertainty prediction—28.0 kilo-tonnes compared with 32.7 ± 8.9 kilo-tonnes for 2019 and 23.2 kilo-tonnes compared with 29.5 ± 8.1 kilo-tonnes for 2020.

Although the NAEI estimates are within the modelled uncertainties of NOX estimated in this study, the introduction of the newest EU Stages IV and V emission standard machinery into the UK NRMM fleet will lead to the most significant reduction in NOX, as demonstrated by the FTM developed in this study. The implementation of policy measures such as London’s Clean Air Zones (CAZ) for NRMM will lead to an acceleration of the fleet turnover, thereby phasing out older Stages III-A and III-B machines to incorporate the latest Stages IV and V machines. However, the implementation of the CAZ for NRMM in London and possibly other major cities and infrastructure projects across the UK will lead to a shift of the older NRMM fleet to other parts of the UK, where such localised policies do not exist. As such, a national policy is required to clean up the UK NRMM fleet. The significant emission reduction demonstrated in this research justifies the requirement for a national policy on cleaner NRMM with rapid adoption across the UK. However, adopting the cleanest machines does not solve the air pollution issue, as small machines such as mini-excavators are not required to have exhaust gas after-treatment technology and hence will continue to remain a significant source of emissions, as demonstrated by this research. Hence, electrification of this machine type or the adoption of other alternative technology such as spark ignition engines or gas engines is vital to reduce the NOX emissions from this machine type in the future.

Figure 5 shows a map of the summed total tonnes of NOX emissions per local area in the UK for 2018. Emissions were calculated based on the total NRMM population, disaggregated by EU emission standards for individual machines. The map shows that major cities (e.g., London, Birmingham, Liverpool, Manchester, Glasgow, Edinburgh) in the UK tend to emit higher overall NOX when compared to smaller cities and other areas (e.g., areas of outstanding natural beauty, nature parks) where NRMM are less frequently used.

4 Conclusions

In this study, a fleet-turnover model was developed to estimate the population of the NRMM fleet in the UK, which was coupled with measured exhaust emissions and machine activity, to calculate the NOX emissions from this sector. This approach was designed to address some of the limitations in the top-down methodology applied in the UK National Atmospheric Emissions Inventory. Furthermore, it provides the ability to disaggregate emissions by machine type, emission standard, and geographical location, leading to an improved ability to develop targeted emissions abatement policies.

The calculated population was used to estimate that the NRMM UK fleet emitted 36.6 kilo-tonnes of NOX in 2018. In comparison, the NAEI methodology estimated 27 kilo-tonnes of NOX in 2018.

The 2018 population of the NRMM fleet in the UK was estimated to be ~ 148,000 machines. By 2025, the number of backhoe loaders, rough-terrain forklifts, skid-steer loaders, and wheeled excavators was predicted to decrease. In contrast, the population of compaction equipment, crawler excavators, mini-excavators, telescopic handlers, and wheeled loaders is expected to remain constant.

A 42% decrease in NOX emissions was projected for 2025, when compared to 2018, primarily due to the increased uptake of cleaner Stage V machines and the subsequent scrapping of high-emitting Stages III-A and III-B machines.

Overall, a 55% uncertainty was computed for the model; individual uncertainty was also estimated for each of the parameters included in the fleet turnover model—fleet population, hours of operation, machine power, load factor, and emission factor.

There are no EU Stage IV emission standards for machines below 55 kW engine size, so current Stage III-B machines with this engine size are required to meet Stage V EU emission standards. However, there is no change in the NOX emission standards for Stage V machines when compared with the corresponding previous emission standard (Stage III-B) for the same engine size category (below 55 kW). As no after-treatment systems are required on EU Stage V machines below 55 kW, tailpipe emissions from this category are likely to remain the same as the machines adhering to older Stage III-B standards. Hence, emissions from mini-excavators do not decrease corresponding to other machines.

Mini-excavators are now the primary source of NOX from the NRMM fleet. The number of machines is predicted to remain relatively constant, but there is no improvement in emission standards at Stage V for these small machines. Therefore, unlike for the larger machines, renewal of this part of the fleet does not reduce the emissions, and the calculated contribution from mini-excavators to NOX emissions increases from 24% in 2018 to 55% in 2025.

Policy options to reduce NOX emissions from the NRMM fleet should therefore focus on these smaller machines. As mentioned, there is minimal tailpipe emission reduction benefit from older Stage III-B machines below 55 kW when compared to their newer Stage V counterparts. Hence, alternative technologies such as spark ignition engines, gas engines, hybrid machines, or electric drivetrains must be explored for this engine size category. Either tighter emissions standards for this engine size category in future Stage VI emission standards or alternative power sources such as electrification which is feasible for this power requirement would reduce the impact of this sector on air quality.

Data Availability

Part of the data used in this project is confidential and cannot be shared due to non-disclosure agreements.

References

Department for Environment Food & Rural Affairs. Improving air quality in the UK: tackling nitrogen dioxide in our towns and cities. Draft UK Air Quality Plan for tackling nitrogen dioxide. (2017). Available from: https://consult.defra.gov.uk/airquality/air-quality-plan-for-tackling-nitrogendioxide/supporting_documents/Draft%20Revised%20AQ%20Plan.pdf. Accessed 15 Dec 2023

World Health Organization. Ambient air pollution: A global assessment of exposure and burden of disease. Available from: https://www.who.int/publications/i/item/9789241511353. Accessed 15 Dec 2023

London Datastore, London Atmospheric Emissions Inventory [Internet]. Greater London Authority (2016). Available from: https://data.london.gov.uk/dataset/london-atmospheric-emissions-inventory-2013. Accessed 15 Dec 2023

European Parliament. Regulation 2016/1628 on requirements relating to gaseous and particulate pollutant emission limits and type-approval for internal combustion engines for non-road mobile machinery. Regulation (EU) 2016/1628 of the European Parliament and of the Council, p. 65 (2016). Available from: https://www.legislation.gov.uk/eur/2016/1628/contents. Accessed 15 Dec 2023

United States – Environmental Protection Agency. Emission Standards reference guidance. EPA Emission Standards for Nonroad Engines and Vehicles (2016). Available from: https://www.epa.gov/emission-standardsreference-guide/epa-emission-standards-nonroad-engines-and-vehicles. Accessed 15 Dec 2023

Desouza, C.D., Marsh, D., Beevers, S.D., Molden, N., Green, D.C.: Real-world emissions from non-road mobile machinery in London. Atmos. Environ. 223, 10 (2020)

Desouza, C.D., Marsh, D., Green, D.C.: Portable Emission Measurement System (PEMS) Testing of a 100kVA Generator using Red Diesel and ISO grade Diesel. London: King's College London (2016). Available from: https://clec.uk/projects/case-studies. Accessed 15 Dec 2023

Fulper, C.: PEMS: A look at EPA’s “Real world” Test Programs: Pilot Nonroad Equipment & HDDV "Drayage". PEMS Conference; 24 March 2011; UC-CERT, California (2011). Available from: https://documents.pub/document/pems-a-look-at-epas-real-world-test-programs-pilot-nonroad-equipment-test.html. Accessed 15 Dec 2023

Frey C.H., Rasdorf, W., Kim, K., Pang, S.-H., Lewis, L., Abolhasani, S.: Real-world duty cycles and utilization for construction equipment in North Carolina. North Carolina State University, Transportation NCDo; 4 Jan 2008. Report No.: FHWA/NC/2006-55 (2008). Available from: https://repository.lib.ncsu.edu/items/73b132ee-a8b7-4c9a-a71f-8c184243f635. Accessed 15 Dec 2023

Abolhasani, S., Christopher Frey, H., Rasdorf, W., Kim, K., Lewis, P., Pang, S.-H.: Real-world in-use activity, fuel use, and emissions for nonroad construction vehicles: A case study for excavators. J. Air Waste Manag. Assoc. 58(8), 15 (2008)

Johnson, K., Burnette, A., Cao, T., Russell, R., Scora, G.: Characterization of the emissions impacts of hybrid excavators with a portable emissions measurement system (PEMS)- based methodology. Sci. Total Environ. 635, 112–119 (2018). https://doi.org/10.1016/j.scitotenv.2018.04.011

Johnson, K., Barth, M., Durbin, T., Miller, W, Russell, R., Cocker, D., Scora, G.: Measuring and modelling PM emissions from heavy-duty construction equipment. CE-CERT, University of California, Innovation DoRa. Report No.: CA11-1204 (2012). Available from: https://rosap.ntl.bts.gov/view/dot/27671. Accessed 15 Dec 2023

Johnson, K., Cao, T., Durbin, T., Russell, R., Cocker, D., Scora, G., Maldonado, H.: Evaluations of in-use emission factors from off-road construction equipment. Atmos Environ. 147, 12 (2016)

Durbin, T.D., Johnson, K., Jung, H., Russell, R.: Study of in-use emissions from diesel offroad equipment. California: CE-CERT, University of California, California Air Resources Board RD (2013). Available from: https://www.semanticscholar.org/paper/Study-of-in-use-emissions-from-diesel-off-road-Durbin/d948951da21ea881d4b756fc5b84f309cd10ba38. Accessed 15 Dec 2023

Shen, X., Barati, K.: Operational level emissions modelling of on-road construction equipment through field data analysis. Autom. Constr. 72, 9 (2016)

Mingliang, F., Ge, Y., Tan, J., Zeng, T., Liang, B.: Characteristics of typical non-road machinery emissions in China by using portable emission measurement system. Sci. Total Environ. 437, 255–261 (2012). https://doi.org/10.1016/j.scitotenv.2012.07.095

Chen, J., Li, Y., Meng, Z., Feng, X., Wang, J., Zhou, H., Li, J., Shi, J., Chen, Q., Shi, H., et al.: Study on emission characteristics and emission reduction effect for construction machinery under actual operating conditions using a portable emission measurement system. Int. J. Environ. Res. Public Health. 19, 9546 (2022). https://doi.org/10.3390/ijerph19159546

Tan, D., Tan, J., Peng, D., Mingliang, F., Zhang, H., Yin, H., Ding, Y.: Study on real-world power-based emission factors from typical construction machinery. Sci. Total Environ. 799 (2021). https://doi.org/10.1016/j.scitotenv.2021.149436

Gautam, M.: Testing for exhaust emissions of diesel powered off-road engines. West Virginia University, Agency CARBaCEP (2002). Available from: https://ww2.arb.ca.gov/sites/default/files/classic/research/apr/past/98-317.pdf. Accessed 15 Dec 2023

Barth, M., Durbin, T.D., Miller, J.W., Scora, G.: Evaluating the emissions from heavy-duty construction equipment. California Department of Transportation, Innovation DoRa. Report No.: RTA 65A0197 (2008). Available from https://rosap.ntl.bts.gov/view/dot/27551. Accessed 15 Dec 2023

Miersch, W., Sachse, J.: Emission testing of engines to be installed in non-road mobile machinery. Berlin: European Commission, Environment Nuclear Safety and Civil Protection. Contract No.: 1445-99 (1999). Available from: https://www.environmental-expert.com/articles/emission-testing-of-engines-to-be-installedin-non-road-mobile-machinery-1676. Accessed 15 Dec 2023

ICCT. European Stage V non-road emission standards. (2016). Available from: https://theicct.org/sites/default/files/publications/EU-Stage-V_policy%20update_ICCT_nov2016.pdf. Accessed 15 Dec 2023

Perujo A.: Non-road engines conformity testing based on PEMS. Luxembourg: Joint Research Centre; 2013. Contract No.: EUR 26438EN. Available from: https://op.europa.eu/en/publication-detail/-/publication/5d1158d8-5833-4e5c-ba15-e650245019fe/language-en/format-PDF/source-240824810. Accessed 15 Dec 2023

United States Environmental Protection Agency. Managing air quality - emissions inventories. Available from: https://www.epa.gov/air-quality-management-process/managing-air-quality-emissions-inventories. Accessed 15 Dec 2023

Department of Agriculture Environment and Rural Affairs. Integrated pollution prevention and control. Available from: https://www.daera-ni.gov.uk/topics/pollution/pollution-prevention-and-control. Accessed 15 Dec 2023

Beevers, S., Kitwiroon, N., Williams, M., et al.: Air pollution dispersion models for human exposure predictions in London. J. Expo. Sci. Environ. Epidemiol. 23, 647–653 (2013). https://doi.org/10.1038/jes.2013.6

Tsagatakis, I., Ruddy, M., Richardson, J., Otto, A., Pearson, B., Passant, N.: UK Emission Mapping Methodology – A report of the National Atmospheric Emission Inventory 2016. Department for Business Energy and Industrial Strategy, Food and Rural Affairs; The Scottish Government; Welsh Government; Department of Agriculture, Environment and Rural Affairs for Northern Ireland, editor.: Ricardo Energy & Environment (2018). Available from: https://naei.beis.gov.uk/reports/. Accessed 15 Dec 2023

Department for Environment Food & Rural Affairs. Defra National Statistics Release: Emissions of air pollutants in the UK, 1970 to 2016. Available from: https://www.gov.uk/government/statistics/emissions-of-airpollutants/emissions-of-air-pollutants-in-the-uk-summary. Accessed 15 Dec 2023

Digest of United Kingdom Energy Statistics: Main report 2018. Available from: https://www.gov.uk/government/statistics/digest-of-uk-energy-statistics-dukes-2018-main-report. Accessed 15 Dec 2023

Department for Transport. Transport statistics Great Britain. (2016). Available from: https://www.gov.uk/government/statistics/transport-statistics-great-britain-2016. Accessed 15 Dec 2023

McGinlay, J., Murrells. T. Non-road mobile machinery usage, life and correction factors. (2004). Available from: https://uk-air.defra.gov.uk/library/reports?re:port_id=304. Accessed 15 Dec 2023

Adams M. EMEP/EEA air pollutant emission inventory guidebook 2016. Report No.: 21/2016 (2016). Available from: https://www.eea.europa.eu/publications/emep-eea-guidebook-2016. Accessed 15 Dec 2023

Acknowledgements

The authors would like to thank Emissions Analytics for providing the measurement equipment used to establish emission factors and JCB for providing the information on sales data.

Funding

This work was partly funded by the Centre for Low Emission Construction, Emissions Analytics and the National Institute for Health Research (NIHR) Health Protection Research Unit in Environmental Exposures and Health with a partnership between the UK Health Security Agency (UKHSA) and Imperial College London.

Author information

Authors and Affiliations

Contributions

The authors made the following contributions: Desouza: conceptualisation, methodology, software, formal analysis, investigation, data curation, writing—original draft, and visualisation; Marsh: resources, funding acquisition, project administration, and writing—review and editing; Beevers: supervision, and writing—review and editing; Molden: resources, funding acquisition, and writing—review and editing; Green: conceptualisation, methodology, validation, investigation, writing—review and editing, supervision, and funding acquisition.

Corresponding author

Ethics declarations

Ethical Approval

Not applicable.

Statement on Consent to Participate and Consent to Publish

Not applicable.

Competing Interests

The authors declare that they have no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

• Novel fleet turnover model was developed to calculate NRMM population

• Calculated fleet coupled with measured emissions improved emissions inventory

• Future emissions inventory can develop decarbonisation policy for construction.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Desouza, C., Marsh, D., Beevers, S. et al. Emissions from the Construction Sector in the United Kingdom. Emiss. Control Sci. Technol. 10, 70–80 (2024). https://doi.org/10.1007/s40825-023-00237-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40825-023-00237-w