Abstract

Coal gangue is the main pollution source of mining areas. When coal gangue is stacked and recycled, the heavy metal elements contained in it are released by natural weathering and leaching, which causes damage to the surrounding ecological environment. In this study, the leaching and precipitation characteristics of heavy metals in low-sulfur coal gangue under different environmental conditions were simulated by indoor dynamic leaching experiments, which provided a theoretical basis for environmental restoration of the mining area. The conclusions are as follows: higher heavy metal content in low-sulfur coal gangue is associated with greater, leaching of heavy metals; acidic conditions promote the release of heavy metals in low-sulfur coal gangue; and more precipitation is associated with better release of heavy metals from the low-sulfur coal gangue.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Coal gangue is an industrial solid waste inevitably produced in coal mining and coal washing, and its emissions account for approximately 10%–15% of coal production (Zhou et al. 2014a, b). China is the country with the highest coal production in the world, and a large amount of coal gangue waste is piled on the surface at mining sites to form coal gangue hill, occupying a large area of land resources (Ding et al. 2015). In addition to wasting land resources, the hazards of coal gangue include the potential ecological and environmental impacts caused by harmful heavy metals (Dang et al. 1998). The stacking of coal gangue will cause the soil around the waste rock mountain to be polluted by the heavy metals in the coal gangue, and the main cause is the weathering of the coal gangue (Liu et al. 2003). Coal gangue contains a large variety of macroelements and heavy metals such as Cd, Cr, Hg, Mn, Pb, and Zn, which are harmful to the environment (Cai et al. 2008). Heavy metals are not biodegradable and have long lasting effects in soil due to the strong adsorption of many metals on humid and clay colloids in soils (Sun et al. 2010). Harmful heavy metal elements in coal gangue are released into the environment through atmospheric dusting and rain leaching under natural weathering conditions, endangering human health through the food chain (Hua et al. 2018). For example, the excessive intake of Pb can damage the nervous, skeletal, circulatory, enzymatic, endocrine, and immune systems of human beings (Zhang et al. 2012a, b) and chronic exposure to As can cause adverse effects such as dermal lesions, peripheral neuropathy, skin cancer and squamous cell carcinoma (Żukowska and Biziuk 2008).

Precipitation is main way for the harmful heavy metal elements contained in coal gangue to migrate to the environment (Zhang et al. 2012a, b). Leaching has been proven to be one of the primary pathways for harmful heavy metal elements to enter the environment (Liu et al. 2016). Through indoor leaching simulation experiments, heavy metal pollution caused by coal gangue piles in the Jiaozuo mining area is studied. Heavy metals were precipitated into the soil near the gangue pile under the action of water, and the Zn and Mn contents in the leachate were higher than those of other heavy metals. The content in the coal gangue remains corresponding (Wang et al. 2006). With the leaching of precipitation, most of the harmful heavy metals migrate into the soil under the coal gangue hill and undergo transformation, where they are retained in more stable forms such as secondary ferric minerals (Lin et al. 1997). Studying the dissolution characteristics and release processes of heavy metals in coal gangue can provide a basis for controlling the impact of coal gangue on environmental pollution (Zhou et al. 2014a, b).

The coal gangue are backfilled in the subsidence area and covered by soils, or stacked to be the coal hill, that can be a long physical and chemical reaction time. Numerous studies have been conducted to determine heavy metals in single factor as different weathering years or type of coal gangue, it must consider the influence of multiple factors and different conditions. The reserves of low-sulfur coal in the Linhuan mining area of Anhui Province are large, which produces predominantly low-sulfur coal (Zheng et al. 2008). Because of the characteristics of heavy metal leaching of low-sulfur coal gangue is not yet clear, coal gangue samples of the large coal gangue hill in the Linhuan mining area of Huaibei are selected as the research objects, and an indoor leaching experiment is carried out with these samples. This study choose different weathering years, type of coal gangue and experimental conditions, are used to simulate the effects of the release of heavy metals in the ecological environment under natural conditions. The objectives of this study: (1) to reveal influence of heavy metal content in low-sulfur coal gangue on its leaching effect, (2) to identify leaching characteristics of heavy metals in low-sulfur coal gangue in natural environment, (3) to provide suggestion for the management and comprehensive utilization for coal gangue.

2 Materials and methods

2.1 Sampling and preprocessing

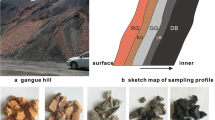

The research area selected is the Linhuan mining area, which is located in the southwestern part of the Huaibei Plain in China. The terrain is flat, with an elevation of + 20.78 to + 28.58 m, and the deepest subsidence water area is about 14 m. The coal-bearing strata in Linhuan mining area are mainly the Carboniferous to Permian Taiyuan Formation, Shanxi Formation, Xiashihezi Formation and Shangshihezi Formation. The coal-bearing seams are 4–12 layers, with a thickness of 4.74–18.48 m, and the main body is one Set of sea-land alternating facies coal-bearing clastic rock combination. The low-sulfur coal gangue sample was provided by the Anhui Mining Ecological Remediation Engineering Laboratory (and the total sulfur contents of all the coal gangue were less than 1%). The coal gangue samples were collected from a large coal gangue hill in the Linhuan mining area of Huaibei, Anhui, China. The typical coal gangue sample source of the coal gangue hill was coal gangue produced from roadway excavation and washed stone from the coal preparation plant. In the geological tectonic unit, the coal gangue samples all belong to the same mining area, and the coal-bearing strata and the mining coal seams belong to the Lower Permian. The rock type and combination characteristics of the selected coal gangue are basically the same, so the mineral rock composition of coal gangue is not significantly different (Yan et al. 2017). The location of the coal gangue hill is shown in the Fig. 1. Five sets of samples were collected from the top of coal gangue hill by the serpentine sampling method (i.e., collecting coal gangue samples at 20 cm below the surface layer), and the five groups of samples were uniformly mixed and denoted as TS (typical sample). In addition, a group of weathered coal gangue samples from coal gangue hill that had been stacked for more than 5 years and a set of fresh coal gangue samples discharged underground were denoted as WS (weathered sample) and FS (fresh sample), respectively. The data of FS sample analysis and leaching experiment used by 5 years ago.

Seven TS samples of 4 kg each were taken by using the quarter method, and the samples were ground through a mortar and passed through a 2 mm mesh nylon sieve. Then, after grinding, the WS and FS, samples passed through a 2 mm mesh nylon sieve. All samples were immediately stored and sealed in a plastic bag for subsequent experiments.

2.2 Leaching experiments

According to the past results of dynamic leaching research, a series of dynamic leaching experiments can naturally estimate the release and migration of harmful elements in the ecological environment (Zhao et al. 2013; Gupta et al. 2017; Zhao et al. 2019). The leaching experimental setup is shown in Fig. 2. To better mimic natural precipitation (The annual average rainfall in Linhuan Mine is 830 mm), the influent leaching solutions used in the leaching experiments are solutions of different pH values made from deionized water. The pH values of the influent leaching solutions are as follows: the lowest pH value of precipitation in Huaibei city over the years, the average pH value of precipitation for the year, and the average pH value of the coal mining subsidence area near the coal gangue hill. The flow rate of the whole leaching experiment time was set according to the average annual precipitation of Huaibei city, the inlet water flow rate was set to 3.56 mL/min, and the different flow rates were set by increasing the values twice (Set the rate of the peristaltic pump in advance through the value). The trend of heavy metal element concentrations provided from long-term leaching experiments is more representative, but due to the limitation of objective conditions, the time periods of the leaching experiments used in this study of low-sulfur coal gangue samples were 4 h, 12 h, 28 h, 60 h, 124 h. The release process of heavy metal elements occurs within 124 h.

The heavy metal release of coal gangue is affected by various natural factors, such as rainfall and weathering. Through many previous studies, it has been found that weathering of rocks, rainfall and pH in the water environment are the main factors affecting the release of heavy metals in coal gangue. For example, the weathering of rocks will promote the release of some heavy metals in coal gangue, while the acidic conditions will also promote the leaching of heavy metals, and the heavy precipitation in the rainy season will also promote the leaching. Therefore, we select the different year coal gangue, the pH of the solution, and the flow rate as the basis for grouping. The groups were set according to the different leaching conditions, as shown in Table 1. For each experiment, 4 kg of low-sulfur coal gangue sample was weight into the leaching column, and the upper and lower ends of the leaching column were covered with 5 cm thick quartz sand that was soaked with dilute nitric acid (the top portion of the quartz sand was used to ensure uniform penetration of the leachate, and the bottom portion of the quartz sand was used to prevent the coal gangue sample from flowing out from the bottom of the leaching column). Before the leaching experiment began, the leaching column was wetted using the corresponding influent leaching solution, and a peristaltic pump was used to provide the constant incremental flow rate of the leaching solution. The leachate sample was removed at the set sampling time, and then the sample was centrifuged and tested.

2.3 Detection of heavy metal content in leachate

In addition to the typical heavy metals in coal gangue, heavy metals that have toxic effects on the human body are also added. At last, we choose the Ba, Co, Cr, Mn, Ni, V, Zn, Cd, Hg and Pb, these heavy metal elements will cause harm to the human body in the environment that exceeds Chinese standards (GB/ T 14848–93). The Ba, Co, Cr, Mn, Ni, V, and Zn contents in the low-sulfur coal gangue sample and the leachate sample were measured using ICP-AES (Thermo Ltd.), and Cd and Pb contents in the sample were determined using GFAAS (Thermo Ltd.). The Hg content in the low-sulfur coal gangue sample was measured using DMA-80 (Milestone Ltd.), and the Hg in the leachate sample is determined using AFS (Haiguang Instrument Ltd.).

Analytical accuracy was guaranteed by establishing reagent blanks, employing parallel samples and inserting standard soil samples (China Standard Soil GBW07403). The test results showed that the relative standard deviations of trace elements in the parallel samples were less than 10%, the extraction rates of heavy metal elements were between 80% and 120%, and the measured values of the standard samples reached the accuracy specified by the standard, indicating that the test results meet quality requirements.

2.4 Calculation of leaching rate

In different low-sulfur coal gangue samples, the contents of various heavy metal elements is quite different. To better compare these leaching effects, the leaching rate (Lr) is introduced (Song et al. 2005; Wang et al. 1996), that is, the ratio of the heavy metal element content in the leachate to the element at content in the low-sulfur coal gangue sample during the entire leaching process.

where Lr is the leaching rate (%) of element x, ax is the content of element x in the leachate (µg/L), V is the influent flow rate (mL/min), t is the leaching time (h), Ax is the content of element x in the coal gangue sample (mg/kg), and m is the mass (kg) of the coal gangue sample used in the leaching experiment.

3 Results and discussion

3.1 Contents of heavy metals in low-sulfur coal gangue

The heavy metal contents in the different types of low-sulfur coal gangue were tested, and the content characteristics of different heavy metals are shown in Table 2. The heavy metals with the highest contents in the low-sulfur coal gangue samples are Ba and Mn, with contents of 436.57 mg/kg and 373.02 mg/kg, respectively, and those with the lowest contents are Cd and Hg, with a value of 0.13 mg/kg. Through the data results, the following rules can be summarized: The Cd, Co, Cr, Mn, Ni, and Zn content in fresh samples are higher than those in other samples, indicating that these contents are related to the type of low-sulfur coal gangue samples, and thus that these elements content are greatly affected by weathering. The Ba and V contents in the weathered samples are higher than those in other samples, and have no obvious relationship with the sample type, indicating that these elements are basically not affected by weathering. The Pb and Hg contents in typical samples and fresh samples are higher than those in the weathered coal gangue samples, indicating that the Pb and Hg contents have a weak relationship with the type of low-sulfur coal gangue, and are less affected by weathering.

3.2 The leaching of harmful heavy metals from different types of coal gangue samples

Different types of low-sulfur coal gangue samples were used as leaching media, and the changes in the heavy metal content and leaching rate in the leachate with time are shown in Fig. 3. Because the gangue samples from the different leaching media are different, the contents of heavy metal elements are also different, resulting in large differences in the contents of various heavy metal elements in the leachate. Mn is the most abundant heavy metal elements in the leachate. After 4 h from the start of the experiment with a fresh coal gangue sample as the leaching medium, the Mn content of the leachate reached 1250 µg/L. The least abundant heavy metal element in the leachate was Cd, with a content of 0.008 µg/L occurring when the weathered sample was used as the leaching medium. When the typical coal gangue sample from a large coal gangue hill is used as the medium, the Cd content in the leachate is significantly higher than that in the leachate of the other two coal gangue samples. When the weathered sample coal gangue is used as the medium, the Cd content in the leachate is the lowest. The large accumulation of coal gangue promotes the enrichment of Cd, and Cd is more easily released into the surrounding environment by precipitation.

As shown in Fig. 3, the leaching rate of heavy metals tends to increase slowly with the extension of the experimental time. After 124 h, the leaching rate of Ba, Cr, Pb and V were higher in the weathered samples than in fresh samples, indicating that weathering promoted the release of these four harmful heavy metals. The analysis of coal gangue with different weathering years in the Huainan mining area showed that with the increase of weathering years, the heavy metal contents in coal gangue would gradually decrease (Yan et al. 2017). In leaching experiments on the Huainan Xinzhuang coal gangue samples, it was found that lower heavy metal contents in coal gangue can decrease the leaching effect of heavy metal elements gradually (Zheng et al. 2016). Furthermore, the weathering effect obtained from the above experimental results promotes the release of the four heavy metal elements. After 124 h, the highest leaching rate was found when the fresh gangue sample was used as the medium, the leaching rate of Mn was the highest, reaching 4.25 %, and the Mn content in the fresh sample was also the highest. Simultaneously, the leaching rates of Co, Hg, Ni and Zn from the fresh samples are higher than those from other samples at 124 h, thus the higher the contents of some heavy metal elements in the coal gangue are under the same conditions, the higher the leaching rates of these heavy metals. Through the dynamic leaching experiment on coal gangue in the Shandong Jining Coal Mine, it was found that the higher the background value of heavy metals in the coal gangue is the higher the concentration of heavy metals in the leachate, this conclusion is similar to the results of this study (Cao et al. 2016).

3.3 Effect of the pH value of different influent leaching solutions on the leaching of harmful heavy metals

The changes in heavy metal content and leaching rate in the leachate when subjected to different influent pH values are shown in Fig. 4. From the figure, it can be observed that the maximum amount of heavy metal leaching occurs for Mn, and the maximum leaching amount is 744 µg/L after 4 h from the start of the experiment when the pH value of the water is 5.10. The lowest amount of heavy metal leaching occurs with Cd. The minimum leaching amount was 0.002 µg/L, at 12 h after the experiment started and a pH of 8.43. The maximum amount of the heavy metal elements in Ba, Cd, Cr, Hg, Mn, Ni, Zn in the leachate occurs when the influent pH is 5.10, the maximum leaching amount of Co, and V occurs when the influent pH value is 7.16, and the maximum leaching amount of Pb occurs when the influent pH is 8.43. Observing the amount of heavy metal elements in the leaching solution under the different pH conditions indicates that the heavy metal elements have a tendency to decrease with the pH value and the amount of heavy metal leaching. Static leaching experiments on coal gangue in Hubei were carried out to determine the effects of solutions at different pH values on the dissolution of heavy metals in coal gangue, and it was found that the dissolved amount of heavy metals increased with a decrease in the pH value of the solution (Lin et al. 2017), this achievement support the experimental results of this study.

The figure shows that as the experiment time was prolonged, the figure that the leaching rate of heavy metals other than Mn exhibited a slowly rising trend. The leaching rate of heavy metals is generally lower when the influent pH value was 8.43 than when the pH value was 5.10. It has further been verified that as the pH value decreases, the more acidic influent leaching solution facilitates the release of heavy metals from the coal gangue into the environment. The difference in the experimental results is that Cd shows a high leaching rate when the pH value is 7.16, indicating that the release of Cd may be more favored when the pH value is more neutral. Leaching experiments on coal, fly ash and bottom ash of a power plant in China showed that heavy metal elements such as As, Ni, Pb, Sr and Zn showed an increasing trend with increasing of acidity of the solution (Wang et al. 1999). An oscillating leaching experiment was carried out on coal gangue in four coal mining areas in Guizhou using six different pH leaching agents. The experimental results verified that all heavy metals have a large amount of leaching in a strong acidic environment and less leaching with increasing pH value, which is consistent with the conclusion of this experiment (Wang et al. 2010).

3.4 Effect of different influent flow rates on the leaching of harmful heavy metals

Under the influence of different influent flow rates, the change in heavy metal contents and leaching rates in leachates with time is shown in Fig. 5. The maximum leaching amount of each heavy metal differed greatly. When the influent flow rate was 3.56 mL/min, the amount of leached Mn reached the maximum at 4 h of the experiment. The element with the lowest leaching amount detected was Cd, at the influent flow rate of 14.24 mL/min 124 h after the experiment began. The maximum amount of leached Cd appeared at the lowest flow rate, and the amount of leached Cd decreased with increasing flow rate during the different time periods, indicating that the leaching of Cd is slow. The leaching amounts of Ba, Co, Cr, Mn, Ni, Pb and V decreased with increasing leaching time, indicating that the release of heavy metals increased with time, and the heavy metals remained in the coal gangue. The overall heavy metal content in the coal gangue decreased, which led to a gradual decrease in the heavy metal content in the leachate. During the leaching process, different heavy metals exhibit different dissolution rules, which is mainly related to the adsorption performance of solid colloids to heavy metal ions and the nature of heavy metal ions themselves. In the environment of coal gangue, heavy metals not only have adsorption and exchange with solid colloid, but also have complexation and adsorption exchange with organic colloid in the environment. Different heavy metals have different binding capacity to colloids, which affects the release ability of heavy metal ions under leaching conditions. When the heavy metals are distributed in the coal gangue in a soluble state, they are easier to release. As time goes by, the heavy metals in the titanium oxide or complex state are more difficult to release, which leads to a reduction in the amount of heavy metals released later (Bai et al. 2009).

Observing the changing trend in the leaching rate in the figure, it is found that the leaching rate increases with different degrees of leaching time. Further, most of the heavy metals in the coal gangue enter the solution through leaching. In addition, this figure also indirectly verified that heavy metals in the gangue hill entered the environment through precipitation. When the maximum influent flow rate of Hg, Mn, Ni, Pb and Zn is 14.24 mL/min, the leaching rates at the different time periods are significantly higher than those the other flow rates, indicating that the leaching of heavy metals is affected by the influent flow rate; thus, the flow rate has a great influence on the leaching of heavy metals; moreover the higher the flow rate is, the greater the leaching rate of heavy metals, which also shows that a greater a amount of water in natural conditions leads to a greater release of heavy metals from the coal gangue. The leaching experiment on the surface-weathered mixed coal gangue of the coal gangue hill near a certain expressway showed that the increase in rainfall times and rainfall can promote the dissolution and release of heavy metal elements in coal gangue. The experimental conclusions indicate that the larger the flow rate is, the greater the leaching rate (Zhang et al. 2014). The form of heavy metals plays an important role in controlling their precipitation from coal gangue and determines the ability of heavy metals to be released into the environment. In coal gangue, heavy metals have the possibility of being in an inorganic state and an organic state, but with different degrees of binding. When the heavy metals are mainly in the organic state, that is, the heavy metals participate in the macromolecular structure of the organic matter, and when they are bonded by carbon-hydrogen bonds, they are generally not easily leached out. Heavy metals exist mainly in inorganic or adsorbed forms. When combined with sulfides, sulfates, carbonates or other compounds, under the action of the leaching solution, the heavy metals are easily decomposed and enter the leaching solution. Under the same conditions, heavy metals in the organic state are more difficult to precipitate during leaching, while heavy metals in the inorganic state, especially in the adsorbed state, are easily precipitated from coal gangue when they are leached (Liu et al. 2001).

As mining operations continue, the increase in coal gangue is inevitable. Large amount of coal gangue waste is piled on the surface at mining sites to form coal gangue hill, occupying a large area of land resources. In addition to wasting land resources, the hazards of coal gangue include the potential ecological and environmental impacts caused by harmful heavy metals. In order to reduce pollution to the ecological environment, making full use of coal gangue resources, and turning coal gangue into treasure are the only effective ways to control it. For example, in order to prevent spontaneous combustion caused by the accumulation of coal gangue, coal gangue can be stacked in a layered and compacted manner. Reusing coal gangue can reduce the stock of coal gangue. Coal gangue can be used to produce cement, brick, and other chemical products. Coal gangue as an inevitable product in coal production, people need to formulate a series of reasonable measures for prevention and treatment in the future.

4 Conclusions

-

(1)

The Cd, Co, Cr, Mn, Ni, Zn, Pb, Hg contents have certain dynamics in low-sulfur coal gangue that are affected by natural weathering; however, the Ba and V contents are independent of sample type. Thus, the same type is basically not affected by spontaneous combustion weathering.

-

(2)

Through leaching experiments, the pH value of the influent solution, the flow rate and the content of heavy metals in the coal gangue affect the release of heavy metal elements in the coal gangue. Simultaneously, the increase in leaching time will also lead to an increase in the leaching rate of heavy metals in coal gangue.

-

(3)

When the pH value of the influent leaching solution is decreased, the leaching rate of the heavy metal element is gradually increased. When influent flow rate increases, the leaching rate of heavy metals in the coal gangue increases. The higher the content of heavy metals in the coal gangue is, the greater the leaching rates.

-

(4)

In nature, lower precipitation pH values, more precipitation, and higher heavy metal content in the coal gangue are associated with more heavy metals release into the environment through precipitation, which has an impact on the ecological environment.

References

Bai XY, Jia HX (2009) Release of heavy metals in gangue leaching process. Environ Sci Technol 22(2):5–8

Cai F, Liu ZG, Lin BQ, Li W, Lv Z (2008) Study on trace elements in gangue in Huainan mining area. J China Coal Soc 33(8):892–897

Cao YQ, Zhang SS, Liu HH, Liu W (2016) Leaching characteristics of heavy metals in coal gangue in both dynamic leaching and static immersion. J Hebei Univ Eng (Nat Sci Ed) 27(1):76–80

Dang Z, Fowler M, Watts S (1998) Coal gangue natural heavy weathering geochemical behavior of genus. Nat Sci Prog 8(3):314–318

Ding SS, Zheng LG, Cheng H (2015) Study on the occurrence of trace elements in low-sulfur coal gangue and their environment effect by inductively coupled plasma-optical emission spectrometry with sequential extraction procedure. Rock Min Anal 34(6):629–635

Gupta N, Gedam VV, Moghe C, Labhasetwar P (2017) Investigation of characteristics and leaching behavior of coal fly ash, coal fly ash bricks and clay bricks. Environ Technol Innov 7:152–159

Hua CY, Zhou GZ, Yin X, Wang CZ, Chi BR, Cao YY et al (2018) Assessment of heavy metal in coal gangue: distribution, leaching characteristic and potential ecological risk. Environ Sci Pollut Res 25(32):21–31

Lin ZX, Roger B (1997) Heavy metal retention in secondary precipitates from a mine rock dump and underlying soil. Dalarna Sweden Environ Geol 33(1):1–12

Lin H, Li G, Dong Y, Li J (2017) Effect of pH on the release of heavy metals from stone coal waste rocks. Int J Miner Process 165:1–7

Liu GJ, Yang PY, Peng ZC, Wu EJ, Wang GL (2001) Study on leaching of potentially hazardous trace elements from coal-waste rocks. Geol J China Univ 7(4):423–427

Liu YR, Dang Z, Shang AA (2003) Environmental effects of heavy metals in soil from weathered coal mine spoils. J Agroenviron Sci 22(4):64–66

Liu Y, Song JF, Bai X et al (2016) Leaching behavior and potential environmental effects of trace elements in coal gangue of an open-cast coal mine area, inner Mongolia, China. Minerals 6(50):1–18

Song DY, Qin Y, Zhang JY, Wang WF, Zheng CG (2005) Leaching characteristics of hazardous trace elements in coal and ash. Acta Sci Circum 25(9):1195–1201

Sun RY, Liu GJ, Zheng LG, Chou CL (2010) Characteristics of coal quality and their relationship with coal-forming environment: a case study from the Zhuji exploration area, Huainan coalfield. Anhui China Energy 35:423–435

Wang YQ, Reng DY, Li YN, Wang XQ, Xie HB (1996) Study on the leaching experiments of minor and trace elements in coal and its burnt products. Environ Sci 17(1):16–20

Wang YQ, Ren DY, Zhao FH (1999) Comparative leaching experiments for trace elements in raw coal, laboratory ash, fly ash and bottom ash. Int J Coal Geol 40:103–108

Wang XY, Yang J, Guo HX (2006) Study on heavy metals in soil contaminated by coal waste rock pile. J China Coal Soc 31(6):808–812

Wang J, Wu YG, Liu F, Yu YH, Zeng L, Qin Z, Su LW (2010) Various pH values of extractant impact on the leaching characteristics of coal mining discharge waste pollutants. J Agroenviron Sci 29(6):1144–1149

Yan JP, Chen XY, Cai Y, Huang H (2017) Physicochemical property change regularities of coal gangue with different weathering ages in Huainan minging area. Trans Chin Soc Agric Eng 33(3):168–174

Zhang J, Zhang S, Li CY et al (2012a) Coal gangue saturated solute release process based on the soil column leaching experiments. Coal Geol Explor 4(5):56–59

Zhang XW, Yang LS, Li YH, Li HR, Wang WY, Ye BX (2012b) Impacts of lead zinc mining and smelting on the environment and human health in China. Environ Monit Assess 184:2261–2273

Zhang YQ, Huang MQ, Qi FF, Du YL (2014) The leaching characteristics of metals and acid radical ions in gangue. Environ Chem 33(3):452–458

Zhao FH, Sun HF, Liu NL (2013) Evaluation of Soxhlet leaching experiment of acid-producing potential of rock from coal-bearing measures. J China Univ Min Technol 42(2):214–220

Zhao FH, Guo Y, Sun HF et al (2019) Free draining column leaching experiment and mechanism of water–rock interaction in main aquifer of Xinzhi coal mine. J China Coal Soc 044(004):1207–1215

Zheng LG, Liu GJ, Chou CL (2008) Abundance and modes of occurrence of mercury in some low-sulfur coals from China. Int J Coal Geol 73:19–26

Zheng LG, Ding SS, Liu CC, Jiang CL, Chen YC (2016) Leaching characteristics of environmentally sensitive trace elements in different types of coal gangue. J Cent South Univ (Sci Technol) 47(2):703–710

Zhou CC, Liu GJ, Cheng SW, Fang T (2014a) Thermochemical and trace element behavior of coal gangue, agricultural biomass and their blends during co-combustion. Bioresour Technol 166:243–251

Zhou CX, Li XQ, Zhou JW (2014b) Leaching experiment and environmental effect of heavy metals of coal gangue in Heshan mining area, Guangxi province. Hydrogeol Eng Geol 41(3):135–141

Żukowska J, Biziuk M (2008) Methodological evaluation of method for dietary heavy metal intake. J Food Sci 73:R21–R29

Acknowledgements

The project is supported by the National Natural Science Fund Project of China (41373108) and the Mining Group Project of Huaibei (K160139078). We acknowledge editors and reviewers for polishing the language and in-depth discussion.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Li, C., Zheng, L., Jiang, C. et al. Characteristics of leaching of heavy metals from low-sulfur coal gangue under different conditions. Int J Coal Sci Technol 8, 780–789 (2021). https://doi.org/10.1007/s40789-021-00416-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40789-021-00416-6