Abstract

The CrO2 micro rod powder was synthesized by decomposing the CrO3 flakes at a specific temperature to yield precursor and annealing such a precursor in a sealed glass tube. The magneto-transport properties have been measured by a direct current four-probe method using a Cu/CrO2 rods/colloidal silver liquid electrode sandwich device. The largest magnetoresistance (MR) around ~72 % was observed at 77 K with applied current of 0.05 μA. The non-linear I–V curve indicates a tunneling type transport properties and the tunneling barrier height is around 2.2 ± 0.04 eV at 77 K, which is obtained with fitting the non-linear I–V curves using Simmons’ equation. A mixing of Cr oxides on the surface of CrO2 rod observed by X-ray photoemission spectroscopy provides a tunneling barrier rather than a single phase of Cr2O3 insulating barrier. The MR shows strong bias voltage dependence and is ascribed to the two-step tunneling process.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Oxide half metallic materials in which electrons express only one spin orientation at the Fermi level, such as CrO2, La1−xAxMnO3 (A = Sr, Ca, etc.), and Fe3O4, show the advantages of high spin polarization, environmental stability, and efficient spin injection which are expected to be superior to pure metals as a spin injection source [1]. Traditionally, CrO2 with relatively high Curie temperature of 398 K and theoretical saturation magnetization around 2 μB/f.u. was used as information storage materials for magnetic recording tapes. Nowadays, CrO2 attracted wide interesting for its half metallic properties, such as the double exchange coupling interaction due to the self doping effect [2], the spin-dependent magneto-transport properties in cold-press CrO2 powder [3, 4], and polycrystalline CrO2 thin films with large magnetoresistance (MR) effect [5], since it has been experimentally confirmed to exhibit almost 100 % spin polarization near the Fermi level at least in low temperatures [6, 7]. Moreover, Chromium dioxide is a meta-stable oxide of Cr ion and it can be easily further reduced to Cr2O3 in the surface of CrO2 [4, 5, 8]. The formed surface Cr2O3 layer was treated as a tunneling barrier between CrO2 particles in the spin-dependent transport measurements due to its antiferromagnetic insulating properties by the super-exchange coupling among Cr ions. Recently, Bajpai et al. also have reported related magnetoelectric effect due to the antiferromagnetic and magnetoelectric Cr2O3 layer formation in the surface of CrO2 [9, 10] and Zhang et al. reported the magnetic properties of epitaxial CrO2 thin films grown on TiO2 (001) substrates [11].

In this work, the rarely reported bias voltage-dependent spin transport properties of CrO2 micro rods are investigated. The naturally formed Cr oxidation layer on the surface of CrO2 micron rods was investigated by X-ray photoemission spectroscopy (XPS). A Cu/CrO2 rods/silver paint electrode sandwich device, in which the particles are naturally coalesced by the van der Waals force, was utilized for magneto-transport measurement [12]. The barrier thickness and barrier height based on the formation of other Cr oxidation layer in the surface of CrO2 were investigated. Furthermore, a two-step tunneling mechanism was used to understand the strong bias dependence of MR effect.

2 Experimental

The CrO2 rod powder was synthesized by decomposing the CrO3 flakes at a specific temperature to yield precursor. Such a precursor is sealed in a quartz-glass tube with hydrogen brazing and annealed at 395 °C for 3 h [13, 14]. The crystal structure, morphology, and microstructure of the sample were characterized by a Rigaku D/Max-2400 powder x-ray diffraction (XRD) using Cu Kα radiation, a Joel 6610 scanning electron microscopy (SEM) and a FEI G2 F30S transmission electron microscope (TEM) with an accelerating voltage of 300 kV, respectively. XPS was performed using a Kratos Axis Ultra DLD photoelectron spectrometer with a monochromatic aluminum Kα source at 300 W (20 mA × 15 kV) and pass energy of 20 eV for high-resolution scans. In order to investigate the surface layer properties of CrO2 sample, an ion beam etching process with the source of Argon and the rotation of sample for steps of 30 s was used after obtaining a set of XPS spectrum. The static magnetic properties were characterized by a Lakeshore 7304 vibrating sample magnetometer (VSM) and a superconducting quantum interference device (SQUID).

The transport properties of CrO2 rod powder were investigated through a Cu/CrO2 rods/silver paint electrodes sandwich device which was also used in our previous work [12]. It should be mentioned that the device was vacuumed by a mechanical pump after putting CrO2 rods into the hole and spreading the silver paint to eliminate the adsorbed moisture and chemical solvents. A direct current four-terminal method with various bias voltages was used to conduct the transport measurement in a vacuum chamber with a Dewar filled in liquid nitrogen. A Keithley 220 current source was used to apply a constant current between the top and bottom electrode. A Keithley 2000 multimeter was used to detect the voltage between another two top and bottom electrodes.

3 Results and Discussion

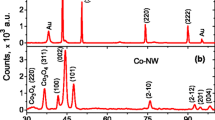

X-ray diffraction was used to determine the crystal structure of the obtained samples. The experimental and calculated XRD patterns, their difference and the expected peak positions of CrO2 rod powder based on Rietveld method refinement with P42/mnm space group, are shown in Fig. 1. It can be seen that there are no other chromium oxides phases appeared and all of the diffraction peaks correspond to the PDF card #841819 of CrO2. A typical rutile structure calculated from the XRD observed data via J2006 and Diamond 3.2 is obtained in the inset of Fig. 1. The XRD pattern can be well indexed using tetragonal P42/mnm space group with lattice parameters a = b = 4.423 Å, c = 2.918 Å. The lattice parameters are quite close to the reported values [7, 15]. It indicates that a quite pure phase of CrO2 rod powder was obtained in this work.

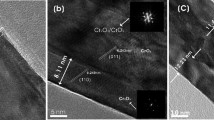

From the SEM images in Fig. 2a, b, one can see the appearance of CrO2 powder sample of a typical rod shape and the aspect ratio of the rod is 5:1 or less, which is different from those of 8:1 or 9:1 in the previous reports [3, 16]. The typical rod size is about 5 μm long and 1.2 μm wide. TEM images of small CrO2 rods are exhibited in Fig. 2c, d. The inset of Fig. 2c gives the Fourier transformation of the block area in Fig. 2c, whose pattern is consistent with the structural feature of tetragonal single crystal. Figure 2d shows a high-resolution TEM image of CrO2 rod, from which one can see the one-dimensional illustration of atomic array of CrO2 rod. The distance between the two nearby lattice arrays is 2.449 Å, which is quite close to the interplanar spacing of the (101) plane of CrO2. TEM observation is consistent with the result of XRD investigation.

The surface chemical state of CrO2 rods was investigated by XPS through Ar ion beam etching with sample rotating speed around 15 rad/s to uniformly remove the surface layer of powder samples. Figure 3 shows the Cr 2p and O 1 s core level XPS spectra of CrO2 sample at room temperature as a function of etching time. For the sample without etching, the deconvolution of Cr 2p3/2 (2p1/2) and O 1s is shown in Fig. 3a, b, respectively. The peak at 574.9 (584.4) eV corresponds to the metal Cr, which may be concluded to the defects in the surface [17]. The peak at 575.9 (585.5) eV is related to CrO2 [18, 19]. The peaks at 576.9 (586.9) eV and 578.5 (588.2) eV correspond to Cr2O3 and CrO3, respectively [17]. The peak of O 1s can be fitted by muti-peaks, and the deconvolution shows different chemical states of O in the surface of CrO2 rods. O 1s with binding energy of 529.0 eV is derived from CrO2. The peaks at 529.9 and 531.0 eV correspond to the oxides from Cr2O3 and CrO3, respectively [18, 19]. The peaks at 532.4 and 533.7 eV belong to the absorption of oxygen. After 30 s etching, the shoulders in the main peak of Cr 2p3/2 (2p1/2) and O 1s are all disappeared in Fig. 3c, d, indicating the surface layer of CrO2 rod is effectively removed by etching. From the deconvolution of Cr 2p3/2 (2p1/2), the peak at 576.0 (585.7) eV comes from CrO2 [18, 19]. The peaks at 577.0 (587.3) and 578.4 (589.2) eV are corresponded to the oxides from Cr2O3 and CrO3 [17]. The peak of O 1s at 529.5 eV is come from CrO2. The peaks at 530.4 and 531.2 eV are corresponded to the oxides from Cr2O3 and CrO3, respectively [18, 19]. The peaks at 532 and 533.1 eV are come from adsorbates and their intensities become lower after etching. Moreover, the intensities of the peaks from Cr2O3 and CrO3 become weak after etching. The deconvolution of Cr 2p3/2 (2p1/2) and O 1s suggests that the surface of the CrO2 rod sample contains a mixing of Cr oxides rather than the reported formation of single phase of Cr2O3 in the previous works [4, 5, 8]. Thus, a mixing of Cr oxides exists in the surface of CrO2, and this may play a tunneling barrier between the CrO2 rods.

Figure 4 shows the hysteresis loops of CrO2 powder at 300 and 10 K. It can be seen that the saturation magnetization increases from 108 to 133 emu/g with temperature decreasing from 300 to 10 K. The saturation magnetization at 10 K is similar to the theoretical value of 2.0 μB/f.u. for CrO2, indicating the pure phase of the sample and the quite thin layer of other Cr oxidation in the CrO2 rods surface. The hysteresis loops show small coercive force of 35 Oe at 300 K and 51 Oe at 10 K which is similar to that of epitaxial thin films of CrO2 [20]. Figure 4b shows the temperature dependence of the magnetization in an applied field of 500 Oe. The Curie temperature (TC) of the CrO2 is about 396 K in the previous reports [16]. Two different methods were used to determine TC: (i) a linear extrapolation of the M(T) to zero magnetization and (ii) the first derivative of the M(T) curves as shown in Fig. 4b. TC is around 399 and 376 K from method (i) and (ii), respectively. The values of TC obtained from the linear extrapolation are about 23 K higher than those calculated from the derivative method. This difference of TC results from that the extrapolated values correlates to the contribution from the strongest magnetic interactions, while the derivative approach is related to the average intensity of magnetic interactions [21, 22].

Regarding to the transport properties, the conductivity in this kind of powder heterogeneous system is determined by the chains of granules with a maximum probability of tunneling between neighboring grains. The number of such chains decreases with decreasing temperature and voltage. Heterogeneity will grow, and in the limit of very low temperatures and applied voltages, the resistance of the entire system can even be determined by a single conductive chain. However, considering CrO2 rod-shaped powder having large size around several microns in this work, the percolation effect can be neglected. Figure 5 shows the typical I–V curves of CrO2 rod powder at 300 and 77 K without magnetic field. The non-linear I–V curve indicates that there is indeed a barrier among particles. It can be seen that the nonlinearity of I–V curve becomes stronger at 77 K. According to the tunneling theory and Simmons’ equation [23],

where e is the charge of the electron, m is the mess of the electron, and h is the Plank’s constant. One can fit I–V curve to extract the junction area A, the mean barrier heightϕ, and the barrier thickness d for a magnetic tunnel junction [23, 24]. In this work, the adjacent of two CrO2 rods can be considered as a tunnel junction since a mixing of Cr oxides layer formation in the surface of CrO2 rod observed by XPS. The electron transport is through the network of CrO2 junctions. We roughly assume that the number of series junctions is equal to that of parallel junctions and all tunnel junctions are the same, then the I–V character of the network junctions is equal to that of one tunnel junction. Then we can fit I–V curves of CrO2 rod at 300 and 77 K using Simmons equation with A, ϕ and d as the fitting parameters. The fitting results are shown in Table 1. For a real tunnel junction, the junction area and barrier thickness should be temperature independent. While in this work, the effective junction area and the thickness of the effective barrier become small with temperature increasing, which may be ascribed to assumption of the contraction of CrO2 rod at low temperature. This assumption can explain the increased barrier height with the decreasing of the temperature. However, there is a lack of experimental data on the temperature dependence of the thermal expansion coefficients of CrO2.

Magneto-transport properties of CrO2 particles at 77 K and various currents are shown in Fig. 6. We define that the MR is equal to R(H)/R(H0)-1, in which R(H) and R(H0) standing for the resistance at field H and zero field, respectively. The low-field MR (LFMR) always occurs at low magnetic field (<5,000 Oe). At room temperature, the LFMR is not observed. While, at 77 K, the LFMR of CrO2 rod is ~16 and ~72 % with applied different currents of 1.0 and 0.05 μA at 3,500 Oe, respectively. The fluctuation of the MR data point in Fig. 6a may be caused by the displacement of the CrO2 rod, because the magnetic field force is larger than the van der Waals force since the rod sample with large size and strong magnetization. It can be seen that the LFMR ratio decreases as the applied current increasing, which is a typical behavior for magnetic tunnel junctions. This strong bias dependence of LFMR also proves that the MR is an inherent property of the tunneling barrier.

The process of resistance with the change of the applied magnetic field corresponds to the hysteresis loop, and the maxima MR always happen at Hc, as a result,

α is relative to the ultimate size of the MR. Its magnitude depends on spin-dependent scattering, M is the global magnetization, and Ms is the saturation magnetization [25]. Figure 6a also shows the square of the normalized magnetization ~0.72(M/Ms)2 (solid line). This curve almost follows the MR curve, which suggests that the LFMR is induced by spin-dependent transport. Thus, LFMR must come from the spin-dependent tunneling between the CrO2 rods through other Cr oxides. According to the Jullière’s model and considering the randomly oriented magnetic moment at the coercive field for a system of non-interacting nanoparticles assemblies, Maekawa et al. derived a theoretical expression of the TMR = −P2, where P is the spin polarization of the magnetic material [26]. Then, we can estimate the spin polarization of the CrO2 rod roughly to P~84.9 % at 77 K. The two-step tunneling model based on a second tunneling via defect states in the barrier, in addition to the spin-dependent direct tunneling, is proposed to account for the MR-V dependence. The model assumes that the defect states in the barrier are uniformly distributed, both spatially and energetically, and the energy distribution of the available defect states is governed by a Fermi–Dirac function [27]. Similarly, for CrO2 rod powder, the tunneling barrier is mainly the space between the rods and the other chromium oxides on the surface, and this barrier can be more easily affected by the temperature and voltage compared defect states in the barrier of tunneling junctions. Thus, the bias dependent of MR can be fitted as shown in Fig. 6b. The consistence of the experimental data and the fitting curve indicates that the current in CrO2 rod is mainly carried by the spin-dependent direct tunneling at low bias voltage in contrast with the spin-independent two-step tunneling through barrier defects at high bias voltage. Spin-dependent magneto-transport properties of CrO2 with different structures have been studied by different groups as shown in Table 2. Comparing to those results, one can see that the CrO2 rods have shown a higher MR value with a lower applied field in this work.

4 Conclusions

In summary, we have fabricated single-phased CrO2 rod powder. The largest MR around ~72 % was observed using a Cu/CrO2 powder/silver paint electrode sandwich device at 77 K. The tunneling barrier height is around 2.2 ± 0.04 eV at 77 K, which is obtained by fitting the non-linear I–V curves using Simmons’ equation. A mixing of Cr oxides on the surface of CrO2 observed by XPS provides a tunneling barrier in contrast with a single phase of Cr2O3 insulating barrier as reported in the previous report. The MR shows strong bias voltage dependence and is ascribed by the two-step tunneling process. The quite thin mixing Cr oxides layer on the surface of the CrO2 may have defects, in which the two-step tunneling process happening at high bias voltage and resulting in the strong decay of magnetoresistance with the increase of bias voltage.

References

R.J. Soulen Jr, J.M. Byers, M.S. Osofsky, B. Nadgorny, T. Ambrose, S.F. Cheng, P.R. Broussard, C.T. Tanaka, J. Nowak, J.S. Moodera, A. Barry, J.M.D. Coey, Measuring the spin polarization of a metal with a superconducting point contact. Science 282(5386), 85–88 (1998). doi:10.1126/science.282.5386.85

J.H. Shim, S. Lee, J. Dho, D.H. Kim, Coexistence of two different Cr ions by self-doping in half-metallic CrO2 nanorods. Phys. Rev. Lett. 99(5), 057209 (2007). doi:10.1103/PhysRevLett.99.057209

J.M.D. Coey, A.E. Berkowitz, L. Balcells, F.F. Putris, Magneto resistance of chromium dioxide powder compacts. Phys. Rev. Lett. 80(17), 3815 (1998). doi:10.1103/PhysRevLett.80.3815

J. Dai, J. Tang, Junction-like magneto resistance of intergranular tunneling in field-aligned chromium dioxide powders. Phys. Rev. B 63(5), 054434 (2001). doi:10.1103/PhysRevB.63.054434

H.Y. Hwang, S.W. Cheong, Enhanced intergrain tunneling magnetoresistance in half-metallic CrO2 films. Science 278(5343), 1607–1609 (1997). doi:10.1126/science.278.5343.1607

K. Schwarz, CrO2 predicted as a half-metallic ferromagnet. J. Phys. F 16(9), L211 (1986). doi:10.1088/0305-4608/16/9/002

A. Anguelouch, A. Gupta, G. Xiao, D.W. Abraham, Y. Ji, S. Ingvarsson, C.L. Chien, Near-complete spin polarization in atomically-smooth chromium-dioxide epitaxial films prepared using a CVD liquid precursor. Phys. Rev. B 64(18), 180408 (2001). doi:10.1103/PhysRevB.64.180408

J. Dai, J. Tang, H. Xu, L. Spinu, W. Wang, K. Wang, A. Kumbhar, M. Li, U. Diebold, Characterization of the natural barriers of intergranular tunnel junctions: Cr2O3 surface layers on CrO2 nanoparticles. Appl. Phys. Lett. 77(18), 2840–2842 (2000). doi:10.1063/1.1320845

A. Bajpai, P. Borisov, S. Gorantla, R. Klingeler, J. Thomas, T. Gemming, W. Kleemann, B. Büchner, Interface-driven magnetoelectric effects in granular CrO2. Europhys. Lett. 91(1), 17006 (2010). doi:10.1209/0295-5075/91/17006

A. Bajpai, R. Klingeler, N. Wizent, A.K. Niga, S.W. Cheong, B. Büchner, Unusual field dependence of remanent magnetization in granular CrO2: the possible relevance of piezomagnetism. J. Phys.: Cond. Matt. 22(9), 096005 (2010). doi:10.1088/0953-8984/22/9/096005

X. Zhang, X. Zhong, P.B. Visscher, P.R. LeClair, A. Gupta, Structural and magnetic properties of epitaxial CrO2 thin films grown on TiO2 (001) substrates. Appl. Phys. Lett. 102(16), 162410 (2013). doi:10.1063/1.4802957

L. Xi, J.H. Du, J.H. Ma, Z. Wang, Y.L. Zuo, D.S. Xue, Spin-dependent transport properties of oleic acid molecule self-assembled La 0.7Sr0.3MnO3 nanoparticles. J. Alloy. Compd. 550, 365–369 (2013). doi:10.1016/j.jallcom.2012.10.126

A. Bajpai, A.K. Nigam, Synthesis of high-purity samples of CrO2 by a simple route. Appl. Phys. Lett. 87(22), 222502 (2005). doi:10.1063/1.2136411

L. Xi, Y.K. Yang, Ultrawide band microwave absorption properties of ultrasound processed CrO2–paraffin wax composites. Jpn. J. Appl. Phys. 50(3), 035805 (2011). doi:10.7567/JJAP.50.035805

M.A. Korotin, V.I. Anisimov, D.I. Khomskii, G.A. Sawatzky, CrO2: a self-doped double exchange ferromagnet. Phys. Rev. Lett. 80(19), 4305 (1998). doi:10.1103/PhysRevLett.80.4305

G.P. Singh, S. Ram, J. Eckert, H.J. Fecht, Synthesis and morphological stability in CrO2 single crystals of a half-metallic ferromagnetic compound. J. Phys.: Conf. Ser. 144(1), 012110 (2009). doi:10.1088/1742-6596/144/1/012110

P.G. Halada, R.C. Clayton, Photoreduction of hexavalent chromium during X-Ray photoelectron spectroscopy analysis of electrochemical and thermal films. J. Electrochem. Soc. 138(10), 2921–2927 (1991). doi:10.1149/1.2085340

H.A. Bullen, S.J. Garrett, Epitaxial growth of CrO2 thin films on TiO2 (110) surfaces. Chem. Mater. 14(1), 243–248 (2002). doi:10.1021/cm0105256

N.F. Heinig, H. Jalili, K.T. Leung, Fabrication of epitaxial CrO2 nanostructures directly on MgO (100) by pulsed laser deposition. Appl. Phys. Lett. 91(25), 253102 (2007). doi:10.1063/1.2822394

X.W. Li, A. Gupta, X. Giang, Influence of strain on the magnetic properties of epitaxial (100) chromium dioxide (CrO2) films. Appl. Phys. Lett. 75(5), 713–715 (1999). doi:10.1063/1.124491

J. Navarro, J. Nogues, J.S. Muñoz, J. Fontcuberta, Antisites and electron-doping effects on the magnetic transition of Sr2FeMoO6 double perovskite. Phys. Rev. B 67(17), 174416 (2003). doi:10.1103/PhysRevB.67.174416

L. Chen, C.L. Yuan, J.M. Xue, J. Wang, Enhancement of magnetization and curie temperature in Sr2FeMoO6 by Ni doping. J. Am. Ceram. Soc. 89(2), 672–674 (2006). doi:10.1111/j.1551-2916.2005.00718.x

J.G. Simmons, Generalized formula for the electric tunnel effect between similar electrodes separated by a thin insulating film. J. Appl. Phys. 34(6), 1793–1803 (1963). doi:10.1063/1.1702682

R.P. Tan, J.L. Carrey, M. Respaud, Voltage and temperature dependence of high-field magnetoresistance in arrays of magnetic nanoparticles. J. Appl. Phys. 104(2), 023908 (2008). doi:10.1063/1.2957061

J.Q. Xiao, J.S. Jiang, C.L. Chien, Giant magnetoresistance in nonmultilayer magnetic systems. Phys. Rev. Lett. 68(25), 3749–3752 (1992). doi:10.1103/PhysRevLett.68.3749

J. Inoue, S. Maekawa, Theory of tunneling magnetoresistance in granular magnetic films. Phys. Rev. B 53(18), 11927–11929 (1996). doi:10.1103/PhysRevB.53.R11927

J. Zhang, R.M. White, Voltage dependence of magnetoresistance in spin dependent tunneling junctions. J. Appl. Phys. 83(11), 6512–6514 (1998). doi:10.1063/1.367644

Acknowledgments

This work was supported by the NNSF of China (Nos. 51171076, 51101079), the Natural Science Foundation of Gansu Province (No. 145RJZA154), the Fundamental Research Funds for the Central Universities (No. Lzujbky-2012-27, Lzujbky-2010-172) and the CERS of China (No. CERS-1-89).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution License (http://creativecommons.org/licenses/by/4.0/) which permits any use, distribution, and reproduction in any medium, provided the original author(s) and the source are credited.

About this article

Cite this article

Wang, Z., Xi, L., Yang, Y. et al. Spin-dependent Transport Properties of CrO2 Micro Rod. Nano-Micro Lett. 6, 365–371 (2014). https://doi.org/10.1007/s40820-014-0010-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40820-014-0010-8