Abstract

Coal bed methane (CBM), the high-quality and efficient fuel, has caught the interest of many nations as they strive for environmentally friendly development. Therefore, the efficient exploitation and utilization of CBM has become one of the international focal research problems. A significant factor affecting the mining of CBM is coal permeability. To better capture the changes that occur during the extraction of CBM, the internal swelling coefficient of matrix (ISCM) has been gradually in permeability introduced into the permeability models, and such models have become an important type of the development of permeability models. The goal is to find out more precisely the evolution mechanism of the ISCM and its influence on the permeability models. In this paper, the selection of coal structure, determination of boundary conditions and influencing factors of permeability for were first analyzed. Then, according to the research process of ISCM, the permeability models including the ISCM were reviewed and divided into four phases: proposal phase, development phase, evaluation phase and display of internal structure phase. On the basis of the ISCM values in the current coal permeability models, the primary influencing factors and evolutionary laws of the ISCM are explored. The results obtained provide guidance for future theoretical refinement of permeability models with the ISCM.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Along with energy depletion and green development, the development of new low-carbon and clean energy sources has become particularly important (Chen et al. 2021; Guo et al. 2021; Zhao et al. 2016; Zhao et al. 2020). CBM is regarded as a kind of quality and highly efficient fuel attracting much attention. CBM mining can not only obtain the efficient and clean energy, but also ensure production safety during underground coal mining, and reduces the emission of greenhouse gas CH4 (Liang et al. 2021; Liu et al. 2021b; Yi et al. 2021). The coal body is made up of matrixes and fractures (Li et al. 2023; Liu et al. 2021c; Liu et al. 2022b; Shu et al. 2022; Shu et al. 2023). Figure 1 shows that the forms of gas migration in matrix and fracture are diffusion and seepage respectively (Ullah et al. 2022; Wang et al. 2022). Due to the size of fracture being significantly lower compared to the matrix, a small deformation of the matrix can result in a large variation in permeability when it is used to change the fracture (Liu et al. 2022a; Lu et al. 2015; Zhang et al. 2021). as shown in Fig. 1. Therefore, the permeability is a vital influencing factor for CBM mining, and the CBM production and permeability changes can be reliably predicted by the permeability models (Lu et al. 2021; Lu et al. 2019).

Forms of gas migration during coalbed methane mining (Zhao et al. 2019)

To describe and predict the variation of permeability in the field, much research on permeability models under uniaxial strain conditions (USC) have been established, such as P-M model (Palmer et al. 1998), S-D model (Shi and Durucan 2004), S–H model (Creusot 1980), and so on. In the above models, the change of fracture is completely due to the deformation induced by gas adsorption. Robertson and Christiansen (2005) found that the above models under USC showed a large deviation in fitting experimental permeability data under constant confining stress condition (CCSC), and they concluded that the deviation was due to the overestimation of the influence of matrix adsorption strain on permeability. After they used a variable strain factor to improve the fitting accuracy of above models. At the same time, it is worth pointing out that the boundary conditions between the model and experimental data used by Robertson and Christiansen (2005) are not uniform. Therefore, the fitting deviation not only comes from the overestimation of the influence of matrix expansion strain on permeability, but also from mismatch of the boundary conditions between models and experimental data (Lu et al. 2016). Liu and Rutqvist (2009) discovered that when the permeability model under CCSC was used to fit the experimental permeability data under the identical conditions, there was also the problem of matrix expansion strain being overestimated, so the idea of the internal swelling coefficient of matrix (ISCM) was first proposed. They held the view that the matrix in coal is linked by matrix bridges, and that the matrix expansion deformation will alter both the internal fracture deformation and the external deformation of the coal body through the matrix bridge. Therefore, the ISCM is a parameter used to modify the effect of the expansion strain on the permeability in the permeability model. Connell et al. (2010a; 2010b) established the permeability model including ISCM under triaxial stress condition (TSC) and they got more accurate results between the model and experimental data under the same boundary conditions. Chen et al. (2012) introduced a partition of ratio to define the contribution of swelling strain to the fracture aperture reduction. After that, Many scholars have used and studied the ISCM from different perspective (Guo et al. 2014; Lu et al. 2016; Lu et al. 2015; Peng et al. 2017; Teng-long et al. 2018; Wang et al. 2014; Xiao et al. 2021; Zhou et al. 2016). And then, the influencing factors and evolutionary mechanism of ISCM were studied (Liu et al. 2017; Rong et al. 2022; Zang et al. 2015). Finally, the application of ISCM has also been extended (Bin et al. 2021; Bobo et al. 2019a; Bobo et al. 2019b; Bobo et al. 2020; Gao et al. 2021; Li et al. 2019; Li et al. 2020; Jia et al. 2022; Duan et al. 2022).

Since the ISCM was proposed, it has been widely used in permeability models under various boundary conditions. Therefore, the models including the ISCM have become an important type of permeability models (Liu et al. 2022b; Liu et al. 2022; Shu et al. 2022). In recent years, the review of permeability models has been carried out. Palmer (2009), Liu et al. (2011), Pan and Connell (2012) reviewed permeability models in the elastic phase. Zhou et al. (2019) reviewed the permeability models of coal under mining and analyzed the major issues in model establishment. Lu et al. (2022) reviewed the permeability models of mining-damaged coal and divided them into four types, and main influence factors of permeability were divided into 18 indexes. Xue et al. (2021) reviewed the types, theoretical basis, boundary conditions and applications of permeability models, and only one permeability model of damaged coal was involved. Zhang et al. (2014) reviewed the relative permeability model of wet coal, the method of development the model and the influencing factors of permeability and so on. Gao et al. (2022) reviewed the existing permeability models and believed that the models can be characterized by a combination of internal structure of coal, boundary conditions and equilibrium state within the controlled volume.

In summary, the review of permeability models including the ISCM has not been carried out specifically. In this paper, the coal structure, boundary conditions and the major factors affecting permeability were first analyzed when developing the permeability models. Secondly, permeability models including the ISCM were reviewed and classified according to the research and development process. Thirdly, the range and evolution law of the ISCM were discussed, and the main research methods of ISCM were summarized and analyzed. Finally, the potential research directions of ISCM were put forward. Above research results provide a crucial foundation for the improvement of permeability models including ISCM.

2 Structure of coal body, boundary conditions and influencing factors of permeability

For accurately establishing permeability models, the actual conditions of coal seam mining should be restored. Firstly, the geometric structure of coal seam should be determined, the boundary conditions are then determined based on actual field or laboratory conditions. Secondly, the influencing factors affect the permeability by changing the fracture aperture or fracture ratio, the expression between the factors and fracture are established. Finally, the permeability models are established by the cubic law or other relations between the fracture and permeability.

2.1 Structure of coal body

For the convenience of research, the complex actual structure of the coal body is often simplified for use. The most used simplified structure is the double porosity model, which is composed of matrix and fracture. Figure 2 shows a mass of double porosity models (Lu et al. 2016).

The matrixes and fractures in the coal body are separated from each other. In the early field experience, the permeability models established under USC were assumed that the strain induced by the matrix adsorption expansion would completely change the permeability. Nevertheless, for other boundary conditions, this assumption was not applicable, which resulted in a large deviation between the permeability model and the experimental data. Several studies have been done to learn more about the internal structure of coal body. Pone et al. (2009) utilized high magnification CT to observe the deformation of coal under confining stress conditions. When adsorbed gas is injected into coal, the coal matrix expands due to existence of fractures, However, there exists a difference between the normal strain and volume strain in the degree of coal sample expansion, resulting in simultaneous local expansion of coal. Karacan et al. (2007) found that the adsorption-induced swelling deformations differ between regions containing inorganic minerals and those lacking them. Zhou et al. (2016) found that the mesostructured deformation of coal during methane adsorption and desorption can be classified into expansion and extrusion deformations, which exhibit different changes in density. The aforementioned research demonstrates that there exist interconnections among coal matrices, as well as some inseparable matrixes and inorganic minerals, which impede the closure of fractures caused by matrix expansion. The volume of coal will be changed by the strain generated from matrix adsorption expansion, while the remaining portion of strain will cause changes in fracture aperture. Therefore, Liu and Rutqvist (2009) proposed the "matrix bridge" model, where the unseparated matrixes are simplified into bridges that connects the two adjacent matrixes, as shown in Fig. 3.

“Matrix bridge” model (Liu and Rutqvist 2009)

Liu and Rutqvist (2009) used the “matrix bridge” model to represent a simplified structure of the coal body and believed that the internal swelling stress would prevent the fracture from closing during matrix adsorption expansion. And it makes only a part of the matrix deformation change the fracture aperture and permeability. In the establishment of permeability model, the ISCM is used to modify the influence of matrix expansion on permeability.

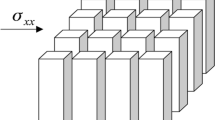

By reason of the foregoing, the geometrical model of coal body is the necessary basis for establishing permeability models, and the “matrix bridge” model is more similar to the actual coal seam. The coal body is simplified to the cube model. The "matrix bridge" model can be used to represent the concept that the matrixes are not entirely separated from one another and that some unseparated matrixes also include inorganic minerals, as shown in Fig. 4 (Liu and Rutqvist 2009; Rong et al. 2022).

Geometric model of coal body (Rong et al. 2022)

2.2 Boundary conditions for permeability models of coal

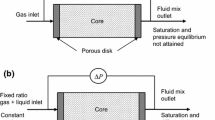

After the geometric structure of the coal is obtained, determining the boundary conditions of coal body under actual conditions during the establishment process of permeability models is the next critical step. Figure 5 shows boundary conditions commonly used in laboratory or field conditions, such as constant volume conditions, uniaxial strain conditions and triaxial stress conditions.

Diagram of common boundary conditions (Lu 2016)

In fact, the coal seam may be under constant volume conditions, which are maintained over time by the bending and tensile strength of overlying strata (Xuehai et al. 2022). Uniaxial strain conditions, which are more suitable for large scale coal seams, are the simplified forms of stress–strain during coal mining. But the mechanical conditions for a local scale are more complex, and the permeability models under USC cannot adequately describe the evolution law of experimental data. Therefore, the USC are more commonly used for large scale conditions in coal seams. The influencing factors of coal permeability could be studied by the permeability models under TSC (Guo et al. 2014). Also, all the boundary conditions can be obtaining by the triaxial stress, only the transformation paths of stress are different. Therefore, many permeability models are established under TSC, and they can be transformed into other permeability models under various boundary conditions.

2.3 Influencing factors of coal permeability

In the double porosity model of coal seam, the small deformation of matrix can induce a large deformation of fracture, which can lead to a large influence on permeability. As a result of the matrix permeability is significantly lower than the fracture permeability, and it often not is considered. The changes of fractures in coal, which significantly affect coal permeability, are primarily caused by effective stress and adsorption expansion (Cui et al. 2018). The primary determinants of coal permeability are those affecting effective stress and adsorption expansion.

During CBM mining and CO2 storage, stress and gas are the primary determinants of permeability. And the permeability also can be influenced by temperature and water content in some coal seams. The influencing factors and evolution mechanisms of coal permeability are analyzed in this section.

-

1.

Stress

The ground stress compresses coal seams when they are buried hundreds to thousands of meters below the surface. Usually, experiments could be used to study how stress affects permeability. During CBM mining. The two aspects of how stress affects permeability include how stress affects matrix deformation and how stress affects gas adsorption (Lu et al. 2022). The main way that stress affects matrix deformation is via altering the fracture aperture, which then has an impact on permeability. By altering the adsorption amount of coal, stress’s impact on ability of coal to absorb gas has an indirect impact on permeability. Different boundary conditions will directly affect the change of stress, which changes the structure of coal body. In the above case, not only the coal permeability will be affected, but also the ISCM. Effective stress is a direct factor affecting the ISCM (Liu et al. 2017).

-

2.

Gas

The primary component of CBM is methane gas, which can be found in the coal seam in two different states: free state and adsorbed state. The three aspects of how gas affects permeability include how gas affects the effective stress, how gas affects matrix deformation, and how gas affects mechanical characteristics (Lu et al. 2022). It is an isothermal process for gas adsorption, so the Langmuir equation is useful to calculate the matrix expansion strain. At the same time, for the same kind of coal, because the εL and pL of different adsorbed gases are different, the coefficient of internal expansion will also produce different sizes.

-

3.

Temperature and Moisture

During CBM mining, the range of variation of temperature and water content are not significant and have little effect on permeability. Therefore, in the establishment process of permeability models, the factors including temperature and water content are ignored. However, in coal seams with high temperature or water content, its influence cannot be ignored. The effects of temperature and water content on gas adsorption and matrix deformation, respectively, make up the two portions of the affects of temperature and water content on permeability. The matrix deformations brought on by temperature and water content work similarly to the matrix deformations brought on by gas adsorption, which are utilized to change permeability in part. The influence of temperature and moisture on matrix deformation directly affects the coefficient of internal expansion. These factors will affect the structure of the matrix bridge, which changes the degree of matrix deformation. Finally, the ISCM will be affected.

In addition to the above influence factors of the ISCM, when the matrix adsorbs or desorbs gas, the coal matrix will swell or shrinkage, which will lead to changes in stress (Liu and Harpalani 2013a, 2013b, 2013c; Liu et al. 2012; Mitra et al. 2012). When the change of stress reaches or exceeds the Mohr–Coulomb strength criterion, macroscopic destruction occurs in coal (Liu et al. 2021a; Liu and Harpalani 2014a, 2014b; Zhou et al. 2021). Since the ISCM discussed in this paper is mainly in the elastic stage and no destruction occurs, the stress–strain relationship caused by swell is further not discussed.

3 Permeability models of ISCM

Liu and Rutqvist (2009) used the ISCM to solve the problem of large deviation between permeability models and experimental data under CCSC, and the ISCM was used in the permeability models under TSC by Connell et al. (2010b). Then, the ISCM was widely used in the permeability models under various boundary conditions. With further research, not only the ISCM is used in the establishment of permeability models, but also the influencing factors and evolution mechanism have been discussed by scholars. The theoretical inversion and numerical simulation are used to reveal the evolution laws of ISCM. Zang et al. (2015) and Liu et al. (2017) evaluated and researched the ISCM, obtaining the relationships between the ISCM and influence factors. Rong et al. (2019, 2022) further studied the evolution mechanisms and influencing factors of ISCM by numerical simulations, which enriched the theory related to ISCM. In this chapter, according to the research and development process of ISCM, the permeability models were summarized and divided into four phases: proposal phase, development phase, evaluation phase and internal structure display phase, as shown in Fig. 6.

3.1 Proposal of the ISCM

Although the permeability models under USC can well describe the field permeability data, they may overestimate the effect of gas adsorption expansion strain of matrix on the permeability obtained under CCSC. To deal with this above problem, Robertson and Christiansen (2005) improved the fitting accuracy of models by a variable strain factor. On the other hand, Liu and Rutqvist (2009) proposed the concept of ISCM in the permeability models after precisely defining it. Then, the ISCM has since been cited and developed by scholars. The ISCM is a parameter that indicates that only the sectional matrix expansion deformation affects the coal permeability during gas absorption. The ISCM, also known as the internal expansion deformation rate of matrix, is defined in this study as the ratio of the part of matrix expansion deformation used to change the fracture volume to the total matrix expansion deformation (Lu 2016).

-

1.

Model of Liu and Rutqvist (2009)

Liu and Rutqvist (2009) considered that the matchstick model of coal was oversimplified and the interaction between matrixes and fractures was ignored, which resulted in a large deviation between the models and experimental data under CCSC. Therefore, the “matrix bridge” model and internal expansion stress were proposed. In the establishment process of permeability models, they considered the matrix-fracture interaction and used f to represent the ISCM. The equations under the USC and CCSC are as follows.

where σI is the internal swelling stress.

Meanwhile, Liu and Rutqvist (2009) used their permeability models to fit experimental data (2005) under CCSC, and compared the experimental data with models with different values of f.

It can be seen from Fig. 7, If the appropriate value is obtained for f, the fitting degree of the model is better than that of the same value without fracture effect. When f = 1, matrixes are completely separated, the predicted data value of the model is lower than the experimental data. Therefore, when the ISCM and matrix-fracture interaction are both considered, the fitting results in this case are better than those in other cases. Figure 7 shows the fitting results.

Model and data comparison of Liu and Rutqvist (2009)

Connell et al. (2010b) proposed the constant ratios between induced fracture strain by adsorption, matrix strain and coal body strain such as: splitting factors γ and β, which reduce the influence of swelling strain on permeability and further extend the application of the ISCM. The two forms of permeability models under TSC were established. The exponential type model and cubic type model are as follows, respectively.

where pc is the confining pressure; fγ and fβ are the two different splitting factors, which are used to relate pore adsorption strain and matrix adsorption strain to volume strain:\(\tilde{\varepsilon }_{\text{p}}^{\left( \text{S} \right)} = f^{\gamma } \tilde{\varepsilon }_{\text{b}}^{\left( \text{S} \right)}\),\(\tilde{\varepsilon }_{\text{m}}^{\left( \text{S} \right)} = f^{\gamma } \tilde{\varepsilon }_{\text{b}}^{\left( \text{S} \right)}\) Connell et al. (2010b) validated the models with splitting factors, according to the model and experimental data, the good fitting results were obtained, as shown in Fig. 8.

Model and data comparison of Connell et al. (2010b)

Liu and Rutqvist (2009), Connell et al. (2010b) revealed the reasons for the large deviation between the models and experimental data under CCSC from the inside of the coal body, and they concluded that the matrix adsorption expansion deformation affects not only the fracture aperture but also the volume of coal body. Their studies had led scholars to think about the matrix-fracture interaction when establishing permeability models, and the ISCM was introduced into the permeability models as an important parameter. In the references of Liu and Rutqvist (2009), Connell et al. (2010b), the ISCM values were first assumed, tested and then were used to fit experimental data, and only CCSC and constant pore pressure condition (CPPC) were used. Therefore, the evolution mechanism and application scope of ISCM need to be further studied.

3.2 Development of the ISCM

The ISCM was first proposed to modify the gas adsorption expansion deformation used to change the fracture aperture in permeability models, because the stress and gas were the first factors to be considered during CBM mining. Later, with further research, the influences of temperature and moisture on permeability were also considered, and the ISCM was extended to modify the matrix expansion deformation induced by temperature and moisture. The existing expressions of the ISCM in the permeability model were divided into two forms: one is that the ISCMs (internal swelling coefficients of matrix) of gas adsorption expansion, thermal expansion and moisture adsorption expansion as the whole ISCM expansion, which is used to modify the matrix expansion deformation. The other is that the ISCMs of gas adsorption expansion, thermal expansion and moisture adsorption expansion are respectively used to modify the corresponding matrix expansion deformation.

Although the definitions of ISCM were slightly different in literature, they all represent only a part of matrix expansion deformation to change permeability. In this section, the permeability models including the ISCM were summarized.

3.2.1 The models considering the gas ISCM

-

1.

Model of Chen et al. (2012)

Although the distribution factor (ISCM) f was also used to represent that only a certain amount of matrix expansion deformation can change the fracture aperture, the permeability model was established by equation Sf = f/ϕf0 (Chen et al. 2012). The fitting results were better than those of other literature, which indicated that the ISCM is not constant, but a parameter affected by coal structure. The specific equation under constant pressure difference is as follows.

-

2.

Model of Guo et al. (2014)

There was a parameter of coal structure known as effective coal matrix deformation factor fm. It was a coal structure parameter that was influenced by fracture distribution, fracture filling characteristics, and other factors (Guo et al. 2014). Therefore, the fm may be a complex function, which is related to fracture characteristics and other factors. The specific equation under TSC is as follows.

-

3.

Model of Wang et al. (2014)

Under unconfined conditions, the f was utilized to represent the ratio of internal expansion to total matrix expansion (Wang et al.2014), and the impact of several influencing factors on the ISCM was investigated using permeability models and experimental data. The specific equation is as follows.

-

4.

Model of Lu et al. (2016)

According to matrix-fracture interaction, Lu et al. (2016) established a permeability model under TSC, which was transformed into permeability models under five boundary conditions. They developed the permeability models under various boundary conditions to fit permeability data under corresponding boundary conditions. Their fitting results were better than others, which used the permeability models to fit experimental data without considering the corresponding boundary conditions. Therefore, the boundary conditions for the experimental data and permeability models should be same as a result. The specific permeability model under TSC is as follows:

-

5.

Model of Zhou et al. (2016)

The ISCM can be directly reflected in the variation of pore size (Zhou et al. 2016), and the permeability model including the ISCM under CCSC was established. There is a considerable difference between the f values obtained by Zhou et al., (2016) with those in the reference (Pini et al. 2009). The specific equation is as follows:

-

6.

Model of Liu et al. (2017)

The dual porosity-matrix fracture interaction model (DP-MFI) was established by Liu et al., (2017), which was evaluated according to the field and experimental data, and the evolution laws and influencing factors of ISCM under various boundary conditions were studied. The specific equation is as follows:

-

7.

Model of Peng et al. (2017)

According to non-equilibrium, Peng et al.,(2017) explained the internal expansion strain. There was a transfer process exciting, the internal expansion strain dominated at the beginning of transfer process. Then the volume strain dominated and finally the internal expansion strain in the transfer process would completely disappear when the gas pressure is in equilibrium between the matrixes and fractures. The strain splitting function was used to respond to the effect of inhomogeneous distribution of the internal expansion strain on permeability. The specific equation is as follows:

where εv is the volumetric strain of coal; \(C = {{\overline{\varepsilon }_{\text{Lm}} } \mathord{\left/ {\vphantom {{\overline{\varepsilon }_{\text{Lm}} } {\varepsilon_{\text{L}} \phi_{0} }}} \right. \kern-0pt} {\varepsilon_{L} \phi_{0} }}\), is a constant; \(\overline{\varepsilon }_{\text{Lm}}\) is the average Langmuir strain constant for matrix; fβ is the strain splitting function; εL is the overall Langmuir strain constant for coal.

-

8.

Model of Liu et al. (2018)

Based on the matrix bridges mode, Liu et al. (2018) discussed the effect of effective stress and adsorption expansion on fracture aperture, and established an evolutionary model considering the competition between them. They focused primarily on the extraction pressure and permeability rebound affecting factors. The specific equation is as follows:

where a is the fracture aperture; a0 is the initial fracture aperture.

-

9.

Model of Zhang et al. (2018)

The problem of overestimation of permeability model was explained from a non-equilibrium perspective (2018). They believed the existence of local strains and matrix-fracture interaction, and established matrix and fracture permeability models, respectively. The specific equations are as follows. The matrix permeability model is Eq. (13). The fracture permeability model is Eq. (14).

where εmv and εfv are the volume strains in the matrix and fracture respectively; \(c_\text{lm} = {{p_{f} - p_\text{m} K_{f} } \mathord{\left/ {\vphantom {{p_{f} - p_{m} K_{f} } {\Delta P_{\max } K_{m} }}} \right. \kern-0pt} {\Delta P_{\max } K_\text{m} }}\) is the local strain coefficient, and ΔPmax is the maximum difference in pore pressure between the fracture and the matrix; \(c_\text{lf} = {{p_{f} - p_\text{m} K_\text{m} } \mathord{\left/ {\vphantom {{p_{f} - p_{m} K_{m} } {\Delta P_{\max } K_{f} }}} \right. \kern-0pt} {\Delta P_{\max } K_{f} }}\) is a local strain coefficient.

-

10.

Model of Rong et al. (2019).

According to the definition of ISCM by Wang et al. (2014), a permeability model was established for the permeability evolution of deep coal under mining disturbance (Teng-long et al. 2018). The exponential type formula is shown in Eq. (15), and the cubic type formula is shown in Eq. (16).

where D = 1-Eb/Eb0; Δσc is the confining pressure increment.

-

11.

Model of Jiang et al. (2021).

The effect of gas pressure on fracture deformation and permeability was researched by Jiang et al. (2021). Under constant external stress condition, the competition between the effective stress and adsorption expansion leads to fluctuations in permeability, which first decrease and then increase as gas pressure increases. As a result, the gas pressure-fracture coupling coal permeability model was established. The specific equation is as follows:

-

12.

Model of Xiao et al. (2021).

Xiao et al. (2021) used the ISCM to modify the influence of matrix adsorption on fracture aperture and external stress. They also considered the influence of effective stress on fracture and matrix deformation in the permeability models. The specific equation is as follows:

where s and s0 are the matrix width and initial matrix width respectively; b and b0 are the fracture aperture and the initial fracture aperture.

3.2.2 The models considering the gas, thermal and moisture ISCM

In the above permeability models, the main considered factors were the stress and gas adsorption expansion. The application of ISCM was also based on the "gas ISCM". With further research, the application of ISCM has been extended. The thermal ISCM (TISCM) and moisture ISCM (MISCM) are used to modify corresponding adsorption expansion deformation of matrix. In this section, the temperature and moisture are main factors considered among the permeability models.

-

1.

Model of Rong et al. (2019).

Based on the Eq. (15), Rong et al. (2019) considered the effect of temperature on matrix expansion deformation. The concept of "thermal ISCM" was introduced. They considered the fracture deformation, which was induced by the gas adsorption and thermal expansion strain and established a permeability model. The specific equation is as follows:

where Dst = Ds + Dt-DsDt, is the damage variable, Ds is the coal damage variable caused by mining disturbance; Dt is the thermal damage due to temperature change; αt is the thermal expansion coefficient of coal; c1 and c2 are respectively the pressure and temperature coefficients of adsorption.

-

2.

Model of Zhou et al. (2020)

An anisotropic permeability model that considers the stress, gas adsorption and temperature under three-dimensional stress conditions was established by Zhou et al., (2020) to better restore actual conditions of coal seam. Moreover, the modified Langmuir equation for describing fracture deformation induced by adsorption was used. The thermal expansion strain and gas adsorption expansion strain were distinguished. which were modified respectively by the thermal ISCM and gas ISCM. The specific equations are as follows.

where φv and φpl are the volume porosity and plane porosity respectively; αt is the thermal expansion coefficient; c1 is the stress coefficient; c2 is the temperature coefficient.

(3) Models of Li et al., (2019, 2022).

In the above two models (Teng-long et al. 2019; Zhou et al. 2020), the main influencing factors of ISCM were not only the gas but also temperature and moisture. Li et al.’s team (Bin et al. 2021; Bobo et al. 2019a; Bobo et al. 2019b; Bobo et al. 2020; Gao et al. 2021; Li et al. 2019, 2020; Jia et al. 2022; Duan et al. 2022) have done many research of permeability models that include ISCMs from 2019 to 2022. These models extended the applications of ISCM further from gas to temperature and moisture, as shown in Table 1.

The permeability models of Li et al.’s team (Bin et al. 2021; Bobo et al. 2019a; Bobo et al. 2019b; Bobo et al. 2020; Gao et al. 2021; Li et al. 2019, 2020; Jia et al. 2022; Duan et al. 2022)considering gas, temperature and moisture were summarized in Table 1. In the establishment process of permeability models, in addition to stress and gas, the temperature and moisture also need to be considered necessary factors under certain circumstances. These factors of temperature and moisture will also cause the matrix to expand, which indicates that only a part of the deformation induced by matrix expansion will affect the permeability due to the "matrix bridge". In the above situation, the ISCM can also be used to correct the influence of temperature and moisture induced matrix expansion strain on permeability. Therefore, the application of ISCM was extended the TISCM and MISCM.

4 Evaluation of ISCM

As to the analysis above, the ISCM has been widely used and is a necessary parameter during the establishment process of permeability models. The value of ISCM, which has a large influence on permeability and can be influenced by many factors, is particularly important for describing the evolution of permeability. Therefore, it is important for CBM mining to identify the main influencing factors and evolution mechanism of ISCM. In the current evaluation of ISCM, Shi et al. (2014) found the relevant influencing factors by deriving a discretized internal expansion term. Zang et al. (2015) and Liu et al. (2017) used the permeability models to fit experimental data, then, they derived the effect laws of boundary conditions and other factors on f value. In this section, the permeability models and evaluation results of f value under specific boundary conditions are reviewed and compared.

4.1 Models of Zang et al. (2015)

According to the porosity of the face cut of unitary, an anisotropic permeability model was established by Wang et al. (2014). Since most isotropy permeability models have met the needs of production practice, Zang et al. (2015) took Eq. (7) into isotropy equations under various boundary conditions. Then, they used these permeability models to research the evolution laws of f value for various boundary conditions. The specific equations are as follows:

Constant confining stress conditions

Constant effective stress conditions

Constant pore pressure conditions

where ∆σt is the total stress.

Based on the permeability models under three boundary conditions (Zang et al. 2015), the permeability data from Pini et al. (2009) and Connell et al. (2010b) were used to evaluate the ISCM. Here are the key conclusions. Under CCSC, the values of ISCM increased as pore pressure increased. Under CPPC, the values of ISCM increased as pore pressure increased. Under constant effective stress conditions (CESC), the values of ISCM decreased and then increased as pore pressure increased. Figures 9, 10 and 11 show that the different fitting results respectively. According to the study of Zang et al. (2015), the ISCM is affected by pore pressure, confining stress, sorbate type, coal structure and coal lithotypes and so on.

Connection between ISCM and pore pressure under CCSC (Zang et al. 2015)

Connection between ISCM and effective stress under CPPC (Zang et al. 2015)

Connection between ISCM and pore pressure under CESC (Zang et al. 2015)

4.2 Evaluation model of Liu et al. (2017)

According to Eq. (10), Liu et al. (2017) established the permeability models under USC, constant external stress condition and CESC and used them to evaluate the ISCM. The specific equations are as follows.

Uniaxial strain condition

Constant external stress condition

Constant effective stress condition

Liu et al. (2017)mainly used data from references (Connell et al. 2010b; Liu and Harpalani 2013c; Pini et al. 2009; Robertson and Christiansen 2005), which is used to fit models to study the trends of the ISCM under various boundary conditions. Here are the key conclusions. Under USC, the values of ISCM increased overall as pore pressure increased including decreasing fluctuations in between. When the external stress remains constant, the values of ISCM decreased with increasing pore pressure. and the values of the ISCM increase as external stress increased. Under CESC, the values of ISCM increased as pore pressure increased, as shown in Fig. 12. According to the study of Liu et al.(2017), effective stress and adsorption-induced deformation are the factors that directly affect the ISCM, and other factors will affect them, which will change the ISCM.

The values of ISCM with pore pressure under various boundary conditions (Liu et al. 2017)

Both Zang et al. (2015) and Liu et al. (2017) evaluated values of f by their respective models and data from other literatures, and their conclusions are compared here, as shown in Table 2.

Table 2 shows the fitting results of permeability models, Zang et al. (2015) and Liu et al. (2017) both researched the evolution law of ISCM under various boundary conditions. In the above two references, the evolution laws of the ISCM under CESC were researched, although the same experimental data from Connell et al. (2010b) was used, the fitting results were different due to the different models. Under CESC, in reference (Zang et al. 2015), the variation trend of f value first decreases and then increases, while in reference (Liu et al. 2017), it always shows an increasing trend. By comparing Eq. (23) and Eq. (27), Liu et al.’s model (2017) shows that the effect of matrix adsorption expansion strain on permeability is \(\frac{{3f\varepsilon_\text{L} }}{{\phi_{f0} }}\left( {\frac{{p_\text{m} }}{{p_\text{L} + p_\text{m} }} - \frac{{p_\text{m0} }}{{p_\text{L} + p_\text{m0} }}} \right)\). Zang et al.’s model (2015) shows that the effect of matrix adsorption expansion strain on permeability is \(\frac{1}{{\phi_{0} }}\left[ {\varepsilon_\text{L} \left( {\frac{fp}{{p_\text{L} + P}} - \frac{{f_{0} p_{0} }}{{p_\text{L} + p_{0} }}} \right)} \right]\) and in this formula, f = f0, the meaning of other symbols is the same as that in Eq. (23), so \(\frac{1}{{\phi_{0} }}\left[ {\varepsilon_\text{L} \left( {\frac{fp}{{p_\text{L} + P}} - \frac{{f_{0} p_{0} }}{{p_\text{L} + p_{0} }}} \right)} \right]\) is simplified to \(\frac{{f\varepsilon_\text{L} }}{{\phi_{0} }}\left( {\frac{p}{{p_\text{L} + p}} - \frac{{p_{0} }}{{p_\text{L} + p_{0} }}} \right)\). Additionally, Table 3 shows the basic parameters of coal.

In both the two equations, εL is the Langmuir volume strain and the value of other parameters are relatively similar. In the equation of Liu et al. (2017), the matrix expansion strain has a three times bigger impact on permeability than it does in Zang et al (2015). Under CESC, as pore pressure increases, the effect of adsorption expansion on permeability is more obvious than that of effective stress matrix. With regard to the formula of Liu et al. (2017), its influence on permeability is always more obvious than that of effective stress due to the three times matrix adsorption expansion strain, so there is no fluctuation.

In the above references, theoretical inversions based on the permeability model and experimental data were used to obtain the values of f, and the ISCM evolution is significantly influenced by the accuracy of permeability models and experimental data. Therefore, the accuracy of values of ISCM obtained by this method needs to be discussed further.

4.3 Internal structure display of the ISCM

The ISCM, which is controlled by the structural characteristics of coal body, can be obtained by the theoretical inversion. However, the results of theoretical inversion is limited by the permeability models and experimental data, and only the macro evolution law of ISCM can be obtained by this method. With further research, the scholars found that it was not enough to study the internal expansion coefficient only by the theoretical inversion, the methods of internal structure display can be more intuitive analyze the evolution law of ISCM.

There are two main methods of internal structure display of ISCM, including the direct observation of internal structure of coal body by CT and SEM equipment and numerical simulation method.

4.3.1 Scanning display of the ISCM

For verifying the hypothesis that the matrix expanded as the gas was injected into coal, they used CT, SEM and other equipment to observe the internal structure of coal body in their literatures (Dong 2017; Dong et al. 2016; Karacan 2007; Pone et al. 2009). At the same time, they also found that inorganic minerals and unbroken matrix structures in coal can prevent fracture closure during matrix expansion. Figures 13, 14 and 15 show these images observed by them.

CT image of longitudinal cross-section of coal sample (Pone et al. 2009)

Scanning electron microscope image of coal seam (Karacan 2007). (a) SEM images taken at clay and inertite layer with 10um. (b) SEM images taken at clay and inertite layer with 1um. (c) Internal structure of coal cample by X-ray. (d) SEM images taken at a vitrite and clarite layer with 10um

SEM images of areas characterized by the distribution of different clay minerals (Dong 2017)

Pone et al. (2009) used the CT techniques to analyze the sample under confining pressure conditions. The CT image of longitudinal cross section of sample were obtained, in which the white layer represented mineral bands with relatively high density. The light shadows represented high density materials, and dark shadows represented low density materials, as shown in Fig. 13. Karacan et al. (2007) studied the expansion behavior of confined and stressed coal during CO2 adsorption. The brighter layers were denser clay and rock layers, and the darker layers were organic rock types with different microscopic components as shown in Fig. 14. Both Figs. 13 and 14 show that there are fractures in coal body which can be squeezed in the process of gas adsorption, resulting in a reduction in fractures aperture.

Karacan et al. (2007) found that the SEM images of coal demonstrated the existence of inorganic minerals such as kaolinite between the fractures, which can increase the CO2 adsorption capacity and also hindered matrix expanding towards the fractures. In the coal samples scanned by SEM (Dong et al. 2016), the distribution areas of clay minerals are different. Clay minerals are aqueous silicate minerals mainly containing aluminum and magnesium, which have certain methane adsorption capacity. Due to special bedding structure, distribution mode and large density, coal meso-structure deformation will be significantly impacted by methane adsorption, as shown in Fig. 15.

Karacan et al. (2007) and Zhou et al. (2016) showed that there was a specific quantity of minerals in the fractures of coal body. These minerals hindered the coal matrixes being completely separated from each other, which also hindered the expansion of the matrix into fractures during the gas adsorption process. Due to the differences in the quantity and density distribution of minerals, the effects of minerals on matrix expansion vary across regions. Dong (2017) also analyzed the change of porosity and volume of coal body during adsorption. They discovered that changes in coal volume are accompanied by changes in porosity, which confirmed “matrix bridge” hypothesis that the matrix expansion changes the fracture aperture as well as the volume of coal body.

4.3.2 Numerical simulation display of the ISCM

With the development of computer simulation, the internal structure of ISCM can now be researched using numerical simulations. In the study of CBM, the main physical fields involved are solid mechanics, fluid and other physical fields or the coupling of multiple physical fields, and the solution of multiple sets of partial differential equations. As a multi-physical numerical analysis software, COMSOL has a unique role in multi-physical field coupling and partial differential equation solving, which makes it used by many scholars to study problems related to coal mines (Liu 2015). For example, the evolution laws of ISCM with change in external factors were investigated by simulating the gas adsorption process of the coal matrix using COMSOL software (Rong 2019). Rong et al (2022) simplified the coal body into matchstick model including matrix bridges, and studied the evolution laws of ISCM with the change of characteristics of matrix bridges under CCSC, as shown in Fig. 16.

A COMSOL-based model for the numerical calculation of ISCMs (Rong 2019)

In Fig. 16, coal body is composed of matrixes and fractures, and the porosity is a constant with neglecting the volume of matrix bridges. The boundary conditions of model are CCSC, and the graph is axisymmetric. Results of the semi-model can be used to represent the evolution laws of ISCM in the entire model (Rong et al. 2022). Average values of the horizontal displacement of deformation of fracture and coal body were used to calculate the values of ISCM, as shown in Eq. (28). Figures 17 and 18 show a simulation of the evolution law of the ISCM with changing gas pressure and temperature.

where \(\Delta L^{{\text{f}}}\) is the incremental fracture deformation, \(\Delta L^\text{b}\) is the incremental deformation of coal body, and η is the ISCM.

Deformation of the Matrix at different gas pressures (Rong 2019)

Deformation of the Matrix at different temperatures (Rong 2019)

Rong et al. (2019) obtained the deformation of coal body after gas adsorption through the COMSOL simulation, and then took the numerical results into Eq. (28) to obtain the evolution laws of ISCM, as shown in Fig. 19. Finally, based on Fig. 18, here are the key conclusions. Under CCSC, with an increase in pore pressure, the ISCM decreases; with an increase in temperature, the ISCM increases. The conclusions of numerical simulation are consistent with those of theoretical inversion by Liu et al. (2017). And the laws of numerical simulation results show better monotonicity, while there are some fluctuations in the theoretical inversion results.

Effect of pore pressure a and temperature b on the ISCM under constant confining pressure conditions (Rong 2019)

In the above studies, by changing the single factor under certain boundary conditions, the evolution laws of internal expansion coefficient and external factors were obtained (Rong 2019). However, this study ignored the fact that changes of external factors can affect the characteristics (width, height, number) of matrix bridges, which are the direct cause of the change of ISCM. Rong et al. (2022) studied the variation of the ISCM when the characteristics (width, height and number) of matrix bridges were changed under CCSC. And the width, height and number of matrix bridges respectively were changed, as shown in Fig. 20.

Rong et al. (2022) took the values of matrix and fracture deformation into Eq. (28) to obtain the evolution laws of ISCM, and the simulation mainly followed four assumptions. First, the coal is made up of matrixes and fractures, and only partial variations are taken into account. Second, the deformation of coal matrix is consistent with the small strain assumption, and only isotropic is considered. Third, only the impact of gas pressure on the adsorption expansion of matrix is taken into account while the temperature of the coal body remains constant. Fourth, the values of coal matrix deformation under various situations are determined after the gas adsorption equilibrium, and the gas diffusion process is not taken into account. Table 4 shows the key results.

As can be seen from Table 4, the ISCM is linearly related to the properties of matrix bridges, which include height width and number, and influence laws of gas on the ISCM is the same as that of Liu et al. (2017). Therefore, the numerical simulation can further verify the results of theoretical inversion. Based on the numerical simulation result, Rong et al. (2022) further fit the relationship between the ISCM and gas pressure and obtained the Eq. (29). This equation is useful for subsequent studies about the effect of the ISCM on permeability.

Rong et al. (2019; 2022) studied the evolution law of ISCM with the changes of external factors and properties of matrix bridge. However, only the evolution law of ISCM under CCSC was analyzed, and the effect of external factors on the characteristics of matrix bridge was neglected. Therefore, the evolution law of ISCM under other boundary conditions and the relationship between external factors and the properties of matrix bridge need to be further studied.

5 Discussion

5.1 The theoretical inversion of the ISCM

The method of theoretical inversion could be used to obtain the value of the ISCM by the permeability model and experimental data or study the connection between the ISCM and influencing factors. The advantages of theoretical inversion are simple and easy to obtain the values of the ISCM. The disadvantage is that it is limited by experimental data and permeability models. The impact of matrix expansion strain on permeability is represented by the ISCM, which is typically used as a constant between 0 and 1 when developing permeability models. Both the internal structure of the coal body and the inorganic minerals present in the fractures control the ISCM. When the coal matrixes are completely separated from each other, the value of f is about 1. When there is only coal matrix without fractures in the coal body, the value of f is about 0, as shown in Fig. 21. In addition, the values of ISCM fluctuate as external conditions change, which is a crucial point to remember.

The range of ISCM is between 0 and 1, but the values vary greatly. Some values are only suitable for fitting the corresponding permeability models, when the same values are used to other models leading to a large deviation. Liu and Rutqvist (2009) used the permeability model to fit the experimental data, and obtained f values are 0.30 and 0.45. Then, they compared the experimental permeability data with the permeability model curves for f values of 1. The fitting results demonstrate that permeability models considering matrix-fracture interaction and suitable f values can better explain the permeability changes. Connell et al. (2010b) also used the permeability models to fit experimental data under the same TSC and obtained a good result. In the subsequent studies, the ISCM was often directly cited as a constant to establish permeability models. However, it is not perfect for fitting results due to the neglect of the effect of boundary conditions on ISCM. The ISCM is a parameter that is controlled by the fracture distribution, fracture filling characteristics and other factors (Guo et al. 2014). Therefore, for obtaining the values of ISCM under different boundary conditions, verifying the evolution laws of ISCM is an important project. The evolution laws of ISCM are one of main research directions.

To compare the ISCMs of matrix in the permeability models, the influence factors, applications and range of values were summarized in this section, as shown in Table 5.

In Table 5, the range of ISCM is between 0 and 1. The data sources for the values of the ISCM above are mainly the following three kinds: hypothesis, fitting, experiment and reference. The range of gas ISCM are concentrated between 0.1 and 0.5. While the ranges of the thermal ISCM and moisture ISCM are sometimes less than 0.1, as shown in Fig. 22.

The change of ISCM is essentially the change of characteristics of matrix bridges. All the boundary conditions of models, pore pressure, adsorbed gas types and basic parameters of coal will affect the characteristics of matrix bridges. However, in the current research, the influence of one factor on the ISCM is mainly considered. The connection between influencing factors and properties of matrix bridges is ignored. Therefore, the research on the evolution laws of ISCM still needs to be refined, and the influence of different factors on the characteristics of matrix bridges should be emphasized.

5.2 The experimental measurement of the ISCM

The experimental measurement of ISCM is to measure the expansion deformation of coal body and coal matrix respectively under the same conditions. The advantage of experimental measurement is that the values of ISCM obtained are accurate. The disadvantage is that the operation is complicated, and the experimental measurement cannot be carried out under field conditions. The values of ISCM can also be obtained directly by measuring in the laboratory (Lu et al. 2022). There are two main methods for the measuring ISCM in the laboratory.

The value of the ISCM can be determined from the definition of coal matrix expansion deformation by attaching strain gauges to coal matrix blocks, which convert coal deformation into electrical signals, which are then transformed into data of adsorption deformation by data acquisition cards. Another method involves using an optical microscope to take pictures of the deformation of coal matrix under various situations. The photos are then processed to the adsorption deformation of coal matrix using computer software. Finally, the values of ISCM will be calculated and obtained by the adsorption deformation of coal matrix (Lu et al. 2022). The more accurate values of ISCM can be obtained by experimental measurement, but these methods are more complex with a long time and are limited by space and equipment.

The above two measuring methods are both indirect method of obtaining the ISCMs, which need to be measured with several times. The experimental devices for the direct measurement of ISCM are still relatively fewer. In this paper, the experimental devices and method that can directly measure the three-dimensional ISCM of coal matrix are provided, as shown in Figs. 23 and 24.

The invention is to simultaneously measure the deformation of coal matrix and coal body in a uniform environment as shown in Figs. 23 and 24. And the three-dimensional ISCM of coal matrix under various temperature, loading condition and gas pressure condition can be obtained. The invention is consisted of the pneumatic system, data acquisition system, coal matrix deformation measurement system, coal deformation measurement system and constant temperature water bath system. Except for the system in Fig. 24, the temperature water bath system is also part of the whole invention. The constant temperature water bath system contains distilled water and a temperature sensor is installed on the water bath box. Heating tubes are installed on the bottom and sides of the water bath to heat the distilled water to a pre-set temperature according to the predicted temperature of the temperature sensor.

The main measurement methods are as follows:

-

(1)

Firstly, the coal matrix and coal body are respectively placed on the deformation measurement platform of them, respectively. The length, width and height of coal matrix are recorded as Lm0, Wm0, Hm0 and those of coal body are recoded as L0, W0 and H0. Then the displacement of displacement measuring instrument support in three directions are recorded as Dx1, Dy1 and Dz1.

-

(2)

Set the temperature of water bath to T0 and maintain the temperature of distilled water at temperature T0.

-

(3)

The loading stresses of three directions are set as Sx1, Sy1 and Sz1 respectively, so that the loading pressure given by loading piston to coal body in the three directions is Sx1, Sy1 and Sz1; meanwhile record the displacement of displacement measuring instrument in three directions as Dx1, Dy1 and Dz1.

-

(4)

The invented device is vacuumed for 24 h. Then pump helium in to coal matrix and coal body, and record the value in pressure gauge 2 as P1.

-

(5)

The deformation of coal matrix was observed by microscope, and the length of coal matrix in three directions are Mx1-He-P1, My1-He-P1 and Mz1-He-P1 after the images were processed by computer software. At the same time, the displacement of the displacement measuring instrument in three directions were recorded as Dx1-He-P1, Dy1-He-P1 and Dz1-He-P1.

-

(6)

The invented device is vacuumed again for 24 h. Then pump methane into coal matrix and coal body, and record the value in pressure gauge 2 as P1.

-

(7)

The deformation of coal matrix is observed by microscope, and the length of coal matrix in three directions are Mx1-CH4-P1, My1-CH4-P1 and Mz1-CH4-P1 after the images are processed by computer software. At the same time, the values of the displacement measuring instrument in three directions are recorded as Dx1-CH4-P1, Dy1-CH4-P1 and Dz1-CH4-P1.

-

(8)

In the x direction, the deformation of coal matrix per unit length is \(m_{x1} = \frac{{M_{x1 - \text{CH}_4 - P1} - M_{x1 - \text{He} - P1} }}{{L_{m0} }}\); In the x direction, the coal deformation of coal body per unit length is \(d_{x1} = \frac{{D_{x1 - \text{CH}_4 - P1} - D_{{x1 -\text{He}} - P1}} }{{L_{0} + D_{{{\text{x1}}}} - D_{{{\text{x0}}}} }}\).

-

(9)

Under the condition that the temperature is T0, the loading stresses in the three directions are Sx1, Sy1 and Sz1 respectively, and P1 is the gas pressure. Therefore, in the x direction, the ISCM can be expressed as:

$$f_{x1} = 1 - \frac{{d_{x1} }}{{m_{x1} }} = 1 - \frac{{L_{m0} \left( {D_{x1 - \text{CH}_4 - P1} - D_{{x1 - \text{He} - P1}} } \right)}}{{\left( {L_{0} + D_{x1} - D_{x0} } \right)\left( {M_{x1 - \text{CH}_4 - P1} - M_{{x1 - \text{He} - P1}} } \right)}}$$(30)

Similarly in the y direction, the ISCM can be expressed as:

Similarly in the z direction, the ISCM can be expressed as:

Finally, the ISCM can be measured under a variety of temperature, stress, and gas pressure circumstances by repeatedly performing the aforementioned processes. The method of measuring the ISCM provided by this invention, which can avoid most the disadvantages of previous indirect methods. The setting of different temperature, stress and gas pressure conditions is also more consistent with field conditions.

5.3 Internal display of the ISCM

Both the methods of theoretical inversion and experimental measurements of ISCM can reveal the evolution laws of ISCM from the outside. The internal display of ISCM is to show the internal structure of coal body by CT or simulate the change of matrix bridges in the process of matrix gas adsorption by numerical simulation software. The application of above two research methods in ISCM is relatively few, and their advantages and disadvantages are relatively obvious. Therefore, these methods need to be combined with field conditions.

-

1.

Scanning experiments.

The way to show the ISCM from the inside is by the scanning experiments. The purpose of the scanning studies is to better understand the internal structure of the coal body using CT and other tools, as well as to reveal the composition of the coal matrixes and fractures. The advantage of equipment is that coal can be studied on the nanometer scale. The ISCM is a parameter of coal matrix, which is controlled by the matrix bridges between the coal matrixes. The values of ISCM are related to the changes of characteristics of matrix bridges. Therefore, CT and other equipment can be used to study the relationship between the ISCM and the characteristics of matrix bridges from a microscopic perspective. And this method is used to provide a basis for theoretical research. However, the CT and other equipment are limited by the high cost of equipment and maintenance. The study is more inclined to qualitative analysis, and it is difficult to control the variables of coal structure. At the same time, most of the research samples of CT and other equipment are the original collected coal samples. Studies on coal with gas or stress are lacking, and there are certain limitations in the observation of internal changes of coal samples. The actual conditions have not been completely restored in the existing research, and the accuracy of equipment and experimental conditions need to be further improved.

-

2.

Numerical simulation.

Another way to reveal the ISCM from the inside is the numerical simulation by computer simulation software. The numerical simulation is to use COMSOL or other software to restore the process of matrix adsorption to study the evolution laws of ISCM. The numerical simulation is easy to operate and requires less equipment. The advantage of numerical simulation is that it can combine the experimental data and control any certain variable to study the quantitative relationship between ISCM and external factors. However, the numerical simulation is a hypothetical study within a certain theoretical framework. The assumptions about the internal structure of coal body and the assumptions made for the convenience of research cannot completely restored the actual situation in the process of coal adsorption. The artificially set variable is different from the variation in the actual environment, and it cannot replace the role of experiment in the study of ISCM. The studies of ISCM by numerical simulation needs to be enriched and improved.

At present, the research and theory of ISCMs is not yet abundant. The ISCM is more often studied only by the method of theoretical inversion, in which the ISCM are limited by permeability models and experimental data. In this paper, four research methods of ISCM are discussed, including theoretical inversion, experimental measurement, scanning experiments and numerical simulation. The ISCM is difficult to be fully revealed by one method, and the multiple methods should be combined and validated with each other.

6 Conclusions

Permeability changes during CBM mining can be more accurately described by the permeability models including the internal swelling coefficient of matrix (ISCM). Regarding the review of this kind of permeability models, here are the key conclusions:

-

(1)

The key aspects such as the structure of coal body, boundary conditions and influencing factors in the establishment of permeability models including ISCM were studied. The structure of coal body is usually simplified as the cubic model, which is extended as the “matrix bridge” model. With the conversion of stress paths, the permeability model under TSC can be modified into other permeability models under other boundary conditions. The Stress and gas are the main influencing factors of permeability during CBM mining. The impact of temperature or moisture should be considered for coal seams with high geothermal or water content.

-

(2)

According to the research and development process from the proposal, development, evaluation and internal structure display, the permeability models including the ISCM was reviewed, and the range of values and evolution laws of ISCM were analyzed. Although the range of ISCM is 0 to 1, the ISCM is often taken as a constant concentrated in the range of 0.1–0.5 in the references. However, the ISCM is not a constant, and it can be controlled by characteristics of matrix bridges, which is affected by the external factors such as the boundary conditions, adsorbed gas types and gas pressure and so on.

-

(3)

The current research methods for ISCMs are the theoretical inversion, experimental measurement, scanning experiments and numerical simulation. The experimental devices and method that can directly measure the three-dimensional ISCM of coal matrix were provided in this paper. Based on the advantages and disadvantages of current research methods of ISCM, the drawbacks of the research methods and the directions for improvement, as well as the potential research directions of ISCM, were pointed out. The study of ISCM should combine the theoretical inversion, experimental measurements, scanning experiments and numerical simulations to analyze and verify the influencing factors and evolution mechanisms of ISCM from multiple perspectives.

It is the goal of this review paper to identify the areas of existing research that need improvement and provide suggestions for improving the theoretical research on permeability models including the ISCM.

Availability of data and materials

The datasets used or analysed during the current study are available from the corresponding author on reasonable request.

Abbreviations

- k :

-

Coal permeability

- C f :

-

Fracture compressibility

- σ :

-

Stress

- υ :

-

Poisson’s ratio

- P :

-

Gas pressure

- ϕ :

-

The initial fracture porosity

- f :

-

Internal swelling coefficient of matrix (ISCM)

- f t :

-

Temperature internal swelling coefficient of matrix (TSCM)

- K :

-

Bulk modulus

- α :

-

Biot’s coefficient

- E :

-

Young's modulus of the matrix

- ε :

-

Strain

- ε max :

-

Maximum adsorption strain

- p L :

-

Isothermal adsorption deformation constant

- ∆:

-

The incremental value

- — :

-

Mean value

- T :

-

Temperature

- ρ c :

-

Density of coal

- R :

-

Universal gas constant

- ρ abs :

-

Density of the adsorbed phase

- E A :

-

Modulus of adsorption Induced expansion of coal

- f:

-

Fractures

- m:

-

Matrix

- s:

-

Sorption-induced strain

- e:

-

Effective stress

- i,j,k,x,y,z :

-

Coordinate axes

References

Bin W et al (2021) Research on permeability characteristics under the interaction of coal matrix and fracture. Coal Sci Technol 50:110–115

Bobo L et al (2019a) Deformation and permeability model of coal and rock considering moisture content. J China Coal Soc 44:1076–1083

Bobo L et al (2019b) Coal permeability model and evolution law considering water influence. J China Coal Soc 44:3396–3403

Bobo L et al (2020) Study on fracture compression and permeability of water-bearing coal. Chin J Rock Mech Eng 39:2069–2078

Chen Z, Liu J, Pan Z, Connell LD, Elsworth D (2012) Influence of the effective stress coefficient and sorption-induced strain on the evolution of coal permeability: Model development and analysis. Int J Greenhouse Gas Control 8:101–110

Chen S, Zhang C, Li X, Zhang Y, Wang X (2021) Simulation of methane adsorption in diverse organic pores in shale reservoirs with multi-period geological evolution. Int J Coal Sci Technol 8:844–855

Connell LD, Lu M, Pan Z (2010b) An analytical coal permeability model for tri-axial strain and stress conditions. Int J Coal Geol 84:103–114

Connell, L., Pan, Z., Lu, M., Heryanto, D.D. and Camilleri, M., (2010a.) Coal permeability and its behaviour with gas desorption, pressure and stress. Society of Petroleum Engineers

Creusot, 1980. The reservoir engineering aspects of fractured formations. The reservoir engineering aspects of fractured formations.

Cui G, Liu J, Wei M, Shi R, Elsworth D (2018) Why shale permeability changes under variable effective stresses: New insights. Fuel 213:55–71

Dong Z, Chen W, Zeng-chao F, Dong Z, Ting-ting C (2016) Experiment on the deformation of the meso-structure of coal during the methane adsorption and desorption. J China Coal Soc 41:2238–2245

Dong Z (2017) Study on the thermal and deformation effects in tthe process of methane adsorption/desorption in coal. Ph.D. Thesis, Taiyuan University of Technology

Duan S et al (2022) The evolution of permeability of coal with different water contents and the mechanism of dynamic slippage effect. Chin J Rock Mech Eng 41:798–808

Gao Z et al (2021) Coal permeability related to matrix-fracture interaction at different temperatures and stresses. J Petroleum Sci Eng 200:108428

Gao Q et al (2022) A critical review of coal permeability models. Fuel 326:125124

Guo P et al (2014) Impact of effective stress and matrix deformation on the coal fracture permeability. Transp Porous Media 103:99–115

Guo H et al (2021) Evaluation of the weakening behavior of gas on the coal strength and its quantitative influence on the coal deformation. Int J Min Sci Technol 31:451–462

Jia L et al (2022) Study on the evolution mechanism of coal permeability during gas production and coal mining. Chin J Rock Mech Eng 41:132–146

Jiang C, Yu T, Duan M, Yin W (2021) Study on permeability model under the influence of gas pressure and stress on fracture. Coal Sci Technol 49:115–121

Karacan CÖ (2007) Swelling-induced volumetric strains internal to a stressed coal associated with CO2 sorption. Int J Coal Geol 72:209–220

Li B, Yang K, Ren C, Li J, Xu J (2019) An adsorption-permeability model of coal with slippage effect under stress and temperature coupling condition. J Nat Gas Sci Eng 71:102983

Li J et al (2020) An anisotropic permeability model for shale gas recovery considering slippage effect and embedded proppants. Nat Resour Res 29:3319–3333

Li W et al (2023) A lattice Boltzmann model for simulating gas transport in coal nanopores considering surface adsorption and diffusion effects. Fuel 106:285–301

Liang Y, Tian F, Guo B, Liu Z (2021) Experimental investigation on microstructure evolution and spontaneous combustion properties of aerobic heated coal. Fuel 306:1217661–12176614

Liu S, Harpalani S (2013a) Determination of the effective stress law for deformation in coalbed methane reservoirs. Rock Mech Rock Eng 47:1809–1820

Liu S, Harpalani S (2013b) A new theoretical approach to model sorption-induced coal shrinkage or swelling. AAPG Bull 97:1033–1049

Liu S, Harpalani S (2013c) Permeability prediction of coalbed methane reservoirs during primary depletion. Int J Coal Geol 113:1–10

Liu S, Harpalani S (2014a) Compressibility of sorptive porous media: Part 1. Background and Theory AAPG Bulletin 98:1761–1772

Liu S, Harpalani S (2014b) Compressibility of sorptive porous media: Part 2. Exper Study Coal AAPG Bull 98:1773–1788

Liu H-H, Rutqvist J (2009) A new coal-permeability model: internal swelling stress and fracture-matrix interaction. Transp Porous Media 82:157–171

Liu J, Chen Z, Elsworth D, Qu H, Chen D (2011) Interactions of multiple processes during CBM extraction: a critical review. Int J Coal Geol 87:175–189

Liu S, Harpalani S, Pillalamarry M (2012) Laboratory measurement and modeling of coal permeability with continued methane production: Part 2 – Modeling results. Fuel 94:117–124

Liu T, Lin B, Yang W (2017) Impact of matrix–fracture interactions on coal permeability: model development and analysis. Fuel 207:522–532

Liu Z et al (2018) Analysis of coal permeability rebound and recovery during methane extraction: Implications for carbon dioxide storage capability assessment. Fuel 230:298–307

Liu A, Liu S, Liu P, Harpalani S (2021a) The role of sorption-induced coal matrix shrinkage on permeability and stress evolutions under replicated in situ condition for CBM reservoirs. Fuel 294:1205301–12053014

Liu A, Liu S, Liu P, Wang K (2021b) Water sorption on coal: effects of oxygen-containing function groups and pore structure. Int J Coal Sci Technol 8:983–1002

Liu T, Lin B, Fu X, Liu A (2021c) Mechanical criterion for coal and gas outburst: a perspective from multiphysics coupling. Int J Coal Sci Technol 8:1423–1435

Liu J et al (2022) Dynamic multifractal characteristics of acoustic emission about composite coal-rock samples with different strength rock. Chaos, Solitons Fractals 164:112725

Liu Z et al (2022a) Experimental investigation on the diffusion property of different form coal: Implication for the selection of CO2 storage reservoir. Fuel 318:123691–123691

Liu Z et al (2022b) Modeling and experimental study on methane diffusivity in coal mass under in-situ high stress conditions: a better understanding of gas extraction. Fuel 321:124078

Liu, Q., 2015. Damage and Permeability Evolution Mechanism of Dual-porosity Coal under Multiple Stress Paths and Its Application. Ph.D. Thesis, China University of Mining and Technology.

Lu S et al (2015) Gas desorption characteristics of the high-rank intact coal and fractured coal. Int J Min Sci Technol 25:819–825

Lu S, Cheng Y, Li W (2016) Model development and analysis of the evolution of coal permeability under different boundary conditions. J Nat Gas Sci Eng 31:129–138

Lu S et al (2019) Numerical assessment of the energy instability of gas outburst of deformed and normal coal combinations during mining. Process Saf Environ Prot 132:351–366

Lu S et al (2021) Gas time-dependent diffusion in pores of deformed coal particles: model development and analysis. Fuel 295:1205661–12056612

Lu S, Li M, Ma Y, Wang S, Zhao W (2022) Permeability changes in mining-damaged coal: a review of mathematical models. J Nat Gas Sci Eng 106:104739

Lu, S., 2016. Mechanical failure and permeability evolution mechanism of coal based on equivalent matrix scale and its application. Ph.D. Thesis, China University of Mining and Technology.

Mitra A, Harpalani S, Liu S (2012) Laboratory measurement and modeling of coal permeability with continued methane production: Part 1 – Laboratory results. Fuel 94:110–116

Palmer I (2009) Permeability changes in coal: Analytical modeling. Int J Coal Geol 77:119–126

Palmer I, Mansoori and John, (1998) How permeability depends on stress and pore pressure in coalbeds: a new model. SPE Reservoir Eval Eng 1:539–543

Pan Z, Connell LD (2012) Modelling permeability for coal reservoirs: a review of analytical models and testing data. Int J Coal Geol 92:1–44

Peng Y et al (2017) Impact of coal matrix strains on the evolution of permeability. Fuel 189:270–283

Pini R, Ottiger S, Burlini L, Storti G, Mazzotti M (2009) Role of adsorption and swelling on the dynamics of gas injection in coal. J Geophys Res. https://doi.org/10.1029/2008JB005961

Pone JDN, Hile M, Halleck PM, Mathews JP (2009) Three-dimensional carbon dioxide-induced strain distribution within a confined bituminous coal. Int J Coal Geol 77:103–108

Robertson EP, Christiansen RL (2005) Modeling Permeability in Coal Using Sorption-Induced Strain Data, SPE Annual Technical Conference and Exhibition SPE, pp. SPE-97068-MS

Rong T, Liu K, Guan C (2022) Evolution of internal swelling coefficient under different geometric conditions and its influence on gas drainage. Nat Resour Res 31:1027–1044

Rong, T., 2019. Study on permeability evolution of deep coal under the combined influence of multi-field. Ph.D. Thesis, China university of mining and technology(Beijing).

Shi JQ, Durucan S (2004) Drawdown induced changes in permeability of coalbeds: a new interpretation of the reservoir response to primary recovery. Transp Porous Media 56:1–16

Shi J-Q, Durucan S, Shimada S (2014) How gas adsorption and swelling affects permeability of coal: a new modelling approach for analysing laboratory test data. Int J Coal Geol 128–129:134–142

Shu L et al (2022) A novel physical model of coal and gas outbursts mechanism: insights into the process and initiation criterion of outbursts. Fuel 323:1243051–12430513

Shu L et al (2023) Response characteristics of gas pressure under simultaneous static and dynamic load: Implication for coal and gas outburst mechanism. Int J Min Sci Technol 33:155–171

Teng-long R, Hong-wei Z, Lu-jun W, Wei-guang R, Yi-bao G (2018) A damage-based permeability models of deep coal under mining disturbance. Rock Soil Mech 39:3983–3992

Teng-long R et al (2019) Study on coal permeability model in front of working face under the influence of mining disturbance and temperature coupling. Rock Soil Mech 40:4289–4298

Ullah B et al (2022) Experimental analysis of pore structure and fractal characteristics of soft and hard coals with same coalification. Int J Coal Sci Technol. https://doi.org/10.1007/s40789-022-00530-z

Wang K, Zang J, Wang G, Zhou A (2014) Anisotropic permeability evolution of coal with effective stress variation and gas sorption: Model development and analysis. Int J Coal Geol 130:53–65

Wang K et al (2022) A numerical investigation of hydraulic fracturing on coal seam permeability based on PFC-COMSOL coupling method. Int J Coal Sci Technol 9:183–199

Xiao Z, Wang C, Wang G, Jian Y, Yu J (2021) Influences of matrix-fracture interaction on permeability evolution: considering matrix deformation and stress correction. Chin J Geotech Eng 43:2209–2219

Xue S et al (2021) Coal permeability models for enhancing performance of clean gas drainage: a review. J Petroleum Sci Eng 199:108283

Xuehai F, Qi Q, Ming C, Baoxin Z (2022) Review of research on test, simulation and prediction of coal reservoir permeability. J China Coal Soc 47:2369–2385

Yi M, Wang L, Hao C, Liu Q, Wang Z (2021) Method for designing the optimal sealing depth in methane drainage boreholes to realize efficient drainage. Int J Coal Sci Technol 8:1400–1410

Zang J, Wang K, Zhao Y (2015) Evaluation of gas sorption-induced internal swelling in coal. Fuel 143:165–172

Zhang J, Feng Q, Zhang X, Wen S, Zhai Y (2014) Relative permeability of coal: a review. Transp Porous Media 106:563–594

Zhang S, Liu J, Wei M, Elsworth D (2018) Coal permeability maps under the influence of multiple coupled processes. Int J Coal Geol 187:71–82