Abstract

Solid oxide fuel cell combined with heat and power (SOFC-CHP) system is a distributed power generation system with low pollution and high efficiency. In this paper, a 10 kW SOFC-CHP system model using syngas was built in Aspen plus. Key operating parameters, such as steam to fuel ratio, stack temperature, reformer temperature, air flow rate, and air preheating temperature, were analyzed. Optimization was conducted based on the simulation results. Results suggest that higher steam to fuel ratio is beneficial to the electrical efficiency, but it might decrease the gross system efficiency. Higher stack and reformer temperatures contribute to the electrical efficiency, and the optimal operating temperatures of stack and reformer when considering the stack degradation are 750 °C and 700 °C, respectively. The air preheating temperature barely affects the electrical efficiency but affects the thermal efficiency and the gross system efficiency, the recommended value is around 600 °C under the reference condition.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The global demand for electricity and energy is constantly increasing. China, India, and the United States of America are the three most populous countries in the world, and meanwhile the three most energy-consuming countries (Wei et al. 2020). At present, the world's electricity mainly relies on fossil fuels, such as coal and natural gas. However, the conversion efficiency of traditional power generation units is low, and the massive use of fossil fuels has caused high greenhouse gas emissions and aggravated global warming (Ahmad et al. 2017; Nikzad and Sedigh 2017; Zecca and Chiari 2010). To reduce the impact of power generation on the global environment, developing clean power generation techniques has drawn more and more attention.

The solid oxide fuel cell (SOFC) is an electrochemical device that can directly convert the chemical energy of fuel into electrical energy. Comparing to traditional power generation devices, SOFCs have the advantages of higher efficiency and low pollutant emission, such as SOx and NOx (Fernandes et al. 2018; Lu et al. 2018). Due to high operating temperatures, the efficiency of the SOFC combined heat and power (SOFC-CHP) system can achieve 80% and even more (Wang et al. 2021). Various systems at different scales have been applied in Europe, the United States, Japan, and other places, ranging from kilowatt to megawatt, from household cogeneration systems to large-scale power generation systems (Choudhury et al. 2013; Nakao et al. 2019; Santarelli et al. 2019). However, the operation conditions of SOFC-CHP systems both in articles and markets are different from each other. To promote the localization and commercialization of SOFC systems in different areas of China, it is important to analyze the key factors which may influence the performance of the system according to different fuels.

Working conditions are vital for the performance and lifetime of SOFC systems. Lyu et al. (2020) studied the effects of different fuel flow rate, operating current, anode off-gas recirculation (AOGR) ratio on the performance of SOFC stacks based on the Aspen software. Results showed that a higher flow rate of CH4 will decrease the electrical efficiency of the stack, the electrical efficiency of the stack will firstly increase before decline when more current was been drawn. The larger AOGR ratio will have a negative impact on the electrical efficiency of the stack. Anode off-gas recirculation is also used in the SOFC system to achieve higher fuel utilization. Research conducted by Powell et al. (2012) proved that although increasing the AOGR ratio of anode off-gas could increase the overall fuel utilization, it impacts the system efficiency at the same time. Anode gas recirculation can help the system to achieve a fuel utilization of 93% while single-pass fuel utilization is around 55%. Furthermore, research conducted by Zhang et al. (2017) suggested that the AOGR rate of 0.7 is a turning point. Lower than 0.7 will promote electrical efficiency while larger than 0.7 will help to improve the thermal efficiency. Xu et al. (2013) studied the impact of the cell output voltage and the fuel flow rate on the system performance, indicating that the cell voltage decreased but the SOFC stack efficiency and the electrical efficiency of the system increased when the average current density rose. Under the condition that the output voltage was constant, as the inlet fuel flow rate increased, the fuel utilization rate changed conversely. Peters et al. (2016) discussed the effects of operational parameters such as the AOGR ratio and fuel utilization rates, with the hope of achieving higher system efficiency. This study suggested that enlarging the fuel utilization rate and the anode off-gas recirculation would promote the electrical efficiency but suppress the thermal efficiency of the system. However, the air mass flow and the air blower power consumption could reduce by increasing the fuel utilization rate. In summary, although many researches have been conducted on system operation parameters, there are many limitations. First of all, existing studies mainly focus on the parameters of the SOFC stack. However, the balance of plant (BOP) such as reformer, heat exchangers has the same importance as the stack, can also influence the system performance and stability. From a system-level perspective, the coupled effects of BOP operating parameters on the system performance still need to be further studied. Furthermore, most of the existing system studies are conducted with pure fuel, but impurities are very common in real applications.

The SOFC system performance will be greatly affected by different fuels, and the system components, configurations, and performances differ a lot when using different fuels (Rokni 2017). Cinti et al. (2019) simulated different mixtures of methane and hydrogen, compared the performances of SOFC-CHP systems with different fuels under the same system structure and working conditions. The results revealed that the system fed with pure methane had higher electrical efficiency, but the overall system efficiency could be higher when the fuel was mixed with hydrogen. Cheng et al. (2019) designed different SOFC systems for hydrogen and methane fuel and compared the system performances. Their study indicated that with the increase of system output power, the electrical efficiency of both the hydrogen-fueled and methane-fueled SOFC systems would decrease after the initial increase. Although the trend of the electrical efficiency was similar, there was some difference. The electrical efficiency of the latter was higher when the output power varied from 1 to 8 kW, but the electrical efficiency of the hydrogen-fueled system would be higher if the output power was between 8 and 10 kW. Rokni (2017) simulated several systems fueled by hydrogen, ammonia, methanol, ethanol and dimethyl ether, suggesting that the plant efficiency is larger on the ethanol fuel and the AOGR rate should be 20% when the system is fed by pure hydrogen and the fuel utilization is 80%.

In summary, although the fuels and working conditions of SOFC systems have been widely discussed, previous researches were mainly conducted under one kind of pure fuel or the mixture of several pure fuels. In real industrial applications, impurities, such as non-flammable gas, may exist in the fuels. It may deviate the system performance from the design point which was normally established based on pure fuel. On the other hand, the investigation and optimization of key operating parameters are important to guarantee system efficiency and lifetime.

Coalbed methane (CBM) is one kind of combustible syngas consisting primarily of methane and carbon dioxide and can be used as fuel for SOFC power systems. Besides, the SOFC-CHP system is suitable for the coal mine because there are much the CBM and large demands of power and heat in coalfield.

To improve the performance of the SOFC-CHP system with the CBM (87.79% CH4, 10.83% CO2, 1.38% N2) in the coalfield of Zhunnan coal mine in Xinjiang province, a 10 kW class SOFC-CHP system model was established on Aspen plus. The influence of key parameters such as steam–fuel ratio, stack working temperature, reformer temperature, air flow rate, and preheating temperature on the system performance was investigated.

2 System model and verification

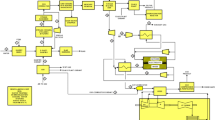

To establish a reliable SOFC-CHP system model, stack experiments and the process of electrochemistry reaction need to be conducted and analyzed. Stack experiments were firstly carried out in Suzhou Huasting Jingkun New Energy Technology Co., Ltd and partial stack parameters are shown in Table 1. Then, electrochemistry parameters and related expressions were fitted and identified based on the experimental data. The stack model was built in Aspen Plus with the fitted parameters. Finally, the model data and experimental data were compared to verify the accuracy of the stack model. The experiment and the establishment and verification of the stack model were detailed in the literature (Lyu et al. 2020). Based on the established SOFC stack model, a 10 kW SOFC-CHP system was built in Aspen plus. The system establishment process is shown in Fig. 1. The reference condition of the system is shown in Table 2.

Due to the high operating temperature and free of Pt electrode, CO and CH4 can be accepted by the SOFC than other low temperature fuel cells. However, many experiments proved that the microstructure and long-term operating performance of the SOFC stack could be damaged if the content of CO in anode inlet was too large (Stoeckl et al. 2017a, b, 2018). Besides, other studies suggested that more uneven temperature distribution inside the stack, obvious voltage degradation, and lower electrical performance were observed when the methane or methane reforming gas (CH4, CO, CO2, H2, H2O), instead of hydrogen, was fed to SOFC stack (Zhang et al. 2020; Saadabadi et al. 2021). To achieve long-term performance and stability, increasing H2 concentration and decreasing the concentration of CH4, CO, CO2, and H2O in anode inlet should be considered. Therefore, a palladium membrane was employed in this paper.

Figure 2 shows the structure of the10 kW SOFC-CHP system with the CBM. Tap water and the CBM are preheated and mixed into the reformer, which is heated by the off-gas of the afterburner. The reformer off-gas is separated by a palladium membrane, hydrogen enters the stack, and the rest of the reformed gases enter the burner. Air is preheated to 600 °C before stepping into the SOFC stack.

The gross electrical efficiency is calculated as follows:

where, P is the gross system power, kW; n is the fuel flow rate, mol/s; HHVvalue is the high heating value of the fuel, kJ/mol.

The parasitic electrical is calculated as follows:

where, the Pair, Pfuel, Pwater are the power consumption of the air blower, fuel blower and water pump, kW, respectively.

The net electrical efficiency is calculated as follows:

The thermal efficiency is calculated as follows:

where the c and m stand for the specific heat capacity and flow rate of the cooling water, \(\Delta T\) is the temperature difference between the inlet and the outlet water.

The gross system efficiency and the net system efficiency can be respectively calculated as follows:

3 Results and discussion

The optimal operation condition is vital for the stable and efficient operation and long lifetime of the SOFC-CHP system. The simulation was conducted based on the CBM (87.79% CH4, 10.83% CO2, 1.38% N2) of the No. 39 coal seam at the Fukang mining area of the Zhunnan coalfield in Xinjiang Province. Effects of the steam–fuel ratio, stack temperature, reformer temperature, air flow rate, and air preheating temperature on system performance were investigated, and the optimized parameter values were proposed.

3.1 The effect of steam–fuel ratio

Methane, directly used as fuel, may cause carbon deposits on the cell anode, which is not conducive to the long-term stable operation of the SOFC. Therefore, the SOFC system usually adopts an external reformer to avoid carbon deposition at the anode and increase the hydrogen concentration in the fuel. Therefore, choosing the right steam–fuel ratio (water flow rate/fuel flow rate) is very important for the SOFC system. The steam–fuel ratios are set as 1.0, 1.5, 2.0, 2.5 and 3.0, the corresponding steam to carbon ratios (water flow rate/methane flow rate) are 1.14, 1.71, 2.28, 2.85 and 3.42. The stack temperature is 750 °C and the reformer temperature is 700 °C.

Figure 3 depicts the flow rates and components of reformer off-gas, cell voltage, power and efficiency of the system. With the increase of the steam–fuel ratio, the flow rate and content of each component of the reformer off-gas changes differently. For instance, the flow rate of hydrogen increases but the content decreases, while the flow rate and content of steam vapor gradually increase. When the steam–fuel ratio increases from 1.00 to 3.00, the hydrogen flow rate will increase by 0.21 kmol/h while the content decreases by 5.35%, while the steam flow rate and content increase by 0.24 kmol/h and 28.18%, respectively. When the steam–fuel ratio is between 1.00 and 2.00, the flow rate of each gas changes more drastically.

As the steam–fuel ratio increases, the cell voltage gradually rises, resulting in that the gross and net power of the system gradually increases. The electrical efficiency of the system increases slightly but the thermal efficiency decreases obviously. As a result, the gross system efficiency increases initially but decreases eventually. The steam–fuel ratio increases from 1.00 to 3.00, the cell voltage enlarges from 0.69 to 0.72 V. The gross and net power increase from 9.74 to 10.13 kW, and from 9.09 to 9.48 kW, an increase of 0.39 kW respectively. The increase in power generation leads to an improvement in power generation efficiency. When the steam–fuel ratio increases from 1 to 3, the gross electrical efficiency will increase by 1.29%, and the thermal efficiency decreases on contrary. With the ratio from 1 to 3, the thermal efficiency drops by 4.14%. The gross system efficiency originally increases but eventually decreases. The system efficiency meets the maximum value of 81.42% when the steam–fuel ratio is 1.5.

As discribed in Table 3, the larger steam–fuel ratio will promote the methane-steam reforming reaction, beneficial to the process of methane conversion and hydrogen generation, which will improve the hydrogen partial pressure in the anode and eventually promotes the cell voltage. Therefore, both the system power generation and power generation efficiency increase. However, an increase in the steam–fuel ratio will also dilute the combustible gas concentration at the burner inlet, which is not conducive to combustion. Therefore, the thermal efficiency of the system decreases as the steam–fuel ratio increases. From the above analysis, it can be seen that both the electrical efficiency and the system efficiency are higher under the steam–fuel ratio of 1.5.

3.2 The effect of stack temperature

SOFC stack is the core equipment of the SOFC-CHP system, its performance is vital to the whole system. In this section, the gross power, electrical efficiency, and gross system efficiency are studied under different stack temperatures. The reformer temperature is fixed at 700 °C.

Figure 4 gives the generating power and electrical, thermal, and system efficiency. As shown in Fig. 4, as the operating temperature rises, all of the gross and net power, electrical efficiency, thermal efficiency, gross and net system efficiency increase. As the stack temperature increases from 700 to 800 °C, the gross and net power both increase by 2.15 kW, respectively. The gross electrical efficiency, net electrical efficiency, thermal efficiency, gross system efficiency, and net efficiency increased by 7.16%, 7.16%, 0.64%, 7.80%, and 7.80%, respectively. The higher operating temperature of the stack has a positive effect on the power generation and overall system efficiency.

Higher stack temperature can improve the cell voltage by lower the polarization impedance. Therefore, the output voltage of the stack increases as the temperature, which eventually promotes the power generation and the gross electrical efficiency. The SOFC stack should work at high temperatures to meet the high electrical and system efficiency. However, the degradation is more active for the SOFC stack at high temperatures. Therefore, the working temperature of the stack should not be too high, the recommended value is 750 °C.

3.3 The effect of reformer temperature

As an important component of the SOFC system fueled by hydrocarbons, the performance of the reformer is important to the whole system. To study the influence of the reformer's temperature on the overall performance of the SOFC-CHP system, the SOFC-CHP system was simulated and the impact of this temperature on the system performance was analyzed under different reformer temperatures (600, 650, 700, and 750 °C, respectively) based on the stack temperature of 750 °C. The results are shown in Fig. 5.

As shown in Fig. 5a, as the working temperature of the reformer rises, the off-gas composition of the reformer changes monotonously with a decreasing change rate. The contents of hydrogen and carbon monoxide gradually increase, but the contents of water, carbon dioxide, and methane gradually decrease. Meanwhile, the change rate of different components is not the same. The reformer temperature is from 600 °C up to 750 °C, the hydrogen content increases from 48.60% to 58.69%, increasing by 10.09%, but the methane content decreases from 7.42% to 0.41%, decreasing by 7.01%. The influence of reforming temperature on exhaust gas composition gradually decreases with the reformer temperature. When the reformer temperature grows from 700 to 750 °C, the hydrogen and methane content in the reformer off-gas increases by 0.86% and − 0.93%, respectively, which means that the system efficiency may be promoted more when the temperature is lower than 700 °C. As the methane-steam reforming process is endothermic, resulting in that higher reforming temperature is more advantageous to the reaction. Therefore, the hydrogen content increases and the methane content decreases while the temperature gets higher.

As shown in Fig. 5b, thanks to the increase of hydrogen content, the cell voltage and the power generation also gradually increase. The reformer temperature rises from 600 to 750 °C, the cell voltage increases from 0.69 to 0.72 V, and the gross and net power of the system increase from 9.68 to 10.10 kW and 9.03 kW to 9.45 kW, respectively.

As shown in Fig. 5c, as the operating temperature of the reformer rises, the gross electrical efficiency of the system becomes a little larger, the thermal efficiency is slightly suppressed, but the gross efficiency shows a slight uptrend. The reformer temperature is from 600 °C up to 750 °C, the gross electrical efficiency grows from 32.16% to 33.55%, the thermal efficiency decreases from 48.37% to 47.41%, and the gross system efficiency increases from 80.54% to 80.97%, an increase of 1.39%, − 0.96% and 0.43%, respectively. As the temperature of the reformer rises, the hydrogen content at the reformer outlet increases, so the cell voltage, power generation, and electrical efficiency get promoted. However, the absorbed heat increases with the reformer temperature, resulting in less heat that can be recovered. Eventually, the thermal efficiency decreases.

Higher reformer temperature is beneficial to the electrical efficiency and overall system efficiency. However, the positive effect on the system will be little when the reformer temperature is higher than 700 °C. The reforming temperature increased from 700 to 750 °C, and the gross power generation and gross electrical efficiency increased by only 0.02 kW and 0.07%. Therefore, the reformer temperature is optimized to 700 °C.

3.4 The effect of air flow rate

Air is not only the participant of the electrochemical reaction but also the heat carrier that is responsible for transferring excess heat from the stack inside to outside during the power generation process. That is, air is of great significance to the performance and stability of the system. To study the influence of air flow rates on system performance, simulations were conducted under different air flow rates. The stack and air preheating temperatures are fixed at 750 °C and 600 °C in this section, respectively. The relevant results are shown in Fig. 6.

As shown in Fig. 6, the gross power increases slightly, but the parasitic power mainly caused by the air blower grows larger with the increase of air flow rates, which causes the decrease of the net power. The air flow is from 3 kmol/h up to 4 kmol/h, and the gross power, parasitic power, and net power of the system increased by 0.01 kW, 0.18 kW, and − 0.17 kW, respectively. With the increase of air flow rates, the gross power efficiency slightly increases, while the net power efficiency slightly decreases, however, all of the thermal efficiency, gross system efficiency, and net system efficiency increase. When air flow rate grows from 3 kmol/h up to 4 kmol/h, the net electrical efficiency decreased by 0.56%, while the gross electrical efficiency, thermal efficiency, gross system efficiency, and net system efficiency increases by 0.03%, 2.70%, 2.74%, and 2.14%, respectively.

The main reason is that a larger air flow rate makes the oxygen partial pressure on the cathode side bigger, resulting in a slight increase in output voltage, therefore, the gross power and gross electrical efficiency get larger. Meanwhile, more air can carry more heat from the stack, which causes an increase in thermal efficiency. However, more air also means more power consumption of the air blower. Therefore, the parasitic power increases, finally resulting that the net electrical efficiency decreases.

3.5 The effect of air preheating temperature

Appropriate air preheating temperature is important to the temperature balance of the stack. To determine suitable air preheating temperature, the influence of air preheating temperature on system performance was discussed under the condition of a stack temperature of 750 °C. The air flow rate is set as 0.83 mol/s. as shown in Table 2. The results are displayed in Fig. 7.

As shown in Fig. 7a, the cell voltage, gross and net power of the system are very stable against the air preheating temperature from 600 to 650 °C. It should be noted that the Aspen model was operated in stable condition, the transient heat transfer and uneven temperature distribution in the SOFC stack under different air preheating temperatures cannot be expressed. Therefore, the effect of the air preheating temperature on the cell voltage, gross and net power of the system seems stable.

Figure 7b displays the thermal loss of the air heat exchanger (HX1) and the heat recovery temperature under different air preheating temperatures. As the preheating temperature increases, the heat loss of the HX1 increases but the heat recovery temperature decreases. The preheating temperature up from 600 to 650 °C, the heat loss of the HX1 increases from 0.79 to 0.90 kW, an increase of 0.11 kW, the heat recovery temperature decreases from 84.67 to 75.89 °C, a decrease of 8.77 °C. That means that higher air preheating temperature results in the high thermal loss of the whole system, a disadvantage to the system. This phenomenon can be explained as follows: the temperature of the HX1 rises with the air preheating temperature, namely that the heat dissipated to the environment becomes easier. In turn, more wasted heat of the system makes recovered heat less, which causes the temperature drop of the heat recovery.

From Fig. 7c, it is clear that the air preheating temperature has a small effect on the gross electrical efficiency and net electrical efficiency of the system, but as the air preheating temperature increases, the thermal efficiency, gross, and net system efficiency gradually decreases. When the preheating temperature increases from 600 to 650 °C, the thermal efficiency, gross and net system efficiency reduce from 49.96% to 42.62%, from 83.45% to 76.10%, and from 81.29% to 73.94%, respectively. From the above analysis, it can be seen that a moderate reduction of the air preheating temperature is beneficial to improve the thermal efficiency and the overall system efficiency, and the optimized preheating temperature is 600 °C.

4 Conclusions

In this paper, a semi-empirical SOFC stack model was established in Aspen plus based on the experimental data of a 3-cell stack. The 10 kW SOFC-CHP system was built after the reliability and accuracy of the stack model were proved by the experimental data. To reveal the optimized operating conditions and ensure the system efficiency and lifetime under syngas, key operating parameters were investigated. Increasing steam–fuel ratio, stack temperature and reformer temperature can contribute to the electrical efficiency but air flow rate and preheating temperature show little effect on it. As far as the system efficiency is concerned, it prefers to higher steam–fuel ratio, stack temperature, reformer temperature, air flow rate, and lower air preheating temperature. Under the reference condition in the present paper, the optimal values of the steam–fuel ratio, stack temperature, reformer temperature, and air preheating temperature are 1.5, 750 °C, 700 °C, and 600 °C, respectively.

References

Ahmad S, Nadeem A, Akhanova G, Houghton T, Muhammad-Sukki F (2017) Multi-criteria evaluation of renewable and nuclear resources for electricity generation in Kazakhstan. Energy 141:1880–1891

Cheng T, Jiang J, Wu X, Li X, Xu M, Deng Z, Li J (2019) Application oriented multiple-objective optimization, analysis and comparison of solid oxide fuel cell systems with different configurations. Appl Energy 235:914–929

Choudhury A, Chandra H, Arora A (2013) Application of solid oxide fuel cell technology for power generation—a review. Renew Sustain Energy Rev 20:430–442

Cinti G, Bidini G, Hemmes K (2019) Comparison of the solid oxide fuel cell system for micro CHP using natural gas with a system using a mixture of natural gas and hydrogen. Appl Energy 238:69–77

Fernandes MD, Andrade STP, Bistritzki VN, Fonseca RM, Zacarias LG, Goncalves HNC, Castro AF, Domingues RZ, Matencio T (2018) SOFC-APU systems for aircraft: a review. Int J Hydrog Energy 43(33):16311–16333

Lu Y, Cai Y, Souamy L, Song X, Zhang L, Wang J (2018) Solid oxide fuel cell technology for sustainable development in China: an overview. Int J Hydrog Energy 43(28):12870–12891

Lyu Z, Meng H, Zhu J, Han M, Sun Z, Xue H, Zhao Y, Zhang F (2020) Comparison of off-gas utilization modes for solid oxide fuel cell stacks based on a semi-empirical parametric model. Appl Energy 270:1–14

Nakao T, Inoue S, Uenoyama S, Takuwa Y, Suzuki M (2019) Progress of SOFC residential CHP system: over 50,000 units market experience of Osaka gas. ECS Trans 91(1):43–49

Nikzad R, Sedigh G (2017) Greenhouse gas emissions and green technologies in Canada. Environ Dev 24:99–108

Peters R, Deja R, Engelbracht M, Frank M, Nguyen V, Blum L, Stolten D (2016) Efficiency analysis of a hydrogen-fueled solid oxide fuel cell system with anode off-gas recirculation. J Power Sources 328:105–113

Powell M, Meinhardt K, Sprenkle V, Chick L, McVay G (2012) Demonstration of a highly efficient solid oxide fuel cell power system using adiabatic steam reforming and anode gas recirculation. J Power Sources 205:377–384

Rokni M (2017) Addressing fuel recycling in solid oxide fuel cell systems fed by alternative fuels. Energy 137:1013–1025

Saadabadi SA, Illathukandy B, Aravind PV (2021) Direct internal methane reforming in biogas fuelled solid oxide fuel cell; the influence of operating parameters. Energy Sci Eng 00:1–17

Santarelli M, Gandiglio M, Acri M, Hakala T, Rautanen M, Hawkes A (2019) Results from industrial size biogas-fed SOFC plant (DeMosofC project). ECS Trans 91(1):107–116

Stoeckl B, Subotić V, Reichholf D, Schroettner H, Hochenauer C (2017a) Extensive analysis of large planar SOFC: operation with humidified methane and carbon monoxide to examine carbon deposition based degradation. Electrochim Acta 256:325–336

Stoeckl B, Subotić V, Preininger M, Schroettner H, Hochenauer C (2017b) SOFC operation with carbon oxides: experimental analysis of performance and degradation. Electrochim Acta 275:256–264

Wang Y, Wehrle L, Banerjee A, Shi Y, Deutschmann O (2021) Analysis of a biogas-fed SOFC CHP system based on multi-scale hierarchical modeling. Renew Energy 163:78–87

Wei C, Löschel A, Managi S (2020) Recent advances in energy demand research in China. Econ Rev 63(101517):1–6

Xu H, Dang Z, Bai BF (2013) Analysis of a 1 kW residential combined heating and power system based on solid oxide fuel cell. Appl Therm Eng 50(1):1101–1110

Zecca A, Chiari L (2010) Fossil-fuel constraints on global warming. Energy Policy 38(1):1–3

Zhang L, Xing Y, Xu H, Wang H, Zhong J, Xuan J (2017) Comparative study of solid oxide fuel cell combined heat and power system with multi-stage exhaust chemical energy recycling: modeling, experiment and optimization. Energy Convers Manag 139:79–88

Zhang H, Qin H, Zhao W, Jiang J, Li J (2020) Thermoelectrical-based fuel adaptability analysis of solid oxide fuel cell system and fuel conversion rate prediction. Energy Convers Manag 222:113264

Acknowledgements

This work was supported by the National Key R&D Program of China (2017YFB0601903).

Author information

Authors and Affiliations

Contributions

Biao Li: Conceptualization, Methodology, Investigation, Writing original draft, Writing—review and editing. Zewei Lyu: Software, Validation, Writing—review and editing. Jianzhong Zhu: Visualization, Investigation, Supervision. Minfang Han: Resources, Supervision, Project administration.

Corresponding author

Ethics declarations

Conflict of interests

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Li, B., Lyu, Z., Zhu, J. et al. Study on the operating parameters of the 10 kW SOFC-CHP system with syngas. Int J Coal Sci Technol 8, 500–509 (2021). https://doi.org/10.1007/s40789-021-00451-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40789-021-00451-3