Abstract

Efficient and accurate monitoring and early warning of coal dynamic disaster and other disasters can provide guarantee for the efficient operation of mine transportation system. However, the traditional threshold early warning method often fails to warning some accidents. To address above issues, a new early warning method was proposed based on "quiet period" phenomenon of AE and EMR during fracture. It is found that, a "quiet period" of AE and EMR was present before the load reaches the peak stress, which could be used as one of the precursors to warn the imminent failure of coal and rock specimens. MS and AE signals increased abnormally followed by the phenomenon of "quiet period" before the occurrence of coal dynamic disaster on site, and the decrease of MS events in the "quiet period" is about 57%–88% compared with that in previous abnormal increase stage. During the damage evolution of coal and rock, "quiet period" phenomenon usually occurred at 85%–90% of the peak stress, where the slope of damage parameter curve is almost zero. The "quiet period" of the AE-EMR signals and the low change rate of damage parameter before failure provide a theoretical foundation for the coal dynamic disaster warning based on the "quiet period" precursor found in MS-AE-EMR monitoring system. These findings will help reduce the number of under-reported events and improve early warning accuracy.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

In recent years, with the development of high-yield and efficient mine construction and intensive production, the degree of mining mechanization has been gradually improved, and the coal transportation in the mine has realized the belt and automation from the working face to the shaft bottom yard and the ground (Pan et al. 2021). However, due to the restriction of mine dynamic disasters, the development of mine transportation system is limited (Ding et al. 2019). It is mainly reflected in that the mines with mine dynamic disasters often have large mine pressure and serious deformation. What's worse, after coal dynamic disasters, the underground roadway will collapse in a large area and destroy the mine transportation system, which is not conducive to the improvement of the automation level of coal mine transportation. Efficient and accurate monitoring and early warning technology is the key to prevent and control mine coal dynamic disaster and other disasters (Xie 2019), and it is also the guarantee for the policy operation of mine transportation system (Binay and Arun 2019).

However, with the increase of the construction depth coal mines, the encountered dynamic disturbance showed a significant growth trend. Meanwhile, the structure and basic mechanical response of rock mass and coal undergo fundamental changes, leading to continuously increased coal dynamic disaster counts and intensities (Jiang et al. 2018). By 2021, more than 140 rock burst coal mines in China, and disasters occur from time to time. On February 22, 2020, a rock burst accident occurred in Xinjulong coal mine in Shandong Province, China, killing four miners. On October 11, 2021, a rock burst accident occurred in Hujiahe coal mine in Shaanxi Province, China, killing four miners. On February 25, 2022, a roof collapse accident occurred in Sanheshunxun coal mine in Guizhou Province, China, killing fourteen miners. The cause factors of coal dynamic disaster are complicated and the early warning of hazards is challenging. With the growing mine safety concern worldwide, the coal dynamic disaster warning has become a hot research topic in this field. Now the rapid developments have been made in the field for the prevention and coal dynamic disaster control around the world (Pan et al. 2015; Bai et al. 2022).

In terms of monitoring and early warning of rock burst, the commonly used monitoring and early warning technologies mainly include the traditional drilling cuttings method and the geophysical technology developed in recent years. The latter includes early warning technology of micro-seismic (MS) monitoring, the elastic wave CT test, underground sound monitoring and acoustic emission (AE) monitoring, as well as the monitoring and early warning technology of electromagnetic radiation (EMR). Compared with drilling cuttings method, geophysical technology method does not need drilling test, and has the advantage of nondestructive monitoring. In field application, MS monitoring technology has the advantages of real-time, dynamic and continuous monitoring, and EMR monitoring has the advantages of non-contact, continuous monitoring and relatively simple layout. Precursors found to early warn the coal dynamic disaster occurrence have been explored in several studies. Two seismic damage indices (cluster index and degradation index) according to MS monitoring information aimed to identify and quantify rock mass degradation were introduced by Falmagne (2001). Frid and Vozoff (2005) reported that the anomalously high EMR signals was detected before roof fall. Song et al. (2017) concluded that when the EMR reaches a certain intensity, it indicates that the strain and rupture of the coal or rockmass is reaches the threshold and coal dynamic disaster may occur at any time soon. Cao et al. (2015) used tomography technology to analyze the coal dynamic disaster risk region and proposed that high wave velocity anomaly coefficient An and wave velocity gradient anomaly VG correspond to high coal dynamic disaster risk. Feng et al. (2015) proposed a MS method for the dynamic warning of coal dynamic disaster development in tunnels. Cao et al. (2016) proposed bursting strain energy index Wes, and it was further used for short-term spatial–temporal early warning of coal dynamic disaster. The temporal sequence curve indicates that the levels of coal dynamic disaster risk can be quantitatively and rapidly analyzed in short time window using the corresponding intervals (0 ≤ Wes < 0.25, 0.25 ≤ Wes < 0.5, 0.5 ≤ Wes < 0.75 and Wes ≥ 0.75, for no, low, moderate and high coal dynamic disaster risk, respectively). Dai et al. (2016) used apparent volume VA and apparent stress σA to forecast rock mass deformation in hydropower station. They concluded that a sharp increase in apparent stress associated with a steady increase in apparent volume can be seen as a precursor to rock mass deformation. Cai et al. (2018) constructed a multi-parameter warning model using MS multi-dimensional warning indicators. The corresponding intervals of coal dynamic disaster risk assessment index Vindex are: 0 ≤ Vindex < 0.25, 0.25 ≤ Vindex < 0.5, 0.5 ≤ Vindex < 0.75 and Vindex ≥ 0.75, for no, low, moderate and high coal dynamic disaster risk, respectively. Qiu et al. (2020a, b) found the coal low frequency EMR exhibited a sharp increase for a period of time before the occurrence of dynamic appearance. He et al. (2021) proposed early warning indicators such as Fr, Dp, DF, DME, DAE, and Ds by mining a large amount of MS and AE monitoring data, and achieved accurate early warning of partial coal dynamic disaster by using criteria of high critical values.

At present, the wide application of AE and EMR technology in coal mine have improved the timeliness of monitoring and early warning of coal rock dynamic disasters, compared with the traditional drilling cuttings technology, which was recognized by miners and technicians. However, the existing warning methods mainly warn through high critical threshold approach. Some coal dynamic disaster accidents are still failed to foresee using the current warning criteria. Due to the complexity of coal and rock failure, the corresponding relationship between EMR, AE and coal rock damage is not very accurate, which leads to the unclear precursor characteristics of dynamic disasters. At present, in the application of AE and EMR technology, the main work is to reveal the signals response law before disasters such as rock burst, accurately identify precursor information and make accurate prediction (Qiu et al. 2020a, b). How to quickly and efficiently identify the precursory signals of coal and rock damage and accurately monitor and warn the dynamic disasters is the future development trend of this technology. A large amount of MS and EMR monitoring data in the field indicates a phenomenon of "quiet period" before the occurrence of coal dynamic disaster (Tan et al. 2015; Jiang et al. 2016). Whether the "quiet period" can be used as effective precursor for early warning of those missed coal dynamic disaster accidents using existing criterion deserves in-depth investigation.

In order to accurately capture the precursory information of coal and rock damage and improve the accuracy of disaster monitoring and early warning, the characteristics of the "quiet period" of the AE and EMR signal before the failure of coal and rock specimens during uniaxial loading explored firstly. Then, the MS and AE signals before the occurrence of coal dynamic disaster in coal mines is studied. Finally, the mechanism resulting in the signal "quiet period" is explained. These research results are of great significance to further improve the accuracy of coal dynamic disaster warning. At the same time, it is conducive to ensure the safety of mine transportation system and promote the development of mine transportation automation and intelligence.

2 Experimental design and methods

2.1 Experimental system

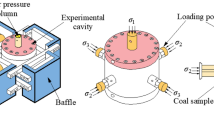

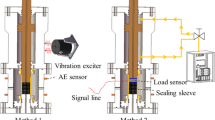

The stress-AE-EMR experimental system is shown in Fig. 1. The system consists of loading system (SANS microcomputer-controlled servo press), electromagnetic shielding system, AE acquisition system (DS5-16C), and EMR acquisition system (CTA-1). The electromagnetic shielding system has a comprehensive shielding effectiveness of more than 75 dB, which reduces the interference of stronger external electromagnetic fields on the experimental signal. The AE data acquisition system has 16 channels, which can collect AE parameters in any time, the sensor response frequency range is 50–400 kHz. EMR sensor adopts circular magnetic field antenna, the receiving frequency range is 20 Hz to 2 MHz. The AE-EMR system includes preamplifier, filter circuit, A/D conversion module, filter processing module and computer. The amplification factor of AE preamplifier is 20, 40 and 60 dB, and the amplification factor of EMR amplifier is 80, 78, 76, 72 and 64 dB, respectively. Since we mainly analyze the variation characteristics of AE and EMR in this work, and we don't pay special attention to their absolute values, obtaining significant signals is our goal. In order to avoid that the signal is too strong beyond the range of the acquisition instrument or too weak to analyze, after a large number of tests, we find that the signals obtained are the best. when the AE and EMR are in the amplification gear of 40 and 64 dB, respectively. The outer skin of the connecting wire of acoustic emission and electromagnetic radiation is wrapped with a shielding layer to ensure that the sensors will not affect each other.

2.2 Specimen preparation and experimental methods

The sample is made of large coal and roof rock obtained from the coal mine. By coring and grinding, coal and rock are made into cylindrical specimens with a size of ϕ 50 mm × 100 mm. The specimens were flat at both ends, and the specimens that did not meet the dimensional requirements or had obvious fissures were excluded. It should be noted that specimens are prepared parallel to bedding. After the sample is prepared, it is placed in the drying room and dried for more than 10 days. Five coal and five rock specimens were selected for experiments, numbered C1, C2, C3, C4, C5 and R1, R2, R3, R4, R5, respectively. Coal rock specimens are shown in Fig. 2. The uniaxial compression tests of coal and rock specimens were performed by stress-controlled loading with loading rates of 10 N/s and 200 N/s, respectively. The layout of sensor and specimen is shown in Fig. 3. AE sensor was attached to the surface of the specimen, and EMR sensor was arranged 5 cm near specimen parallel to the loading direction.

3 Experimental results

3.1 AE response characteristics before coal and rock failure under load

Figure 4 shows the temporal evolution of accumulative AE energy, accumulative AE pulses and stress during uniaxial loading of coal and rock specimens. The evolution of the accumulative AE energy and pulses during the loading of coal specimens can be divided into five stages: (oa), (ab), (bc), (cd), and (de) (Fig. 4a, b). In the initial loading stage (oa), the original pores and fissures inside the coal sample are compacted and tend to close, leading to linearly and slowly increase of AE pulses and energy. After the original fractures are closed and the elastic deformation stage (ab) is experienced; the AE activity decreased and the accumulative AE energy and pulses were almost unchanged. With the further increase of the load, new fractures inside the coal sample start to develop (bc) and a large number of AE events occur, showing a rapid growth trend of accumulative AE energy and pulses. In the (cd) stage, AE showed an obvious phenomenon of "quiet period" with unchanged accumulative AE energy and pulses. In Fig. 4a, the length of stage (cd) exceeds 50 s, which shows that during this period, there is no obvious fracture in coal, and the crack propagation is basically stagnant. The existence of stage (cd) indicates that the internal damage accumulation of coal body has stagnated and silent before the main fracture. Although AE pulses and energy of the rock in Fig. 4c did not stagnate at this time, its increasing speed decreased significantly. Compared with the subsequent main fracture process, the silence phenomenon is also obvious. The AE activity is intense at the final stage (de), and the AE pulses and energy increase significantly. The accumulative AE energy and pulses in stage (de) grow faster than that in stage (bc), which is closely related to the load intensity. In stage (de), the microcracks starting to expand, penetrate, and form macroscopic rupture until the coal specimen is completely destroyed. The evolution of the accumulative AE energy and pulses during the loading of rock specimens is shown in Fig. 4c, d. Compared with the results when loading coal specimens, there are only two stages: (oa) and (ab). The AE events at (ab) stage are more frequent and have greater amplitudes than that at (oa) stage. Before the failure of rock specimen, it can be found that the phenomenon of "quiet period" is also exhibited near point a, and the AE energy and pulses are almost zero in this period.

The possible reason for the "quiet period" of AE is that the energy stored inside the specimen is consumed during the microcrack formation process, and the energy consumption rate is larger than the energy accumulation rate inside the coal and rock sample under the stress. When the internal residual energy is not enough to make the cracks continue to expand, the AE activity is weakened. As the load increases, the specimen starts to seek a new equilibrium and the energy starts to accumulate, and when the accumulated energy reaches a certain level, the microscopic cracks start to expand and coalesce until collapse (Li et al. 2016). The phenomenon of AE "quiet period" during uniaxial compression can be regarded as a precursor for coal and rock failures.

3.2 EMR response characteristics before coal and rock failures under load

Frid et al. (2003) and Rabinovitch et al. (2017) concluded that the oscillating dipole generated by the breakage of chemical bonds at the crack tip is the source of EMR during crack generation in coal and rock bodies. It is closely related to the crack generation and expansion. Figure 5 shows the evolution law of accumulative EMR energy, accumulative EMR pulses, and stress during uniaxial compression of coal and rock specimens. The evolution of the accumulative AE energy and pulses during the loading of coal and rock specimens can be divided into five stages: (oa), (ab), (bc), (cd), and (de). It can be seen from the figure that the EMR signals are generated at the initial loading stage of the coal and rock specimen, mainly generated by the crushing closure of the original pores and cracks inside the coal and rock at the loading stage. Accumulative EMR energy and pulses show a linear growth trend (oa). After the original pores and cracks closed, it entered the elastic deformation stage (ab); the EMR signal decreases and the accumulative EMR energy and pulses are almost unchanged. Subsequently, with the increase of load, new internal microcracks are presented randomly (bc) and the EMR signal is generated intermittently. After the initial formation of microcracks, the energy stored inside the coal and rock specimen is partially consumed, and the energy consumption rate is larger than the energy accumulation rate under load. The energy stored inside the coal and rock specimen is not enough to make the crack expand. The EMR signal appears as a "quiet period" phenomenon at stage (cd), with the accumulative EMR energy and pulses remain unchanged. Similar to the phenomenon of AE, in the "quiet period" coal basically does not produce EMR signal, and the stage (cd) of coal is much longer than that of rock. As the load increases, the specimen starts to seek a new equilibrium and the energy starts to accumulate, and when the accumulated energy reaches a certain level, the new equilibrium is broken and the cracks start to expand and coalesce, producing new crack tips and increasing the EMR activity. Due to the difference in load intensity, the accumulative EMR energy and pulses in stage (de) grows faster than stage (bc).

Generally speaking, during loading, the numbers of AE and EMR signals show a good positive correlation with the stress, but more accurate observation shows that they are not synchronized, especially in stage (cd). Although the stress still increases linearly, coal hardly produces EMR and AE signals, and the signals produced by rock are also less. This shows that the "quiet period" phenomenon exists objectively. After stage (cd), coal and rock will be destroyed soon. The releasable strain energy stored inside coal and rock during the "quiet period" is not enough to extend the existing cracks, but can accumulate energy for the main fracture. Therefore, the "quiet period" phenomenon of stage (cd) can be regarded as the precursor of coal and rock destruction, and this precursor is very obvious and easy to capture and analyze.

4 MS-AE temporal variation before coal dynamic disaster

With the aim of exploring whether there is a "quiet period" before the larger-scale fractures of coal and rock mass in the field as those found during uniaxial tests, further researches have been carried out in a case study mine—Wudong coal mine.

Wudong coal mine is located in the northeast of Xinjiang Autonomous Region, China. The East–West length of the mine field is 10.8 km, the North–South width is 0.7 to 2.7 km, and the mine field area is 20.28 km2. The proven amount of coal resources in the mine field is 1.28 billion tons, and the design production capacity is 6.0 Mt/a.

Badaowan syncline and Qidaowan anticline exist within the mine field of Wudong Coal Mine. The north mining area of Wudong Coal Mine is located in the north wing of Badaowan syncline. The coal bearing system is Jurassic sandstone, mudstone and Quaternary loose sedimentary layer. The stratum attitude of the mining area is 155° to 159°, and the dip angle is 43° to 51°. The total thickness of coal bearing stratum is 164.29 m, and the coal content coefficient is 21.54%. The coal types are low metamorphic bituminous coal, long flame coal, etc.

The coal seam structure in Wudong Coal Mine is simple. The main coal seams in the north mining area of Wudong Coal Mine are the No. 43 and the No. 45 coal seams. The thickness of the two coal seams is 28 m and 21 m respectively. The strike of the coal seam is 247°, the dip is 157°, and the dip angle is 45°.

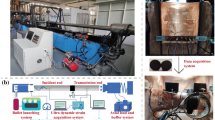

4.1 Evolutionary characteristics of MS signals

MS monitoring system mainly aims to detect large-scale failures that generate low-frequency high-energy MS signals with a regional monitoring range about 4 km (Li et al. 2018). The Wudong mine is a typical coal dynamic disaster-prone mine. Three severe coal dynamic disaster accidents occurred in the + 450 level of B3 + 6 coal seam on November 24, 2016, February 1, 2017, and April 26, 2017 since mining started. The energy value of these coal dynamic disaster accidents is 9.5 × 106 , 2.1 × 108 , 2.2 × 106 J, respectively. MS monitoring system is now used for coal dynamic disaster risk monitoring and early warning.

The Fig. 6 shows the temporal evolution of daily MS total energy during a month before the occurrence of the three coal dynamic disaster accidents. Through the analysis of MS waveform, the energy value contained in each event is calculated and accumulated according to one day as a statistical cycle. The daily MS total energy decreases significantly before the occurrence of coal dynamic disaster, showing a "quiet period” of MS activity, and the number of high-energy MS events also decreased during this period. The main reason of "quiet period” is that in the early stage, under the action of high stress, the coal and rock in the stress concentration area ruptured to produce a large number of MS events, and the elastic deformation energy accumulated in the coal and rock was released in a large amount. Then, the energy inside is not sufficient to destroy the new equilibrium, so the MS activities of the roof, floor and coal sample enter the "quiet period", resulting in a decrease in the daily MS total energy. During the "quiet period", the high stress still acts on the coal and rock, and the inner energy starts to accumulate. When the accumulated energy reaches the limitation, the coal dynamic disaster is triggered by the external dynamic disturbance. In response, the energy is suddenly released and the daily MS total energy increases sharply.

The daily MS total energy before the coal dynamic disaster also shows a "quiet period" phenomenon, which again indicates that the phenomenon of "quiet period" can be one of the precursors of coal and rock failure and coal dynamic disaster.

The temporal-spatial evolution of the MS sources in 9 days before the occurrence of coal dynamic disaster is shown in Fig. 7. The figures show the location of each MS event on different dates. Two types of anomalies are shown during this period: abnormal increase of MS events and "quiet period". The MS events decreased significantly from 1 to 2 days before the occurrence of the "11·24", "2·1", "4·26" coal dynamic disaster accidents, and the number of events decrease 57.1%, 85.7% and 88.2% respectively compared with the previous abnormal increase stage, showing the phenomenon of "quiet period". Due to the release of a large amount of elastic deformation energy accumulated in the coal and rock mass during the abnormal increase stage, the elastic deformation energy stored inside the coal and rock is not enough to make the cracks expand, and it starts to accumulate gradually under the action of high stress. On the day of coal dynamic disaster, the MS events gather again, and the high-energy events (energy > 103 J) increase significantly, indicating that the energy stored inside the coal and rock is enough to break the equilibrium at this time, causing the internal cracks develop, expand and form macroscopic failure. Then, the energy is released instantaneously to induce coal dynamic disaster. The phenomenon of "quiet period" on the temporal sequence of mine-scale MS events again is line with the one found in previous analysis.

Figure 6 shows the time variation characteristics of energy dissipation of coal and rock before rock burst, while Fig. 7 shows the spatial distribution characteristics. Both reveal the energy dissipation of coal and rock before rock burst, and both of them show the phenomenon of "quiet period".

4.2 Evolutionary characteristics of AE signals

The AE monitoring system is mainly used to monitor the microcracking that generates high-frequency low-energy AE signals, with a local monitoring range about 50 m. The KJ623 AE monitoring system is now employed in the Wudong coal mine for joint monitoring and early warning of coal dynamic disaster risk. The temporal evolutions of AE pulses and AE energy within 24 h before the occurrence of the "11·24", "2·1", and "4·26" coal dynamic disaster accidents are shown in Fig. 8. A few hours before coal dynamic disaster occurs, the number and energy of AE pulses experience an abnormal increase followed by a "quiet period" phenomenon, which lasts for several hours, after which coal dynamic disaster occurs. The existence of "quiet period" before coal dynamic disaster has two possibilities: (1) it indicates that the microcrack generation and expansion activity inside the coal and rock is weakened, and the input elastic deformation energy starts to accumulate at this time under the action of surrounding stress, preparing for the subsequent emergence of larger damage events; (2) the microcrack starts to expand and coalesce, exceeding the range of the frequency band monitored by the AE monitoring system, and larger damage is about to occur. Overall, the phenomenon of "quiet period" after the abnormal increase of AE energy and pulse can be used as one of the precursors for coal dynamic disaster early warning, supplementing with MS precursors.

Response characteristics of AE and EMR signals during the uniaxial compression of laboratory specimens and the evolution law of MS and AE signals before the occurrence of coal dynamic disasters show that the AE-EMR signals before the failure of coal and rock and the occurrence of coal dynamic disaster have a "quiet period" phenomenon. Therefore, the "quiet period" phenomenon can be used as one of the precursors for the imminent failure of coal and rock specimens or the occurrence of coal dynamic disaster, which can supplement the existing monitoring and warning methods, reduce the missing warning rate and improve warning accuracy.

The phenomenon in the laboratory is the result of small-scale coal and rock failure, and the phenomenon in the coal mine site is the result of large-scale coal and rock failure. Although the scale of the two is different, the mechanism is the same. In the previous research on coal mine dynamic disasters monitoring and early warning technology, it is generally carried out in this way. Liu and Wang (2018) studied the law of EMR signal generated in the process of coal and rock failure in the laboratory, and applied it to the early warning test of EMR signal generated by surrounding rock of Hongtoushan copper mine. Li (2020) established a gas bearing coal load failure experimental system, studied the EMR characteristics of gas bearing hard coal under different conditions, and applied it to the monitoring and early warning of a mine.

The existing warning methods mainly warn through high critical threshold approach, often fails to warning some accidents which don’t lead a growth of AE or EMR. This method proposed in our work will be able to identify these phenomena and help reduce the number of under-reported events and improve early warning accuracy. If there is a "quiet period" in the continuous growth of AE or EMR signals, disasters are likely to occur if factors such as man-made risk relief activities can be eliminated. It should be noted that, our method is not to give early warning of low value, but to give early warning of calm period in growth period. The mechanism of coal and rock dynamic disasters is particularly complex, and more work is needed for more accurate early warning.

5 Discussion

The above laboratory and field research results show that the phenomenon of "quiet period" in the AE and EMR signals occurs before the failure of coal and rock specimens or coal dynamic disaster. Under high stress, coal and rock experience micro deformation, macro fracture and final failure, and its internal damage experienced the failure process from rheology to mutation. In this paper, the damage parameters (abbreviated as D) proposed by Tang and Xu (1990) were used to investigate the internal damage evolution of coal and rock specimens and to reveal the causes of the "quiet period" of AE and EMR signals under uniaxial compression. D was calculated as follows.

where Sm represents the initial cross-sectional area of the specimen, S′ represents the effective area, S represents the area of the damaged cross-section. D ranges from 0 to 1, D = 0 means the specimen without any damage, D = 1 corresponds to the complete damage of the specimen, which is only a reference condition.

The evolution of damage parameters of coal and rock specimens during uniaxial loading is shown in Fig. 9. The damage parameters of coal and rock specimens in the OA loading stage show an increasing trend related to the existence of original pores and fissures inside the coal and rock specimens. The damage parameters in OA stage increase when the original pores are closed under the action of load and the effective bearing area S′ is reduced. After the original pores and fissures are closed under the load, with the further increase of the load, the coal and rock specimens in AB stage are gradually compacted, the effective bearing area S′ increases and the damage parameter decreases. The change rate of damage parameters before and after the point B (generally corresponding to 85%–90% of the peak loading stress) is almost zero, indicating that the damage inside the coal and rock does not continue to expand at this time. The "quiet period" in the AE and EMR signals (Figs. 4, 5) is consistent with the period where damage parameters remaining unchanged during the tests. All of EMR, AE and MS are generated in the process of coal and rock fracture. The difference is that AE and MS are mechanical waves, which is the coal and rock vibration caused by crack propagation in the process of coal and rock fracture, while EMR is electromagnetic wave, which is excited by charge motion caused by stress and crack propagation. Therefore, all of them are related to damage, the energy accumulation and dissipation of coal and rock. According to the principles of MS, AE, and EMR signal generation, the constant damage parameters before the peak stress can be the explanation for the "quiet period" phenomenon in AE and EMR signals.

Xie et al. (2008) obtained the energy equation for the deformation of the coal and rock under external stresss with the assumption that there is no heat exchange with the surrounding environment:

where Ui represents the total energy input to the coal and rock specimen during the work of the external stress, Uid represents the energy consumed by the damage and deformation of the coal and rock under the action of the external stress, \(U_{i}^{d} = U_{i}^{a} + U_{i}^{b}\). Uis represents the releasable strain energy stored in the coal and rock,\(U_{i}^{s} = U_{i}^{e} + U_{i}^{f}\), as shown in Fig. 10.

Relationship between dissipated energy and releasable strain energy of coal and rock under loading (Xie et al. 2008)

As shown in Fig. 10, point B corresponds to the already dissipated energy of Uia, and the internally stored releasable strain energy of Uie. The change rate of damage parameters near point B is almost zero (Fig. 9), indicating that the releasable strain energy Uie stored inside the coal and rock specimen is not enough to make the damage or the original crack expansion occur. The crack generation and expansion activities inside the coal and rock specimen are weakened at this stage, resulting in a "quiet period" phenomenon of the AE-EMR signal. The evolution characteristics of damage parameter and energy change in the coal and rock further reveal the principle for the appearance of the AE-EMR "quiet period". The zero-change rate of damage parameter and the relationship between dissipation energy and releasable strain energy during uniaxial tests provide a theoretical foundation for the "quiet period" in MS-AE-EMR monitoring system as a precursor to predict coal dynamic disaster. This new precursor can effectively supplement the existing monitoring and warning methods to reduce the missing events.

The generation of AE and EMR is related to the failure of coal and rock. Principle diagram of AE and EMR induced by crack propagation is shown in Fig. 11 (Qiu et al. 2022), which shows that the generation of AE and EMR signals is closely related to the process of coal and rock crack propagation. When coal and rock are in the process of energy accumulation, the releasable strain energy stored inside coal and rock is not enough to extend the existing cracks, which will lead to the emergence of "quiet period". When the energy accumulates to a certain level, the main fracture will occur, and AE and EMR will increase significantly.

Schematic diagram of AE and EMR induced by coal crack propagation (Qiu et al. 2022)

On the whole, the failure process of coal and rock under load is a dynamic process of energy input, accumulation, dissipation and release. The work done by external load on coal and rock is partly stored in the material as elastic energy and partly dissipated in the form of plastic property and damage energy. Therefore, the loading failure process of coal and rock is a dynamic balance process of energy accumulation and dissipation. When the energy accumulation exceeds the local bearing capacity, the coal and rock will be damaged locally. The generation of damage releases part of energy to the outside, reduces the elastic potential energy of coal and rock itself, and enables it to bear more energy than before. Therefore, after the local damage, AE and EMR tend to be silent for a period of time, resulting in a "quiet period". The appearance of "quiet period" is essentially caused by the increase of energy storage capacity due to the release of part of energy during local failure of coal and rock. When judging the silent period, firstly, before the trough, the energy dissipation (such as MS or AE) must be at a high level to determine that the coal and rock are in the state of deformation and failure. Secondly, compared with the average level of energy dissipation before the trough, the lower the trough, the more severe the instability and failure to occur.

This conclusion has also been verified in another research. For example, when Zhao et al. (2021) carried out a loading test on granite, the similar result emerged. The test result was shown in Fig. 12. The loading method in their work was displacement control, and the loading rate was 0.002 mm/s. Before rock failure, there was less AE signal near 400 s, and a "quiet period" appeared.

Research result of Zhao et al. (2021)

6 Conclusions

In order to accurately capture the precursory information of coal and rock damage, the characteristics of the "quiet period" of the AE and EMR signal before the failure of coal and rock specimens during uniaxial loading and variation law of MS and AE signals before rock burst in coal mine were explored, and the mechanism resulting in the signal "quiet period" is explained. The main conclusions are as follows.

-

(1)

During uniaxial loading, there are differences of AE and EMR at different stages. Before the failure, AE and EMR signals show the phenomenon of "quiet period", during which the specimen interior starts to accumulate energy. The "quiet period" after the abnormal increase of AE and EMR activities can be regarded as one of the precursors of the imminent failure of coal and rock specimens.

-

(2)

The phenomenon of "quiet period" after the abnormal increase of the daily MS total energy, MS event count, AE energy and AE pulses before the occurrence of coal dynamic disaster can be regarded as one of the precursor characteristics of coal dynamic disaster. The decrease of MS counts in the "quiet period" is about 57%–88% compared with the anomalous increase stage.

-

(3)

Damage evolution during uniaxial loading of coal and rock specimens can be divided into four stages. For the same sample, the "quiet period" in the AE and EMR signals is consistent. The releasable strain energy stored inside coal and rock during the "quiet period" is not enough to extend the existing cracks, but can accumulate energy for the main fracture.

-

(4)

The laboratory exploration of the "quiet period" during the uniaxial tests provides a theoretical foundation for coal mine dynamic disaster warning based on the "quiet period" precursor of MS, AE and EMR, which will effectively help coal mine reduce the number of under-reported dynamic disaster accidents and ensure the mine safety.

References

Bai G, Su J, Zhang ZG, Lan AC, Zhou XH, Gao F, Zhou JB (2022) Effect of CO2 injection on CH4 desorption rate in poor permeability coal seams: An experimental study. Energy 238:121674. https://doi.org/10.1016/j.energy.2021.121674

Cai W, Dou LM, Zhang M, Cao WZ, Shi JQ, Feng LF (2018) A fuzzy comprehensive evaluation methodology for rockburst forecasting using microseismic monitoring. Tunn Undergr Sp Tech 80:232–245. https://doi.org/10.1016/j.tust.2018.06.029

Cao AY, Dou LM, Cai W, Gong SY, Liu S, Jing GC (2015) Case study of seismic hazard assessment in underground coal mining using passive tomography. Int J Rock Mech Min Sci 78:1–9. https://doi.org/10.1016/j.ijrmms.2015.05.001

Cao AY, Dou LM, Cai W, Gong SY, Liu S, Zhao YL (2016) Tomographic imaging of high seismic activities in underground island longwall face. Arab J Geosci 9(3):232–242. https://doi.org/10.1007/s12517-015-2087-x

Dai F, Li B, Xu NW, Fan YL, Zhang CQ (2016) Deformation forecasting and stability analysis of large-scale underground powerhouse caverns from microseismic monitoring. Int J Rock Mech Min Sci 86:269–281. https://doi.org/10.1016/j.ijrmms.2016.05.001

Ding X, Xiao XC, Wu D (2019) Mechanical properties and charge signal characteristics in coal material failure under different loading paths. Int J Coal Sci Technol 6:138–149. https://doi.org/10.1007/s40789-019-0239-4

Falmagne V (2001) Quantification of rock mass degradation using microseismic monitoring and applications for mine design. Queen’s University, Kingston

Feng GL, Feng XT, Chen BR, Xiao YX, Yu Y (2015) A microseismic method for dynamic warning of rockburst development processes in tunnels. Rock Mech Rock Eng 48:2061–2076. https://doi.org/10.1007/s00603-014-0689-3

Frid V, Vozoff K (2005) Electromagnetic radiation induced by mining rock failure. Int J Coal Geol 64:57–65. https://doi.org/10.1016/j.coal.2005.03.005

Frid V, Rabinovitch A, Bahat D (2003) Fracture induced electromagnetic radiation. J Phys D 36:1620–1628. https://doi.org/10.1088/0022-3727/36/13/330

He SQ, Song DZ, Mitri H, He XQ, Chen JQ, Li ZL, Xue YR, Chen T (2021) Integrated rockburst early warning model based on fuzzy comprehensive evaluation method. Int J Rock Mech Min Sci 142:104767. https://doi.org/10.1016/j.ijrmms.2021.104767

Jiang BY, Wang LG, Lu YL, Wang CQ, Ma D (2016) Combined early warning method for rockburst in a deep island, fully mechanized caving face. Arab J Geosci 9:731–743. https://doi.org/10.1007/s12517-016-2776-0

Jiang F, Yang G, Wei Q, Wang C, Qu XC, Zhu S (2018) Study and prospect on coal mine composite dynamic disaster real-time prewarning platform. J Chin Coal Soc 43:333–339. https://doi.org/10.13225/j.cnki.jccs.2017.4152

Li JD (2020) Research on electromagnetic radiation monitoring and identification of abnormal area in front of hard coal excavation. China University of Mining and Technology. https://doi.org/10.27623/d.cnki.gzkyu.2020.000067

Li XL, Wang EY, Li ZH, Liu ZT, Song DZ, Qiu LM (2016) Rockburst monitoring by integrated microseismic and electromagnetic radiation methods. Rock Mech Rock Eng 49:4393–4406. https://doi.org/10.1007/s00603-016-1037-6

Li ZL, He XQ, Dou LM, Wang GF (2018) Rockburst occurrences and microseismicity in a longwall panel experiencing frequent rockbursts. Geosci J 22:623–639. https://doi.org/10.1007/s12303-017-0076-7

Liu XF, Wang EY (2018) Study on characteristics of EMR signals induced from fracture of rock samples and their application in rockburst prediction in copper mine. J Geophys Eng 15:909–920. https://doi.org/10.1088/1742-2140/aaa3ce

Pan JF, Qin ZH, Wang SW, Xia YX, Feng MH (2015) Preliminary study on early warning method based on weight comprehensive and different-load sources of coal bump. J China Coal Soc 40:2327–2335. https://doi.org/10.13225/j.cnki.jccs.2015.6012

Pan WD, Luo JY, Fan L, Li SC (2021) Slope stability of increasing height and expanding capacity of south dumping site of Hesgoula coal mine: a case study. Int J Coal Sci Technol 3:427–440. https://doi.org/10.1007/s40789-020-00335-y

Qiu LM, Liu ZT, Wang EY, He XQ, Feng JJ, Li BL (2020a) Early-warning of rock burst in coal mine by low-frequency electromagnetic radiation. Eng Geol 279:105755. https://doi.org/10.1016/j.enggeo.2020.105755

Qiu LM, Song DZ, He XQ, Wang EY, Li ZL, Yin S, Wei MH, Liu Y (2020b) Multifractal of electromagnetic waveform and spectrum about coal rock samples subjected to uniaxial compression. Fractals 28:2050061. https://doi.org/10.1142/S0218348X20500619

Qiu LM, Zhu Y, Song DZ, He XQ, Wang WX, Liu Y, Wei MH, Yin S, Liu Q (2022) Study on the nonlinear characteristics of EMR and AE during coal splitting tests. Minerals 12:108. https://doi.org/10.3390/min12020108

Rabinovitch A, Frid V, Bahat D (2017) Directionality of electromagnetic radiation from fractures. Int J Fracture 204:239–244. https://doi.org/10.1007/s10704-016-0178-7

Samanta B, Samaddar AB (2019) Underground mining slurry transportation viability. Int J Coal Sci Technol 6:430–437. https://doi.org/10.1007/s40789-019-0257-2

Song DZ, Wang EY, Li ZH, Qiu LM, Xu ZY (2017) EMR: an effective method for monitoring and warning of rockburst hazard. Geomech Eng 12:53–69. https://doi.org/10.12989/gae.2017.12.1.053

Tan YL, Yin YC, Gu ST, Tian ZW (2015) Multi-index monitoring and evaluation on rockburst in Yangcheng Mine. Shock Vib. https://doi.org/10.1155/2015/624893

Tang CA, Xu XH (1990) Evolution and propagation of material defects and kaiser effect function. J Seismol Res 13:203–213

Xie HP (2019) Research review of the state key research development program of China: Deep rock mechanics and mining theory. J Chin Coal Soc 44:1283–1305. https://doi.org/10.13225/j.cnki.jccs.2019.6038

Xie HP, Ju Y, Li LY, Peng RD (2008) Energy mechanism of deformation and failure of rock masses. Chin J Rock Mech Eng 27:1729–1740. https://doi.org/10.3321/j.issn:1000-6915.2008.09.001

Zhao K, Liu YG, Zeng P, Wu WK, Wang JJ (2021) Study on the acoustic emission characteristics of granite in relative calm period based on GBM model of particle flow code. Metal Mine 543:27–36. https://doi.org/10.19614/j.cnki.jsks.202109004

Acknowledgements

This study was supported by Grants from the National Natural Science Foundation of China (No. 52004016), the Postdoctoral Research Foundation of China (No. 2021M700371), the Major Science and Technology Innovation Project of Shandong Province (No. 2019SDZY02), the Open Fund Project of Shaanxi Key Laboratory of Prevention and Control Technology for Coal Mine Water Hazard (No. 2021SKMS05), Science and Technology Support Plan Project of Guizhou Province (No. [2021]515). The authors are grateful to the anonymous referees for their precious comments and suggestions.

Author information

Authors and Affiliations

Contributions

SH carried out the experimental studies and processed the data, MQ conducted the data analysis, LQ is the idea owner and carried out the theoretical studies, DS and XZ conducted the field test. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflicts of Interest

The authors declare that the data and materials are effective, and there is no conflict of interests regarding the publication of this paper. The funding is showed in the “Acknowledgements”, and authors' contributions are as following, Shengquan He processes the data and is funder of the project No. 2021M700371, Mengli Qin is the co-researcher to conduct the data analysis, Liming Qiu is the idea owner and the funder of the project No. 52004016, No. 2019SDZY02 and No. 2021SKMS05, Dazhao Song is funder of the project No. [2021]515, Xiufeng Zhang is the co-researcher to conduct the field test.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

He, S., Qin, M., Qiu, L. et al. Early warning of coal dynamic disaster by precursor of AE and EMR "quiet period". Int J Coal Sci Technol 9, 46 (2022). https://doi.org/10.1007/s40789-022-00514-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40789-022-00514-z