Highlights

-

The development history and working mechanism of dual-ion batteries are reviewed, with an emphasis on the latest advancement in anode materials.

-

A comprehensive and detailed summary of the synthesis strategies, structural optimization, performance characterization, and reaction principles of four types of anode materials for dual-ion batteries is presented.

-

The current challenges of anode materials are highlighted, and the optimization strategies of advanced anode materials and battery systems are discussed, providing future research directions for the design of commercial dual-ion batteries.

Abstract

Distinct from "rocking-chair" lithium-ion batteries (LIBs), the unique anionic intercalation chemistry on the cathode side of dual-ion batteries (DIBs) endows them with intrinsic advantages of low cost, high voltage, and eco-friendly, which is attracting widespread attention, and is expected to achieve the next generation of large-scale energy storage applications. Although the electrochemical reactions on the anode side of DIBs are similar to that of LIBs, in fact, to match the rapid insertion kinetics of anions on the cathode side and consider the compatibility with electrolyte system which also serves as an active material, the anode materials play a very important role, and there is an urgent demand for rational structural design and performance optimization. A review and summarization of previous studies will facilitate the exploration and optimization of DIBs in the future. Here, we summarize the development process and working mechanism of DIBs and exhaustively categorize the latest research of DIBs anode materials and their applications in different battery systems. Moreover, the structural design, reaction mechanism and electrochemical performance of anode materials are briefly discussed. Finally, the fundamental challenges, potential strategies and perspectives are also put forward. It is hoped that this review could shed some light for researchers to explore more superior anode materials and advanced systems to further promote the development of DIBs.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The development based on traditional fossil fuels is unsustainable and will result in serious pollution to the environment [1, 2]. With the increasing severity of energy and environmental issues, it is vital to develop a clean and sustainable energy supply, hence the emergence of electrochemical energy storage technology. Since the commercialization in 1991, lithium-ion batteries (LIBs) have dominated the market for electric vehicles and portable electronic devices due to their high energy density and long cycle life [3,4,5]. However, the operating voltage of LIBs is relatively low compared to the future demand for electrochemical energy storage, and the scarcity and uneven distribution of lithium and cobalt resources make cathode materials unsustainable and expensive, which also enhance the manufacturing and utilization costs of LIBs [6,7,8]. Furthermore, LIBs display a relatively high security risk. As a matter of fact, the news about the spontaneous combustion or explosion of electric vehicles using LIBs has been frequent in recent years [9, 10]. Therefore, LIBs are not suitable for large-scale energy storage applications, and the exploration and development of novel high-performance, non-polluting, and low-cost energy storage devices has become an urgent global issue, which requires the joint efforts of researchers.

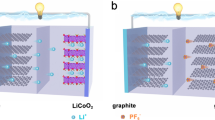

Currently, research based on the earth-abundant cations has been reported one after another [11,12,13]. As shown in Fig. 1a, these cations such as Na+ and K+ exhibit similar properties to Li+ but with higher elemental abundance in the crust (2.7 wt% Na and 2.4 wt% K, vs. 0.002 wt% Li) and lower cost [14, 15]. Therefore, a series of innovative energy storage battery systems have been subsequently developed, for instance, monovalent sodium-ion batteries (SIBs) [16, 17], potassium-ion batteries (PIBs) [18, 19]; bi-valent zinc-ion batteries (ZIBs) [20,21,22], magnesium-ion batteries (MIBs) [23, 24], calcium-ion batteries (CIBs) [25, 26]; tri-valent aluminum-ion batteries (AIBs) [27,28,29] as well as dual-ion batteries (DIBs) [30,31,32,33], etc. Some battery systems exhibit superior electrochemical performance, lower cost, and greater safety than conventional batteries (e.g., lead-acid batteries, nickel–cadmium batteries, and LIBs) as illustrated in Fig. 1b. Among them, DIBs are a battery system that balances both cations and anions, exhibiting a unique working mechanism different from that of "rocking-chair" batteries, in which the anions also act as charge carriers and participate in the electrochemical reactions. Specifically, to visualize the differences in the working mechanism between the two systems, as depicted in Fig. 1c, d, different from LIBs, during charging, active anions derived from the electrolyte move toward the cathode and intercalated into the electrode structure. Meanwhile, active cations shift to the anode and participate in the electrochemical reactions such as intercalation, alloying, conversion, and enolization reactions [34,35,36]. The discharging process is opposite, with active anions and cations returning to the electrolyte from the cathode and anode, respectively. The electrode reactions involved are indicated in Eqs. (1–3) (taking the classical dual-carbon electrodes and LiPF6 electrolyte as an example):

where CA and CC are negative and positive carbon, respectively. In particular, as the single source of active ions in the DIBs system, the electrolyte acts as both an ion transport medium and an active material, which plays a key role in enhancing energy density and electrochemical energy storage of DIBs. Therefore, rational design and optimization of the electrolyte system is important to improve the electrochemical performance of the target anode materials. Besides, cost and safety are also important issues to be considered in the practical application of electrolyte design. For example, a variety of phosphate esters, phosphonates, and ionic liquids with flame-retardant properties can be employed as electrolyte and demonstrate good compatibility with the electrode materials of DIBs, which significantly improves the safety and electrochemical performance of DIBs [37,38,39]. In addition, graphite, which is completely free of metal elements, can be used as the cathode active material for DIBs, thus remarkably reducing the cost compared to the commonly used expensive cathode materials for LIBs (LiCoO₂, LiMn₂O₄, LiFePO₄, and Ni-Co-Mn ternary materials, etc.) [40, 41]. Further, since the high positive potential (~ 5.0 V vs. Li/Li+) of anion insertion into graphite results in higher working voltage and energy density of DIBs compared to commercial LIBs [42, 43]. The special reaction mechanism of DIBs requires that the cathode materials should possess fast ionic insertion kinetics, excellent structural stability, and abundant active sites to rapidly and repeatedly store as many large-sized reactive anions as possible and is expected to solve the capacity mismatch of the cathode and anode. The electrolyte should be stable at high potentials without oxidative decomposition and co-insertion of solvent molecules, with no side reactions and corrosion of the collector during cycling, and good compatibility with the electrodes. To sum up, owing to the advantages of low cost, environmentally friendly, high operating voltage, DIBs have attracted extensive attention in recent years and gradually evolved into the state-of-the-art battery energy storage system, which is highly promising to become a strong candidate for the next generation of efficient large-scale energy storage batteries. The continued increase in research interest can also be evidenced in Fig. 1e, f, where the number of publications and citations related to DIBs has increased rapidly over the last decade [44,45,46,47]. However, although some review articles about DIBs have been published sequentially, most of them basically focus on the preparation and performance studies of cathode materials, the exploration and optimization of electrolyte systems or a general and brief overview of the research progress of DIBs. Most important of all, to the best of our knowledge, up to now there is no dedicated review to summarize the synthesis, performance research, structure characterization and mechanism derivation of DIBs anode materials in detail. Actually, for the anode, it should feature high theoretical capacity and low operating potential to essentially achieve the high specific discharge capacity, remarkable working voltage and energy density of DIBs. More importantly, the anode materials should have efficient cation reduction reaction and rapid transport kinetics to match the fast insertion kinetics of anions on the cathode side and achieve superior rate capability; high binding capability to avoid spontaneous release of active ions, thereby reducing self-discharge rate; favorable compatibility with the electrolyte to form a solid electrolyte interphase (SEI) with good mechanical strength and ion transport, and to realize the stabilization and concentration requirements of the electrolyte under high voltage. Therefore, the anode materials equally play an essential role, and a rational design and performance optimization of the anode material is urgently needed. It is necessary to go for a systematic review of the latest research progress of DIBs anode materials, including synthesis, modification, performance testing, structural characterization, and mechanism exploration. Finally, some outstanding challenges faced by the current DIBs anode materials are discussed and corresponding improvement strategies and perspectives are proposed, aiming to provide researchers with a clearer understanding and better promote the realization of advanced dual-ion batteries with low cost and high performance.

a Comparison of comprehensive properties of various metal elements. b Comparison of the overall performance of various types of batteries. c Schematic of the working mechanism of LIBs and d the operating mechanism of DIBs. e The number of articles on DIBs published in the past decade. f The citations of articles on DIBs in the last ten years

2 Development History of DIBs

In order to better understand the dual-ion battery, a brief review of its development history is described in Fig. 2. As an innovative battery energy storage system, DIBs have been developed in leaps and bounds in recent years, but the related concept of anion insertion was introduced as far back as 1938, when Rüdorff and Hofmann confirmed the reversible insertion of HSO4− into graphite and prepared a type of graphite-based battery [48]. Later in 1989, McCullough et al. introduced the concept of "double graphite cell" or "double intercalation" to explain the reaction process of the cell [49]. Then in 1994, Carlin et al. reported the room-temperature ionic liquid-based dual-graphite batteries (DGBs), demonstrating that the large-size 1-ethyl-3-methylimidazolium (EMI+) cation could be reversibly intercalated in the graphite anode [50]. In 2000, Seel et al. demonstrated that the insertion of active ions into electrodes is a stage process through in situ XRD characterization [51]. Ishihara et al. explored the effect of graphite crystallinity on the intercalation of reactive ions in 2007, proving that an increase in crystallinity favors the intercalation of reactive ions [52]. It was not until 2012 that the concept of the "dual-ion battery" was formally put forward by Placke et al. and has been applied ever since [53]. In 2014, Read et al. reported the realization of a 5.2 V high-voltage dual-graphite battery based on fluorinated electrolytes and additives [54]. In 2015, Dai et al. reported the Al-DIBs based on Al metal anode, while Tang et al. discovered the Li-DIBs based on Al anode in 2016 [55, 56]. To further reduce the cost, in 2017, Sheng et al. reported the sodium-based dual-ion batteries (Na-DIBs) based on Sn anode, and Ji et al. debuted the potassium-based dual-ion batteries (K-DIBs) with Sn and Pb foil as anode, respectively [57, 58]. In 2018, Wang et al. reported the calcium-based dual-ion batteries (Ca-DIBs) that could cycle stably at room temperature [59]. The concept of a reverse dual-ion battery (RDIB) based on ferrocene nanocomposite anode was first proposed by Wu et al. in 2019 [60]. In 2020, Lei et al. debuted the magnesium-based dual-ion batteries (Mg-DIBs) based on 3,4,9,10-perylenetetracarboxylic diimide (PTCDI) organic anode [61]. While Tong et al. reported a type of DIBs based on a high-concentration sulfone-based electrolyte in 2021, which could further increase the oxidation potential to 6.0 V [62]. More recently, Yuan et al. proposed a novel class of DIBs based on an innovative concentrated organic solvent-ionic liquid hybrid electrolyte in 2023, which can increase the specific discharge capacity (SDC) beyond 350 mAh g−1 [63]. While Wang et al. increased the median discharge voltage of DIBs to 4.67 V through the synergistic solvation effect of anions, which further advance the practical application of DIBs [64].

Copyright 1938, Wiley. The concept of "double graphite cell" or "double intercalation", reproduced with permission [49]. Copyright 1989, US Patent. The room-temperature ionic liquid-based DGBs, reproduced with permission [50]. Copyright 1994, The Electrochemical Society. The demonstration that the insertion of active ions is a staged process, reproduced with permission [51]. Copyright 2000, The Electrochemical Society. Formally introduced the concept of a "dual-ion battery", reproduced with permission [53]. Copyright 2012, The Electrochemical Society. The 5.2-V class dual-graphite battery, reproduced with permission [54]. Copyright 2014, The Royal Society of Chemistry. The Li-DIBs based on Al anode, reproduced with permission [56]. Copyright 2016, Wiley. The Na-DIBs and K-DIBs based on Sn anode, reproduced with permission [57, 58]. Copyright 2017, Wiley. The first reverse dual-ion battery, reproduced with permission [60]. Copyright 2019, American Chemical Society. The Mg-DIBs, reproduced with permission [61]. Copyright 2020, American Chemical Elsevier. The 6-V class DIBs, reproduced with permission [62]. Copyright 2021, Wiley. The dual-carbon battery with a capacity over 350 mAh g−1, reproduced with permission [63]. Copyright 2023, Wiley

Development history of dual-ion batteries. A type of graphite-based battery, reproduced with permission [48].

Nevertheless, compared with state-of-the-art of LIBs, the current research on DIBs is still in the primary stage with the technology still immature. Although the electrochemical reactions on the anode side of DIBs are similar to that of LIBs, in fact, to match the rapid insertion kinetics of anions on the cathode side and consider the compatibility with electrolyte system which also serves as an active material, the anode materials play an extremely crucial role, and there is an urgent demand for rational structural design and performance optimization. Therefore, in the following sections, the research progress of DIBs anode materials will be discussed in detail, including the synthesis strategy, structural optimization, performance characterization and reaction mechanism of anode materials. Moreover, the current challenges are summarized and the potential solutions, as well as the future development direction of anode materials for DIBs are put forward. Meanwhile, it is also expected that this review can draw the attention of more researchers to DIBs, attract more people to join the research field of DIBs, and promote its practical application faster. As displayed in Fig. 3a, c, based on the unique physicochemical properties of the material itself, the anode materials currently applied in DIBs can be broadly divided into four categories, which are carbonaceous materials, metallic materials, organic materials, and emerging materials in recent years such as MOFs, COFs, and MXenes materials. Accordingly, there are four main working mechanisms involved in these materials, namely, intercalation reaction, alloying reaction, conversion reaction, and adsorption reaction (Fig. 3b, d). In the following, these four types of materials will be discussed separately, aiming to provide readers with a clearer understanding of DIBs, especially the anode materials, and to promote the development of advanced DIBs.

3 Carbonaceous Materials

3.1 Graphitized Carbon Materials

As mentioned above, the development of DIBs was initially facilitated by the study of graphite intercalation compounds (GICs). Meanwhile, the inspiring thing about graphite is that it exhibits redox duality, which can not only accommodate anions (PF6−, TFSI−, ClO4−, BF4−, TfO−, etc.), but also store cations (Li+, Na+, K+, Zn2+, Ca2+, Mg2+, Al3+, etc.) [65,66,67,68,69]. Therefore, graphite-based materials not only have been one of the most successful materials applied in the DIBs cathode system, but also is the dominant anion host material of DIBs at present. It is well known that graphite is a three-dimensional (3D) material consisting of two-dimensional (2D) graphene sheets stacked together in ABAB order through π–π interactions and van der Waals forces stacking with a layer spacing of 0.335 nm (Fig. 4a) [70, 71]. This unique layered structure features excellent mechanical strength (130 GPa) and high Young's modulus (1 TPa), allowing stable and reversible intercalation/de-intercalation of charge carriers [72, 73], wherein the reaction formula of the cations insertion into the graphite layered structure can be expressed as follows:

Copyright 2011, Elsevier. b Schematic illustration of different stages of intercalated graphite, reproduced with permission [74]. Copyright 2014, Royal Society of Chemistry. c Working principle of the polarity-switchable DGDIBs, reproduced with permission [75]. Copyright 2018, Wiley. d Schematic diagram of NDIBs at the states of pristine, charging process, fully charged, discharging process, and fully discharged, reproduced with permission [77]. Copyright 2017, Wiley. e Schematic diagram of the working mechanism of KDGBs, reproduced with permission [78]. Copyright 2023, Springer Nature. f Battery configuration and working mechanism of the K-ion dual-graphite battery, reproduced with permission [79]. Copyright 2020, Wiley. g Illustration of the CEI evolution during cycling in electrolyte with and without LiDFOB additive, reproduced with permission [84]. Copyright 2021, Wiley. h Schematic diagram of the chemical coating and in situ polymerization of CEI on LTO-modified MCMB, reproduced with permission [85]. Copyright 2019, Wiley

Schematic representation of the reaction mechanism and the corresponding modification strategies for graphitized materials. a Crystal structure of graphite, reproduced with permission [70].

Interestingly, when the intercalation reaction occurs, the reactive ions are not intercalated into the graphite layer structure at the same time, but rather, the process is carried out step by step in a certain order. This process is defined as "staging", as shown in Fig. 4b, and the stage number represents the number of graphene layers between adjacent intercalated active ions [74]. However, graphite-based anode materials face a relatively slow desolvation process, leading to unsatisfactory cation reaction kinetics on the anode side, which is difficult to match the fast anion insertion kinetics on the cathode side. Therefore, rational design of the electrolyte system or relevant modification of the material is needed to avoid the desolvation process and improve the cation reduction reaction rate and transport kinetics on the anode side. Specifically, Feng et al. ingeniously designed a polarity-switchable DIBs presented in Fig. 4c, in which graphite was used as both anode and cathode, and the electrolyte was 2 M LiPF6-3 wt% VC [75]. During the charging process, anions and cations shift toward the cathode and the anode, respectively, when the polarity is switched, the roles of the cathode and the anode are interchanged, the reversible intercalation/de-intercalation of active ions can still be achieved. Impressively, the electrodes are continuously activated during polarity switching, while the functional additive VC facilitates the formation of a more stable SEI and reduces the anion insertion potential. Thus, it effectively inhibits the further decomposition of the electrolyte and leading to faster reaction kinetics and superior electrochemical performance relative to the initial battery system, with a median voltage as high as 4.5 V and a high energy density (ED) of 227 Wh kg−1 (based on the total mass of anode and cathode). Xu et al. introduced a fluorinated solvent and additive (1.7 M LiPF6 in FEC: EMC = 4:6, w:w + 5 mM HFIP) into a DIB system based on a mesophase carbon microspheres (MCMB) anode [76]. This fluorinated electrolyte can in situ generate a protective SEI on the MCMB that is rich in inorganic components such as Li-F and is mechanically strong, which significantly enhances the Li+ transport kinetics and support the efficient insertion of Li+ into the anode at potentials as low as 0.2 V, thus enabling the DIBs to perform redox reactions at 5.2 V.

Besides, several DIBs systems based on sodium and potassium salt electrolytes have been reported. For example, Lu et al. developed a high-performance sodium-based DIB (SDIB) with soft carbon anode and 1 M NaPF6-EC-DMC electrolyte (Fig. 4d), which delivered a high SDC of 103 mAh g−1 and a high discharge platform of 3.58 V at 200 mA g−1 [77]. Even at a high current density of 1000 mA g−1, the SDIB can be stably cycled for 800 cycles with a capacity retention (CR) of 81.2%. Li et al. reported a potassium-based DIB (KDIB) based on graphite anode and KFSI-TEP electrolyte with a salt-to-solvent molar ratio of 1:1.3 (Fig. 4e), which exhibited a high operating voltage of 4.3 V and favorable stability with a CR of 98% after 350 cycles at 1 A g−1 [78]. In particular, the electrolyte employed is highly non-flammable, which in turn significantly improves the safety of DIBs. To further increase the operating voltage and energy density of KDIBs, a kind of DIBs based on high-concentration potassium-based electrolyte (5.2 m KFSI-TMS) and expanded graphite (EG) cathode has been developed. This high-concentration electrolyte displays an oxidation potential of up to 6.0 V, which promotes the reaction kinetics of active ions and notably improves the intercalation reversibility and capacity of K+ on the graphite anode side, and the employed TMS solvent is non-flammable, thereby boosting the cycling performance, energy density, and safety of DIBs [79]. The constructed proof-of-concept KDIBs exhibit an SDC of 83.4 mAh g−1 at 100 mA g−1 and a CR of 81% after the 400 cycles at 300 mA g−1 (Fig. 4f). The ED is up to 130 Wh kg−1 (based on the total mass of cathode, anode, and electrolyte), which is the highest value reported at that time. Moreover, dual-graphite batteries based on metal-free electrolyte systems such as pure ionic liquids (ILs) have also been developed. Yuan et al., respectively, investigate the DIBs based on PP14TFSI and Pyr14TFSI ionic liquid electrolytes with composite graphite (CG) anode, the results indicate that the PP14TFSI electrolyte demonstrates a wider electrochemical window, better compatibility with the anode, and the ability to form thinner and stable SEI. The corresponding DIBs based on PP14TFSI pure ionic liquid electrolyte possess a median discharge voltage up to 4.4 V and excellent cyclic performance, which can be stably cycled for 600 cycles without capacity degradation [80, 81]. Additionally, a lower self-discharge rate is presented due to the higher binding capability between PP14+ and the anode after intercalation compared to Pyr14+, resulting in a more difficult spontaneous detachment of PP14+.

However, although exhibiting decent cation storage performance, graphitized anode materials are limited by some shortcomings such as severe structural exfoliation and continuous decomposition of the electrolyte during the repeated intercalation/de-intercalation process at high potential, resulting in performance degradation of anode, reduction of the cycle life and Coulombic efficiency, which undoubtedly hinders the further development of DIBs [82, 83]. Accordingly, researchers have adopted appropriate modification strategies to address these drawbacks. The introduction of suitable electrolytes or functional electrolyte additives can form a SEI layer with better performance, which can play a good passivation effect on the surface of the anode, promote the compatibility between the anode and the electrolyte, inhibit the further decomposition of the electrolyte and boost the kinetics of the active ions transport [37, 38, 43, 53, 54]. Specifically, as shown in Fig. 4g, a robust artificial electrode–electrolyte interfacial layer is fabricated on the surface of graphite electrode (MTI SAG-R) upon the introduction of 5 wt% lithium difluoro(oxalato)borate (LiDFOB) film-forming additive, which in turn notably improves the electrochemical performance of the dual-graphite battery [84]. The DIBs exhibit an ED of 179.8 Wh kg−1 (based on the total mass of cathode and anode) and a high SDC of 97.6 mAh g−1 at 10C (1C = 100 mA g−1). After 6500 cycles, the DIBs still show a CR of 92.4% with Coulomb efficiency (CE) remains at 99.4%. Functional modulation of morphology and structure is also a commonly employed modification strategy for DIBs. By adopting Li4Ti5O12 (LTO) with functional activity to modify the MCMB anode and pre-lithium treatment, as shown in Fig. 4h, it can not only maintain the structural integrity of electrode to avoid the collapse of graphite layer structure, but also improve the thermodynamic behavior of active ions and inhibit the further decomposition of electrolyte [85]. The corresponding dual-ion full battery exhibits a high ED of about 200 Wh kg−1 (based on the total mass of cathode and anode) with a CR of 93.5% after 1000 cycles at 5C. Additionally, heteroatom doping and layer spacing modulation strategies are also attractive for improving the performance of DIBs. Therefore, a type of modified graphite anode (N-LIDG-800) with large layer spacing and nitrogen atom doping is synthesized for DIBs by a one-step catalytic pyrolysis method, which possesses a remarkably higher layer spacing than that of pristine graphite (0.51 vs 0.335 nm) and provides more storage space for reactive ions [86]. Furthermore, the defects induced by nitrogen doping not only strengthen the adsorption of reactive ions and reaction kinetics, but also supply additional active sites. This synergistic effect enables the DIBs to achieve an ultra-high SDC of 240 mAh g−1 at 1C and be able to cycle stably for 2400 cycles.

3.2 Non-Graphitized Carbon Materials

Compared with graphitized carbon, non-graphitized carbon materials exhibit batter electrochemical performance, such as:

-

(1)

Relatively larger layer spacing, generally greater than 0.38 nm [87].

-

(2)

Higher theoretical capacity, usually greater than 500 mAh g−1 [88].

-

(3)

Better rate capability and stability, and its special amorphous structure not only facilitates the storage and transport of reactive ions, but also exerts better buffering ability against the volume expansion caused by the insertion of reactive ions [89, 90].

-

(4)

Exhibit inherent superiority for the storage of Na+ and K+ [91, 92].

-

(5)

Potential cost advantage, which can be synthesized from a variety of abundant precursors with simple preparation process [93, 94].

Although the structure of non-graphitized carbon materials is complex and diverse, there are abundant active sites for the storage of active ions. As illustrated in Fig. 5a, these active sites can be broadly divided into the following categories [95,96,97]:

-

(1)

Adsorption on open pore surfaces, influenced by the specific surface area of materials.

-

(2)

Adsorption of reactive ions at defect sites, including edges, heterogeneous elements, and vacancies, etc., influenced by precursor material and degree of defects.

-

(3)

Insertion of reactive ions in graphene layers, influenced by the occupancy of pseudo-graphite nanodomains.

-

(4)

Pore filling for the formation of quasi-metallic clusters, influenced by the number and size of pores.

Copyright 2022, Wiley. b Potential storage mechanisms for alkali metal ions in non-graphitized carbon, reproduced with permission [89]. Copyright 2021, Wiley. c Four types of storage mechanisms for hard carbon, reproduced with permission [98]. Copyright 2022, Wiley. d Schematic illustration of the WSC–1200/K SDIBs, reproduced with permission [105]. Copyright 2023, Elsevier. e Schematic illustration of the Na+-DCB using NaTFSI-TMP electrolyte, reproduced with permission [106]. Copyright 2018, Wiley. f Percentage of pseudo-graphite regions at different temperatures and g the schematic illustration of the AK-DIB with SP-HC-1200 anode, reproduced with permission [107]. Copyright 2019, Elsevier. h Schematic image for aqueous DIB using AC anode and LiFSI-LiTFSI bisalt electrolyte, reproduced with permission [113]. Copyright 2021, Elsevier

Storage mechanism of non-graphitized carbon anode materials and their application in DIBs. a Microstructure of hard carbon and the major active sites with the ability to store reactive ions, reproduced with permission [98].

Especially, Fig. 5b summarizes the potential storage mechanisms for alkali metal ions in non-graphitized carbon [89]. Among them, hard carbon (HC), as a typical non-graphitized carbon anode material with decent electrochemical performance, has received more and more attention and is widely applied in Li/Na/K-ion batteries [98, 99]. In recent years, HC materials have also been gradually implemented in DIBs with promising outcomes, even delivering better performance than graphite [100,101,102]. HC features a house of cards-like structure, consisting of curved and irregularly distributed graphene nanosheets with an amorphous structure, which is difficult to graphitize even at temperatures above 3000 °C [103, 104]. The exploration of the energy storage mechanism is essential to understand the influence of the anode materials' structure on their electrochemical performance and to guide the pre-design and synthesis of materials. Based on the theoretical calculations and experimental investigations, various mechanism models have been proposed. Although controversially, the energy storage mechanisms of HC can be roughly classified into four types, including "intercalation-adsorption", "adsorption-intercalation", "stage-to‐stage" and "adsorption-pore filling" models, as presented in Fig. 5c [98]. A number of researchers have already expanded their research direction to the application of HC in DIBs, e.g., Huang et al. prepared the biomass walnut shell-derived hard carbon (WSC) via a two-step pyrolysis method and attempted to improve the Na+ storage performance by modulating the area ratio of the capacitance-controlled disordered region and the diffusion-controlled pseudo-graphitic region (DR/PGR) [105]. As a result in Fig. 5d, the DIBs based on a WSC anode with an optimal DR/PGR ratio and 1 M NaPF6-EC/DMC (1:1, v/v) electrolyte exhibited an ultra-high SDC of 245.6 mAh g−1 with an ED of 172.06 Wh kg−1 (based on the total mass of cathode and anode). The battery system also shows a long cycle life of 30,000 cycles at 5 A g−1 with a low decay rate of 0.049% per cycle. To further improve safety, a non-flammable trimethyl phosphate-based concentrated electrolyte system (NaTFSI-TMP) is developed for SDIBs [106]. The electrolyte is also capable of forming a stable SEI on HC anode, which inhibits the decomposition of electrolyte and displays a decent rate capability (Fig. 5e). In this case, the Na-DIB can deliver an operating voltage of 4.0 V with no degradation after 750 cycles. As mentioned previously, the pseudo-graphite structure in HC is favorable to bring higher capacity and improved rate performance. To this end, Sichuan pepper was used as a precursor, and the HC synthesized at 1200 °C (SP-HC) was discovered to possess abundant pseudo-graphite regions through the exploration and optimization of pyrolysis temperature in Fig. 5f [107]. The K+ storage mechanism is investigated via combining in situ XRD characterization and kinetic analysis, and the results demonstrate that the adsorption-insertion-filling synergistic effect of SP-HC brings good storage performance (Fig. 5g). When employed in the DIBs system based on 0.8 M KPF6-EC-DEC electrolyte, the full battery exhibits an SDC of 67 mAh g−1 with a CR of 90% after 300 cycles. To promote the K+ storage capability of HC further, a kind of hard carbon with porous nanoparticles (NOCNBs) derived from lobster shells containing abundant active sites was synthesized by a self-template-assisted pyrolysis strategy, which demonstrates satisfactory K+ storage performance [108]. Density-functional theory (DFT) indicates that NOCNBs present a hierarchical multi-scale structure of microporous/mesoporous/macropore with a large layer spacing of 0.4 nm, which greatly enhances the adsorption and diffusion of K+, thus facilitating the capacitive-adsorptive storage. As an anode for KDIBs, the system exhibits a median voltage of 4.05 V and a SDC of 89 mAh g−1 with a CR of 95% after 2000 cycles.

Activated carbon (AC), as a commonly used adsorbent, is also employed in energy storage due to its high specific surface area (> 2000 m2 g−1) and good conductivity (~ 60 S m−1) [109,110,111,112]. Ishihara et al. reported an aqueous DCBs system based on the KS6 graphite cathode and AC anode, specifically, a novel LiFSI/LiTFSI (9:1, molar ratio) water-in-bisalt aqueous electrolyte was designed, and the effect of the variation in solvation structure was additionally investigated in detail [113]. The electronic interactions between the two supporting salts boost the oxidation potential of this aqueous electrolyte to 5.0 V, which widens the electrochemical window of DCBs to 3.1 V (Fig. 5h). The corresponding full battery delivers a SDC of 72 mAh g−1 and a high ED of 214 Wh kg−1 (based on the mass of anode) with no capacity degradation at 500 mA g−1 for 100 cycles. However, the cost of this water-in-salt aqueous electrolyte is too expensive. To realize the cost advantage, a class of peanut-skin-derived ACs were prepared by the KOH activation method to serve as both cathode and anode of DIB, and the cheap 1 M NaClO4-EC-DEC was used as the electrolyte [114]. The constructed DCBs exhibit an ED of 112 Wh kg−1 (based on the total mass of cathode and anode) and display stable cycling performance with a CR of 85% after 3000 cycles. While Wang et al. synthesized an AC anode with a hollow sphere structure through the SiO2 templating method, and designed the PDIBs based on 1 M-KPF6-EC-DEC-PC electrolyte, which exhibited a median voltage of up to 4.3 V and a SDC of 89.8 mAh g−1 at 100 mA g−1 with a high CR of 96.6% after 200 cycles [115]. Apart from alkali metal ions, AC can also be utilized to store divalent metal ions and non-metal cations. For instance, Placke et al. constructed a type of DCBs based on AC anode, graphite cathode, and magnesium-based ionic liquid electrolyte of 0.3 M Mg(TFSI)2-Pyr14TFSI, which exhibited a high SDC of 87 mAh g−1 with a CE of 98% in the voltage window of 5.2 V and can be stably cycled for 50 cycles without degradation [116]. Zheng et al. proposed the DCBs based on EMImPF6 pure ionic liquid electrolyte and AC anode, the full batteries exhibited an ED of 43 Wh kg−1 (based on the total mass of cathode and anode) with a CR of 83% after 50 cycles [117]. Other than that, some non-graphitized amorphous carbon materials are also highly promising anode materials for DIBs. As Lu et al. reported a 4.5 V-grade lithium-based full DCBs that amorphous carbon nanospheres were both as cathode and anode, which can achieve a high ED of 206.7 Wh kg−1 (based on the total mass of cathode and anode) and be stably cycled for 10,000 cycles with a capacity degradation rate as low as 0.0013% per cycle [118]. Hou et al. synthesized an in situ phosphorus-doped hollow carbon nanorods material (P-HCNs) with a high P doping of 7.5 at.% through the hard template method [119]. When employed in a sodium-based DIB, the full batteries supply an initial Coulombic efficiency (ICE) of up to 73%, an ED of 138 Wh kg−1 (based on the total mass of cathode and anode) and a high SDC of 158 mAh g−1 at 500 mA g−1 with a CR of 78.5% after 1200 cycles. The impressive reversible capacity is attributed to the strong Na+ adsorption capability of P=O and P–C bonds as determined through the first-principle calculations. Tang et al. designed a 3D nanoporous locally ordered composite carbon nanowire material (CCNW) for stable K+ storage [120]. The proof-of-concept potassium-based DIBs exhibit good stability and decent capacity, which deliver a high SDC of 134.4 mAh g−1 at 100 mA g−1 and are stable to cycle for more than 1000 cycles. In particular, no binder is required for the preparation of CCNW anode, which further improves the energy density.

3.3 Emerging Carbon Materials

Compared with the above-mentioned carbon materials, several emerging carbon materials may exhibit better energy storage capability owing to their unique physicochemical properties, thus making them potentially attractive host materials for cations, such as locally graphitized carbon, heteroatom-doped amorphous carbon, heterostructure carbon and carbon quantum dots. As one of the representatives, locally graphitized carbon acts between graphitized and non-graphitized, while combining the advantages of both [121, 122]. The locally ordered graphitized carbon (LOGC) interconnected with disordered carbon is able to weaken the van der Waals interactions between adjacent graphene sheets, which enhances the transport kinetics of reactive ions and reduces the corresponding diffusion energy barriers [71, 121]. Conversely, the non-graphitized disordered carbon regions not only enable the interconnection of dispersed nanographite domains, but also partially buffer the volume expansion effect caused by the severe ion interactions and provide additional capacitive active storage sites. Yang et al. compared the proof-of-concept potassium-based DIBs systems based on three typical carbon materials (fully graphitized carbon: graphite, non-graphitized disordered carbon: AC and locally ordered graphitized carbon: LOGC) [121]. Experiments and calculations concluded that the graphite-anode-based DIBs exhibit a low SDC of only ~ 50 mAh g−1, while the AC-anode-based DIBs also only show a slightly higher SDC of ~ 70 mAh g−1. Surprisingly, DIBs based on the LOGC anode display an ultra-high SDC of 232 mAh g−1 at 100 mA g−1 within 1.5–4.5 V, which shows no degradation after 1000 cycles at 300 mA g−1, further proving the great advantage of LOGC. The role of doping effects in carbon materials has also been comprehensively investigated, and the heteroatom doped amorphous carbon materials (HDCMs) are widely employed in the field of electrochemical storage as important candidates [123,124,125]. By controlling the content and typology of heteroatom-containing reagents, the physicochemical properties of the materials not only can be tuned, but also the morphology can be modulated to optimize the specific surface area and pore volume, thus improving the electrochemical performance of HDCMs [126,127,128]. Zhao et al. Prepared lignin-derived mesopore-rich disordered carbon materials with 21.6 at.% N doping and 0.8 at.% S doping via employing a novel supramolecular-mediated pyrolysis strategy [129]. In this regard, high N doping induces the generation of abundant defects and active sites, which in turn promotes K+ adsorption and reaction kinetics (Fig. 6a). Besides, it is proved that mesopores can also store a considerable number of reactive ions and inhibit the system swelling caused by ion insertion [130, 131]. As shown in Fig. 6b, X-ray photoelectron spectroscopy (XPS) demonstrated that pyridine nitrogen and pyrrole nitrogen undergo a blueshift with decreasing potential, which can be attributed to the large amount of K+ adsorbed by the disordered defect structure and active sites. As the potential recovered, a redshift happens and returns to the initial position, a similar phenomenon was observed for S 2p. With the decrease and increase of the potential, the reversible redshift and blueshift phenomenon occurs in Fig. 6c. The designed proof-of-concept full batteries exhibit a SDC of 45 mAh g−1 at a high rate of 1 A g−1 and are capable of stable cycling for 2000 cycles with a CR of 91%. DFT calculations and experiments indicate that only edge-nitrogen doping can induce the creation of defects and active sites, whereas nitrogen oxide with graphitized nitrogen is able to enhance the conductivity and provide a certain pseudocapacitive effect [132]. On this basis, a class of 3D amorphous hierarchical porous carbon microspheres were engineered through one-step direct pyrolysis of melamine foams with high total nitrogen and edge-nitrogen levels of 36.46% and 29.8%, respectively [63]. Such a high edge-nitrogen content can yield plentiful defects and edge-active site, which is expected to contribute to a high discharge capacity. Furthermore, a novel high-concentration organic solvent-ionic liquid hybrid electrolyte (4 M-EMC-Pyr14TFSI-5%ES, 1:1, v/v) is designed (Fig. 6d). This novel high-concentration electrolyte not only broadens the electrochemical window and increases the oxidation potential, but also alters the solvated structure of Li+, significantly increasing the proportion of anions in the solvated sheath. This anion-dominated solvation structure facilitates the formation of a denser inorganic-rich interfacial layer to passivate the anode, which in turn leads to an improved electrochemical performance. The proposed proof-of-concept DIBs not only offer an ultra-high SDC of 351 mAh g−1 at 100 mA g−1, but also exhibit good rate capability, maintaining stable GCD curves and smooth charge/discharge platforms at high current densities in Fig. 6e. Even at a high rate of 15C, the full DIBs still provide a stable cycling life up to 1300 cycles without degradation (Fig. 6f), which is one of the best results for the reported Li-based DIBs.

Copyright 2023, Springer Nature. d Working mechanism of the full battery based on nitrogen-doped carbon microsphere anode and concentrated organic-IL mixed electrolyte. e Galvanostatic charge–discharge curves under different rates and f the long-term cycling performance under 15 C, reproduced with permission [63]. Copyright 2023, Wiley. g Comparison of the characteristics and energy storage performance of hard, soft, nanostructured and heterostructure carbon, reproduced with permission [135]. Copyright 2021, Wiley. h Four types of fluorescent CDs, reproduced with permission [139]. Copyright 2021, Elsevier

Application of emerging carbon materials in DIBs. a Schematic illustrating the configuration of the battery based on NSLPCs anode. b Ex situ N 1s spectra of NSLPC-700 anode during the charge/discharge process and c K+ storage in amorphous defect-rich carbons, reproduced with permission [129].

Heterostructure carbon is a kind of functional carbon material with special structure and favorable performance composed of two or more carbon layers with different properties, in which the various carbon layers share different carbon crystal structures, physicochemical characteristics and performance. Therefore, heterostructure carbon materials are capable of performing multiple unique functions simultaneously and can showcase more superior electrochemical performance than carbon materials with a specified structure [133,134,135]. As illustrated in Fig. 6g, heterostructure carbon is one of the promising functional materials for energy storage, as it is expected to bring improved comprehensive competitive advantages in various aspects (e.g., capacity, rate, ICE, yield, economy, and cycling stability). Shen et al. designed a high edge-nitrogen-doped carbon nanofiber/g-C3N4 heterostructure carbon material by electrostatic spinning and high-temperature pyrolysis sequentially, which show superior K+ storage performance, outstanding rate capability and satisfactory cyclic life [136]. When 3 M KFSI-DME was employed as electrolyte, the full batteries can deliver a high SDC of 106 mAh g−1 with an energy density of 62.3 Wh kg−1 (based on the total mass of cathode and anode) at 1 A g−1 and are stable for 5000 cycles at 5 A g−1 with a CE close to 100%. The synthesis and application of carbon dots (CDs) have developed into a dynamic and exciting emerging research field in recent years, and the 2023 Nobel Prize in Chemistry was awarded to the discovery and synthesis of quantum dots, further proving the extraordinary significance and application of CDs. CDs are a class of zero-dimensional carbon nanomaterials with distinctive properties, which consist of ultra-fine, dispersed, quasi-spherical carbon nanoparticles with sizes below 10 nm [137, 138]. As depicted in Fig. 6h, according to the difference of carbon nuclei, CDs can be classified into four categories, namely graphene quantum dots (GQDs), carbon quantum dots (CQDs), carbon nanodots (CNDs), and carbon co-polymer dots (CPDs). Especially, CDs are widely adopted in the field of advanced rechargeable batteries owing to their diverse and fascinating physicochemical properties, structures, and excellent electrochemical activities, which makes them promising electrode materials for energy storage and conversion [139]. Feng et al. prepared a class of GQDs materials through an electrochemical stripping method and employed them as both cathode and anode of DIBs, in which the electrolyte used was 2 M NaPF6-DEGDME, which can realize the stable and reversible insertion/desertion of both anions and cations [140]. The designed sodium-based DIBs exhibited an operating voltage of 4.0 V, a SDC of 68 mAh g−1, and a high ED of 250 Wh kg−1 (based on the total mass of cathode and anode) at 300 mA g−1 and can be cycled stably for 200 cycles with a CR of 95%, which represents one of the best performances reported at that time.

In summary, although carbonaceous materials possess the advantages of low cost, environmental friendliness, wide sources, and low insertion potential, they still suffer from some limitations, such as lower theoretical capacity, poor rate performance and structural stability, and higher self-discharge rate. It is possible to improve the specific discharge capacity, cycling performance and inhibit the spontaneous detachment of active ions from the electrode structure from the viewpoint of developing novel carbonaceous materials such as carbon-based materials or carbon-quantum dots with a large layer spacing, surface-active functional group, heterogeneous element doping, a high degree of disorder and defects, and a low interlayer van der Waals effect force. Furthermore, carbonaceous materials are able to store more cations as anode compared to the limited storage of anions at the cathode, which inevitably leads to a capacity mismatch between the cathode and anode. Generally, it is necessary to increase the active mass loading on the cathode side or decrease the loading on the anode side to achieve an active mass loading ratio of 3:1 or even higher for the cathode and anode. Further thinking is needed in the future on how to solve the capacity mismatch problem more rationally. For the convenience of comparison and better understanding by researchers, the configuration and electrochemical performance of DIBs based on various carbonaceous anode materials are listed in detail in Table 1.

4 Metallic Materials

4.1 Alloying-Type Materials

Compared with carbon-based materials, alloyed materials can undergo alloying reactions with metal ions to form metal binary compounds, thus exhibiting high theoretical capacity [141,142,143]. Meanwhile, the alloying materials can act as both anode and current collector, thereby reducing the inactive mass, which undoubtedly increases the energy density and is considered as one of the most promising anode materials for next-generation DIBs [144, 145]. The alloying reaction equations involved are as follows, where A is the alloying element and Mn+ is the metal ion. Due to their nice inherent ability to store cations, these materials have attracted increasing attention in the field of DIBs.

Copyright 2016, Wiley. d Long cycling test of the DIBs and e Ragone plot of current work and previously reported results of DIBs based on 7.5 m LiFSI electrolyte at 200 mA g−1, reproduced with permission [147]. Copyright 2020, Wiley. f Schematic illustration of the fabrication process of nAl@C, reproduced with permission [151]. Copyright 2018, Wiley. g Schematic illustration of the fabrication process to make the pAl/C anode material, reproduced with permission [152]. Copyright 2016, Wiley. h Schematic illustration of the ACNI/Al anode fabrication process, reproduced with permission [153]. Copyright 2021, American Chemical Society. i Fabrication of the Cu–Al nanocomposite film on an Al anode and the schematic diagrams of the different Al anode structures, reproduced with permission [154]. Copyright 2019, Wiley

Alloying materials and corresponding modification strategies. a Schematic illustration of the AGDIB in the initial and charged state. b XRD patterns of a fresh Al foil and an Al electrode in a charged battery and c galvanostatic charge–discharge curve of the AGDIB at 0.5C, reproduced with permission [56].

As a typical representative, Al is the first alloy-type material employed as the anode of DIBs, which boasts a satisfactory theoretical capacity (2980 mAh g−1) compared to that of graphite (372 mAh g−1). Moreover, Al displays superior electrical conductivity (3.8 \(\times\) 107 S m−1), ductility and low discharge potential, which is one of the most successful anode materials so far [56, 146]. Al was first applied as an alloy-type anode in the Li-DIBs system in 2016, as illustrated in Fig. 7a, during charging the following reactions (6–8) took place:

In which the Li+ come from electrolyte was deposited on the Al anode and undergoes alloying reactions, of which the formation of an AlLi alloy was proved by the X-ray diffraction (XRD) in Fig. 7b [56]. Simultaneously, PF6− was intercalated into the graphite cathode, and it can be seen from the galvanostatic charge–discharge (GCD) curves and differential-capacitance curves in Fig. 7c that the process of PF6− insertion/desertion from graphite was mainly composed of three main regions: in which the charging process is 4.08 ~ 4.59 V (stage III), 4.59 ~ 4.63 V (stage II), and 4.63 ~ 5.0 V (stage I); each region corresponds to a different anion insertion stage, respectively.

Specially, Al acts as both anode and current collector, greatly enhancing the mass/volume energy density. When natural graphite and 4 M-LiPF6-EMC-2%VC are employed as cathode and electrolyte, respectively, the constructed Gr//Al dual-ion batteries (AGDIBs) exhibit a high median voltage of 4.2 V, which can easily light up two LEDs with a nominal voltage of 2.5 V (insert of Fig. 7c). Moreover, the AGDIBs not only achieve an SDC of 104 mAh g−1 at 2C and a CR of 88% after 200 cycles, but also exhibit an ED of 222 Wh kg−1 (based on the total mass of cathode and anode) at a power density (PD) of 132 W kg−1, which is significantly higher than that of commercial LIBs. In order to further improve the energy density and cycle stability, a concentrated electrolyte system based on carbonate electrolyte (7.5 m LiFSI in EC-DMC, 1:1, v/v) was developed [147]. Compared with conventional electrolytes, this high-concentration electrolyte features several advantages:

-

(1)

LiF-rich SEI layer can be formed to optimize the structural stability of the Al anode.

-

(2)

The oxidation stability of electrolyte is greatly improved, and the insertion capability and cycling stability of the graphite cathode are also enhanced.

-

(3)

The dosage of electrolyte is reduced, and the energy density of DIBs is increased.

Accordingly, the proof-of-concept AGDIBs based on this concentrated electrolyte display a SDC of 94 mAh g−1 at 200 mA g−1 with a CR of up to 96.8% after 500 cycles (Fig. 7d). Furthermore, calculated based on the total mass of electrodes and electrolyte, the ED of AGDIBs is as high as 180 Wh kg−1 (based on the electrode materials and electrolyte), which is considerably higher than that of commercial LIBs in Fig. 7e.

However, Al anode not only suffers from severe volume expansion (100% for AlLi) and structural pulverization during alloying/dealloying, but also forms lithium dendrites and generates large amounts of dead lithium. On the one hand, this will lead to an increasing impedance and a sharp decline in capacity and cyclic stability. On the other hand, lithium dendrites would easily puncture the separator, leading to an explosion in serious cases, which brings a certain safety hazard and seriously hampers the practical application of Al-based DIBs [148,149,150]. Therefore, it is crucial to overcome these challenging problems through wide-ranging techniques and strategies. Encouragingly, promising solutions have been devised to avoid battery failures caused by imperfect aluminum foil anode. First and foremost among them are morphology and structure regulation strategies such as core–shell structure and porous structure design, which are considered to be extremely viable approaches. Tong et al. developed a scalable and low-cost method to synthesize core–shell Al@carbon nanorods (nAl@C) anode with a mangosteen-like structure [151]. The specific synthesis steps are depicted in Fig. 7f, as a result, the nanoscale framework of nAl@C consists of aluminum nanorods and a surface amorphous carbon layer, which is about 5 nm thick and highly conductive and protective, contributing to the formation of a stable SEI film. Compared with pure Al foil, nAl@C shows a better adaptation to mechanical strains and stresses, which enables effective suppression of volume expansion and structural comminution. The DIBs based on the nAl@C anode exhibit good cyclic stability, with up to 94.6% CR even after 1000 cycles at a high rate of 15C in the voltage range of 3–5 V. SEM and TEM characterizations demonstrate that nAl@C still maintains favorable structural integrity. In addition, a 3D porous aluminum foil (pAl/C) coated with a carbon layer was designed as anode and current collector, as illustrated in Fig. 7g, in which the unique porous structure not only enlarges the contact area with electrolyte and offers a rapid active ion and electron transport channel, but also effectively prevents the volume expansion caused by the AlLi alloying process [152]. The constructed DIBs achieve a CR of 89.4% even after 1000 cycles at a low rate of 2C and provide a satisfactory ED of 232 Wh kg−1 (based on the total mass of cathode and anode) at a PD of 446 W kg−1. The strategy of fabricating artificial SEI also holds great promise for improving the structural stability of the Al anode and inhibiting the excessive decomposition of electrolyte. As shown in Fig. 7h, an amorphous carbon nanointerface (ACNI) with a thickness less than 10 nm was deposited as a functional nanofilm on the surface of Al foil by direct-current magnetron sputtering (DC-MS) [153]. The ACNI acts as an artificial SEI, which not only possesses high mechanical strength and favorable structural stability, but also effectively restrains the continued growth of the already-generated SEI to modify the kinetics of electrochemical reactions. The ACNI anode-based full batteries deliver a SDC of 115 mAh g−1 at 2C and are stable for 1000 cycles with a CR of 94%. Interfacial modification engineering is also a simple but effective strategy [154,155,156]. Figure 7i demonstrates one of the approaches, which employs inactive Cu to modify the interface of active Al and form a Cu-Al heterojunction nanoalloy material (Cu-Al@Al) via co-deposition [154]. Compared with the unmodified Al, Cu-Al@Al not only notably reduces the Li+ diffusion barrier and inhomogeneous deposition sites to achieve a homogeneous alloying reaction, but also facilitates the dispersion of volume expansion stresses to improve the structural stability of the Al anode. As a result, the assembled full batteries could achieve 200 stable cycles with a CR of 88% even with an electrode active mass load of up to 7.4 mg cm−2, implying the remarkable electrochemical performance far beyond that of commercial LIBs.

Compared with the Al anode, Sn exhibits higher reactivity and theoretical capacity for non-Li metal cations such as Na+, K+, Ca2+, and Mg2+, as well as lower cost and environmental friendliness. So it is also an appealing alloy-type candidate that has been widely utilized in DIBs [157,158,159]. Tang et al. took the international lead in applying Sn as an anode in different DIBs systems such as Na-based [57], K-based [58], and Ca-based DIBs [59]. As for Na-based DIBs, his group employed expanded graphite (EG) as the cathode and 1 M NaPF6-EC-EMC-DMC (1:1:1, v/v/v) as the electrolyte [57]. As presented in Fig. 8a, during the charge process, Na+ in the electrolyte migrates to the anode and participates in the subsequent alloying reaction with Sn to form NaSn alloy.

Copyright 2016, Wiley. c XRD profiles of a fresh Sn foil anode and a Sn anode in a charged battery, the inset shows the crystal structure of K2Sn. d GCD curves of the K-DIBs with K, Na, Pb, and Sn metal foils as anode and e long cycling performance at 50 mA g−1 for 300 cycles, reproduced with permission [58]. Copyright 2017, Wiley. f XRD profiles of a Sn anode cycled to different charge states and the detailed view of the boxed area showing the XRD patterns of a Sn anode from 22° to 24°. g Four different bonding situations for Ca and Sn in the Ca7Sn6 alloy, reproduced with permission [59]. Copyright 2018, Springer Nature. h Diffusion energy barriers of K in Sn, Li2Sn5, and LiSn3 crystals, and Li in the Sn crystal, reproduced with permission [161]. Copyright 2021, Chinese Chemical Society. i Proposed schematic to reveal the phase transformation for the Ge/CNF electrode during the cycling process, reproduced with permission [163]. Copyright 2020, Royal Chemical Society

The application and modification strategies of Sn and non-metallic alloys in DIBs. a Schematic illustration of the working mechanism of Sn-G DIB and b charge/discharge capacities and corresponding Coulombic efficiencies of at various rates, reproduced with permission [57].

At the same time, PF6− shifts to the cathode and intercalates into the EG to form graphite-intercalated compounds (GICs). On the contrary, during the discharged state, Na+ undergoes a dealloying reaction, and PF6− is de-intercalated from EG back into the electrolyte. The constructed Sn-G DIB exhibits excellent cyclic stability and outstanding rate capability as presented in Fig. 8b, and the GCD curves at different rates show clear charge/discharge platforms with small polarization effects. Particularly, Sn acts as both the anode and current collector, which reduces the dead load and dead volume, and this is beneficial for improving SDC and ED. The Sn-G DIB achieves a SDC of 74 mAh g−1 at 2C and a high CR of 94% after 400 cycles at 2C in the 2–4.8 V operating voltage range, as well as an ED of 144 Wh kg−1 (based on the mass of cathode) at a PD of 150 W kg−1. Similarly, for the K-based DIBs, during charging, K+ reacts with Sn to form K2Sn alloy as proved by XRD in Fig. 8c, the involved reaction equation is as follows:

Furthermore, the electrochemical performances based on K, Na, Pb and Sn metal anodes are comprehensively compared [57,58,59]. Figure 8d represents the corresponding GCD curves for various systems where the anode and electrolyte are EG and 1 M KPF6-EC-DMC-EMC (4:3:2, v/v/v), respectively, and it can be seen that all of the systems exhibit reversible electrochemical activities with various degrees [58]. However, the DIBs based on K and Na foil anodes both show low SDCs (< 30 mAh g−1), and the Pb foil anode-based DIBs, although possessing a relatively high SDC, the cyclic stability is poor, with the discharge platform gradually disappearing during cycling, and the polarization effect is intensified. Conversely, the DIBs based on Sn foil anode not only display the highest SDC and the best electrochemical performance, but also the GCD curves at different cycles basically overlap with minimal polarization. A 93% CR is achieved after 300 cycles at 50 mA g−1 (Fig. 8e), and an ED of 155 Wh kg−1 (based on the mass of cathode) is provided at a PD of 116 W kg−1. Inspiringly, Sn can even undergo a stable and reversible alloying reaction with Ca2+. The feasibility of the Ca-based dual-ion battery based on the Sn anode, natural graphite (NG) cathode and 0.8 M Ca(PF6)2-EC-PC-EMC-DMC (1:1:1:1, v/v/v/v) electrolyte is verified to be able to work stably at room temperature within a high-voltage window of 3–5 V, breaking through the bottleneck of room-temperature irreversibility in Ca-ion batteries [59]. As shown in Fig. 8f, in situ XRD was employed to trace the alloying/dealloying reaction of Ca2+ with Sn. At the onset, only diffraction peaks corresponding to tetragonal Sn are observed, when further charged to 4 V, a new characteristic peak appears at 22.8°, which is attributed to the (201) peak of Ca7Sn6, indicating that Ca2+ undergoes alloying reaction with Sn. As charging continues, the intensity of the (201) peak increases and reaches its strongest level when fully charged, and the signal of the (201) peak diminishes during the subsequent discharge process, suggesting that a dealloying reaction has occurred. The signal does not disappear completely after being fully discharged, which is due to the slow kinetics of the solid-state electrochemical reaction. Additionally, four possible crystal structures of Ca7Sn6 in Fig. 8g are simulated by DFT, two of which are a Ca atom surrounded by six nearest Sn atoms to form a distorted octahedron (P1 and P2), while the other two are surrounded by seven nearest Sn atoms and form a distorted decahedron (P3 and P4). Furthermore, the binding energies of P1-P4 are calculated separately, all of which are negative and P1 > P2 > P3 > P4, indicating that P4 possesses the most stable structure, which is consistent with the reversible alloying/dealloying process between Ca2+ and Sn. Finally, the as-constructed Ca-DIBs achieve an average discharge voltage of up to 4.45 V with a SDC of 72 mAh g−1 at room temperature and exhibits excellent stability with a 95% CR for 350 cycles at 100 mA g−1, which is considerably higher than other reported performance on Ca-ion batteries. In addition to the above-mentioned metal cations, Sn can react with divalent Mg2+ in a reversible alloying reaction, and the Mg-based DIBs designed on the basis of this reaction principle display exceptional electrochemical performance [160]. The corresponding SDC at 100 mA g−1 is 133 mAh g−1, and the CR after 1000 cycles at 1000 mA g−1 is up to 97.3% with an ED of 394 Wh kg−1 (based on the mass of cathode) at the PD of 293 W kg−1. Unfortunately, Sn experiences more severe volume expansion (120% for NaSn) and structural pulverization during alloying than that of Al anode, ultimately leading to a battery failure. Similarly, the above strategies used to improve Al alloy are equally applicable to Sn. Jiang et al. proposed an ionic-drill strategy to enhance the K-Sn alloying reaction [161]. Specifically, 20 atom% Li+ was added to the K+-based electrolyte, this small portion of Li+ exhibits a lower diffusion energy barrier and faster reaction kinetics than K+ and can act as an ionic drill, thus preferentially alloying with Sn to form tin-rich phases such as Li2Sn5 and LiSn3, which significantly decreases the diffusion energy barrier of K+ (Fig. 8h), opening up the diffusion channel and accelerating the kinetics for K+ considerably. Moreover, the introduction of Li+ can also form a LiF-rich SEI layer on the Sn surface with higher mechanical strength, which can effectively inhibit the volume expansion caused by K-Sn alloying. Thanks to the ion-drill strategy, the constructed KDIBs showed unprecedented results, with a SDC of 106 mAh g−1 and a median voltage of 4.1 V at 5C and can be stably cycled for 500 cycles without capacity degradation.

In addition to Al and Sn, there are other metals that are capable of reversible alloying reactions with metal cations. Zhang et al. reported a heteroatom-doped hierarchical porous antimony nanoparticle/carbon nanofiber-modified Sb alloy (HPSbCNFs) as a flexible freestanding anode for high-performance K-DIBs [162]. HPSbCNFs with extraordinary mechanical flexibility, hierarchical porous structure and high content of nitrogen doping can mitigate volume variation during alloying, enhance electronic and ionic conductivity and supply additional active sites for K+ storage. The fabricated K-DIBs deliver an ultra-high SDC of 440 mAh g−1 with a high medium discharge voltage of 4.5 V at 200 mA g−1 and can be cycled stably for 1440 cycles at 500 mA g−1. While Zhou et al. integrated Ge nanoparticles into one-dimensional (1D) carbon nanofiber to form a nanocomposite Ge/CNFs anode and applied it to Li-DIBs (Ge/CNFs-G DIB) [163]. As shown in Fig. 8i, during the charge process, the initial crystalline Ge experiences a phase transition to form an amorphous LixGe alloy, and then the amorphous LixGe alloy is converted to amorphous Ge by dealloying. Besides, the 1D carbon nanofibers can effectively suppress the volume expansion induced by the alloying process and maintain the structural stability, as well as shorten the Li+ diffusion pathway and improve the conductivity. The corresponding Ge/CNFs-G DIB exhibited a SDC of 281 mAh g−1 at 250 mA g−1 and are capable of stable cycling for 500 cycles at 2500 mA g−1. Moreover, as a powerful supplement to the non-metallic alloying-type anode materials, Si and red phosphorus also possess superior intrinsic ability to store metal cations [164,165,166,167,168]. Among them, the alloy reaction equations of Si and Li are as follows:

However, the volume expansion of Si after complete lithiation can be up to 300%, which severely hampers the application of the Si anode in DIBs. To this end, a flexible interface design strategy that can adjust stress distribution is proposed [169]. By constructing the Si anode on a soft nylon fabric modified with a conductive Cu-Ni transition layer, the flexible interface between Si and soft polymer substrate is rationally devised to regulate the alloying stress of the Si anode, which endows Si with remarkable flexibility and stability, thus greatly improves the structural stability of Si. The designed DIBs achieve a record-breaking ultra-high rate capability of 150C with a SDC of 96 mAh g−1 at 2C and a high CR of 97% after 2000 cycles at 10C. Red phosphorus has been proven to be an excellent Na+ storage anode material due to its low electrochemical plateau, high theoretical capacity and elemental abundance. Yu et al. prepared RP/CNT@GO composite anode via ultrasound-self-assembly, paired with the graphite cathode and 1 M NaPF6-EC-DMC-EMC (1:1:1, v/v/v) electrolyte, and the corresponding proof-of-concept P-G SDIBs exhibit an operating voltage of 3.9 V [170]. The alloying reaction between Na+ and red phosphorus during charging and discharging is demonstrated as follows by XRD and XPS techniques:

Furthermore, the P-G SDIBs delivered a reversible capacity of up to 373 mAh g−1 with an ED of 176 Wh kg−1 (based on the total mass of cathode and anode) at 200 mA g−1 and are capable of stable cycling for 400 cycles.

4.2 Conversion-Type Metal Materials

Conversion materials typically refer to transition metal sulfides, selenides, or oxides, etc., as shown in Fig. 9a [171,172,173,174]. These materials can perform a conversion reaction with active cations and undergo a phase decomposition process to transform into the metal elements and the corresponding sulfides or oxides, as presented in the following reaction formula:

where T is a transition metal element, N is a non-metal element (S, O, Se, F, P, N), M is an alkali metal element (Li, Na, K) and x is the formal oxidation state of N. Conversion-type materials indicate promising prospects as anode materials for DIBs because of their high theoretical capacity and relatively long cycle life. Nevertheless, the unmodified conversion active materials commonly experience serious volume expansion and structural collapse after the phase transition or phase decomposition process, resulting in a low discharge capacity and poor cyclic stability in practice [175,176,177,178]. So it is urgent to adopt corresponding measures to overcome these drawbacks in order to boost the electrochemical performance. Wen et al. present a delicately designed nitrogen-doped carbon film-modified MoSSe nanosheets anode (MoSSeNSs@NC/hC-NC) loaded on hollow cubic nitrogen-doped carbon for efficient Na+ storage, which plays a role of "killing three birds with one stone" [179]. Specifically, as illustrated in Fig. 9b, the hollow cubic carbon skeleton and the nitrogen-doped carbon film realize the double carbon coating layer inside and outside, which not only prevent the volume expansion and enhance the structural stability, but also extend the contact area with electrolyte and promote the reaction kinetics. Moreover, Se doping not only creates abundant defects and adds active sites, but also enlarges the interlayer spacing and conductivity, which promotes the transport and storage of Na+. Compared with unmodified MoS2@C, the Na-DIBs based on MoSSeNSs@NC/hC-NC anode display high SDC, good rate capability and cyclic stability. On the basis of the operating principle in Fig. 9c, the DIBs provide a SDC of 150 mAh g−1 even at 5 A g−1 and exhibit a long lifetime of 2000 cycles at 1 A g−1 (Fig. 9d), as well as an ED of 101 Wh kg−1 (based on the total mass of cathode and anode) at 1212 W kg−1. Further, the Na+ storage behavior of MoSSeNSs@NC/hC-NC was explored by DFT calculations. Compared with pure MoS2, the binding energy ΔE is remarkably reduced when Se elements and corresponding anionic defects are introduced, and the charge-density difference model of Fig. 9e also indicates that the charge density is more likely to cluster around the sites of Se doping and defects with narrower band gap near the Fermi energy level, proving that Se doping and its induced defects provide a better Na+ adsorption capacity. To further improve the energy density, structural stability and intrinsic conductivity, a single-phase ternary NbSSe/NC nanocompound enriched with defective microstructure was prepared by the synthesis steps depicted in Fig. 9f [180]. NbSSe/NC possesses a wide layer spacing of 0.65 nm and a conductivity of 3.23 × 103 S m−1, which is favorable for the transport of ions and electrons. A reversible conversion reaction happens during the charging process as shown in Fig. 9g, and the specific reaction equation is as follows:

Copyright 2018, Wiley. b Schematic illustration for the synthesis process of MoSSeNSs@NC/hC-NC. c The operating principle of DIBs based on MoSSeNSs@NC/hC-NC anode. d Long-term cycling stability at 1 A g−1. e Electron density differences of intercalated Na in MoS2, MoS1.2Se0.8, MoSSe, MoS0.8Se1.2, MoSSe with one S defect and MoSSe with one Se defect, reproduced with permission [179]. Copyright 2021, Wiley. f Schematic illustration for the synthesis process of NbSSe/NC and g corresponding electrochemical mechanism schematic, reproduced with permission [180]. Copyright 2023, Springer Nature. h Operating principle of DIBs based on nanocubic α-Fe2O3 anode, reproduced with permission [181]. Copyright 2022, Elsevier. i Schematic diagram of the fabrication process of the MoSe2-x/ZnSe@C, reproduced with permission [183]. Copyright 2023, Wiley

Conversion materials and the corresponding modification strategies. a Schematic of the reaction mechanism based on conversion reaction, reproduced with permission [174].

The wide layer spacing and abundant defect architectures enable the structure of NbSSe/NC to remain intact even after repeated phase transitions. The proof-of-concept DIBs show negligible capacity decay after 1000 cycles at 0.5 A g−1 and still deliver a high ED of 230.6 Wh kg−1 based on the total mass of the cathode and anode. Beyond strategies such as heteroatom doping and carbon coating, directly designing the target product to feature a specific morphology at the nanoscale is also beneficial in enhancing the performance of alloying materials. Wu et al. synthesized an α-Fe2O3 anode material with a nanocubic structure as exhibited in Fig. 9h through a nanostructure engineering strategy, which can display excellent Li+/Na+ storage performance and structural stability without any other modifications [181]. While the conversion reaction involved is as follows:

The full batteries share a high SDC of 192 (Li-DIBs) and 197 (Na-DIBs) mAh g−1 at 5C, respectively, and there is no decay even after 520 cycles, which is also evidenced via TEM characterization that the structure of α-Fe2O3 is still stable and not destroyed. Furthermore, the self-discharge rate of the Na-DIBs system is as low as 0.1% h−1, which is notably lower than that of the reported DIBs based on conversion-type anodes. Zhu et al. have designed a class of MoS2 anode with penne-like structure using a microwave-solvothermal method, which shows enlarged layer spacing and enhanced structural stability relative to unmodified MoS2, thus improving the discharge capacity and cycle performance [182]. The constructed sodium-based DIBs provide a SDC of 65 mAh g−1 at 2C with a CR of 85% after 200 cycles. Heterostructure engineering is considered a promising improvement strategy in the field of energy storage in conversion materials as it can yield specific heterogeneous interfaces and ionic vacancies and promote the transfer of electrons and ions due to its powerful interfacial synergistic effect, which remarkably enhances the electrochemical performance and indicates an exceptional potential. Qian et al. introduced metal–organic frameworks (MOFs) from structurally ordered MoSe2 nanorods and finally formed a bimetallic molybdenum selenide/zinc selenide@carbon composite (MoSe2-x/ZnSe@C) with a coaxial heterojunction and vacancy structure induced by metal electronegativity for Na+ storage (Fig. 9i) [183]. The reversible electrochemical reactions occurred during charging and discharging as follows:

The DFT calculations present evidence that the heterogeneous structure improves the adsorption of MoSe2-x/ZnSe@C on reactive ions and facilitates the ion transport, while the vacancies enhance this effect and boost the conductivity. Moreover, in situ electrochemical impedance spectroscopy (EIS) demonstrates that MoSe2-x/ZnSe@C exhibits a high capacitive contribution with a tendency of decreasing charge-transfer impedance (Rct) value during charging, leading to a faster ion transport. Consequently, the full batteries exhibit a SDC of 209 mAh g−1 at 0.5 A g−1 and an ED of 131 Wh kg−1 (based on the total mass of cathode and anode) at 275 W kg−1, which can be cycled stably for 1000 cycles at 1 A g−1.

4.3 Deposition-Type Metal Materials

Deposition-based anode materials, such as metals Li, Na, K, and Zn, can directly act as anode and collector for DIBs and display satisfactory electrochemical performance due to their high theoretical capacity, low reduction potential and superior conductivity [184,185,186,187]. Specifically, the following deposition/stripping reactions will occur during charging and discharging:

Among them, lithium metal shares the highest theoretical capacity (3862 mAh g−1), the lowest standard reduction potential (−3.04 V) and the smallest density (0.53 g cm−3), which holds a great application prospect for realizing high energy density DIBs. A kind of Gr//Li-DIBs based on 3 M LiPF6-EMC show a SDC of 95 mAh g−1 at 0.1C with good rate capability and high operating voltage, and still deliver a CR of 90% with an average CE of 98.5% at a high rate of 12C [188]. Besides, the Gr//Zn DIBs based on Zn metal anode and ionic liquid electrolyte offer an SDC of 57 mAh g−1 at 2C, a median discharge voltage of 1.6 V and a CR of 86% after 500 cycles [189]. However, these metal anodes could cause the formation of metal dendrites and dead metals during the deposition/stripping process, which would undoubtedly result in the continuous consumption of electrolyte and the re-formation of SEI, thus leading to a rapid decay of capacity and CE [190,191,192]. More seriously, it may puncture the separator and cause safety hazards such as short circuit or even fire. Similarly, some relevant solutions can be drawn from the modification strategies of alloying and conversion metal materials, such as the engineering of morphological structures, the construction of protective interfaces and the selection and concentration of electrolytes and additives. Wu et al. proposed to fabricate a highly conductive and robust artificial protective layer on the surface of lithium metal, which can effectively prevent the formation of lithium dendrites and greatly enhance the stability compared to the unmodified lithium metal anode [193]. The designed Gr//Li-DIB boasts a SDC of 95.2 mAh g−1 at 1 A g−1 and a CR of 89.6% after 500 cycles. While Sun et al. introduced a LiNO3 additive into the carbonate electrolyte, which is able to form a dense and smooth SEI rich in high conductivity Li3N, which is highly favorable for Li+ transport and nucleation, and inhibits the generation of lithium dendrites and the decomposition of the electrolyte [194]. The resultant Li-G DIB realizes a SDC of 91 mAh g−1 at 2C with a CR of 97% after 300 cycles, and delivers an ED of 243 Wh kg−1 (based on the mass of cathode) at 234 W kg−1. Zheng et al. designed a type of Zn metal anode with a unique plate-like stacking structure through the strategy of epitaxial metal electrodeposition, which effectively reduces the lattice strain of Zn and alters the deposition pattern of Zn2+ [195]. This enables Zn2+ to be deposited preferentially parallel to the electrode surface during the reaction process, which successfully avoids the formation of Zn dendrites and improves the cycling stability.