Abstract

Coal fly ash (CFA) is a byproduct of thermal power plant and collected from flue gases by separator. Composition of CFA depends on the type of coal used and it has both crystalline and amorphous character. It is considered to be an environmental pollutant and used in number of areas. CFA is a useful material and widely used in cement production and as a promising adsorbent for water remediation. CFA used for remediation of wastewater solves problems related to water quality issues and waste management. The physical properties such as porosity, surface area, morphology, and chemical composition (iron oxide, alumina, silica, titania, etc.) make CFA efficient material for wastewater treatment. CFA is also converted to geopolymer, which is used as an adsorbent and photocatalyst. Dye, organic compounds, toxic heavy metal ions, etc. have been removed using CFA and modified CFA adsorbents. Different adsorption efficiencies have been reported for different adsorbate and CFA adsorbents. Numbers of adsorption isotherm and kinetic models have been discussed.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Coal fly ash (CFA), also known as pulverized fuel ash, is finely divided mineral residue obtained from powdered coal combustion in thermal power plants. During the process of burning, temperature may go above 1600 °C and most of the inorganic materials present in the coal get melted. CFA consists of inorganic matter present in the coal and fused during coal combustion. Materials present in CFA solidify in exhaust gases and are collected. A series of physicochemical changes occur in the particles, particularly the rapid conversion of particles to a spherical form (0.5–100 µm). CFA is of varying composition. Only 1/4th CFA produced is utilized (Fig. 1) (Gollakota et al. 2019).

CFA production and utilization (Gollakota et al. 2019)

A small percentage of CFA is used for useful purposes but a large amount is still discharged into ash ponds. The major utilization of CFA is shown in Fig. 2 (Yao et al. 2015).

Applications of CFA (Yao et al. 2015)

CFA consisting fine particles, either solid or hollow, are normally spherical in shape and mostly glassy (amorphous) in nature. Shape and size of CFA depend on the type and source of the coal, combustion environment, degree of pulverization prior to burning, uniformity of combustion, etc. Number of value-added applications of CFA are known (Zhou et al. 2022). Physical and chemical properties of CFA make it useful material for producing high quality and cost-effective bricks, blended cement, kerbstones, interlocking pavers, hallow blocks and mosaic tiles (Khairnar et al. 2013). CFA is widely used in construction industry. Out of two varieties of CFA (F and C), class C has both cementitious (high CaO content) and pozzolanic properties, whereas class F has only pozzolanic properties. CFA is used for making blended cement, which reduces energy consumption in Portland cement clinker manufacturing and also reduces cost. Now-a-days CFA—based geopolymer is coming up as a green binder and an alternative to Portland cement (Alterary and Marei 2021).

Further CFA contains a large number of oxides such as SiO2, Fe2O3, Al2O3, and CaO which can be used for preparation of different ceramics. For the ceramic industry, these oxides are considered as low-cost materials and numbers of ceramic materials have been made by using CFA (Alterary and Marei 2021). Glass–ceramics are also made from CFA (Belviso 2018). CFA has been converted to zeolites by alkaline hydrothermal treatment. This is similar to natural zeolites (Kumar et al. 2001).

The fly ash which is considered to be harmful, when settles on leaves, become beneficial. In agricultural field, when used as a soil modifier, it increases the moisture retaining capacity and the fertility of soil. It also helps in root protection of plants from soil borne diseases and increases the crop yield.

CFA is used for reclamation of sodic soils by mixing it with press mud, which enhances the soil physicochemical property, microbial, and enzymatic activities and the crop growth (Singh et al. 2016). CFA is reported as a potential soil pH ameliorator and has multiple benefits for the establishment and growth of plants via nutrient availability, reducing metal toxicity, etc. Figure 3 shows that CFA improves the physicochemical and biological properties as a potential pH ameliorator (Pandey 2020).

CFA is widely used as a land fill material and in making eco-friendly bio-compatible zeolite material which can be used for variety of applications. It is also used as sensors for detecting CO and CO2 gases (Khairnar et al. 2013).

CFA is a cheap material and can be used as adsorbent for many gases such as CO2. Porous materials generated from CFA such as zeolites, activated carbon, and mesoporous silica, have been tested and applied with promising results as sorbents. CFA and derived materials are also used as CO2 storage materials (Dindi et al. 2019). Fly ash or more specifically, fly-ash-based sorbents, may be used for the removal of NO2 from flue gas. It is known that NO2 is adsorbed on a molecular sieve (zeolite) and mesoporous molecular sieves. It is also recognized that the use of a commercial molecular and mesoporous sieves is not cost-effective (Ściubidło and Majchrzak-Kucęba 2019). CFA can also be used in the hydrogen storage process (Czarna-Juszkiewicz et al. 2020).

CFA is used in an effective manner for the preparation of porous materials. Preparation of ceramic membranes, adsorbents and thermal insulation materials from CFA has achieved a lot of importance because of their excellent performance, low cost and important role in “treating waste and turning waste into wealth” (Wang et al. 2021a, b). CFA derived ceramic membranes are very efficient for filtering applications, these can replace traditional oxide ceramic membranes (Wang et al. 2021a, b).

Miricioiu et al. (2021) developed high selective membranes for natural gas purification and separation. Mixed matrix membranes (MMMs) using polysulfone as matrix and MCM-41-type silica material derived from CFA as filler were developed (Miricioiu et al. 2021). These membranes have efficiently been used for CO2/CH4 separation.

Composite of CFA (matrix) with Aluminium–silicate eutectic/fly ash matrix has been used for sliding wear and corrosion behaviors. CFA-ZnO nanocomposite has been used for anticorrosion coating (Mathapati et al. 2021). CFA can be converted into catalysts, which diminishes the manufacturing costs (Asl et al. 2018).

CFA plays a very important role in the removal of pollutants/contaminants from water. In recent years, CFA and products derived from CFA are being used as low cost and efficient adsorbents for water remediation (Gadore and Ahmaruzzaman 2021; Aigbe et al. 2021). Zeolites, geopolymers and composite materials such as CoFe2O4 (filler) is a very good adsorbent for water remediation. Because, it is magnetic, it is easy to separate the used adsorbent (Zhang et al. 2016). Surface area, shape, chemical characteristics of CFA and many other properties are responsible for water remediation. Mostly CFA is alkaline and at high pH, it has negatively charged surface. Because of negative charge on the surface, it can remove metal ions from aqueous solution by adsorption or precipitation. CFA contains some amount of unburnt carbon, which acts as a good adsorbent and can remove number of pollutants from water. It is already reported that CFA has been used as an adsorbent for adsorption of number of metal ions, inorganic compounds and dyes from wastewater (Yao et al. 2015). CFA could remove more than 95% metal ions. Herbicides removal increased with increase of CFA amount (Yao et al. 2015). For the degradation of dyes and other organic compounds from water, CFA can be used as a photocatalyst or supported photocatalyst based on its constituents (Gadore and Ahmaruzzaman 2021). CFA-copper ferrite nanocomposites have been used for photocatalytic degradation of Methyl Orange (MO) dye in waste water (Nadeem et al. 2021). In this review article, different type of CFA and their characteristic features useful for water remediation have been discussed in detail.

2 Physico-chemical properties of CFA

CFA contains Fe2O3, alumina, CaO, SiO2 and other inorganic compounds. It is a combination of amorphous and crystalline phases. In addition, it also contains unburned carbon. The amount of different oxides in CFA follow the sequence as SiO2 > Al2O3 > Fe2O3. CFA also contains variety of transition metal oxides (Mushtaq et al. 2019). The chemical composition of CFA obtained from different grade coals is given in Table 1 (Gollakota et al. 2019).

Surface area, particle size distribution, porosity, and hydrophilicity of CFA are important for water remediation (Mushtaq et al. 2019). According to ASTM C 618CFA if Al2O3 + SiO2 + Fe2O3 is more than 70%, CFA is called F fly ash, whereas if Al2O3 + SiO2 + Fe2O3 is less than 70%, CFA is called C fly ash. Normally F-type FA is used for water purification. Physico chemical properties of CFA are given in Table 2 (Gollakota et al. 2019).

In order to understand the properties of CFA, characterization of CFA particularly by X-ray diffraction and scanning microscopic techniques are needed. X-ray diffraction patterns are given in Fig. 4. The major peaks in the XRD pattern of CFA are due to crystalline quartz and mullite phases (Nath et al. 2016). Amorphous phases are indicated by hump at 2θ = 15° and 35°. Some variation in XRD patterns (Fig. 4) of CFA may be attributed due to the variety of coals (bituminous, lignite) and method of coal combustion (pulverized coal combustion, fluidized bed combustion, the combustion of coal alone or blended with petroleum coke/biomass) (wang et al. 2020). CFAs have variety of appearances but never exactly the same (Blissett et al. 2012). Figures 5a, b and 5c show three different types of CFA particles (spherical, oval, and irregular) (Wang et al. 2020).

Comparison of the XRD images of four CFAs from different reports a Australian brown coal fly (Tennakoon et al. 2015); b Thermal coal power plant Germany (Li et al. 2016); c Circulating fludized bed fly ash Xishan Thermal Power Plant China (Liu et al. 2019); d Silico aluminous fly ash from power station, Albi, France (Benezet et al. 2008)

Adsorption study of different metal ions on modified CFA under various parameters such as contact time, adsorbent dose, and pH showed increase in adsorption with adsorbent dose and time (Fig. 6). Metals adsorption on CFA is mainly due to carbon content, SiO2 and Al2O3 as surface charge develop on the surface of Silica, Al and Fe, which create suitable sites for the adsorption of metal and metal hydroxide on adsorbent surface. Silica surface is positively charged at low pH and negatively charged at high pH. The zero-point charge (pHZPC) of silica is generally two. This indicates that silica and alumina in the adsorbent, above their respective pHZPC, provide negative charge, (Sahoo et al. 2013).

Effect of the adsorbent dose on metal removal by MFA at 3-h contact time a and effect of contact time on metal adsorption onto MFA b (Sahoo et al. 2013)

3 Wastewater treatment (WWT) with CFA

Number of methods using CFA for WWT have been discussed (Mushtaq et al. 2019) but most commonly used methods are given in Fig. 7. There are variety of pollutants present in water (Fig. 8) (Naseem and Waseem 2021).

Each category of pollutants can be divided into sub categories and are removed either by CFA or modified CFA. These are discussed below.

3.1 Organic pollutants removal by CFA

Organic pollutants may be dyes, drugs, pesticides, phenols, disinfection byproducts, personal care products and polyaromatic hydrocarbons which reach into water bodies through manufacturing industries, agricultureal sites, research institutes, hospitals, live stocks excretion etc. These organic pollutants accumulate into the biological tissues, then cause alteration in food chain, biomagnification, toxicity, liver and bones impairment (Malik and Grohmann 2011; Rzymski et al. 2017; Favier and Harja 2020). Each organic pollutant is discussed separately.

Water pollution caused by dyes and their removal from water is the major global issue. Number of methods is available for dye removal and each method has some advantage and disadvantage. Adsorption is the most efficient and economical method. CFA acts both as an adsorbent and photocatalyst for dyes (Mushtaq et al. 2019; Astuti et al. 2019).

CFA is reported as potential adsorbent for the adsorptive removal of anionic dyes from aqueous solution. Maximum adsorption capacity of CFA (2.012 mg/g for Reactive red and 1.860 mg/g for Reactive blue 171) was observed at pH 7.5 to 8.5, temperature 293 K within 60 min. Within the same time and temperature range, maximum adsorption capacity for acid dyes (10.937 mg/g for Acid Blue 193 and 10.331 mg/g for Acid Black 1) occurred at pH 5 to 6. Langmuir adsorption and pseudo second order kinetic models fitted the data for adsorption of acid dyes. On the other hand, Freundlich isotherm model fitted the data for adsorption of reactive dyes. Thermodynamic parameters predicted the adsorption of dyes on CFA as spontaneous and endothermic in nature (Sun et al. 2010).

CFA has been used for the removal of crystal violet and Rosaline hydrochloride dyes from aqueous solution (Mohan et al. 2002). Adsorption studies were performed at different pH, temperature and particle size of adsorbent. At pH 6 and 8, removal of Rosaline hydrochloride and crystal violet dyes were maximum. Adsorption increases with increasing temperature, showing endothermic process. Adsorption of RB, RR and RY reactive dyes from aqueous solutions by CFA is shown in Fig. 9 (Kara et al. 2007).

Adsorption (%) of RB, RR and RY reactive dyes from aqueous solutions by CFA (Kara et al. 2007)

The comparative study of removal of various dyes by CFA is mentioned in Table 3 (Wang and Wu 2006). Viraraghavan and Ramakrishna (1999) reported the use of CFA for removal of acid dyes (Viraraghavan and Ramakrishna 1999). Janos and coworkers used brown CFA for the adsorptive removal of synthetic dyes. It was observed that adsorption decreased in the presence of solvents such as methanol and acetone (Janoš et al. 2003). Wang and his coworkers have reported the removal of methylene blue from aqueous solution by CFA, which was endothermic (Wang et al. 2005a, b). Table 3 shows that the extent of adsorption of dyes on CFA and the adsorption isotherm models depend on the nature of dyes. Since different dyes contain different type of charge and functional groups, the extent of interaction of dyes on the surface of CFA varies and as a result, the adsorption capacity varies.

Water pollution caused by several organic compounds like pesticides, pharmaceuticals, phenolic compounds (Fig. 10) is the major global concern.

Adsorption of these pollutants from water and waste water using CFA is coming out as a cost-effective solution (Batabyal et al. 1995; Kao et al. 2000; Adegoke et al. 2017). Researchers have reported the use of CFA for the adsorptive removal of quinoline with respect to contact time, CFA dosage and quinoline concentration. The adsorption data is best fitted by Langmuir model. Pseudo 2nd order kinetic model fitted the data. All this indicated chemisorption of quinoline on CFA (Huang et al. 2019).

Removal of paracetamol, ibuprofen and ciprofloxacin using CFA as adsorbent is reported and the results are comparable with activated carbon, bentonite and sugar cane bagasse (Deb et al. 2019). The adsorption study was performed with respect to contact time, concentration of adsorbate and adsorbent dose. A group of researchers have reported the adsorptive removal of PCBs on CFA. The activation energy of the process was found between 5.6 kJ/mol and 49.1 kJ/mol (Nollet et al. 2003). Adsorptive removal of o-, m- and p-nitrophenols by CFA has been reported. The effect of various parameters on adsorption was studied and it was concluded that adsorption increased with decrease in pH and increase with temperature (Singh and Nayak 2004). A comprehensive list of various organic pollutants removed by CFA are given in Table 4 (Wang and Wu 2006; Asl et al. 2019). Phenolic compounds are among the most common organic pollutants of wastewater, and a lot of work has been done on adsorption of phenolic compounds. Fly ash has a good adsorption potential for phenolic compounds. Results presented in Table 4 clearly indicate that CFA and modified CFA act as a good adsorbent with high efficiency for removal of phenolic compounds and organic pollutants from water under optimum conditions. This can be inferred that CFA based adsorbents are suitable for removal of phenolic compounds and other pollutants from water (Ahmaruzzaman 2009).

Pesticides are used worldwide to increase the productivity of crops and also to control insects and pests. They are essential for modern agricultural process due to increased world population. However, overuse of pesticide has led to significant amount of adverse effect on public health. Inappropriate usage of pesticides affects the whole ecosystem. Hence these toxic molecules need to be removed from water by adsorption on fly ash.

Malathion can be removed from water by using CFA obtained from thermal power plant (Singh et al. 2010). The time required to reach the equilibrium is 40 to 60 min at optimum pH value of 4.5 and the adsorption efficiency increased with increase in temperature. A list of various pesticides removed by CFA is given in Table 5 (Ahmad et al. 2010; Behrami et al. 2021). CFA has potential for removal of pesticides from aqueous solutions. It serves two purposes. First CFA is a waste material and poses disposal problems, and second, the removal of pesticides, a toxic substance from environment. Removal depends on the type of pesticide, temperature, pH of solution, source from which CFA is obtained, concentration of adsorbate and adsorbent.

Modification of CFA was achieved by condensation of heat and base treated CFA with 3- mercaptopropyl tri methoxy silane (3-MPTS). The thiol groups on the surface was oxidized by H2O2 to sulphonic group. Different parameters like zeta potential, pH, temperature, time, concentration of dye and adsorbent dose on the removal of dyes is given in Fig. 11 (Dash et al. 2018). For all adsorption study, 25 mL of dye solution was mixed with required amount of HATF-SO3H and for blank study 25 mL of same dye solution was used without adding adsorbent. From the figure, it is clear that zeta potential decreases with increase of pH. Percent adsorption increases with pH, adsorbent dose and time of adsorption. However, after certain time, % adsorption reaches to saturation value and becomes almost constant. With rise in temperature, % adsorption increases and after 310 K, it decreases. As the dye concentration increases, % adsorption decreases.

Different parameters for removal of dyes. a Zeta potential variation with pH, b–f Dye conc-100 ppm; Ads dose-30 mg(R6G) and 40 mg(MG), Temp-313 K (R6G) 308 K (MG); Eq.timwe- 50 min (R6G) and 40 min (MG); Agitation time 105 rpm (MG, r6G) (Dash et al. 2018)

The adsorption data were fitted by pseudo-second-order kinetic and Langmuir isotherm models. Thermodynamic parameters showed spontaneous and endothermic process of adsorption.

The process of adsorption depends on the structures of adsorbate, adsorbent’s surface, textural properties, and interaction between adsorbate and adsorbent molecules. The adsorption of R6G and MG by HATF-SO3H occurs through weak forces (Fig. 12) (Dash et al. 2018). In basic medium, interaction occurs between the positively charged groups of the dyes and negatively charged –SO3H groups.

Mechanism of adsorption of (a) R6G and (b) MG dyes on HATF-SO3H adsorbent (Dash et al. 2018)

Fe3O4 augmented fly ash worked as an effective catalyst in the heterogenous Fenton process for the degradation of persistent organic pollutant (POP) in landfill leachate Fig. 13. The Fe3O4 augmented fly ash catalyst was prepared by chemical precipitation method. XRD analysis shows the crystalline nature of catalyst and 17.1 nm as the crystallite size. The Fe3O4 augmented fly ash catalyst showed the decrease in COD and TOC level of leachate by 84.7% and 68% at pH 3.0, dose of catalyst 1000 mg/L, 0.05 M H2O2 within 100 min (Niveditha and Gandhimathi 2020).

H2SO4 impregnated CFA was used to treat polymer flooding wastewater via heterogenous Fenton process (Fig. 14). The H2SO4 impregnation enhances the surface area from 1.521 to 11.463 m2/g, and decrease the CaO content which is useful for increasing the catalytic efficiency and minimize the effect of pH of wastewater. The removal of polyacrylamide was found 70.3% within 50 min at pH 3.0, dose of modified CFA 20 g/L, dose of H2O2 18 mmol/L and microwave pre enhancement time 7 min (Wang et al. 2021a, b).

Metal or metal oxide nanoparticles (Fe, Fe2O3, Ag, ZnO and TiO2) can deposit on CFA surface and increase the surface area so that more dyes can come in the vicinity of photocatalyst. As a result, more dyes can be degraded. Figure 15 gives different aspects of photocatalytic aspect of CFA containing metal and metal oxides (Mushtaq et al. 2019).

Photocatalytic performance up-gradation by CFA through different strategies (a) Coupling of CFA constituent oxides with themselves or with externally introduced photocatalyst (b) Doping of photocatalysts with metals from CFA (c) Surface features and porosity of CFA-based catalysts for light absorption (d) Photocatalyst coated on CFA (Mushtaq et al. 2019)

Fly ash modified CuO (FA/CuO) has been used for the photocatalytic degradation of methyl orange dye. 99.1% removal of methyl orange dye was observed in 40 min at temperature 303 K (Fig. 16) (Mazumder and Rano 2018).

Coal fly ash supported nano zinc oxide (CFAZ) is used to treat ship yard process water containing triphenyl tin chloride (TPT) as major pollutant (Ayanda et al. 2015). Triphenyl tin is used as fungicide and antifouling agent. CFAZ can remove 99% of triphenyl tin chloride having initial concentration of 100 mg/L within 60 min at 333 K, 200 rpm stirring speed, 8 pH. Adsorption process is found exothermic and data fitted Freundlich isotherm and pseudo second order kinetic models.

3.2 Inorganic pollutants removal by CFA

Heavy metal ions are one of the major inorganic pollutants which pose a severe threat to public health (Ahmed and Ahmaruzzaman 2016). Permissible limits of industrial effluents are given in Table 6 (Ahmed and Ahmaruzzaman 2016).

Among various methods for heavy metal removal, adsorption by CFA is one of the promising methods owing to its easy availability and cost-effectiveness. This method is reported as early as 1975 (Gangoli et al. 1975). Since then, it is used extensively for removal of toxic metal ions. The main components of fly ash are Al2O3 and SiO2 in which the later has enhanced affinity towards heavy metals. When dispersed in water, fly ash shows an alkaline behavior with a pH range of 10–13. At higher pH value, the fly ash surface becomes negatively charged which can remove metal ions by electrostatic adsorption and precipitation (Ahmed and Ahmaruzzaman 2016).

Particle size fraction of fly ash can play a very vital role in toxic ion removal. Police et al. (2020) have reported that fly ash having particle size < 20 μm showed highest adsorptive removal (99%) for U as shown in Fig. 17. It may be due to high surface to volume ratio in this size fraction. The lowest adsorptive removal of 95.8% was reported with size fraction FA > 63–90 μm. The slight increase of U adsorption was found as particle size increases (FA > 90 μm), which may be due to more unburnt carbon content in this fraction (FA > 90 μm) as compared to FA > 63–90 μm size fraction.

Effect of particle size fraction on removal of U (Police et al. 2020)

A comparative uptake study of toxic metal ions was made by systematically varying the particle – size (Itskos et al. 2010). It was observed that highly siliceous CFA was more efficient in precipitating Cr (VI) but less effective in retaining other ions. Reverse situation was obtained by using high—Ca CFA which is more effective in removal of Ni, Cu, Pb, Cd and Zn (Itskos et al. 2010). Other crucial factors in adsorption process include pH and temperature. pH and temperature dependant studies were carried out for removal of Pb2+ and Cu2+ ions. With increase in pH, the metal ions uptake increases. However, with increase in temperature, the uptake initially increased, reached a maximum value between 30–40 °C and then again decreased (Alinnor 2007). Class “F” fly ash which was obtained from Heat and Power (CHP) Plant Brasov (Romania) has a SiO2/Al2O3 ratio of more than 2.4. It was found to be a good adsorbent for Cd (II), Pb (II) and Zn (II) cations from mixed solution (Visa et al. 2012) and maximum adsorption was achieved between pH value of 5.5 to 6.6. Adsorption efficiency of CFA for different metal ions at different temperatures and pH are given Table 7. Among the metal ions, Pb, Ni, Cr, Cu, Cd, and Hg are the most investigated. There are several studies for the removal of Cr (VI). It was observed that the removal was most effective under acidic pH and high temperature. However, particle size has no effect on removal of Cr (VI) ions. It can be predicted that the adsorption process of heavy metals occurs through the exchange of ions, complexation, coordination, chelation, the combination mechanism, microprecipitation as well as the interaction of the electrostatic forces. There are number of parameters such as temperature, pH, the type of adsorption, adsorbent dosage, time of contact, volume treated, the size of the particles, and co-existing ions on the absorption process, the absorbent physicochemical features (such as the chemical, biochemical, and the ability or functionality of the texture) as well as the possessions of the sorbate (Aigbe et al 2021; Duan et al. 2020; Darmayanti et al. 2017; He et al. 2016; Alinnor 2007; Dasmahapatra et al. 1996).

The adsorption capacity of the fly ash can be increased by increasing the surface activity by mechanical activation using planetary ball mill. Using this concept, a comparative study was performed on raw fly ash and mechanically activated fly ash for the removal of some heavy metal ions such as Cu (II), Mn (II), Ni (II), Pb (II) and Zn (II) from aqueous solutions (Xiyili et al. 2017). Mechanical activation leads to increase in surface roughness and decrease in particle size and increased silica content. Table 8 shows the change in percentage composition of coal fly ash by mechanical activation (Sharma et al. 2015). Mechanical activation gives rise to change in degree of crystallinity of some phases which can be visualize in Fig. 18. As expected, activated fly ash performed better compared to raw fly ash in terms of removal percentage. Maximum adsorption was observed in case of Pb (II) ion (68% in raw fly ash and 98% in activated fly ash) (Xiyili et al. 2017).

SEM micrograph of a Fly ash and b Activated fly ash (Xiyili et al. 2017)

A tentative list of metal ions removed by CFA is given in Table 9 (Mushtaq et al. 2019). The modified CFA also acts as an adsorbent under the conditions in which CFA acts as discussed earlier.

Chemical treatment is another method for transforming CFA for an enhanced performance. Removal of toxic metal ions like Cr (VI) and Pb (II) ions have been studied by utilizing chemically treated thermal power plant fly ash with CaCO3 and H3PO4. The efficiency of the fly ash was determined by changing various parameters like pH, temperature, adsorbent dose, contact time etc. The synthesized FA samples showed good metal removal capacity (Shyam et al. 2013).

CFA which has been etched by nitric acid and functionalized with thioglycolic acid and 2-mercaptoethanol had been used successfully for removal of As, Cd, Cu, Al, Mn, Fe, Zn and Hg with 91%–99% efficiency and Pb ions with 90%–97% efficiency (Muñoz et al. 2014).

CFA can also be activated with inorganic nanomaterials which are highly reactive due to high surface to volume ratio. Magnetite modified CFA has been utilized for removal of As (V) from water (Karanac et al. 2018). This type of modification leads to easy magnetic separation of CFA which is otherwise difficult.

In another example, Ag-Fe3O4 loaded CFA was used for efficient removal of Pb (II) ions from water (Joshi et al. 2015). Nucleation sites were provided by fly ash for metal oxide and metallic nanoparticles which gets protonated/deprotonated easily. These charged sites can attract the Pb2+ ions resulting in effective adsorption of the toxic metal ions. The capacities of adsorption of some CFA-based adsorbents are given in Table 9.

In addition to the heavy metal ions, a few inorganic anions are also well known pollutant and dangerous to animals and plants. Most hazardous of them are fluorides and phosphates (John et al. 2018). The source of phosphate is from phosphate fertilizer used in agriculture which gives rise to eutrophication and increased mortality rate of aquatic life (Farmer 2018). As CFA is enriched in oxides of Aluminium, Iron, Calcium and Silica, it can be a suitable material for adsorptive removal of anions as these metal ions can adsorb or precipitate phosphate containing effluents.

3.3 Phosphate removal

Phosphate removal was first reported by Kuziemska (1980) where crown CFA from thermal power plant was used as coagulant to precipitate phosphate. It was observed that phosphate anions were precipitated immediately after coagulant was mixed with the phosphate containing solution (Kuziemska 1980). The coagulation process was investigated with four parameters—coefficient, initial phosphate concentration, total alkalinity of the test and coagulant solution and out of which coefficient and total alkalinity of the test solution were most important parameters. Removal of phosphate can also be achieved by low calcium (approx. 1 wt% as CaO), acidic (pH approx. = 4.5) type F fly ash. The batch equilibrium experiments show removal of phosphate of the order of 100%–75% for 50–100 mg/L phosphate solution (Grubb et al. 2000). The removal was based on the formation of insoluble iron and aluminium phosphate at low or neutral pH range. Under such acidic condition, the phosphate retention amount is about 20%. A comparative study of phosphate removal by slag, OPC (ordinary Portland cement), FA (fly ash) and cement blend was reported by Agyei et al. (2002) and revealed that slag remove the anion faster than FA. A more efficient removal was at pH lower than 7, higher solute concentration and higher temperature. The adsorption capacities of fly ash, slag, OPC, OPC + slag, OPC + fly ash are 32, 60, 83, 78, 75 mg/g for PO43− respectively. In another approach, CFA can be converted to zeolite or zeolite composites and used for anion removal. A novel hybrid adsorbent was reported by Wang et al. by combining zeolite from CFA and hydrous lanthanum oxide. It was then used for removal of phosphate from lake water. The process is pH dependent and percent adsorption decreases with increasing pH. Additionally, the hybrid adsorbent can retain few cations also (Wang et al. 2016).

3.4 Fluoride removal

Excess fluoride ion present in water causes fluorosis which affect the teeth and bones. Number of industries discharge water with high level of fluoride. Several technologies are available for fluoride ion remediation (Reardon and Wang 2000). CFA has been successfully used by Chaturvedi et al. (1990) to remove fluoride from waste water at various temperature, pH and concentration. Acidic pH, low concentration and high temperature favor removal of fluoride. Calcium hydroxide treated CFA has been used for removal of fluoride ions from aqueous solution. The maximum adsorption was reported to be about 89% at an adsorbate dose of 10 mg/L, equilibrium contact time of 120 min and adsorbent dose of 3 g/L at pH = 7. The process followed a pseudo-second order kinetics and fitted Langmuir isotherm model revealing a monolayer chemisorptions (Geethamani et al. 2014). In another research, NaP1 zeolite was produced by washing with NaOH. The zeolite thus formed was more crystalline and contains more positive surface charge. Maximum adsorption of 90% was reported at pH = 6 with a contact time of 30 min. Moreover, the adsorption increases with increase in adsorbent dose due to availability of more surface area and with contact time. The experimental data was found to be consistent with both Langmuir and Freundlich isotherm (Panda and Kar 2018).

3.5 Boron removal

Boron is present in environment as borate ion and boric acid. Acid is used in manufacturing of cosmetics, carpet, leather and photographic chemicals, glass, porcelain for weather proofing, wood and fireproofing fabrics. Fly ash can be used to adsorb boron. Boron adsorption was reported by Hollis et al. (Hollis et al. 1988) and Öztürk and Kavak (2005). The adsorption which is an exothermic process is maximum at pH = 2 and 25 °C.

3.6 Radioactive element (U) removal

Radioactive elements like Uranium are extremely hazardous to animal growth and livelihood. CFA based adsorbent material is effectively used against removal of this toxic metal. Raw CFA has been used for removal of uranyl ion from waste water by Li et al. (2013) Maximum adsorption capacity was reported to be 8.38 mg/g at pH = 5 within 60 min. CFA based zeolite iron oxide magnetic nanocomposite was used to remove U6+ ions from water with almost 100% efficiency under an optimized condition of pH = 3, time = 2.5 h and Co = 100 ppm. The adsorption data fitted well Langmuir isotherm with maximum adsorption capacity of 22.4 mg/g (Fungaro et al. 2012). Along similar line, adsorptive removal of U (VI) was reported by two types of zeolite (A and B) synthesized from CFA. It was found that the radioactive ion was removed with an efficiency of 90% and 99.5% for zeolite-A and zeolite-B respectively within one hour, which showed better removal performance of zeolite-B over zeolite-A for U (VI) (Xie and Zhou 2017).

Mesoporous calcium-silicate derived from CFA was developed for removal of several radioactive nucleotide such as 58Co, 60Co, 51Cr, 54Mn, 58Fe, 95Nb, 95Zr,99Mo and 137Cs. Maximum adsorption was observed for 60Co which was almost 100% removed, other ions are removed with an efficiency of 98%–99% (Qi et al. 2015). Adsorption of radioactive Barium (Ba) and Europium (Eu) from aqueous solution by CFA derived zeolite containing Na-Y and SOD was reported by Noli et al. (Noli et al. 2016). The adsorbent showed excellent removal efficiency (~ 100%) under an optimized condition of pH = 4, time = 2 h and temp. = 31 °C. Type F CFA produced from thermal power plant was assessed for their ability to retain four radioactive cations such as Cs+, Sr2+, Ce3+ and Ce4+ from aqueous solution. Unlike the previously described cases, the mechanism of removal was reported to be formation of coordinative bond between monovalent /divalent cation with negatively charged alumino silicate anions present on the surface of the coal fly ash. It was reported that Ce3+ and Ce4+ ions were completely removed while removal of Cs+ was unsatisfactory (30%) and Sr2+ was not adsorbed at all. The unsatisfactory adsorption of Cs+ may be attributed to its bigger radius (181 pm) compared to the radius of Ce3+ and Ce4+ (115 pm and 101 pm). Strontium was not adsorbed as it is leached out (Lieberman et al. 2015).

4 Comparison of removal of pollutants by modified CFA

CFA, CFA treated with HCl at room temperature (CFA-HCl-RT), CFA treated with HCl at 100 °C (CFA-HCl-100), CFA treated with HCl and ultrasonicated (CFA-HCl-S), CFA treated with HCl and heated in microwave oven for 2 min (CFA-HCl-M1) and CFA treated with HCl and heated in microwave oven for 10 min (CFA-HCl-M2) have different surface area (Table 10) and have different adsorption efficiency for three basic dyes, methylene blue (MB), crystal violet (CV), and rhodamine B (RB) (Fig. 19) (Wang et al. 2005a, b).

CFA untreated (A0), treated with NaOH (A1-A5) (Table 11) have different morphologies (Fig. 20) and removal efficiency for Cd2+ from aqueous solution (Fig. 21) ( Buema et al. 2021).

SEM pictures of untreated and treated CFA (Buema et al. 2021)

Removal of Cd2+ ions from water by CFA and modified CFA (Buema et al. 2021)

A group of researchers synthesized micro and mesoporous silica by using CFA at different pH (13, 11, 9 and 7) and used FA-AT13, FA-AT11, FA-AT9 and FA-AT7 for the removal of parabens (methylparaben, ethyl paraben, propylparaben, and butylparaben) from aqueous solution (Fig. 22). The SEM pictures show a substantial change in morphology by changing the pH. The change in pH affects the surface area of FA-AT13, FA-AT11, FA-AT9 and FA-AT7 also. FA-AT7 showed highest adsorption for all paraben due to its increased surface area (Oliveira et al. 2020).

CFA modification into three different Fenton type heterogenous catalyst showed the variation in p-nitrophenol removal capacity. Acid modification and Fe2O3 loading changed the physiochemical characteristic of CFA and enhanced its removal capacity. The surface area of CFA, MCFA powder, granular MCFA, Fe2O3 granular MCFA were found 19.2, 27, 12.3, 11.1 m2/g, respectively. p-Nitrophenol removal capacity of various CFA, MCFA powder, granular MCFA, Fe2O3 granular MCFA were 32.1% in 60 min, 60.7% in 40 min, 61.8% in 60 min, 80.7% in 60 min, respectively. Out of all Fe2O3/granular MCFA exhibits the best stability and catalytic capacity and can be used at least 6 times, while the removal rate of p-NP remains at no less than 80% (Wang et al. 2017).

5 Regeneration of adsorbent

Researchers have reported the results for regeneration capacity of CFA. The regeneration capacity for sulfonic acid functionalized heat and alkali treated CFA (HATF-SO3H-CFA) was found maximum at pH 8 and minimum at pH 2.0. Percent adsorption and desorption of MG and R6G dyes is given in Fig. 23 (Dash et al. 2018). After third desorption cycle 87.61% for R6G and 88.31% for MG were desorbed.

Adsorption and desorption of MG and R6G on HATF-SO3H (Dash et al. 2018)

Acid treated, pulverized and sieved coal fired fly ash (CFFA) having BET surface area 17.4 m2/g showed excellent adsorption of heavy metal ions Cd (II), Cu (II) and Ni (II) in individual metal and multi metal aqueous system (Kumar et al. 2019). For regeneration of CFFA, 0.1 N HNO3, H2SO4 and HCl were used and the metal adsorbed CFFA was kept in acid solution on orbital shaker at 150 rpm for 24 h. Maximum desorption of metal was achieved with 0.1 N H2SO4. Significant loss in weight of adsorbent CFFA, and decrease in adsorption capacity were also observed after second cycle, which may be due to, some soluble material and functional groups form adsorbent washed out during acid treatment (Kumar et al. 2019).

The persulphate activated fly ash-Fe3O4-Ag nanocomposite act as catalyst and showed 98.6% catalytic activity for the degradation of Corafix Red ME4B dye. The persulphate played a major role in the regeneration of catalyst (fly ash-Fe3O4-Ag nanocomposite) and dye degradation as shown in Fig. 24 (Krishnamoorthy et al. 2021).

Catalytic degradation of Corafix Red ME4B dye by fly ash-Fe3O4-Ag nanocomposite and regeneration of catalyst (Krishnamoorthy et al. 2021)

Three-dimensional electrochemical system prepared using CFA and red mud particles (FRPEs) is used for the degradation of atrazine “90.1% degradation under the optimal conditions: fly ash: red mud = 3:4, FRPEs dosage 100 g/L, cell voltage 5 V, initial pH 6.8 and treatment for 30 min”. The prepared system showed good activity after 7th cycle also. The degradation process takes place at the surface of FRPEs as shown in Fig. 25 (Teng et al. 2021).

Schematic representation of degradation of atrazine and regeneration of FRPEs (Teng et al. 2021)

6 CFA derived membrane for remediation of water

Coal fly ash derived membranes showed high merit for water filtration (Wang et al. 2021a, b). The fly ash derived materials can be used as support materials in membrane or these can be used to prepare microfiltration membranes. The pore size, overall porosity of membrane and flexural strength are important factors in the quality of membrane. The membrane prepared by mixing CFA with bauxite enhance the flexural strength of membrane from 22 to 65 MPa. The bauxite fly ash combination shows highly promising results to prepare multiphase filtration layer with well controlled porosity (Abdullayev et al. 2019). The variety of membranes prepared by coal fly ash, used to treat pollutants in wastewater are given in Table 12.

7 Geopolymer for remediation of water

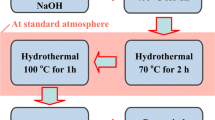

Geopolymers are formed when raw materials containing aluminosilicate mineral like CFA is allowed to react with concentrated NaOH/KOH and sodium silicate and cured at about 90°C. During geopolymerization reaction, steps involved are: Si and Al atoms of the precursor get dissolved by the action of hydroxide ions, monomers are formed and polycondensation of monomers leads to polymeric structures (Acisli et al. 2020). The overall reaction occurs as given in Fig. 26.

The overall process of geopolymerization of FA can be represented by Fig. 27 (Acisli et al. 2020).

Geopolymerization of FA (Acisli et al. 2020)

The geopolymer acts as adsorbent for removal of heavy metal ions and dyes from water.

Number of papers published on the removal of pollutants by using geopolymers as adsorbents between 2010 to 2020 as per Science Direct database are shown in Fig. 28 (Alouani et al. 2021).

Number of papers published on water treatment by geopolymer as adsorbent during the period 2010–2020 (Alouani et al. 2021)

Table 13 gives efficiency of removal of heavy metal ions by conventional geopolymers under different conditions (Tan Tee et al. 2020).

Adsorption and desorption of metal ions on geopolymers and their pores are represented by Fig. 29 (Rasaki et al. 2019). As shown in Fig. 29, adsorption and desorption process of metal ions on the surface of geopolymer can be understood. In the figure uncrushed geopolymer (i), geopolymer crushed into nanosphere shapes with small and approximately equal radius size (ii), transfer of metal-ions through mesopores of the nanosphere geopolymer (iii), accumulation of the metal-ions onto the adsorption active sites (iv) and desorption of the metal-ions from the surface of geopolymer via simple washing process(v) are shown. Adsorption involves removal of metal ions using solid surfaces. Adhesion forces are created between the metal ions and mesopores which is the reason for the observed adsorption. Mesoporous surfaces are also essential for desorption processes relevant for the regeneration/reusability of the adsorbents. This oftentimes is carried out through simple washing, chemical treatment, steam washing or thermal treatment. The adsorption process is either chemisorption or physisorption depending on whether or not the adsorption results in the formation of a chemical bond. Often times, physisorption adsorption process gives favorable adsorption and offers easy regeneration due to the weak Van der Waal interactions involved (Rasaki et al. 2019).

Adsorption and desorption process of metal ionson the surface of geopolymer (Rasaki et al. 2019)

Langmuir adsorption equation fits the adsorption data well. Pseudo second order kinetic model also fits the data. Geopolymers adsorb dyes and metal ions spontaneously, and entropy driven (Rasaki et al. 2019; Acisli et al. 2020).

Adsorbing anionic surfactant like SDBS “sodium dodecyl benzene sulfonate” onto the geopolymer is a chemisorption process (Siyal et al. 2019). Below pH 7.04 geopolymer surface becomes positive and above pH 7.04, it becomes negative. At pH 2, the surface of the geopolymer becomes positive and that of SDBS is negative. Now the adsorption occurs due to electrostatic attraction. The other forces of attraction such as Adsorption of SDBS on geopolymer matrix may also be due to hydrophobic and other weak forces.

Low cost geopolymer water pipe-lines can also be made for water circulation and the threats of toxic effect of heavy metals can be minimized.

CFA based geopolymer has also been used as photocatalyst for degradation of dyes present in water. Geopolymer contains some semiconducting metal oxides like Fe2O3, TiO2, Al2O3, and MgO, which act as photocatalyst (Fig. 30) (Rasaki et al. 2019).

Photocatalytic properties of geopolymer for degradation of dyes (Rasaki et al. 2019)

Porous geopolymer composites are also used as adsorbents for the removal of drugs and dyes (Rozek et al. 2020). Removal efficiency for MB dye is up to 99% (Rozek et al. 2020). During MB adsorption there is an electrostatic interaction as given in Fig. 31 (Zhang et al. 2021a, b; Lee et al. 2017).

8 Zeolite for petroleum compounds removal from water

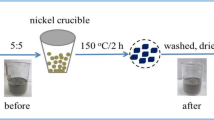

The efficiency of CFA was enhanced by converting it to zeolite as reported by Cardoso et al. (2015). They synthesized NaP1 zeolite under milder condition using Brazilian CFA in pressurized reactors at 150 °C and a glass reactor at 100 °C. This zeolite was then used for treatment of acid mine drainage for adsorptive removal of various metal ions. It was reported that with adsorbent dose of 10 g/L and equilibrium time of 30 min, complete removal of As and Ni was achieved while removal of Calcium, Copper, Iron and Manganese was > 98%, > 96%, > 98% and > 98% respectively. Other cations and anions that were partially removed were ammonium (52%), magnesium (60%), potassium (82%) and zinc ions (79%) and sulphate ions (85%) (Cardoso et al. 2015).

The Na-P1 zeolite was obtained using CFA by hydrothermal conversion method and is reported as good adsorbent for benzene, toluene, xylene, diesel fuel from aqueous solution. Figure 32 shows the SEM, EDX images and adsorption capacity of Na-P1 zeolite. It showed 0.147 mg/g, 0.129 mg/g, 0.050 mg/g and 0.038 mg/g adsorption capacity for benzene, toluene, o-xylene and p-xylene respectively within 24 h with 0.5 g dose (Bandura et al. 2017). For diesel fuel 910 mg/g adsorption capacity was achieved with 5 g dose of Na-P1 zeolite in 24 h (Bandura et al. 2015). Adsorption followed pseudo second order kinetics.

Na-P1 Zeolite a SEM image, b EDX image and c Adsorption capacity for BTX (Bandura et al. 2017)

A more energy consuming method for conversion of coal fly ash to zeolite is by hydrothermal treatment which eventually enhances the efficiency by 2–25 times. Czarna et al. (2018) has synthesized Na-A, Na-X and Ag-X-zeolite from type F fly ash following hydrothermal method. Mercury sorption studies from waste water were carried out by them and compared with commercial zeolites like 4A and 13X. Maximum adsorption efficiency of 90.57% was obtained with Na-A zeolite, while that with Na-X and Ag-X zeolite were 89.4% and 89.6% respectively. The SEM images of synthesized and commercial zeolite are given in Fig. 33 (Czarna et al. 2018).

Morphology of tested fly ash derived zeolite materials (type X and A) and commercial zeolite (4A and 13X) (Czarna et al. 2018)

9 Environmental risk from CFA

CFA contains number of heavy metals in small quantities but nearly 10 times higher than that in coal. These have toxic effect on the environment and human being. This has been discussed in detail by Miricioiu and Niculescu (2020). Metals can easily leach from CFA, go into water and soil and also contaminate air. There are many factors such as rain, wind, pH, particle size, etc. which contribute towards interaction of the metals with humans, reaching significant concentration in soil and water and finally in crops. Since these metals are toxic, may have a negative and toxic effect. Major elements in CFA are Si, Al, and Fe along with considerable amount of Na, K, Ca, and Ti. Al is present normally as alumino-silicate which controls the biological toxicity of CFA. The presence of large quantities of elements increases the edaphic characteristics of soil resulting into enhancement of crop yield (Khan and Rashid 2019). At the same time, it also has adverse effects on environment because of release of number of trace metals like Mn, Zn, Mo, and Cu along with large amount of other toxic elements (i.e. Co, Pb, As, Cr, Ni, Se). Amongst different toxic elements in CFA, arsenic is one of the most hazardous and toxic elements causing ecological problems (Wang et al. 2020). Arsenic in CFA is responsible for skin diseases and lung infections. Soluble salts are also present in CFA which promote pollutants to migrate into groundwater from soils through leaching causing water pollution. Naturally-occurring radionuclides (NORs) such as 238U, 226Ra, 232Th, and 40K might be present in CFA, so before using CFA for water remediation, these aspects should be taken into consideration (Roper et al. 2013; Turhan et al. 2010). Thus, disposal of large amount of CFA in atmosphere, may release large amount of toxic elements which may be responsible for potential environmental hazard. Therefore, disposal and reuse of CFA should be made with care (Miricioiu and Niculescu 2020). There are ways proposed by researchers to minimize the leaching of harmful elements from CFA and to reduce the pollution caused by CFA (He et al. 2015; Huber and Fellner 2018; Mutlu et al. 2018; Valeev et al. 2019). A group of researchers have reported that the increase in alkalinity of CFA reduces the release of Cd, Co, Cu, Hg, Ni, Pb, Sn and Zn metal ions (Izquierdo and Querol 2012). The detailed studies are needed to know the environmental effect and its prevention due to use and disposal.

10 Future direction

Fly ash is a coal combustion residue and has a great potential for water decontamination. CFA may be an important alternative to activated carbon or zeolites for adsorption. Raw CFA normally has low adsorption capacity but modified CFA can be a better alternative. Considering the economics, CFA should be converted to modified CFA and decontamination studies should be carried out under different conditions in detail. CFA obtained from different sources have different compositions and morphologies. A systematic study is needed to know the effect of morphology, composition and surface area.

11 Conclusions

CFA is obtained from power plants by burning fossil fuels. It is basically of two types—Class C and class F. Class C obtained by burning of anthracite or bituminous coal, where major components are SiO2, Fe2O3 and Al2O3. The class F fly ash is produced by burning of lignite and sub-bituminous coal. It majorly contains SiO2, Fe2O3, Al2O3 and silicate glass. Composition and surface area of CFA control the properties. CFA is widely used in construction industry. Now-a-days CFA—based geopolymer is coming up as a green binder and an alternative to Portland cement. In addition, it is also used in agriculture, ceramic industry and preparation of number of materials like zeolite. Activated carbon derived from high carbon coal fly ash is used for hydrogen storage applications. CFA is a good adsorbent for removal of pollutants from aqueous solutions. CFA can also be modified and activated for removal of pollutants. CFA derived membranes showed high potential for water filtration. CFA reduces the cost of membrane. Aluminium extracted from CFA into chloride solution can be used as coagulant for water treatment. Geopolymer obtained from CFA is also used as an effective adsorbent for removal of pollutants. The removal efficiency depends on number of parameters like pH, temperature, adsorbent dose, etc. Depending on the constituents, it also acts as a photocatalyst or supported photocatalyst for the degradation of dyes and organic compounds present as pollutant in water. CFA is economical as an adsorbent but at the same time it is hazardous also since it contains lot of heavy metal ions. Use of CFA as an adsorbent is still in early stage and detailed studies are needed.

References

Abdullayev A, Bekheet MF, Hanaor DAH, Gurlo A (2019) Materials and applications for low-cost ceramic membranes. Membranes 9:105. https://doi.org/10.3390/membranes9090105

Acisli O, Acar I, Khataee A (2020) Preparation of a fly ash-based geopolymer for removal of a cationic dye: isothermal, kinetic and thermodynamic studies. J Ind Eng Chem 83:53–63

Adegoke KA, Oyewole RO, Lasisi BM, Bello OS (2017) Abatement of organic pollutants using fly ash based adsorbents. Water Sci Technol 76(10):2580–2592

Agyei NM, Strydom CA, Potgieter JH (2002) The removal of phosphate ions from aqueous solution by fly ash, slag, ordinary Portland cement and related blends. Cem Concr Res 32(12):1889–1897

Ahmad T, Rafatullah M, Ghazali A, Sulaiman O, Hashim R, Ahmad A (2010) Removal of pesticides from water and wastewater by different adsorbents: a review. J Environ Sci Health C 28(4):231–271

Ahmaruzzaman M (2009) Role of fly ash in the removal of organic pollutants from wastewater. Energy Fuels 23:1494–1511

Ahmed MJK, Ahmaruzzaman M (2016) A review on potential usage of industrial waste materials for binding heavy metal ions from aqueous solutions. J Water Process Eng 10:39–47

Aigbe UO, Ukhurebor KE, Onyancha RB, Osibote OA, Darmokoesoemo H, Kusuma HS (2021) Fly ash-based adsorbent for adsorption of heavy metals and dyes from aqueous solution: a review. J Market Res. https://doi.org/10.1016/j.jmrt.2021.07.140

Alinnor IJ (2007) Adsorption of heavy metal ions from aqueous solution by fly ash. Fuel 86(5–6):853–857

Alouani ME, Saufi H, Moutaoukil G, Alehyen S, Nematollahi B, Belmaghraoui W, Taibi MH (2021) Application of geopolymers for treatment of water contaminated with organic and inorganic pollutants: state-of-the-art review. J Environ Chem Eng 9:105095

Alterary SS, Marei NH (2021) Fly ash properties, characterization, and applications: a review. J King Saud Univ Sci 33:101536

Asl SMH, Ghadi A, Baei MRS, Javadian H, Maghsudi M, Kazemian H (2018) Porous catalysts fabricated from coal fly ash as cost-effective alternatives for industrial applications: a review. Fuel 217:320–342

Asl SMH, Javadian H, Khavarpour M, Belviso C, Taghavi M, Maghsudi M (2019) Porous adsorbents derived from coal fly ash as cost-effective and environmentally-friendly sources of aluminosilicate for sequestration of aqueous and gaseous pollutants: a review. J Clean Prod 208:1131–1147. https://doi.org/10.1016/j.jclepro.2018.10.186

Astuti W, Chafidz A, Wahyuni ET, Prasetya A, Bendiyasa IM, Abasaeed AE (2019) Methyl violet dye removal using coal fly ash (CFA) as a dual sites adsorbent. J Environ Chem Eng 7(5):103262

Ayanda OS, Fatoki OS, Adekola FA, Ximba BJ, Akinsoji OS, Petrik LF (2015) Coal fly ash supported nZnO for the sorption of triphenyltin chloride. Arch Environ Prot 41(1):59–71

Bandura L, Franus M, Józefaciuk G, Franus W (2015) Synthetic zeolites from fly ash as effective mineral sorbents for land-based petroleum spills cleanup. Fuel 147(2015):100–107. https://doi.org/10.1016/j.fuel.2015.01.067

Bandura L, Kołodyńska D, Franus W (2017) Adsorption of BTX from aqueous solutions by Na-P1 zeolite obtained from fly ash. Process Saf Environ Prot 109:214–223. https://doi.org/10.1016/j.psep.2017.03.036

Batabyal D, Sahu A, Chaudhuri SK (1995) Kinetics and mechanism of removal of 2, 4-dimethyl phenol from aqueous solutions with coal fly ash. Sep Technol 5(4):179–186

Behrami E, Xhaxhiu K, Dragusha B, Reka A, Andoni A, Hamiti X, Drushk S (2021) Adsorption of benalaxyl and atrazine in fly ash the coal of power plant (kosovo a) from aqueous solutions. Int J Ecosyst Ecol Sci 11(3):599–610

Belviso C (2018) State-of-the-art applications of fly ash from coal and biomass: a focus on zeolite synthesis processes and issues. Prog Energy Combust Sci 65:109–135

Benezet JC, Adamiec P, Benhassaine A (2008) Relation between silico-aluminous fly ash and its coal of origin. Particuology 6:85–92. https://doi.org/10.1016/j.partic.2007.09.002

Blissett RS, Rowson NA (2012) A review of the multi-component utilization of coal fly ash. Fuel 97:1–23. https://doi.org/10.1016/j.fuel.2012.03.024

Brown P, Jones T, BéruBé K (2011) The internal microstructure and fibrous mineralogy of fly ash from coal-burning power stations. Environ Pollut 159:3324–3333

Buema G, Lupu N, Chiriac H, Ciobanu G, Bucur RD, Bucur D, Favier L, Harja M (2021) Performance assessment of five adsorbents based on fly ash for removal of cadmium ions. J Mol Liq 333:115932

Cardoso AM, Paprocki A, Ferret LS, Azevedo CM, Pires M (2015) Synthesis of zeolite Na-P1 under mild conditions using Brazilian coal fly ash and its application in wastewater treatment. Fuel 139:59–67

Chaturvedi AK, Yadava KP, Pathak KC, Singh VN (1990) Defluoridation of water by adsorption on fly ash. Water Air Soil Pollut 49(1–2):51–61

Chen M, Zhu L, Dong Y, Li L, Liu J (2016) Waste-to-resource strategy to fabricate highly porous whisker-structured mullite ceramic membrane for simulated oil-in-water emulsion wastewater treatment. ACS Sustain Chem Eng 4:2098–2106

Czarna D, Baran P, Kunecki P, Panek R, Żmuda R, Wdowin M (2018) Synthetic zeolites as potential sorbents of mercury from wastewater occurring during wet FGD processes of flue gas. J Clean Prod 172:2636–2645

Czarna-Juszkiewicz D, Cader J, Wdowin M (2020) From coal ashes to solid sorbents for hydrogen storage. J Clean Prod 270:122355. https://doi.org/10.1016/j.jclepro.2020.122355

Darmayanti L, Notodarmodjo S, Damanhuri E (2017) Removal of copper (II) ions in aqueous solutions by sorption onto fly ash. J Eng Technol Sci 49(4):546–459

Dash S, Chaudhuri H, Gupta R, Nair UG (2018) Adsorption study of modified coal fly ash with sulfonic acid as a potential adsorbent for the removal of toxic reactive dyes from aqueous solution: kinetics and thermodynamics. J Environ Chem Eng 6(5):5897–5905

Dasmahapatra GP, Pal TK, Bhadra AK, Bhattacharya B (1996) Studies on separation characteristics of hexavalent chromium from aqueous solution by fly ash. Sep Sci Technol 31(14):2001–2009

de Oliveira FF, Moura KO, Costa LS, Vidal CB, Loiola AR, Nascimento RFD (2020) Reactive adsorption of parabens on synthesized micro- and mesoporous silica from coal fly ash: pH effect on the modification process. ACS Omega 5(7):3346–3357. https://doi.org/10.1021/acsomega.9b03537

Deb C, Thawani B, Menon S, Gore V, Chellappan V, Ranjan S, Ganesapillai M (2019) Design and analysis for the removal of active pharmaceutical residues from synthetic wastewater stream. Environ Sci Pollut Res 26(18):18739–18751

Dindi A, Quang DV, Vega LF, Nashef E, Abu-Zahra MRM (2019) Applications of fly ash for CO2 capture, utilization, and storage. J CO2 Util 29:82–102

Duan C, Ma T, Wang J, Zhou Y (2020) Removal of heavy metals from aqueous solution using carbon-based adsorbents: a review. J Water Process Eng 37:101339

Fang J, Qin G, Wei W, Zhao X, Jiang L (2013) Elaboration of new ceramic membrane from spherical fly ash for microfiltration of rigid particle suspension and oil-in-water emulsion. Desalination 311:113–126. https://doi.org/10.1016/j.desal.2012.11.008

Farmer AM (2018) Phosphate pollution: a global overview of the problem. In: Phosphorus: polluter and resource of the future: motivations, technologies and assessment of the elimination and recovery of phosphorus from wastewater, 35

Favier L, Harja M (2020) TiO2/Fly Ash nanocomposite for photodegradation of organic pollutant. In: Handbook of nanomaterials and nanocomposites for energy and environmental applications, pp 1–24. https://doi.org/10.1007/978-3-030-11155-7_11-2

Fungaro DA, Yamaura M, Craesmeyer GR (2012) Uranium removal from aqueous solution by zeolite from fly ash-iron oxide magnetic nanocomposite. Int Rev Chem Eng 4(3):353–358

Gadore V, Ahmaruzzaman M (2021) Tailored fly ash materials: a recent progress of their properties and applications for remediation of organic and inorganic contaminants from water. J Water Process Eng 41:101910. https://doi.org/10.1016/j.jwpe.2020.101910

Gangoli N, Markey DC, Thodos G (1975) Removal of heavy metal ions from aqueous solutions with fly ash. In: Proceedings of the 2nd national conference on complete water reuse, Chicago, IL, USA

Geethamani CK, Ramesh ST, Gandhimathi R, Nidheesh PV (2014) Alkali-treated fly ash for the removal of fluoride from aqueous solutions. Desalin Water Treat 52(19–21):3466–3476

Gollakota AR, Volli V, Shu CM (2019) Progressive utilisation prospects of coal fly ash: a review. Sci Total Environ 672:951–989

Grubb DG, Guimaraes MS, Valencia R (2000) Phosphate immobilization using an acidic type F fly ash. J Hazard Mater 76(2–3):217–236

He JF, Duan CL, Lei MZ, Zhu XM (2015) The secondary release of mercury in coal fly ash-based flue-gas mercury removal technology. Environ Technol 37:28–38. https://doi.org/10.1080/09593330.2015.1059491

He K, Chen Y, Tang Z, Hu Y (2016) Removal of heavy metal ions from aqueous solution by zeolite synthesized from fly ash. Environ Sci Pollut Res 23:2778–2788

Hollis JF, Keren R, Gal M (1988) Boron release and sorption by fly ash as affected by pH and particle size. J Environ Qual 17(2):181

Huang L, Cao C, Xu D, Guo Q, Tan F (2019) Intrinsic adsorption properties of raw coal fly ash for quinoline from aqueous solution: kinetic and equilibrium studies. SN Appl Sci 1(9):1090

Huber F, Fellner J (2018) Integration of life cycle assessment with monetary valuation for resource classification: the case of municipal solid waste incineration fly ash. Resour Conserv Recycl 139:17–26. https://doi.org/10.1016/j.resconrec.2018.08.003

Itskos G, Koukouzas N, Vasilatos C, Megremi I, Moutsatsou A (2010) Comparative uptake study of toxic elements from aqueous media by the different particle-size-fractions of fly ash. J Hazard Mater 183(1–3):787–792

Izquierdo M, Querol X (2012) Leaching behaviour of elements from coal combustion fly ash: An overview. Int J Coal Geol 94:54–66. https://doi.org/10.1016/j.coal.2011.10.006

Janoš P, Buchtová H, Rýznarová M (2003) Sorption of dyes from aqueous solutions onto fly ash. Water Res 37(20):4938–4944

Jedidi I, Saïdi S, Khemakhem S, Larbot A, Elloumi-Ammar N, Fourati A, Charfi A, Salah AB, Amar RB (2009) Elaboration of new ceramic microfiltration membranes from mineral coal fly ash applied to waste water treatment. J Hazard Mater 172(1):152–158. https://doi.org/10.1016/j.jhazmat.2009.06.151

Jedidi I, Khemakhem S, Saïdi S, Larbot A, Elloumi-Ammar N, Fourati A, Charfi A, Salah AB, Amar RB (2011) Preparation of a new ceramic microfiltration membrane from mineral coal fly ash: application to the treatment of the textile dying effluents. Powder Technol 208(2):427–432. https://doi.org/10.1016/j.powtec.2010.08.039

John Y, David VE, Mmereki D (2018) A comparative study on removal of hazardous anions from water by adsorption: a review. Int J Chem Eng 2018:3975948

Joshi MK, Pant HR, Liao N, Kim JH, Kim HJ, Park CH, Kim CS (2015) In-situ deposition of silver−iron oxide nanoparticles on the surface of fly ash for water purification. J Colloid Interface Sci 453:159–168

Kanchapogu S, Pugazhenthi G (2016) Development of ceramic membranes from low-cost clays for the separation of oil–water emulsion. Desalin Water Treat 57(5):1927–1939. https://doi.org/10.1080/19443994.2014.979445

Kanchapogu S, Pugazhenthi G, Uppaluri R (2016) Fly ash based ceramic microfiltration membranes for oil-water emulsion treatment: parametric optimization using response surface methodology. J Water Process Eng 13:27–43. https://doi.org/10.1016/j.jwpe.2016.07.008

Kao PC, Tzeng JH, Huang TL (2000) Removal of chlorophenols from aqueous solution by fly ash. J Hazard Mater 76(2–3):237–249

Kara S, Aydiner C, Demirbas E, Kobya M, Dizge N (2007) Modeling the effects of adsorbent dose and particle size on the adsorption of reactive textile dyes by fly ash. Desalination 212(1–3):282–293

Karanac M, Đolić M, Veličković Z, Kapidžić A, Ivanovski V, Mitrić M, Marinković A (2018) Efficient multistep arsenate removal onto magnetite modified fly ash. J Environ Manag 224:263–276

Khairnar RS, Lakhane MA, Mahabole MP (2013) Development of fly ash sensors for CO and CO2 gases. Sens Lett 11:1–7

Khan I, Rashid U (2019) Environmental risk assessment of coal fly ash on soil and groundwater quality, Aligarh, India. Groundw Sustain Dev 8:346–357

Krishnamoorthy S, Ajala F, Mohammed SM, Asok A, Shukla S (2021) High adsorption and high catalyst regeneration kinetics observed for Flyash-Fe3O4-Ag magnetic composite for efficient removal of industrial azo reactive dyes from aqueous solution via persulfate activation. Appl Surf Sci 548:149265. https://doi.org/10.1016/j.apsusc.2021.149265

Kumar P, Mal N, Oumi Y, Yamana K, Sano T (2001) Mesoporous materials prepared using coal fly ash as the silicon and aluminium source. J Mater Chem 11:3285–3290

Kumar M, Goswami L, Singh AK, Sikandar M (2019) Valorization of coal fired-fly ash for potential heavy metal removal from the single and multi-contaminated system. Heliyon 5(10):e02562. https://doi.org/10.1016/j.heliyon.2019.e02562

Kuziemska I (1980) Application of water extract of brown coal fly ash to phosphate precipitation from polluted waters. Water Res 14(9):1289–1293

Lee NK, Khalid Hammad R, Lee HK (2017) Adsorption characteristics of cesium onto mesoporous geopolymers containing nano-crystalline zeolites. Microporous Mesoporous Mater 242:238–244

Li SY, Xie SB, Zhao C, Zhang YP, Liu JX, Cai T (2013) Efficiency of adsorption of wastewater containing uranium by fly ash. Advanced materials research, vol 639. Trans Tech Publications Ltd, pp 1295–1299

Li H, Chen Y, Cao Y, Liu GJ, Li BQ (2016) Comparative study on the characteristics of ball-milled coal fly ash. J Therm Anal Calorim 124:839–846. https://doi.org/10.1007/s10973-015-5160-5

Lieberman RN, Green U, Segev G, Polat M, Mastai Y, Cohen H (2015) Coal fly ash as a potential fixation reagent for radioactive wastes. Fuel 153:437–444

Liu Y, Zeng F, Sun B, Jia P, Graham IT (2019) Structural characterizations of aluminosilicates in two types of fly ash samples from Shanxi province, North China. Minerals 9:358. https://doi.org/10.3390/min9060358

Malik A, Grohmann E (eds) (2011) Environmental protection strategies for sustainable development. Springer

Mathapati M, Amate K, Durga Prasad C, Jayavardhana ML, Hemanth Raju T (2021) A review on fly ash utilization. Mater Today Proc 9:99. https://doi.org/10.1016/j.matpr.2021.09.106

Mazumder NA, Rano R (2018) Synthesis and characterization of fly ash modified copper oxide (FA/CuO) for photocatalytic degradation of methyl orange dye. Mater Today Proc 5(1):2281–2286

Miricioiu MG, Niculescu VC (2020) Fly ash, from recycling to potential raw material for mesoporous silica synthesis. Nanomaterials 10:474. https://doi.org/10.3390/nano10030474

Miricioiu MG, Niculescu VC, Filote C, Raboaca MS, Nechifor G (2021) Coal fly ash derived silica nanomaterial for MMMs-application in CO2/CH4 separation. Membranes 11:78. https://doi.org/10.3390/membranes11020078

Mohan D, Singh KP, Singh G, Kumar K (2002) Removal of dyes from wastewater using flyash, a low-cost adsorbent. Ind Eng Chem Res 41(15):3688–3695

Muñoz MI, Aller AJ, Littlejohn D (2014) The bonding of heavy metals on nitric acid-etched coal fly ashes functionalized with 2-mercaptoethanol or thioglycolic acid. Mater Chem Phys 143(3):1469–1480

Mushtaq F, Zahid M, Bhatti IA, Nasir S, Hussain T (2019) Possible applications of coal fly ash in wastewater treatment. J Environ Manag 240:27–46

Mutlu BK, Cantoni B, Turolla A, Antonelli M, Hsu-Kim H, Wiesner MR (2018) Application of nanofiltration for rare earth elements recovery from coal fly ash leachate: performance and cost evaluation. Chem Eng J 349:309–317. https://doi.org/10.1016/j.cej.2018.05.080

Nadeem N, Abbas Q, Yaseen M, Jilani A, Zahid M, Iqbal J, Murtaza A, Janczarek M, Jesionowski T (2021) Coal fly ash-based copper ferrite nanocomposites as potential heterogeneous photocatalysts for wastewater remediation. Appl Surf Sci 565:150542

Naseem T, Waseem MA (2021) comprehensive review on the role of some important nanocomposites for antimicrobial and wastewater applications. Int J Environ Sci Technol. https://doi.org/10.1007/s13762-021-03256-8

Nath SK, Maitra S, Mukherjee S, Kumar S (2016) Microstructural and morphological evolution of fly ash based geopolymers. Constr Build Mater 111:758–765

Niveditha SV, Gandhimathi R (2020) Flyash augmented Fe3O4 as a heterogeneous catalyst for degradation of stabilized landfill leachate in Fenton process. Chemosphere 242:125189. https://doi.org/10.1016/j.chemosphere.2019.125189

Noli F, Kapnisti M, Buema G, Harja M (2016) Retention of barium and europium radionuclides from aqueous solutions on ash-based sorbents by application of radiochemical techniques. Appl Radiat Isot 116:102–109

Nollet H, Roels M, Lutgen P, Van der Meeren P, Verstraete W (2003) Removal of PCBs from wastewater using fly ash. Chemosphere 53(6):655–665

Öztürk N, Kavak D (2005) Adsorption of boron from aqueous solutions using fly ash: batch and column studies. J Hazard Mater 127(1–3):81

Panda L, Kar BB (2018) Preparation of fly ash based zeolite for fluoride removal. Asian J Water Environ Pollut 15(4):105–113

Pandey VC (2020) CHAPTER 3 Scope of fly ash use in agriculture: prospects and challenges. In: Phytomanagement of fly ash, pp 33–101

Police S, Maity S, Chaudhary DK, Dusane CK, Sahu SK, Kumar AV (2020) Effect of coal fly ash’s particle size on U adsorption in water samples and thermodynamic study on adsorption. Environ Chem Ecotoxicol 2:32–38. https://doi.org/10.1016/j.enceco.2020.01.005

Qi G, Lei X, Li L, Yuan C, Sun Y, Chen J, Chen J, Wang Y, Hao J (2015) Preparation and evaluation of a mesoporous calcium-silicate material (MCSM) from coal fly ash for removal of Co (II) from wastewater. Chem Eng J 279:777–787

Rasaki SA, Bingxue Z, Guarecuco R, Thomas T, Minghui Y (2019) Geopolymer for use in heavy metals adsorption, and advanced oxidative processes: a critical review. J Clean Prod 213:42–58

Reardon EJ, Wang Y (2000) A limestone reactor for fluoride removal from wastewaters. Environ Sci Technol 34(15):3247–3253

Roper AR, Stabin MG, Delapp RC, Kosson DS (2013) Analysis of naturally-occurring radionuclides in coal combustion fly ash, gypsum, and scrubber residue samples. Health Phys 104:264–269. https://doi.org/10.1097/HP.0b013e318279f3bf

Rozek P, Krol M, Mozgawa W (2020) Lightweight geopolymer-expanded glass composites for removal of methylene blue from aqueous solutions. Ceram Int 46:19785–19791

Rubio B, Izquierdo MT, Mayoral MC, Bona MT, Martínez-Tarazona RM (2008) Preparation and characterization of carbon-enriched coal fly ash. J Environ Manag 88:1562–1570

Rzymski P, Drewek A, Klimaszyk P (2017) Pharmaceutical pollution of aquatic environment: an emerging and enormous challenge. Limnol Rev 17(2):97–107

Sahoo PK, Tripathy S, Panigrahi MK, Equeenuddin SKMD (2013) Evaluation of the use of an alkali modified fly ash as a potential adsorbent for the removal of metals from acid mine drainage. Appl Water Sci 3:567–576

Ściubidło A, Majchrzak-Kucęba I (2019) Exhaust gas purification process using fly ash-based sorbents. Fuel 258:116126

Sharma A, Kabra S, Katara S, Rani A (2015) Variation of surface morphology and physico-chemical properties of the fly ash through mechanical and thermal activations. J Adv Chem Sci 1(2):70–74

Shyam R, Puri JK, Kaur H, Amutha R, Kapila A (2013) Single and binary adsorption of heavy metals on fly ash samples from aqueous solution. J Mol Liq 178:31–36

Singh BK, Nayak PS (2004) Sorption equilibrium studies of toxic nitro-substituted phenols on fly ash. Adsorpt Sci Technol 22(4):295–309

Singh VK, Singh RS, Tiwari PN, Singh JK, Gode F, Sharma YC (2010) Removal of malathion from aqueous solutions and waste water using fly ash. J Water Resour Prot 2(4):322

Singh K, Pandey VC, Singh B, Patra DD, Singh RP (2016) Effect of fly ash on crop yield and physico-chemical, microbial and enzyme activities of sodic soils. Environ Eng Manag J 15:11

Siyal AA, Shamsuddin MR, Rabat NE, Zulfiqar M, Man Z, Low A (2019) Fly ash based geopolymer for the adsorption of anionic surfactant from aqueous solution. J Clean Prod 229:232–243

Sow M, Hot J, Tribout C, Martin C (2015) Characterization of Spreader Stoker Coal Fly Ashes (SSCFA) for their use in cement-based applications. Fuel 162:224–233

Sun D, Zhang X, Wu Y, Liu X (2010) Adsorption of anionic dyes from aqueous solution on fly ash. J Hazard Mater 181(1–3):335–342

Tan Tee H, Mo Kim H, Tung-Chai L, Hin LS (2020) Current development of geopolymer as alternative adsorbent for heavy metal removal. Environ Technol Innov 18:100684

Teng X, Li J, Wang J, Liu J, Ge X, Gu T (2021) Effective degradation of atrazine in wastewater by three-dimensional electrochemical system using fly ash-red mud particle electrode: mechanism and pathway. Sep Purif Technol 267:118661. https://doi.org/10.1016/j.seppur.2021.118661

Tennakoon C, Sagoe-Crentsil K, San Nicolas R, Sanjayan JG (2015) Characteristics of Australian brown coal fly ash blended geopolymers. Constr Build Mater 101:396–409. https://doi.org/10.1016/j.conbuildmat.2015.10.089

Turhan S, Parmaksız A, Kose A, Yuksel A, Arıkan IH, Yucel B (2010) Radiological characteristics of pulverized fly ashes produced in Turkish coal-burning thermal power plants. Fuel 89:3892–3900. https://doi.org/10.1016/j.fuel.2010.06.045

Valeev D, Kunilova I, Alpatov A, Mikhailova A, Goldberg M, Kondratiev A (2019) Complex utilisation of ekibastuz brown coal fly ash: iron & carbon separation and aluminum extraction. J Clean Prod 218:192–201. https://doi.org/10.1016/j.jclepro.2019.01.342

Viraraghavan T, Ramakrishna KR (1999) Fly ash for colour removal from synthetic dye solutions. Water Qual Res J 34(3):505–518

Visa M, Isac L, Duta A (2012) Fly ash adsorbents for multi-cation wastewater treatment. Appl Surf Sci 258(17):6345–6352

Wang S, Wu H (2006) Environmental-benign utilization of fly ash as low-cost adsorbents. J Hazard Mater 136(3):482–501

Wang S, Boyjoo Y, Choueib A, Zhu ZH (2005a) Removal of dyes from aqueous solution using fly ash and red mud. Water Res 39(1):129–138

Wang S, Boyjoo Y, Choueib A (2005b) A comparative study of dye removal using fly ash treated by different methods. Chemosphere 60:1401–1407

Wang Z, Fan Y, Li Y, Qu F, Wu D, Kong H (2016) Synthesis of zeolite/hydrous lanthanum oxide composite from coal fly ash for efficient phosphate removal from lake water. Microporous Mesoporous Mater 222:226–234

Wang N, Chenab J, Zhaoc Q, Xua H (2017) Study on preparation conditions of coal fly ash catalyst and catalytic mechanism in a heterogeneous Fenton-like process. R Soc Chem 7:52524–52532

Wang N, Sun X, Zhao Q, Yang Y, Wang P (2020) Leachability and adverse effects of coal fly ash: a review. J Hazard Mater 396:122725. https://doi.org/10.1016/j.jhazmat.2020.122725

Wang C, Xu G, Gu X, Gao Y, Zhao P (2021a) High value-added applications of coal fly ash in the form of porous materials: a review. Ceram Int 47:22302–22315

Wang N, Sun X, Zhao Q, Wang P (2021b) Treatment of polymer-flooding wastewater by a modified coal fly ash-catalysed Fenton-like process with microwave pre-enhancement: system parameters, kinetics, and proposed mechanism. Chem Eng J 406:126734. https://doi.org/10.1016/j.cej.2020.126734

Xie X, Zhou SK (2017) Preparation of Modified Fly Ash and its Adsorption Properties for U (VI) Uranium. Applied Mechanics and Materials, vol 873. Trans Tech Publications Ltd, pp 107–111

Xiyili H, Çetintaş S, Bingöl D (2017) Removal of some heavy metals onto mechanically activated fly ash: modeling approach for optimization, isotherms, kinetics and thermodynamics. Process Saf Environ Prot 109:288–300

Yao ZT, Ji XS, Sarker PK, Tang JH, Ge LQ, Xia MS, Xi YQ (2015) A comprehensive review on the applications of coal fly ash. Earth Sci Rev 141:105–121

Zhang M, Mao Y, Wang W, Yang S, Song Z, Zhao X (2016) Coal fly ash/CoFe2O4 composites: a magnetic adsorbent for the removal of malachite green from aqueous solution. RSC Adv 6:93564–93574

Zhang J, Yan M, Sun G, Liu K (2021a) Simultaneous removal of Cu(II), Cd(II), Cr(VI), and rhodamine B in wastewater using TiO2 nanofibers membrane loaded on porous fly ash ceramic support. Sep Purif Technol 272:118888. https://doi.org/10.1016/j.seppur.2021.118888

Zhang X, Bai C, Qiao Y, Wang X, Jia D, Li H, Colombo P (2021b) Porous geopolymer composites: a review. Compos A 150:106629

Zhou H, Bhattarai R, Li Y, Si B, Dong X, Wang T, Yao Z (2022) Towards sustainable coal industry: turning coal bottom ash into wealth. Sci Total Environ 804:149985

Zhu L, Chen M, Dong Y, Tang CY, Huang A, Li L (2016) A low-cost mullite-titania composite ceramic hollow fiber microfiltration membrane for highly efficient separation of oil-in-water emulsion. Water Res 90:277–285

Zou D, Xu J, Chen X, Drioli E, Qiu M, Fan Y (2019) A novel thermal spraying technique to fabricate fly ash/alumina composite membranes for oily emulsion and spent tin wastewater treatment. Sep Purif Technol 219:127–136. https://doi.org/10.1016/j.seppur.2019.02.051

Acknowledgements

Authors are grateful to the Sharda University, Greater Noida, UP, India for granting seed fund (SUSF1902-24) to do the research.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interest

The authors declare that they have no known competing financial interest or personal relationship that could have appeared to influence the work reported in this manuscript.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article