Abstract

The ability to predict gas emissions accurately is pivotal in managing gas control and ensuring safe mining operations. Existing internationally acknowledged gas control and prediction software does not cater to the specific conditions in Chinese coal mines. Hence, this paper introduces an object-oriented programming method to design a software tool for calculating the total gas emission quantity using the MATLAB application program designer runtime environment. The software incorporates an algorithm, data structure, framework, and module functions, all of which enable seamless integration and visualization of gas emission calculation software. This software tool mitigates the inefficiencies and inaccuracies associated with manual, different-source forecast methods. Based on the field data of the Hulonggou Coal Mine in Shanxi province, this technical software was used to predict the gas emission of the mine. The research results show that the predicted value of the technical software is close to the actual measured value. The differing estimates of the working face and coal mine output primarily account for the deviation between the tool's predicted gas emission value and the field-measured value. The underlying design logic of this technical software determines that it has good adaptability to mines with clear mining technology parameters and gas geological parameters. This study provides a valuable method for researchers and engineers seeking to improve gas emission calculation efficiency.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The safety management of coal mining activities is critical in the coal production system. However, gas disasters have always been an important factor affecting safe mining activities. Coal seam gas emission quantity prediction plays a key role in preventing and controlling methane-related disasters in coal seams (Wen et al. 2023; Lu et al. 2009; Mijał et al. 2018; Zhou et al. 2022). In recent years, numerous methods have been proposed to predict gas emission quantity from coal mines. To predict underground gas emissions quantity in various stages of the coal mine life cycle, Lunarzewski proposed a method involving the envelope parameter method for estimating the instantaneous release from potential gas sources (Lunarzewski 1998). Kirchgessner developed a multiple linear regression equation prediction method that relies on coal bed methane content, coal production, and coal mine gas emissions quantity (Kirchgessner et al. 1993). After reviewing various methods for estimating gas emissions, Creedy found that the most effective and reliable method for predicting gas emissions from coal-related sources is based on direct measurement (Creedy 1993). The gas emissions quantity prediction mainly adopts the different-source forecast method and mining statistical method specified by AQ 1018-2006 of the State Administration of Work Safety in China, and the different-source forecast method is the most commonly used (Wei et al. 2015). With the increased demand for mine intelligence, it has become necessary to adopt a complete set of gas emission prediction software. The accurate prediction of gas emission quantity not only lays the foundation for coal mine gas control and extraction but also affects the safety and investment cost of the coal mine (Qin et al. 2020; Zhao et al. 2022, 2020). Methane Control and Prediction (MCP) software is well-established internationally. However, MCP is not suitable for the gas emission prediction of China's coal mines as different methods and regulations are used.

The different-source forecast method requires many parameters and the calculation of a large amount of field data. Currently, there is no relatively simple and fast method to process field data quickly. Manual calculation errors are inevitable. To cope with these challenges, Chinese coal companies need coal mine gas emission quantity prediction software that adapts to domestic regulations, reduces errors, and improves computational efficiency (Wei et al. 2015). The core objective of this technical note is to develop a software for calculating coal mine gas emissions quantity based on the different-source forecast method and to apply it to actual projects on the engineering site.

2 Technical implementation

2.1 Design logic

When calculating gas emissions quantity using the different-source forecast method, the gas sources are divided into two parts. The first part is the gas emissions of the production mining area and the second part is the gas emissions of the mined-out area in the mined area. The gas in the production mining area mainly comes from the gas emissions of the mining workings face, the mined-out area in the working face, and the excavation face. In the excavation face, the gas comes from coal wall emissions and coal falling emissions. It is worth noting that the gas emission from the excavation work layer, the surrounding rock, and the adjacent layer, as well as the gas emission rate from the adjacent layer, have corresponding functions with the layer spacing (Chen et al. 2016).

In summary, the formula (Yu and Cheng 2012) for calculating gas emissions quantity is as follows:

The number of coal seams involved is dictated by the practical conditions of the coal mine. Technical software incorporates interactive functions to enhance the practicality of the software. The users can fill in data for each coal seam, and the background automatically calls the parameters and converts them into a i × j matrix (number of parameters) for iteration. As shown in Fig. 1, the software generates a i × j matrix and fills into the position of the corresponding table component for data visualization after the user input of all coal seam parameters. The “n” in Fig. 1 denotes the number of input coal seam parameters.

Excessive amounts of coal seams will cause inconvenience to calculate cumulative emissions. Therefore, a new variable is required to receive the results of each data iteration and summation. Equation (2) is decomposed into two parts. The first and second parts (i.e., A and B) are used for the cumulative summation calculation, while the other parts are used for direct algebraic operations. The optimized calculation process is shown in Eq. (3):

Before decomposition:

After decomposition:

The software uses a table to display the data entered by the user. It can layer the data of multiple coal seams for comparison. The software generates a statistical table of the corresponding parameters and automatically processes the data in the background. The absolute and relative gas emission quantities are presented in tables and graphs for further analysis.

2.2 Output architecture

The software uses the Axes component to generate bar charts. Since the Axes component relies on numeric vector values to create the scale names on the X-axis, the bar chart must be created using the categorical values on the X-axis. Subsequently, the bar(x) function is used to draw the bar chart.

The MATLAB application designer typically utilizes individual components or parts as classes, where the parameters of each class are generally private. However, the results of these classes need to be used when forming the final statistics table. It is necessary to use the global to handle private variables. After that, the calculation result can be called across the class and output to the statistics table. This process is shown in Fig. 2.

2.3 UI interface

The UI interface is shown in Fig. 3, and the main menu structure consists of four calculation panels and one statistics panel. Four calculation panels are responsible for calculating the gas emissions quantity of the mining working face, the extraction face, the production mining area, and the coal mine. In addition to the corresponding bar charts, the statistics section includes tables of the absolute and relative gas emission quantities.

3 Field application

This technical note selects the #5 minable coal seam of Hulonggou Coal Mine (located in the southwest of Datong Coalfield, Shanxi Province) to carry out gas emission quantity prediction work. The strata relationship between the #5 coal seam and adjacent layers, as well as the relevant input parameters, are shown in Fig. 4. The correlation coefficient will be selected based on the AQ1018-2006 (The predicted method of mine gas emission rate).

The software predicts that the q1 is 1.91 m3/t, q2 is 0.21 m3/t, q3 is 0.87 m3/min, q4 is 0.27 m3/min, qm is 2.12 m3/t, qd is 1.14 m3/min, qa is 4.35 m3/t and qp is 5.00 m3/t, as shown in Table 1.

The qm, qd, and qp of gas emission quantity measured on-site in Hulonggou Coal Mine are 3.20 m3/t, 0.83 m3/min, and 4.38 m3/t, respectively. The actual measured gas emission quantity of various parts of Hulonggou Coal Mine (the data are from the gas emission measurement report of Hulonggou Coal Mine in 2022) were compared with the gas emission quantity predicted by the software. As shown in Fig. 5, the actual measured value of gas emission quantity is less different from the predicted value. However, it cannot be ignored that there is a difference between the actual measured value and the predicted value of gas emission quantity. For qm, the selection of correlation coefficients (i.e., K1, K2, K3, and Kf) directly affects the predicted value of gas emission quantity in the mining working face. The selection of excavation face parameters is based on the actual digging situation of the coal mine. Therefore, the predicted value of gas emission quantity (qd) in the excavation face is close to the measured value. The predicted value of coal mine gas emission quantity is closely related to the output of coal mines, and the small fluctuation of output will lead to a cross-magnitude increase in coal mine gas emission quantity. This situation is likely to lead to errors in the prediction of gas emissions. There is a lack of understanding of the situation of the coal mine site and the reserve of basic knowledge of gas emission, the prediction of gas emission is carried out rashly. This will be inevitable that prediction curve 1 will be changed to prediction curve 2, and the error zone will be further expanded, as shown in Fig. 5.

In addition, there is a distinct difference between thick and thin coal seams solely when calculating q1. Therefore, when predicting the gas emission quantity from coal seams with different thicknesses, it is necessary to manually distinguish and pay attention to the parameter selection differences between thick and thin coal seams. Equation (1) illustrates the parameter value range that influences coal mine gas emission quantity calculation results (Wang et al. 2022). To evaluate three of these parameters, two quasi-Monte Carlo methods (Sobol 1993; Kucherenko et al. 2017) are employed to simulate them individually. K1 and K″ represent the dominant parameters that contribute to model outputs in Eq. (1), while K′ exerts comparatively limited influence.

4 Discussion

This study utilizes the different-source forecast method as its foundational logic, utilizing MATLAB software to develop an efficient, rapid, and visually intuitive tool for gas emission calculation. This technical software hinges upon the accurate and effective collection of field data to predict gas emissions quickly. It was successfully deployed for predicting gas emission quantity in the Hulonggou Coal Mine, facilitating the rapid, precise computation of both relative and absolute gas emission quantities in various mine sectors, encompassing the mining working face, excavation face, and production mining area. Observations from measured and predicted gas emissions in the Hulonggou Coal Mine indicate a significant impact of the chosen correlation coefficient of the relative gas emission quantity (qm) on the mining working face gas emission prediction accuracy. The predicted gas emission quantity from the excavation face (qd) tends to be more accurate based on actual mining conditions. Accurate coal mine output determination is critical for reliable predictions of coal mine gas emissions. Moreover, the numerical evaluation of the effectors of coal mine gas emissions reveals that K1 and K″ substantially influence the calculation model output, whereas K′ has relatively negligible impact. Notably, the usage of this software relies heavily on a thorough understanding of coal mine technical parameters by technical personnel. This is not only a constraint imposed by the software's inherent design logic, but also a requisite for ensuring the reliability of the software's output through accurate parameter input. Consequently, this software is not suitable for newly established coal mines or coal mines where mining engineering and gas geological data are inaccessible. Future versions will strive to enhance repeated gas component detection, among other features, and include a consultation module based on individual gas content. Simultaneously, it will also be demonstrated in more application examples to prove its wide applicability.

Abbreviations

- q m :

-

The relative gas emission quantity of mining face (m3/t)

- q 1 i :

-

The relative gas emission quantity of the mining layer when the thin and medium-thick coal seams are mined without layers (m3/t)

- q 1 j :

-

The relative gas emission quantity of the mining layer when the thick coal seam is mined in layers (m3/t)

- q 2 :

-

The relative gas emission quantity of adjacent layers (m3/t)

- q d :

-

The absolute gas emission quantity of the excavation working face (m3/min)

- q 3 :

-

The absolute gas emission quantity from the roadway coal wall of the excavation working face (m3/min)

- q 4 :

-

The absolute gas emission quantity of falling coal in the excavation working face (m3/min)

- K 2 :

-

The coal and gas emission coefficient of the working face, calculated by the reciprocal of the recovery rate

- K′:

-

The gas emission coefficient of the mined-out area in the production mining area

- q mi :

-

The relative gas emission quantity of the i-th mining face (m3/t)

- A i :

-

The daily output of the i-th mining face (t)

- q di :

-

The absolute gas emission quantity of the i-th excavation face (m3/min)

- A 0 :

-

The average daily output of the production mining area (t/d)

- q p :

-

The relative gas emission quantity of the coal mine (m3/t)

- q ai :

-

The relative gas emission quantity in the i-th production mining area (m3/t)

- K″:

-

The gas emission coefficient of the mined-out area in the mined area

- K 1 :

-

The gas emission coefficient of the surrounding rock; the value selection range is 1.1–1.3; the whole subsidence method manages the roof, and the surrounding rock with more carbonaceous components takes 1.3; the local filling method manages the roof and takes 1.2; 1.1; The value of tight surrounding rocks such as sandy mudstone can be smaller

- m :

-

The thickness of the mining layer (m)

- q m−a :

-

The absolute gas emission quantity in mining face (m3/min)

- W 0 :

-

The original gas content of the coal seam (m3/t)

- W c :

-

The residual gas content of coal after being transported out of the mine (m3/t)

- K f :

-

The layered gas emission coefficient depends on the number and sequence of coal seam layers

- m i :

-

The coal seam thickness of the i-th adjacent seam (m)

- η i :

-

The gas emission rate of the i-th adjacent layer (%)

- W 0i :

-

The original gas content of the i-th adjacent coal seam (m3/t), if there is no actual measured value, can be selected concerning the mining layer

- W ci :

-

The residual gas content of the i-th adjacent coal seam (m3/t) if there is no actual measured value, can be selected concerning the mining layer

- D :

-

The perimeter length of the exposed coal wall in the section of the roadway (m); for thin and medium-thick coal seams, D = 2m0, m0 is the thickness of the mining layer; for thick coal seams, D = 2h + b, h, and b are the height of the roadway and b respectively width

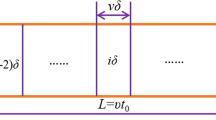

- ν :

-

The raverage driving speed of the roadway (m/min)

- L :

-

The length of the roadway (m)

- q 0 :

-

The initial velocity of gas emission quantity from the coal wall of the roadway (m3/(m2 min))

- V r :

-

The volatile content in coal (%)

- S :

-

The cross-sectional area of the excavation roadway (m2)

- γ :

-

The coal density (t/m3)

- A 0i :

-

The average daily output of the i-th production mining area (t)

- q a :

-

The relative gas emission quantity in the production mining area (m3/t)

- K 3 :

-

The influence coefficient of preparing the roadway pre-drainage gas in the mining area on the gas emission of the mining layer

- M :

-

The mining height of the working face (m)

- q p−a :

-

The absolute gas emission quantity of the mine (m3/min)

References

Chen L, Wang E, Feng J et al (2016) A dynamic gas emission prediction model at the heading face and its engineering application. J Nat Gas Sci Eng 30:228–236

Creedy DP (1993) Methane emissions from coal related resources in Britain: development of a methodology. Chemosphere 26:419–439

Kirchgessner DA, Pieeot SD, Winkler JD (1993) Estimate of global methane emissions from coal mines. Chemosphere 26:453–472

Kucherenko S, Klymenko OV, Shah N (2017) Sobol’ indices for problems defined in non-rectangular domains. Reliab Eng Syst Saf 167(11):218–231

Lu G, Sun Y, Han K et al (2009) Resolution to DM technology for coal mine safety data. In: 2009 International conference on information management, innovation management and industrial engineering, vol 1. IEEE, pp 30–33

Lunarzewski LW (1998) Gas emission prediction and recovery in underground coal mines. Int J Coal Geol 35:117–145

Mijał W, Dang VC, Nguyen TTM (2018) Methane content estimation in DuongHuy coal mine. E3S Web Conf 35:01005

Qin YJ, Su WW, Jiang WZ et al (2020) Research progress and development direction of mine gas emission forecast technology in China. Saf Coal Mines 51(10):52–59

Sobol IM (1993) Sensitivity estimates for nonlinear mathematical models. Math Model Comput Exp 1:407–414

Wei W, Cheng YP, Wang HF et al (2015) Fracture failure analysis of hard–thick sandstone roof and its controlling effect on gas emission in underground ultra-thick coal extraction. Eng Fail Anal 54:150–162

Wang H, Wang E, Li Z (2022) Study on dynamic prediction model of gas emission in tunneling working face. Combust Sci Technol 194(3):506–522

Wen H, Yan L, Jin Y et al (2023) Coalbed methane concentration prediction and early-warning in fully mechanized mining face based on deep learning. Energy 264:126208

Yu QX, Cheng YP (2012) Coal mine gas control. China University of mining and technology press, Xuzhou

Zhao W, Wang L, Chen XJ et al (2020) Analysis of gas adsorption and diffusion characteristics of coal particles in confined space and model adaptation differences. Coal Sci Technol 48(9):146–151

Zhao W, Wang K, Li CW et al (2022) Analysis on the accuracy of laboratory measurement of apparent diffusion coefficient of adsorbed gas in matrix based on the competition relationship between gas flow and gas diffusion. J China Coal Soc 47(2):860–869

Zhou J, Lin H, Jin H et al (2022) Cooperative prediction method of gas emission from mining face based on feature selection and machine learning. Int J Coal Sci Technol 9(1):51

Acknowledgements

The authors are grateful to the financial support from the Beijing Natural Science Foundation (8222070), the National Natural Science Foundation of China (52374250, 52121003, 52130409), the Fundamental Research Funds for the Central Universities (2023ZKPYAQ01).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Zhao, W., Dong, H., Ren, J. et al. A software for calculating coal mine gas emission quantity based on the different-source forecast method. Int J Coal Sci Technol 11, 51 (2024). https://doi.org/10.1007/s40789-024-00703-y

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40789-024-00703-y