Abstract

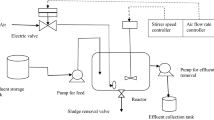

Treatment of tannery industry effluent is a serious challenge due to the presence of toxic pollutants including dyes and heavy metals. This work is focused on the optimization of bed height and air flow rate for tannery industry wastewater treatment in a fluidized bed reactor with low density biomass support. Response surface methodology was adopted for the optimization of process parameters viz air flow rate, bed height and wastewater dilution ratio and the best operating conditions were identified. The optimum values for the maximum chemical oxygen demand (COD) removal are: air flow rate—233 LPH, Bed height—82 cm and wastewater dilution ratio—1:2. The results from the IFBR showed that a maximum of 90.2% of COD reduction obtained at an airflow rate of 233 LPH and initial bed height of 82 cm. In this research, a maximum colour removal of 83.4% was achieved. A high correlation coefficient (R2) value of more than 0.94 for all the three models indicates that the RSM based models predict the data well. The relative effect of variables on COD removal, colour removal and air hold up were depicted in perturbation plots.

Similar content being viewed by others

References

Alvarado-Lassman A, Rustrian E, García-Alvarado MA, Rodríguez-Jiménez GC, Houbron E (2007) Brewery wastewater treatment using anaerobic inverse fluidized bed reactors. Bioresour Technol 99:3009–3015

Aye TT, Loh KC (2003) Biodegradation of high strength phenolic wastewater in a modified external loop inversed fluidized bed airlift bioreactor (EIFBAB). Can J Chem Eng 81:1246–1250

Begum SS, Radha KV (2014a) Hydrodynamic behavior of inverse fluidized bed biofilm reactor for phenol biodegradation using Pseudomonas fluorescence. Korean J Chem Eng 31:436–445

Begum SS, Radha KV (2014b) Effect of gas-Liquid mass transfer coefficient and liquid solid mass transfer resistance on phenol biodegradation in three phase inverse fluidized bed biofilm reactor. J Environ Chem Eng 2:2321–2326

Bhuyan SC, Swain AK, Sahoo A, Bhuyan SK (2020) Nutrient (sulphate) removal from wastewater in inverse fluidized bed biofilm reactor. Mater Today Proc 33:5476–5480

Buffiere P, Moletta R (1999) Some hydrodynamic characteristics of inverse three phase fluidized bed reactors. Chem Eng Sci 54:1233–1242

Cheng KY, Ginige MP, Kaksonen AH (2017) Microbially catalysed selenate removal in an inverse fluidised bed reactor. Solid State Phenom 262:677–681

Han SJ, Tan RBH, Loh KC (2000) Hydrodynamic behaviour in a new gas - liquid - solid inverse fluidization airlift bioreactor. Trans I Chem E 78:207–215

Karamanev L, Nikolov I (1987) Experimental study of the Inverse fluidized bed biofilm reactor. Can J Chem Eng 65:214–217

Kryst K, Karamanev DG (2001) Aerobic phenol biodegradation in an inverse fluidized bed biofilm reactor. Ind Eng Chem Res 40:5436–5439

Loh KC, Liu J (2001) External loop inversed fluidized bed airlift bioreactor (EIFBAB) for treating high strength phenolic wastewater. Chem Eng Sci 56:6171–6176

Loh KC, Ranganath S (2005) External-Loop fluidized bed airlift bioreactor (EFBAB) for the cometabolic biotransformation of 4-Chlorophenol (4-cp) in the presence of phenol. Chem Eng Sci 60:6313–6319

Nikov I, Nikolov V, Dimitrov D (1999) Biodegradation of aniline using light carriers with optimised surface in TPIFB. Bioprocess Eng 21:547–552

Ocheing A, Ogada T, Sisenda W, Wambua P (2002) Brewery wastewater treatment in a fluidized bed bioreactor. J Hazard Mater 90:311–321

Ocheing A, Odiyo JO, Mustago M (2003) Biological treatment of mixed industrial wastewaters in a fluidized bed reactor. J Hazard Mater 96:79–90

Papirio S, Esposito G, Pirozzi F (2013) Biological inverse fluidized-Bed reactors for the treatment of low pH- and sulphate- containing wastewaters under different COD/SO4 conditions. Environ Technol 34:1141–1149

Rajamohan N, Rajasimman M (2018) Treatment of tannery effluent by passive uptake—parametric studies and kinetic modeling. Environ Sci Pollut Res 25(6):5071–5075

Rajasimman M, Karthikeyan C (2007) Aerobic digestion of starch wastewater in a fluidized bed bioreactor with low density biomass support. J Hazard Mater 143:82–86

Rajasimman M, Karthikeyan C (2009a) Performance of inverse fluidized bed bioreactor in treating starch wastewater. Front Chem Eng China 3:235–239

Rajasimman M, Karthikeyan C (2009b) Optimization studies in an inverse fluidized bed bioreactor for starch wastewater treatment. Int J Environ Res 3:569–574

Sabarunisha Begum S, Sikkandar MY, Prakash NB, Bakouri M, Alanazi AB, Alkhatlan NMS (2021) Investigation of flow dynamic characteristics of inverse fluidized bed biofilm reactor for degrading pharmaceutical based biomedical wastewater. Environ Eng Res 26(6):200182

Sahoo A, Lima T (2013) Effect of parameters on treatment of industrial effluents using inverse fluidized bed bioreactor: statistical analysis. Part Sci Technol 32:151–157

Sokol W (2001) Operating parameters for a gas-liquid-solid fluidised bed bioreactor with a low density biomass support. Biochem Eng J 8:203–212

Sokol W (2010) Operational range for a gas-liquid-solid fluidized bed aerobic biofilm reactor with a low density biomass support. Int J Chem React Eng 8:A111

Sokol W, Halfani MR (1999) Hydrodynamics of a gas-liquid-solid fluidized bed reactor with a low-density biomass support. Biochem Eng J 3:185–192

Sokoł W, Korpal W (2006) Aerobic treatment of wastewaters in the inverse fluidised bed biofilm reactor. Chem Eng J 118:199–205

Swain AK, Sahoo A, Jenaa HM, Patra H (2018) Industrial wastewater treatment by aerobic inverse fluidized bed biofilm reactors (AIFBBRs): a review. J Water Process Eng 23:61–74

Tang WT, Fan LS (1990) Gas-Liquid mass transfer in a three phase fluidized bed containing low density particles. Ind Eng Chem Res 29:128–133

Wang L (2020) Extended study of the inverse fluidized bed bioreactor for low C/N ratio wastewater treatment and hydrodynamics. Electronic Thesis and Dissertation Repository. 7145

Wang H, He X, Nakhla G, Zhu J, Su Y-K (2020) Performance and bacterial community structure of a novel inverse fluidized bed bioreactor (IFBBR) treating synthetic municipal wastewater. Sci Total Environ 718:137288

Funding

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

None.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Gopalakrishnan, B., Muthukumarapandian, A., Sujatha, S. et al. Statistical modeling and optimization of tannery wastewater treatment in a fluidized bed bioreactor with low density biomass support. Model. Earth Syst. Environ. 8, 1099–1107 (2022). https://doi.org/10.1007/s40808-021-01143-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40808-021-01143-2