Abstract

Using goof as water storage space plays a vital role in the ecological environment and economic development of arid mining areas, while the rock strength and the stability of coal pillars in underground water reservoirs are closely related to creep process. In this work, triaxial creep-seepage tests were conducted for coal samples to develop new insights into the creep behavior and permeability evolution. The results showed that the creep deformation and permeability evolution of coal samples exhibit three stages, namely, the compaction hardening stage before the stress threshold, volumetric compaction stage, and volumetric dilatancy stage. The coal permeability decreases first and then increases with the creep strain and it is well correlated with the variation of volumetric strain.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Underground water reservoir technology is an effective approach to mitigate the potential damages to water resources in arid regions, which exploits the interspace in the goaf formed by coal mining, connects the section coal pillars with artificial dams, and builds mine-water storage and intake facilities, initially achieving simultaneous extraction of coal and water Gu 2015; Kong et al. 2021; Yao et al. 2019, 2020; Zhang et al. 2021a; Zhao et al. 2021).

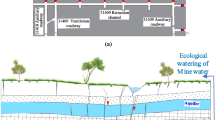

The creep process of a coal pillar dam is one of the key factors that determines the stability of an underground reservoir. As shown in Fig. 1, the coal pillar dam is not only subjected to the triaxial pressure, but also the hydraulic pressure in the bedding direction of the coal seam (Tang et al. 2019). Therefore, the design of a coal pillar dam must consider the creep behavior (Namjesnik et al. 2022). Time-dependent deformation is significant as a long-term process influencing coal permeability (Yang et al. 2015; Zhou et al. 2019, 2020). However, the permeability evolution during the coal creep deformation has not yet been well understood. For development and improvement of sustainable techniques and approaches to mining, understanding of the creep behavior and permeability evolution of coal is critical in engineering analysis of the construction of underground reservoirs or the excavation and stability of access paths/tunnels in coal seams (Zhang et al. 2021b, c, 2022).

Schematic diagram of underground reservoir in coal mine and analysis of force of coal pillars (Tang et al. 2019)

In the present study, triaxial creep-seepage tests are applied to coal samples from underground water reservoir. The relationship between creep behavior and permeability evolution for coal is quantitatively studied.

2 Coal samples and testing scheme

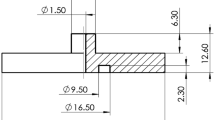

Triaxial creep-seepage tests are performed at ambient temperature of 25 ℃ with rock servo-controlled triaxial equipment (Fig. 2) under drained condition. The cylindrical samples are taken from the Meihuajing coal mine in Ningxia Hui Autonomous Region of China. The specimens have a length of 100 mm and a diameter of 50 mm.

Two coal specimens are tested under different axial stress conditions. Before the test, all samples are fully saturated with water in vacuum. The samples are loaded to the hydrostatic pressure of 2 MPa at a rate of 0.1 MPa/s. Then the axial stress is increased stepwise to a predetermined value until the failure of samples, under a constant radial stress of 2 MPa. A pore pressure of 1 MPa is applied to the samples, and the permeability is measured, keeping the stress state unchanged. The steady state method is employed to determine the permeability of coal. The details on permeability test principle can be found in Zhou et al. (2019).

3 Results and discussion

3.1 Creep deformation

The strain and permeability evolution versus time during the creep tests are shown in Fig. 3. The strain and strain rate as well as permeability at each stress level are plotted in Fig. 4. The axial strain behavior gradually presents time-dependent creep characteristics. The volumetric strain switches from compaction-dominated to dilatancy-dominated. Correspondingly, the permeability firstly decreases and then increases. Therefore, in the creep test of coal, a threshold stress exists.

Under low stress, the coal samples just show transient strain. As the stress is increased, the axial strain exhibits time-dependent deformation, that is, decelerating creep rate and steady state creep. Under high pressure, the axial strain increases significantly with time, showing an accelerating creep stage. Coal sample 1 fails intermediately when loaded to axial stress of 22.5 MPa. Failure of coal sample 2 is finally induced by compressive cataclastic failure during accelerating creep stage owing to the growth and coalescence of cracks.

Under low axial stress, volumetric strain shows transient response and no time-dependence. With the gradual increasing stress, the volumetric strain increases correspondingly. As the stress continues to increase, the volumetric strain turns to decrease, indicating that the volumetric strain switches from the compaction to dilatancy. Under higher stress, the volumetric dilatancy is more significant.

3.2 Permeability evolution

The permeability decreases first and then increases during creep. As shown in Fig. 4, under low axial stress, the permeability decreases slowly. As the creep time increases, the permeability of the coal sample shows a downward trend. After a period of creep deformation, the permeability decreases slightly with the increase of axial stress. As stress increases, the permeability continues to decrease but with a larger decreasing rate. When the stress threshold is reached, the volumetric strain switches from the compaction to dilatancy, and the permeability increases gradually due to the crack development in the sample. The creep deformation and permeability evolution of each sample have three stages: (1) compaction hardening stage, (2) volumetric compaction stage, (3) volumetric dilatancy stage.

-

(1)

Compaction hardening stage This stage corresponds to the stress up to the stress threshold of creep. As the axial stress is increased from hydrostatic pressure of 2 MPa up to the threshold stress, just transient strain is observed without significant time-dependent volumetric deformation. Correspondingly, the permeability decreases slowly in this stage. This is due to the transient compaction and closure of microcracks in the coal under loading. The seepage channels are narrowed, thus contributing to the decrease of permeability.

-

(2)

Volumetric compaction stage As the stress reaches the stress threshold of creep, the coal deformation shows decelerating creep and steady creep in addition to the transient deformation in this stage. Meanwhile, the volumetric deformation shows time-dependent compressive deformation. At each stress level, the permeability continues decreasing with creep until keeping constant when the axial strain and volumetric strain stabilize. This may be attributed to the microstructural adjustment, such as particle dislocation and sliding, etc., under a stress above the threshold. The axial strain gradually exhibits time-dependent decelerating creep with an increase of compressive volumetric strain. The seepage channels are compacted continuously in the process of microstructural adjustment, resulting in a lower permeability. The continuous microstructural adjustment of coal results in equilibrium and uniform distribution of deformation adjusting to meet the new stress state, meaning that the coal sample enters steady creep stage. At the same time, the volumetric compressive strain rate and permeability tend to stabilize.

-

(3)

Volumetric dilatancy stage With the increase of stress level, the axial strain increases significantly, showing accelerating creep characteristics. The volumetric strain turns to decrease as volumetric dilatancy gradually becomes predominant, as a result the permeability begins to increase gradually. This is mainly caused by the accumulation of continuous creep deformation. In this stage the internal damage develops rapidly as well as the seepage channels. Thus dilatancy strain and permeability increase rapidly.

3.3 Relation between stress-strain and permeability evolution

The relation of permeability-axial strain is presented in Fig. 5, and permeability-volumetric strain in Fig. 6. The permeability evolution is closely correlated with the axial strain as well as volumetric strain. The evolution of permeability with volumetric strain is similar to that of permeability with axial strain. The overall permeability evolution is well correlated with the change of volumetric strain.

4 Conclusions

This article reports the results of triaxial creep-seepage tests of coal cored from an underground water reservoir. The time-dependent deformation and permeability evolution in coal pillars for dams in underground storage reservoirs are studied in course of creep tests. The results lead to the following conclusions: (1) The creep deformation and permeability evolution of coal samples undergoes three stages, namely, the compaction hardening stage before the stress threshold, volumetric compaction stage, and volumetric dilatancy stage. The curves of permeability variation–strain show the obvious non-linearity and the evolution feature of each stage. (2) The coal permeability decreases first and then increases with the creep strain and it is well correlated with the variation of volumetric strain. (3) There is a threshold stress existing in the process of transition from compression to dilatancy. Therefore, the volumetric strain can be a good indicator of rock damage and offer a different viewpoint to determine the long-term strength.

References

Gu DZ (2015) Theory framework and technological system of coal mine underground reservoir. J China Coal Soc 40(2):239–246

Kong XS, Xu ZZ, Shan RL, Liu S, Xiao SC (2021) Investigation on groove depth of artificial dam of underground reservoir in coal mines. Environ Earth Sci 80:214

Namjesnik D, Kinscher J, Contrucci I, Klein E (2022) Impact of past mining on public safety: seismicity in area of flooded abandoned coal Gardanne mine, France. Int J Coal Sci Technol 9(1):90. https://doi.org/10.1007/s40789-022-00558-1

Tang CJ, Yao QL, Li ZY, Zhang Y, Ju MH (2019) Experimental study of shear failure and crack propagation in water-bearing coal samples. Energy Sci Eng 7:2193–2204

Yang SQ, Xu P, Ranjith PG (2015) Damage model of coal under creep and triaxial compression. Int J Rock Mech Min Sci 80:337–345

Yao QL, Chen T, Tang CJ, Sedighi M, Wang SW, Huang QX (2019) Influence of moisture on crack propagation in coal and its failure modes. Eng Geol 258:105156

Yao QL, Tang CJ, Xia Z, Liu XL, Zhu L, Chong ZH, Hui XD (2020) Mechanisms of failure in coal samples from underground water reservoir. Eng Geol 267:105494

Zhang C, Wang FT, Bai QS (2021a) Underground space utilization of coalmines in China: a review of underground water reservoir construction. Tunn Undergr Space Technol 107:103657

Zhang L, Huang MQ, Xue JH, Li MX, Li JH (2021b) Repetitive mining stress and pore pressure Effects on Permeability and Pore pressure sensitivity of Bituminous Coal. Nat Resour Res 30:4457–4476

Zhang L, Li JH, Xue JH, Zhang C, Fang XQ (2021c) Experimental studies on the changing characteristics of the gas flow capacity on bituminous coal in CO2-ECBM and N2-ECBM. Fuel 291:120115

Zhang L, Huang MQ, Li MX, Lu S, Yuan XC, Li JH (2022) Experimental study on evolution of fracture network and permeability characteristics of bituminous coal under repeated mining effect. Nat Resour Res 31:463–486

Zhao J, Konietzky H, Herbst M, Morgenstern R (2021) Numerical simulation of flooding induced uplift for abandoned coal mines: simula?tion schemes and parameter sensitivity. Int J Coal Sci Technol 8:1238–1249. https://doi.org/10.1007/s40789-021-00465-x

Zhou HW, Wang LJ, Rong TL, Zhang L, Ren WG, Su T (2019) Creep-based permeability evolution in deep coal under unloading confining pressure. J Nat Gas Sci Eng 65:185–196

Zhou HW, Zhang L, Wang XY, Rong TL, Wang LJ (2020) Effects of matrix-fracture interaction and creep deformation on permeability evolution of deep coal. Int J Rock Mech Min Sci 127:104236

Acknowledgements

This work is supported by National Natural Science Foundation of China (52009131) and Open Funds of State Key Laboratory of Water Resource Protection and Utilization in Coal Mining (GJNY-20-113-05 and GJNY-20-113-04).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare that they have no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Chen, Y., Hao, X., Xue, D. et al. Creep behavior and permeability evolution of coal pillar dam for underground water reservoir. Int J Coal Sci Technol 10, 11 (2023). https://doi.org/10.1007/s40789-023-00563-y

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40789-023-00563-y