Abstract

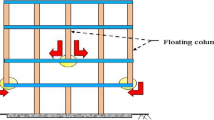

Elastic materials can be used to improve the impact sound insulation performance of the floating floor. In this study, the foam rubber damping pad and polyurethane foam board were used to improve the sound insulation performance in floating floors; the main performance parameters such as thickness, dynamic stiffness, resonance frequency and damping ratio of the foam rubber damping pad and the polyurethane foam board were tested and analyzed under different loading systems. Besides, a reinforced concrete residential compartment was used as experimental background, the foam rubber damping pad and polyurethane foam board were used as elastic damping materials to form the different structures of floating floors with different thicknesses; then the impact sound pressure level and its variation rule were tested under different conditions, and the influence of the reduction of impact sound pressure level on the floating floor was compared and analyzed. The results show that before the pavement, the thickness of the polyurethane foam board is 2 times the thickness of the foam rubber damping pad in the natural state; After pavement, under the action of the load, the thickness of the polyurethane foam board is 1.39–1.42 times that of the foam rubber damping pad. The sound insulation and damping performance of the polyurethane foam board are lower than that of the foam rubber damping pad. When the thickness of the floating plate is increased from 32 to 80 mm, the sound insulation performance of the floating floor structure made of polyurethane foam board and foam rubber damping pad has a deterioration tendency. This study provides a basic reference for the sound insulation of floating floors with the foam rubber damping pad or polyurethane foam board as the elastic damping cushion.

Highlights

-

1.

Under load, the cumulative thickness of polyurethane foam plate reached about 35% of its total thickness at 2 days. After 8–10 days, it tended to be stable, with a total deformation of about 45%.

-

2.

For the floating building sound insulation floor system made of foam rubber damping pad, the frequency varies from 69.8–145.3 Hz, the reduction of impact sound pressure level is 18.7–23.6 dB, the change of frequency is 51%, and the reduction range of impact sound pressure level is 27%;

-

3.

The floating floor of polyurethane foam board has a frequency change of 137.7–254.8 Hz, the reduction of impact sound pressure level is 11.1–17.3 dB, the frequency change is 46%, and the reduction range of impact sound insulation is 35%.

-

4.

The thickness of the polyurethane foam board is about 1 times the thickness of the foam rubber damping pad, but its sound insulation and vibration absorption performance is low. It can be seen that the insulation board used as sound insulation board, its sound insulation and vibration reduction performance can not achieve the expected effect.

Similar content being viewed by others

References

GB3096–2008 (2008) Environmental quality standard for noise [S]. China Environmental Science Press 2–9

GB 50362–2005 (2005) Technical standard for performance assessment of residential buildings [S]. Ministry of Construction of the People's Republic of China 8–15

JGJ /T229–2010 (2012) Code for green design of civil buildings [S], China Building Industry Press 11–18

CECS 179–2009 (2009) Technical specification for construction of healthy housing [S]. China Planning Press 9–11

GB 50118–2010 (2011) Code for design of sound insulation of civil buildings [S]. China Building Industry Press 6–9

GB 50096–2011 (2012) Design code for residential buildings [S]. China Architecture & Building Press 18–19

Rindel JH (2017) Sound Insulation in Buildings (1st ed.). CRC Press, 275–312

Kylliäinen M (2015) The measurement uncertainty of single-number quantities for rating the impact sound insulation of concrete floors. Acta Acust Acust 100:640–648

Ryu J, Song H, Kim Y (2018) Effect of the suspended ceiling with low-frequency resonant panel absorber on heavyweight floor impact sound in the building. Build Environ 139:1–7

Bala A, Gupta S (2021) Thermal resistivity, sound absorption and vibration damping of concrete composite doped with waste tire Rubber: A review. Constr Build Mater, 299(2021):2–16

Patnaik A, Mvubu M, Muniyasamy S, Botha A, Anandjiwala RD (2015) Thermal and sound insulation materials from waste wool and recycled polyester fibers and their biodegradation studies. Energy Build 92:161–169

Schiavi A, Belli AP, Russo F (2005) Estimation of acoustical performance of floating floors from dynamic stiffness of resilient layers. Build Acoust 12(2):99–113

Kim JM, Lee JY (2015) Evaluation of loss factor and deflection of floor damping materials considering loading periods and environmental conditions. J Arch Inst Korea 31(11):11–19

Wang JQ (2020) Experimental Study on the Optimization of Sound Insulation Performance of Residential Floor Structure. Build Sci 36(04):143–148

Schiavi A (2018) Improvement of impact sound insulation: a constitutive model for floating floors. Appl Acoust 129(1):64–71

Park HS, Oh BK, Kim Y, Cho T (2015) Low-frequency impact sound transmission of floating floor: case study of mortar bed on concrete slab with continuous interlayer. Build Environ 94:793–801

Park HS, Oh BK, Cho T (2018) Vibroacoustic behavior of full-scale sandwich floor with softened graphite-incorporated expanded polystyrene core. Compos B 137:74–91

Kylliäinen M, Helimäki H (2002) Effects of new sound insulation requirements on concrete floors in Finland, Balti-Nordic Acoustical Meeting B-NAM 2002, Copenhagen, Denmark

Park HS, Yoon DY, Cho T (2020) Influence of plan configuration on low-frequency vibroacoustic behaviour of floating floor with low natural frequency. Appl Acoust 158:107040, 14

Kim KW et al (2009) Correlation between dynamic stiffness of resilient materials and heavyweight impact sound reduction level. Build Environ 44:1589–1600

Caniato M et al (2016) Time-depending performance of resilient layers under floating floors. Constr Build Mater 102:226–232

Caniato M, Schmid C, Gasparella A (2020) A comprehensive analysis of time influence on floating floors: Effects on acoustic performance and occupants; comfort, Applied Acoustics. Appl Acoust 166:107339

Schiavi A, Belli AP, Corallo M, Russo F (2007) Acoustical performance characterization of resilient materials used under floating floors in dwellings. Acta Acust United Ac 93:477–485

Wang JQ (2019) Research on the acoustic performance optimization of green building floor. Tech Acoust 38(06):665–669

Schiavi A, Prato A, Barbaresi L, Semprini G (2015) The effect of damping in resilient materials used in floating floors on impact sound insulation, ICSV22, Florence

Rushforth I.M, Horoshenkov KV, Mirftab M, Swift MJ (2005) “Impact sound insulation and viscoelastic properties of undeRLay manufactured from recycled carpet waste”. Applied Acoustics 66 (2005):731–749

Schiavi, Pavoni Belli A, Corallo M, Russo F (2006) Acoustical Performance Characterization of Sustainable Materials used under Floating Floors in Dwellings, Euronoise, Acta a Custica United with a Custica 93(2007):477–485

ISO 10140–3 (2021) Acoustics - laboratory measurement of sound insulation of building elements - Part 3: Measurement of impact sound insulation. ISO10140-3, 2–6

EN 12354–2 (2017) Building acoustics - estimation of acoustic performance of buildings from the performance of elements - Part 2: Impact sound insulation between rooms, 4–14

GBT 19889.7 (2005) Acoustics measurement of sound insulation in buildings and of building elements - Part 7: Field measurement of impact sound insulation of floors, 2–5

GBT 19889.14 (2010) Acoustics measurement of sound insulation in buildings and of building elements - Part 14: Guidelines for special situation in the field, 9–24

BS ISO EN12431: 2013(EN) (2013) Thermal insulating products for building applications -determination of thickness for floating floor insulating products[S]. ISO 14431:2013, 5–9

ISO 9052–1 (1989) Acoustics-Determination of dynamic stiffness-materials used under floating floor in dwellings[S]. International Organization for Standardization, ISO 9052–1, 4–7

ISO7626–2:2015 (2015) Mechanical vibration and shock-Experimental determination of mechanical mobility-Part 2: Measurements using single-point translation excitation with an attached vibration exciter[S].ISO7626–2:2015, 2–9

Cremer L, Heckl M (1988) Structure-borne sound: structural vibrations and sound radiation at audio frequencies. Springer-VeRLag, Berlin, 243–263

Acknowledgements

The work is supported by the following fund projects: Major natural science research projects of colleges and universities of Jiangsu province (key technology of heat preservation and sound insulation for ultra-low energy green buildings, Project Number: 17KJA560002); Excellent scientific and technological innovation team of Jiangsu Province (Technology of heat preservation and sound insulation for green buildings); Key research and development projects of Xuzhou City (Research on key technology of noise pollution prevention and sound insulation for green buildings, Project Number: KC18135).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, J., Du, B. Sound Insulation Performance of Foam Rubber Damping Pad and Polyurethane Foam Board in Floating Floors. Exp Tech 47, 839–850 (2023). https://doi.org/10.1007/s40799-022-00579-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40799-022-00579-0