Abstract

Engineering disasters occur frequently and violently with the increase in mining depth, which is mostly due to insufficient study on the failure mechanism of the deep rock mass. In this paper, theoretical and experimental researches on the failure behaviors and deformation control of deep surrounding rock in recent years were reviewed. Macro/meso failure mechanism of deep rock or coal–rock combined body under different loading conditions have been systematically investigated. Stress gradient failure theory of surrounding rock, uniform strength support in the deep roadway, and the analogous hyperbola movement model of overlying strata were preliminary established and a combined grouting control technology for surface and underground was proposed. Abovementioned achievements are expected to offer theoretical bases and technical supports for the exploitation of China’s deep mineral resources in the future.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Economic growth is strongly dependent on the exploitation of mineral resources and the depth of underground mining is increasing with the depletion of resources in the shallow surface. At present, the major mining countries in the world have carried out the excavation of deep mining and coal mining depth has reached 1500 m, geothermal mining depth has exceeded 3000 m, non-ferrous metal mining depth has passed 4350 m, and oil and natural gas resources mining depth has come to 7500 m (Xie et al. 2015a). More than 100 mines with the mining depth over 1000 m are distributed in South Africa, Canada, Germany, Russia, Poland and other countries, of which South Africa is the most representative one. For domestic coal mining, the coal resources mined in the depth exceeding 1000 m account for 53% of the total proved amount of reserves in the country (Xie et al. 2005). There are now about 47 deep mines with an average mining depth of 1086 m in China, and the depth of exploitation is rising at the rate of 10–25 m per year (Xie 2017).

More engineering disasters arose along with the increase of mining depth, and the disasters tend to be more hazardous and critical: severe deformation of roadway, intensive ground pressure at working face, more rock bursts and coal bumps, violent instability of working face, high accumulation of gas, increased gas pressure, increased probability and seriousness of water inrush accidents (Zhou et al. 2005). For the moment, the practice in deep engineering has greatly advanced the basic theoretical research in rock mechanics (Xie et al. 2015a), and the insufficient study on the failure mechanism of deep rock causes difficulties in disaster prevention and control. The engineering practices based on the mechanics for shallow rock are thought to be blind and inefficient, therefore, the research on the failure behavior and mechanism of deep rock and deformation control of deep surrounding rock need to be further studied. In the basic theory of deep rock mechanics, He (2005) and He et al. (2005) explained systematically the concepts and engineering evaluation index of deep rock, illustrating the mechanical properties of rock in deep mining. According to Xie et al. (2015a, b, 2017), four key scientific issues, five major research contents and nine researching frontiers were put forward in the discussion of conceptual and fundamental matters in deep rock mechanics. In the prevention and control of deep surrounding rock dynamic disasters, major scientific problems to be solved in the study of rock burst in coal mining were presented on the basis of the research achievements (Jiang et al. 2014; Jiang and Zhao 2015). Based on the study and site practices on the theory of coal bumps, with the stress control as the center and the unit stress gradient as the coal bumps stress control, the prevention theory was raised by Qi et al. (2013). Pan et al. (2014) established a dynamic model of roadway surrounding rock and support response in the rock burst, and two new support methods that increasing support stiffness and rapid energy-absorption support were proposed. In surrounding rock control in the deep roadway, and Hou (2017a, b) stated effective approaches focus on the technological difficulties. Kang (2005) explained the rock bolting technology can meet the problems of coal bumps (Kang et al. 2015) and floor heave (Zhang et al. 2013) with high efficiency and low cost. Ma et al. (2015) analyzed the formative mechanics and morphological characteristics of the plastic zone of surrounding rock on bidirectional non-constant pressure, developing the long-extension bolt support technology which obtained better supporting results to the intense subsidence of the roof. By analyzing the weakness of the commonly-used bolt supporting, Zhang and Gao (2004) raised the method of pretension bolt with high strength, and a series of critical technologies of surrounding rock control in goaf entry retaining was summed up (Zhang et al. 2014), containing the methods of pre-splitting pressure relief, district control, structure parameters optimization, “three support zones forming one system” surrounding rock control and rapid construction of roadside wall.

In this paper, a series of studies on failure mechanics and control of deep surrounding rock by the authors and their team in recent years were summarized, including macro/meso failure mechanism of deep rock, failure behaviors of deep coal–rock combined body, failure mechanism of deep rock under thermal–mechanical coupling effects, failure mechanism of deep surrounding rock under stress gradient effect, theory and technology of uniform strength support in deep coal mine roadway, theoretical model of overlying strata movement, combined grouting control technology for surface and underground. The abovementioned achievements are expected to enrich the theories of deep rock mechanics and offer practical guidance for deep mining engineering.

2 The failure behaviors of deep and high-stress rock mass

In experimental research, confining pressure is usually applied to simulate the in-situ conditions, and deformation characteristics of rock under compression condition are studied to reveal its failure mechanism. Since Von Kármán (1911) first carried out compression tests of marble under different confining pressures, extensive experiments on the failure characteristics of rock under confining pressure have been conducted by many scholars. The basic mechanical properties of rock deformation and strength under high-stress are summarized as below.

2.1 Brittle–ductile transition of rock deformation

The brittleness (ductility) of rocks shows different features with confining pressure level. The brittle rocks under low confining pressure can be ductile under high confining pressure. Paterson (1958) and Mogi (1966) carried out a series of experiments at room temperature. It was found that the deformation behavior of rock gradually changed from brittleness to ductility with the increase of confining pressure (Fig. 1). Mogi explained that the brittle–ductile transition is related to rock strength in general. The brittle–ductile transition is a universal performance in rock, but the critical confining pressure corresponding to the brittle–ductile transition varies greatly with rock types. According to the previous researches, the confining pressures of brittle–ductile transition of limestone and dolomite are 10–20 MPa (Vajdova et al. 2004) and 100–200 MPa (Handin and Hager 1957; Mogi 1971) respectively, and that of some granite and quartzite still show brittleness under confining pressure of 1000 MPa (Paterson 2005). Based on experimental data of 101 sandstone specimens from Asia, Europe, America and Africa, Kwasniewski (1989) studied the law of brittle–ductile transition of rocks thoroughly and stated that the boundary between brittle and brittle–ductile transition states of sandstone can be expressed as:

where p is the lateral pressure in the triaxial experiment, MPa.

As shown in the stress–strain curves of rocks under different confining pressures (Fig. 2), there is usually no or only a small amount of permanent or plastic deformation when a brittle failure occurs, and the permanent strain is always great when the rock shows ductile failure. The strain value of rock failure is suggested to be a criterion to judge the brittle–ductile transition. Heard (1960) stated that the brittle–ductile transition can be considered to appear if the strain value of rock failure comes to 3%–5%.

The brittle zone (B), ductile zone (D) and brittle–ductile transition zone (T) of sandstone under confining pressure (Kwasniewski 1989)

2.2 Strength criterion of rock

The strength of rock increase with the raise of depth generally, in some mining areas, when the mining depth changed from less than 600 m to 800–1000 m, the proportion of rocks in strength of 21–40 MPa declined from 30% to 24%, while that of 81–100 MPa grew from 5.5% to 24.5% (Li et al. 1996).

The Mohr–Coulomb failure criterion is widely applied to shallow rocks, but for deep rock under high stress, the appropriate failure criterion is thought to be non-linear. And in non-linear analysis, the Hoek–Brown criterion is a well-known empirical strength criterion based on a large number of experiments and field monitoring (Hoek and Brown 1980):

where m and s are empirical constants, m shows the hardness of the rock, and s reflects the fragmentation of rock. Considering the mechanical properties and the complex geological environment of rock, Eq. (2) is further revised to a general form by Heok (1994):

where \(m_{m}\) and \(\alpha\) are parameters related to rock properties. Zuo et al. (2008a, 2015a) proved the Hoek–Brown failure criterion in two-dimensional and three-dimensional scale based on the crack models and fracture mechanics, which provides theoretical bases for the application of the criterion.

Singh et al. (1989) obtained the non-linear strength criterion of rock under highly lateral stress (up to 700 MPa) according to plenty of laboratory data (Fig. 3).

Strength criterions for rocks under highly lateral stress (Singh et al. 1989)

3 Macro/meso failure behaviors of deep rock

The non-linear behavior of deep rock materials is more prominent, and the large-scale disasters with high energy level induced by excavation occur frequently in deep mining (Xie 2017). It is of great theoretical and practical significance to study the mechanical properties of deep rock and reveal its deformation and failure mechanism for disaster prevention in deep engineering projects. During the past decades, considerable efforts have been devoted to investigating the failure mechanism of various rocks. Initially, the rock failure mechanism is mainly studied at macroscale, by analyzing the mechanical behaviors of rock during uniaxial compression tests (Hoek and Bieniawski 1965; Bieniawski 1967; Wawersik and Fairhurst 1970). In recent years, the rapid development of observational technology has made it possible to investigate the rock failure mechanism at mesoscale. Scanning electron microscope (Hull 1999; Zhang et al. 2000; Zhang and Zhao 2013) and computed tomography (Feng et al. 2004; Wang et al. 2014; Yang et al. 2017) are the most commonly used technologies to investigate the failure mechanism at mesoscale, by observing the meso-morphology of rock fracture.

In recent years, the authors have conducted a series of theoretical and experimental researches in macro/meso failure behaviors. Here, we define the mesoscale as the characteristic dimension of the rock microstructure, which is approximately the size of the rock mineral grain. The macroscopic mechanical behavior of rocks is considered to be the result of microcrack interactions at mesoscale scales.

3.1 Macroscopic mechanical behavior

Zuo et al. (2011a) studied the deformation characteristics and failure energy of same rock at various depths, demonstrating that the brittle rock became ductile with the depth. Two parameters were considered important to characterize the mechanical properties of rock: the work done by testing machine and the dissipated energy during the failure process (Fig. 4). The work done by the testing machine was obtained by the integral on the stress–strain curve, wherein the lower limit of the integral was 0, and the upper limit of the integral was the strain value corresponding to the peak stress. The dissipated energy was the difference between the work done by testing machine and the recoverable elastic energy. The recoverable elastic energy could be obtained by:

where WE was the recoverable elastic energy, σ1max was the peak stress in uniaxial compression test, ε1max was the strain corresponding to σ1max and εE was the strain value at the intersection of the rebound curve and the strain coordinate axis, which was an unrecoverable strain.

The deformation and failure characteristics of rock at different depths (Zuo et al. 2011a)

The investigation on the correlation between micro mineral composition and macro-mechanical behavior indicated that, the diversities of mineral composition and particle size of rock at different depths were the main reasons for the significant increase in the above indexes in the long geological movement, and the content of high strength minerals had a great influence on the overall mechanical properties only when it exceeded a certain critical value (Zuo et al. 2015b).

Based on the energy evolution of the whole failure process of rock, the energy-drop coefficient was presented and revised as a new parameter to characterize rock failure (Zuo et al. 2014a; Song et al. 2019):

where \(\Delta W\) is input mechanical energy increment, \(\Delta U^{e}\) is releasable strain energy increment, \(U_{A}^{e}\) and \(W_{A}\) are the total releasable strain energy and total input mechanical energy at peak strength respectively. The experimental results showed that the coefficient can not only depict the brittle–ductile transition under various confining pressures, but also evaluate the brittleness of diverse rocks under the same confining pressure effectively.

Diverse mining layouts lead to distinction among the unloading paths of deep surrounding rocks. Considering the typical mining layouts employed in coal mines in China currently, the authors have carried out theoretical and experimental studies on rock deformation and failure mechanism under different unloading conditions. The loading mode of increasing the axial stress and decreasing the confining pressure is often used in laboratory tests to simulate the stress variation in the surrounding rock during coal mining. Based on the experimental results, a concise three-stage model is suggested by Zuo et al. (2014b) to approximately characterize the stress–strain relationship (Fig. 5), where the non-linear hardening stage and the non-linear softening stage, before and after peak stress respectively, were simplified as two linear stages as they were usually very short.

Stress–strain model of rock under mining unloading (Zuo et al. 2014b)

The properties of deformation and brittle–ductile transition of deep surrounding rock are significantly affected by mining methods, and the failure mode is mainly determined by the confining pressure near the peak or yield strength rather than axial loading stress path (Zuo et al. 2013a) (Fig. 6). While in the conventional triaxial compression tests, shear failure was the most common failure mode.

Failure modes under different loading rates (Zuo et al. 2013a)

3.2 Mecroscopic mechanical behavior

On the mesoscale, the fracture mechanics of deep rock is studied by scanning electron microscope (SEM) with loading and heating devices to reveal the meso-fracture mechanism of deep rock.

Thermal cracking behaviors of different rocks from 25 to 300 °C were observed by SEM in-situ system (Fig. 7), and the corresponding threshold temperatures were obtained (Zuo et al. 2007a, 2010a, 2011b). Fractal models were developed based on the three modes of thermal cracking (an inter-granular, trans-granular, mixture of inter-granular and trans-granular) to quantitatively explain the difficulties of thermal cracking respectively (Fig. 8). Laws of thermal cracks density and fractal dimensions varying with temperatures were described statistically, and revealing the complex effects of the thermal and mechanical properties, shape and structure of mineral particles on thermal cracking.

The thermal cracking behaviors of Pingdingshan sandstone (Zuo et al. 2010a)

Fractal models of different thermal cracking modes (Zuo et al. 2010a)

The digital speckle correlation method (DSCM) and laser-scanner equipment were applied to investigate the meso-deformation field of deep rock under diverse temperatures and stress conditions (Zuo et al. 2008b, 2011c) (Fig. 9a), and fracture morphology (Zuo et al. 2015c) (Fig. 9b). The influence of local rotation and inhomogeneous deformation of the rock surface on crack growth was analyzed, pointing out that DSCM is a new approach for continuous measurement of rock deformation field on the mesoscale. As an external manifestation of intrinsic fracture mechanism, the meso-fracture morphology has the feature of self-similarity, which can be used as a parameter to characterize the energy dissipation of rock failure.

By presetting cracks with different locations and quantities, the micro-fracture process of deep rock under complicated stress state was observed in real time by scanning electron microscope, and the micro-mechanism that the fracture parameters of deep rock increase with the depths were elaborated (Zuo et al. 2013b). A formula to calculate the surface energy considering the non-linear propagation of cracks was proposed, based on which the appearance of cracks in the three fracture modes were explained according to the principle of least energy consumption, and presented the offset notch crack influence coefficient to express the fracture properties for loading direction and nonlinear crack (Zuo et al. 2013c) (Fig. 10a). Taking into account the deviated angle and mode II crack, the fracture toughness function of composite crack was obtained to estimate the influence of shear stress on composite crack failure (Zuo et al. 2014c) (Fig. 10b).

The micro-failure processes of deep sandstone (Zuo et al. 2010b, c, 2014d) in Fig. 11a, and granite (Zuo et al. 2013d, 2017a) under various temperatures were observed in real time by scanning electron microscope. The experimental results indicated the variation of mechanical parameters with thermal effects, namely, fracture toughness, elastic modulus and ductility ratio. The micro-mechanism that the fracture modes transform with the growth of heating temperature was stated, mainly analyzing the influence of water evaporation and the variety of rock micro-structure on the fracture mechanism. The numerical elastic modulus was put forward as a novel parameter to characterize rock material property, which was applied to discuss the relationship between the thermal damage and temperatures (Fig. 11b), and the stress intensity factor of short-span three-point bending specimen was determined by boundary collocation method based on fracture mechanics.

4 The failure behaviors of coal–rock combined body in deep mining

The failure of shallow coal–rock combined body is mainly dominant by its own fissure structural plane while that of the deep combined body is not only affected by its structural plane, but also the overall structure. Coupled with the high stress in deep rock, many disasters of rock burst essentially result from the overall failure and instability of the coal–rock combined body under the strong disturbance of engineering geology (Liu et al.2013). Therefore, it is important to study the mechanical properties and failure mechanism of coal–rock combined body for predicting and preventing impact ground pressure. Predicting rock burst hazard is always a research hotspot. For examples, Lu et al. (2012) investigated the rock burst forecasting method by applying small scale, laboratory modeling of the coal mine roof, coal and its floor. Li et al. (2017) presented a novel application of Bayesian networks to predict rock burst.

In recent years, substantial experiments of uniaxial and step loading and unloading, and acoustic emission tests for rock single body, coal single body, coal–rock combined body have been carried out by author, to analyze the properties of deformation, strength, acoustic emission, outburst proneness, nonlinear energy evolution and crack evolution for coal–rock combined body (Zuo et al. 2017b). The laboratory tests on the mechanical characteristics of coal–rock combined body indicated that the strength and elastic modulus of the combined body is larger compared with those of coal single body, which showed the law of rock–coal–rock > rock–coal > coal–rock combined body in strength and elastic modulus (Zuo et al. 2018a). Peak lateral strain of rock–coal–rock and coal–rock combined body are higher than that of coal single body while almost same to that of rock–coal combined body, and coal–rock combined body performs greater outburst proneness than others (Fig. 12).

The distribution of impact energy index of different coal–rock combined body (Zuo et al. 2018a). M, RM, MR and RMR denote coal, rock–coal, coal–rock and rock–coal–rock respectively

In the research of acoustic emission (Zuo et al. 2011d), owing to the low strength and internal fractured structure of coal, the cumulative AE numbers of rock single body, coal single body and coal–rock combined body were increasing with the load, and the AE numbers of unit volume of coal single body and combined body was nearly 1 order of magnitude more than those of single rock. The essential features of three types of specimens were discussed through the comparison of the AE numbers of different periods. With the increase of load, the AE number in a time interval gradually rose in rock, decreased in coal, and grew initially and then declined in coal–rock combined body. The rule of the tensile strength of three samples was concluded as rock > coal–rock > coal specimens. For the coal–rock combined body, the AE number accounts for 10%–30% in rock, and 70%–90% in coal approximately. In addition, the spatial distribution of AE activity was mainly influenced by the internal micro-structure and primary micro-fissures of the coal body (Fig. 13).

Acoustic emission numbers of coal–rock combined body in different loading periods (Zuo et al. 2011d)

In the study on non-linear energy evolution of failure behaviors of coal–rock combined body (Chen et al. 2017), the experimental results of uniaxial and cyclic loading–unloading compression tests of coal–rock combined body explained that the relationship between input energy density and stress can be expressed as three phases, namely, gradually increase phase, non-linear increase stage and post-peak drop phase. Under uniaxial compression, input energy density and the elastic energy density rose with stress. As the stress rose, the dissipated energy density declined gradually to 0 and then grew rapidly, reflecting sophisticated non-linear characteristics of the combined body. Under cyclic loading and unloading compression, the input energy density, elastic energy density and dissipated energy density grew with the growth of stress. When the sample yields, the proportion of dissipated energy increased and that of elastic energy decreased. The conclusions provide a theoretical reference for the energy driving mechanism of dynamic disasters in the coal mine.

In the investigation on crack evolution of coal–rock combined body (Zuo et al. 2017c), it was found that the whole failure process can be divided into four stages based on the correlation of axial crack strain and axial strain, that is to say initial stage, stable stage, slow-growth stage and rapid-growth stage. The characteristics of the axial crack strain varying with the axial stress were similar to those changing with the axial strain. In the experiment of coal–rock combined body under loading–unloading effects, the primary fissures were compacted by degrees with the cycling times which led to the phenomenon that the proportion of elastic strain raised and axial residual strain dropped.

The rise of load aggravated the dilatancy of coal and produced circumferential cracks, leading to the result that the proportion of circumferential elastic strain increased first and then decreased. The strain of the axial crack grew initially, and then remained basically unchanged with the stress. The inflection point of the strain–stress curve showed the closure of cracks, and the matched stress and strain were the axial crack closure stress and strain. The axial crack stress and strain rose with the loading times since the new cracks and pores were hard to close (Chen et al. 2018). The variation law of cracks in coal–rock combined body under unloading condition was analyzed. The results indicated that the crack closure stress (strain) and recovery stress (strain) grew with the rising cyclic times. New cracks were produced as the raise of stress levels, and the differences of axial crack closure stress, axial crack recovery stress, axial crack stress all increased with the cyclic times (Zuo et al. 2017d).

5 Failure behaviors of deep rock under thermal and mechanical coupled effects

In the projects of deep geological disposal of high-level radioactive waste, deep mining and underground coal gasification, the deformation and failure behaviors of rock are affected by temperature and stress. Therefore, it is of great theoretical and engineering significance to study the deformation and failure mechanism of deep rock under thermal–mechanical coupled effects. Considerable efforts have been devoted to the related researches. For example, Gao et al. (2018) established a statistical constitutive model by introducing a three-parameter Weibull distribution. Based on the adequate assumption of rheological components, the constitutive relation of the rheological model under the thermal and mechanical coupled effects of deep rock was discussed (Fig. 14), and the rheological failure of deep rock at diverse temperatures were forecasted (Zuo et al. 2008c). Taking into account the energy release and dissipation, a failure criterion of deep rocks subjected to couple effects of temperature and load was proposed in view of the principle of least energy consumption. The rock was supposed to failure when the plastic dissipation energy and the dissipation energy caused by the temperature gradient in rocks accumulated to a critical value (Zuo et al. 2005).

Nishihara rheological model of deep rock under thermal–mechanical effects (Zuo et al. 2008c)

The microscopic failure process of sandstone under the coupled thermal–mechanical loading was in-situ observed by the scanning electron microscope. The laboratory results indicated the characteristics of crack position, fracture mode, fracture toughness (Zuo et al. 2009) and tensile strength (Zuo et al. 2012a) varying with temperatures, and the mechanisms of relevant critical temperature and ductile–brittle transition have been discussed. Analysis of 3-parameter Weibull distribution model reliability stated that the thermal cracks will have an evident influence on tensile strength when the crack density is greater than 60 mm−1, as shown in Fig. 15a (Zuo et al. 2016a). The meso-fractographs (Fig. 15b) of sandstone failure under thermal–mechanical coupled effects were compared in detail (Zuo et al. 2007b, c) and the temperature has been confirmed to make an impact on meso-failure mechanism of sandstone. The fracture mechanism will transfer from brittle one to brittle–ductile coupled one with the rising temperature. A failure criterion of rock considering thermal–mechanical coupled effects and a segmented strength theoretical model of sandstone affected by temperatures were established by Zuo (2006).

The meso-failure process of deep granite under thermal–mechanical coupled effects was studied with a scanning electron microscope, pointing out that the fracture path of granite was affected by principal stress, mineral composition and particle size (Zhou et al. 2008). Fracture mechanism transformed from inter-granular mode at low temperature to coupling fracture mechanism of inter-granular and trans-granular modes at high temperature, due to the influence of the increasing thermal cracking and weakening of granular cementation on fracture toughness of granite (Zuo et al. 2012b) (Fig. 16). By introducing the digital image of rock specimen into the finite element program, the numerical model was established (Zhou et al. 2010), representing the real distribution of mineral grains at mesoscale (Fig. 17a). Based on the numerical model, numerical simulations under thermal–mechanical coupled loading were carried out. Comparisons between experimental and numerical simulation results (Fig. 17b) indicated that tensile strength was more accurate at high temperature cases because of the hot melting effects and the initial flaws in rocks. The proposed method offered a new idea for the research on thermal–mechanical coupling effects of failure behaviors for deep rock.

Fracture toughness of deep granite at different temperatures (Zuo et al. 2012b)

Numerical model and results of numerical simulation (Zhou et al. 2010)

6 Stress gradient failure theory of surrounding rock in deep roadway (Zuo et al. 2018b)

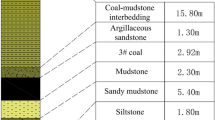

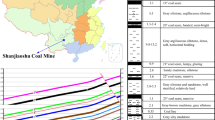

According to the mechanical properties of surrounding rock in the deep roadway (Fig. 18), a theoretical model of surrounding rock failure considering stress gradient was established on the basis of macro/meso failure experiments and numerical analysis (Fig. 19). The effects of average shear stress level and relative gradient were analyzed and the fact that surrounding rock influenced by stress gradient was explained in theory, which resulted in structural gradient damage of surrounding rock. The greater stress gradient would lead to a small contribution of rock stress, thus the destruction was hard to happen. And the stress contribution was inclined to increase when the stress gradient was away from the roadway and close to zero. The theory illustrated the failure of the broken rock zone presenting a feature of the gradient, and was supposed to be a further development of the broken rock zone in the roadway (Dong et al. 1994).

Simplified analysis of surrounding rock in the roadway (Zuo et al. 2018b)

The influence of relative shear stress gradient on the stress and stress contribution (Zuo et al. 2018b)

7 Mining discontinuous deformation analysis (MDDA) and roadway supporting technologies

Based on the existing discontinuous deformation analysis (Shi 1992), a new program named MDDA (mining discontinuous deformation analysis) was developed (Zuo et al. 2016b), which could present the processes of roof movement of surrounding rocks during the continuous excavation in mining engineering (Fig. 20). The calculation results from MDDA were well agreed with the theoretical results and approximately consistent with results from the UDEC (Zuo and Chen 2017).

The roof caving process at working face by MDDA simulation (Zuo et al. 2016b)

With the increase of mining depth, the complex stress environment makes the surrounding rock of the roadway show severe mine pressure characteristics, such as fracture, dilatation and large deformation. Some scholars have conducted in-depth research on the control of surrounding rock deformation. For example, He et al. (2014) invented a high constant resistance large deformation anchor cable which was proved to be effective in absorbing energy while maintaining constant resistance. In a view of dynamic, static load and three-dimensional ground stress, a coordinative support technology of full space pre-stress truss and anchor (Fig. 21) for large cross-section and broken roadway in a deep mine was proposed by the first author of this paper (Zuo et al. 2016c).The 3D space roof pre-stress field distribution of surrounding rock supported by the abovementioned form was obtained by FLAC3D numerical simulation, which showed that the full space truss and anchor support could form a 3D closed loading structure under different pretension conditions.

Structure of full space truss and anchor coordinative supports (Zuo et al. 2016c). (1) Cable, (2) pallet, (3) pull rod, (4) anchor, (5) steel wire mesh, 6) steel strip, (7) roof, (8) coal roadway

A mechanical model of uniform strength support in the deep rectangular roadway was established (Fig. 22) and the characteristics of stress produced in roadway roof were analyzed (Zuo et al. 2018c). The research results stated that high strength and long bolt was regarded to have an appropriate control of the bending deformation in the middle part. As the normal bending stress decreased at ends, the utilized bolts were assumed to reduce in length while enlarging in diameter, and with a certain angle to the vertical direction to improve the shear strength. Based on the study of numerical simulation of roadways in different depth and dimension, it was found that uniform strength support technology could reduce the bolt usage and cut down support cost under the premise of roof stability, which demonstrated the validity of the theory and the feasibility of technology in deep mining.

The mechanical model of uniform strength support in the deep roadway (Zuo et al. 2018c)

8 The movement mechanism and model of rock strata

With the greater demands of the accuracy and reliability in the calculation of surface subsidence caused by the technologies of underbuilding, railways and water bodies mining, the probability integral method has to tackle the problems in adapting to the new circumstances (Yang and Dai 2016), since the coal mine subsidence was deemed to be a typical mechanical behavior (Liu and Dai 2016). As a mathematical approach, the probabilistic integral method was inadequate in interpreting the mechanical mechanism and law of strata movement in deep mining. To solve the imperfect points in the theory, several types of research have been conducted by the first author to discuss the mechanism of rock strata and surface movement.

According to the relationship between the fracture and movement of rock strata and surface subsidence, the analogous hyperbola model was put forward to describe the movement of overlying strata with thick alluvium (Zuo et al. 2017e), and the primary key strata was thought to be the one with least damage in overlying strata (Fig. 23).

Analogous hyperbola model of overlying strata movement with thick alluvium (Zuo et al. 2017e). In (a), I, II and III denote caving zone, fracture zone and continuous subsidence zone respectively. A, B and C denote abutment pressure influenced zone, bed separation zone and recompacted zone respectively

The local plastic hinge substructure model was presented when the key strata fractured (Zuo et al. 2014e) (Fig. 24), and the structure of plastic hinge was obviously influenced by the confining pressure, which exhibited the mechanism of “voussoir beam” structure stability. The three principal differences between the “quasi-plastic hinge” and ideal hinge were compared and analyzed as follows: (1) the “quasi-plastic hinge” could bear bending moments which varied with the forces applied on mesh locations. (2) the “quasi-plastic hinge” possessed a certain length. (3) the effects of the “quasi-plastic hinge” were evident when the rotation of fractured rock was relatively small. (4) the introduction of “quasi-plastic hinge” into the classical “voussoir beam” structure could be better coincident with the deformation and force condition of overlying strata structure in deep mining.

Plastic hinge structure model (Zuo et al. 2014e)

The two-dimensional and three-dimensional models of the continuous curved beam in backfill mining were raised by Liu et al. (2016), and the model gave the explanation that the roof would have bending formation rather than failure when the filling rate of goaf achieved a certain value, leading to the formation of the continuous curved beam (Fig. 25). Focus on the properties and forming conditions in mechanics and geometry of continuous curved beam, the relationship between the continuous curved beam and key strata was illustrated quantitatively.

The model of the continuous curved beam (Liu et al. 2016)

The mine rock mass was thought to be the complicated discontinuum and heterogeneous body, and the inside defects and weak structural planes were likely to be crucial to the rock mass failure. A great deal of field data indicated that the periodic weighting interval of working face is changing as a result of the impact of randomly distributed structural planes inside the main roof on the fracture interval. The field measurement of 7605 working face in Wuyang coal mine was conducted, obtaining the periodic fracturing interval of 9.0–14.0 m which demonstrated the feature similar to “normal distribution” (Zuo et al. 2016b), as showed in Fig. 26.

The normal distribution of periodic weighting interval of working face (Zuo et al. 2016b)

9 A combined grouting control technology for surface and underground

Grouting refers to the physical or chemical methods of improving the physical and mechanical properties of a fractured rock mass or a defective structure by injecting a liquid material that can be solidified into it (Kang and Feng, 2013). Existing cement-based grouting materials for water plugging generally have the shortcomings on poor stability of grouting slurry, a large degree of bleeding and long setting time. The consolidation rate as well as volume stability is relatively low under the influence of dynamic water washout, bringing about the secondary water leakage and cracking of rock in the reinforced area after grouting completion. Aiming at above difficulties, a number of researches are being conducted by authors as follows.

The mechanical model of a composite bearing structure for grouting in overburden bed-separation was established, which explained the law of stress distribution induced by the support of grouting filling body in separated layers to overlying key strata. Also, the additional stress caused by the pressure of filling body, which was transferred through the isolation layer to the compacted area, was also obtained by the model. To achieve the effective control of surface subsidence, the synergistic effects of key strata, grouting filling body and isolated coal pillars, and the mechanical behaviors of grouting filling body supporting system were analyzed in the presented model, the design principle of grouting in overburden bed-separation was shown in Fig. 27.

The properties of waterproof material were investigated in detail, including gelation time, time-dependent cohesion and anti-washout, and the impact of the above properties on the durability of grouting body was studied with the analysis of failure process of consolidation which was observed by various methods, for instance, ion corrosion, acoustic emission, etc. To reveal the mechanical mechanism of the long durability of the material, a refined calculation model describing fiber-substrate-interface characteristics was proposed to simulate the crack propagation after the corrosion of fiber reinforced material. According to the time-dependent rheology of grouting slurry, the features of grout seepage in fractured rock was discussed, and the influences of the aperture, connectivity and distribution of cracks on grout seepage with different ratios were indicated, demonstrating the mechanism of grout-fractured rock under fluid–solid coupling effects.

“Reconstituted compression ring” was put forward. Combined with available support systems, grouting support was supposed to be a valid approach to enhance the bearing capacity, and grouting reinforcement could change the stress state of surrounding rock as well as increase the thickness of the compression ring. At the same time, with the filling and reinforcement to the surrounding rock by grout, rock was prevented effectively from loosening and breaking. Grouting slurry filled interconnected cracks in rock mass of the compression ring, thus restraining the rheology of the rock mass. Due to compaction of rock in compression ring, the closed cracks and fissures which were unfilled could be compressed under the grouting pressure. Therefore, several advantages of grouting reinforcement are exhibited, including increasing strength of rock in compression ring as well as improving bearing capacity, integrity and force condition of the compression ring. The “reconstituted compression ring” was regarded to be formed, since the surrounding rock was expected to restore to the in-situ stress state which was shown before damage and failure, and the supporting effect of surrounding rock was improved.

10 Prospect

At present, some problems center on the failure behaviors of deep rock still needs to be further studied, although numerous theoretical, experimental and numerical simulation researches have been done by the scholars.

Various techniques have been applied to discuss the features of deformation and failure for rocks from a mesoscale, namely, scanning electron microscope, atomic force microscope, computed tomography, nuclear magnetic resonance, etc., but the macroscopic parameters used to demonstrate the mechanical response of rock are assumed to be homogeneous, continuous and isotropic. At the mesoscale, the influence of heterogeneity of rock structure and composition on its deformation and failure mechanism cannot be overlooked. Therefore, on the basis of fine characterization of meso-heterogeneity of rock, a theoretical model of rock mechanics at meso-scale should be established to quantitatively describe its mechanical response and investigate the impact of meso-mechanism on macro-behaviors and properties, thus proposing the mechanical model on multi-scale.

The failure of coal–rock combined body from shallow mining is mainly determined by its fissures and structural planes, while in deep mining, the damage of coal–rock combined body is affected not only by its defects, but also by the integral structure markedly. Generous disasters of coal bumps are essentially the outcomes of the overall instability failure of the combined body under the strong disturbance of engineering geology. Taking into account the complicated geological environment of deep coal–rock combined body, the failure behaviors of coal–rock combined body under the effects of different moisture content, temperatures and mining stress should be further studied.

The scientific and intensive discussion should be launched since it’s difficult to confirm the coupling relationships among multi-physical fields due to the sophisticated geological and mechanical environment of deep rock. In laboratory tests, several troubles are found in the realization of complex coupling condition corresponding to the real geological state of deep rock, which raises higher requirements for experimental technology and equipment.

The theoretical model of surrounding rock failure considering stress gradient in deep roadway preliminarily proposed by authors is based on the ideal roadway model. In the actual projects, complex natural fissures exist in the surrounding rock of roadway, and the complicated fissure field influences the stress distribution significantly. According to the available failure mechanism of the fractured rock mass, further development and relevant test verification of the theoretical model of surrounding rock failure considering stress gradient in the deep roadway are the work to be conducted in future.

On the basis of the thorough understanding of the damage features of surrounding rock, the theory of uniform strength support in the deep roadway is supposed to be investigated in detail.

According to the coupling mechanism among surrounding rock of roadway, other support methods, and concrete-filled steel tube as well as stress distribution of surrounding rock-support system, the concrete filled steel tube is taken as major bearing body and the purpose of simultaneous and uniform compression of the support structure in the roadway section is achieved by adjusting the local support strength, which realizes the effect of uniform support ultimately. The modular standard construction technology and prefabricated support technology of concrete-filled steel tubular support are formed by designing assembled concrete-filled steel support, which ensures the rapid and convenient construction of uniform support of deep surrounding rock.

In the theories of strata movement and control, a mechanical model of overlying strata movement is established in terms of the nonlinear constitutive relation of large deformation of deep rock, and the movement law of internal damage in strata is revealed from a mechanical view. The model can estimate the stability time after the strata failure with greater accuracy and illustrate the shape, process and scale of surface subsidence.

11 Conclusion

The mechanical properties and its complicated geological environment lead to more severe and frequent engineering disasters in deep mining projects. Since the traditional theory of rock mechanics and control method of surrounding rock based on shallow resource exploitation cannot guide the deep mining effectively, it is urgent to develop novel theories and methods applicable for deep engineering. A series of researches on the failure behaviors of deep rock and control technology of deep surrounding rock has been carried out by the author with the approaches of theories, experiments and numerical simulation. In the study of rock failure, the failure mechanisms of deep rock from macro/meso view, coal–rock combined body, macro/meso deformation under thermal–mechanical effects were revealed. To discuss the deformation control of deep surrounding rock, a failure model considering stress gradient and a uniform support theory for deep surrounding rock were proposed based on the stress distribution in rock. And an analogous hyperbola model describing the movement of overlying in terms of the movement laws of surface and overlying strata as well as the combined grouting control technology for surface and underground were put forward rigorously. The abovementioned theories and practical research are willing to offer guidance and reference for the exploitation of deep resources in China.

References

Bieniawski ZT (1967) Mechanism of brittle fracture of rock: Part II—experimental studies. Int J Rock Mech Min Sci Geomech Abstr 4(4):407–423

Chen Y, Zuo JP, Wei X, Song HQ, Sun YJ (2017) Energy nonlinear evolution characteristics of the failure behavior of coal–rock combined body. Chin J Undergr Space Eng 13(1):124–132 (in Chinese)

Chen Y, Zuo JP, Song HQ, Feng LL, Shao GY (2018) Deformation and crack evolution of coal–rock combined body under cyclic loading-unloading effects. J Min Saf Eng 35(4):826–833 (in Chinese)

Dong FT, Song HW, Guo ZH, Lu SM, Liang SJ (1994) Roadway support theory based on broken rock zone. J China Coal Soc 19(1):21–32 (in Chinese)

Feng XT, Chen SL, Zhou H (2004) Real-time computerized tomography (CT) experiments on sandstone damage evolution during triaxial compression with chemical corrosion. Int J Rock Mech Min Sci 41(2):181–192

Gao M, Li T, Wei T, Meng L (2018) A statistical constitutive model considering deterioration for brittle rocks under a coupled thermal–mechanical condition. Geofluids 2018:3269423. https://doi.org/10.1155/2018/3269423

Handin J, Hager RV (1957) Experimental deformation of sedimentary rocks under confining pressure: tests at room temperature on dry samples. AAPG Bull 41(1):1–50

He MC (2005) Conception system and evaluation indexes for deep engineering. Chin J Rock Mech Eng 24(16):2854–2858 (in Chinese)

He MC, Xie HP, Peng SP (2005) Study on tock mechanics in deep mining engineering. Chin J Rock Mech Eng 24(16):2803–2813 (in Chinese)

He MC, Wang J, Sun XM, Yang XJ (2014) Mechanics characteristics and applications of prevention and control rock bursts of the negative Poisson’s ratio effect anchor. J China Coal Soc 39(2):214–221 (in Chinese)

Heard HC (1960) Transition from brittle fracture to ductile flow in Solenhofen limestone as a function of temperature, confining pressure, and interstitial fluid pressure. In: Griggs D, Handin J (eds) Rock deformation (a symposium). Geological Society of America, Boulder. https://doi.org/10.1130/MEM79-p193

Hoek E (1994) Strength of rock and rock masses. ISRM News J 2(2):4–16

Hoek E, Bieniawski ZT (1965) Brittle fracture propagation in rock under compression. Int J Fract 1(3):137–155

Hoek E, Brown ET (1980) Empirical strength criterion for rock masses. J Geotech Eng 106(GT9):1013–1035

Hou CJ (2017a) Effective approach for surrounding rock control in deep roadway. J China Univ Min Technol 46(3):467–473 (in Chinese)

Hou CJ (2017b) Key technologies for surrounding rock control in deep roadway. J China Univ Min Technol 46(5):970–978 (in Chinese)

Hull D (1999) Fractography: observing, measuring and interpreting fracture surface topography. Cambridge University Press, Cambridge

Jiang YD, Zhao YX (2015) State on the art: investigation of mechanism, forecast and control of coal bumps in China. Chin J Rock Mech Eng 34(11):2188–2204 (in Chinese)

Jiang YD, Pan YS, Jiang FX, Dou LM, Ju Y (2014) State of the art review on mechanism and prevention of coal bumps in China. J China Coal Soc 39(2):205–213 (in Chinese)

Kang HP (2005) Study and application of complete rock bolting technology to coal roadway. Chin J Rock Mech Eng 24(21):3959–3964 (in Chinese)

Kang HP, Feng ZQ (2013) Status and development tendency of roadway grunting reinforcement technology in coal mine. Coal Min Technol 18(3):1–7 (in Chinese)

Kang HP, Wu YZ, He J, Fu YK (2015) Rock bolting performance and field practice in deep roadway with rock burst. J China Coal Soc 40(10):2225–2233 (in Chinese)

Kwasniewski M (1989) Laws of brittle failure and of B-D transition in sandstones. In: ISRM international symposium . ISRM-IS-1989:007

Li SP, He YN, Wu ZY, Li X (1996) A concise course on rock mechanics. China Coal Industry Publishing House, Beijing (in Chinese)

Li N, Feng X, Jimenez R (2017) Predicting rock burst hazard with incomplete data using Bayesian networks. Tunn Undergr Space Technol 61:61–70

Liu BC, Dai HY (2016) Research development and origin of probability integral method. Coal Min Technol 21(2):1–3 (in Chinese)

Liu CL, Tan ZX, Deng KZ, Li PX (2013) Synergistic instability of coal pillar and roof system and filling method based on plate model. Int J Min Sci Technol 23(1):145–149

Liu JG, Zhao JW, Li MM, Zuo JP (2016) Continuous curved beam formation and strata control theory in coal backfill mining. J China Coal Soc 41(2):383–391 (in Chinese)

Lu CP, Dou LM, Liu B, Xie YS, Liu HS (2012) Microseismic low-frequency precursor effect of bursting failure of coal and rock. J Appl Geophys 79:55–63

Ma LJ, Zhao XD, Zhao ZQ, Li J, Guo XF (2015) Stability analysis and control technology of mine roadway roof in deep mining. J China Coal Soc 40(10):2287–2295 (in Chinese)

Mogi K (1966) Pressure dependence of rock strength and transition from brittle fracture to ductile flow. Bull Earthq Res Inst Univ Tokyo 44:215–232

Mogi K (1971) Fracture and flow of rocks under high triaxial compression. J Geophys Res 76(5):1255–1269

Pan YS, Xiao YH, Li ZH, Wang KX (2014) Study of tunnel support theory of rockburst in coal mine and its application. J China Coal Soc 39(2):222–228 (in Chinese)

Paterson MS (1958) Experimental deformation and faulting in Wombeyan marble. Geol Soc Am Bull 69(4):465–467

Paterson MS (2005) Experimental rock deformation—the brittle field. Springer, Berlin

Qi QX, Li XL, Zhao SK (2013) Theory and practices on stress control of mine pressure bumping. Coal Sci Technol 41(6):1–5 (in Chinese)

Shi GH (1992) Discontinuous deformation analysis: a new numerical model for the statics and dynamics of deformable block structures. Eng Comput 9(2):157–168

Singh J, Ramamurthy T, Rao GV (1989) Strength of rocks at depth. In: ISRM international symposium ISRM-IS-1989:006

Song HQ, Zuo JP, Chen Y, Li LY, Hong ZJ (2019) Revised energy drop coefficient based on energy characteristics in the whole process of rock failure. Rock Soil Mech 40(1):1–9 (in Chinese)

Vajdova V, Baud P, Wong TF (2004) Compaction, dilatancy, and failure in porous carbonate rocks. J Geophys Res Solid Earth 109:B05204

Von Kármán Th (1911) Festigkeitsversuche unter allseitigem Druck. Zeitschrift des Vereines Deutscher Ingenieure 55:1749–1757

Wang Y, Li X, Zhang B, Wu YF (2014) Meso-damage cracking characteristics analysis for rock and soil aggregate with CT test. Sci China Technol Sci 57(7):1361–1371

Wawersik WR, Fairhurst C (1970) Study of brittle rock fracture in laboratory compression experiments. Int J Rock Mech Min Sci Geomech Abstr 7:561–575

Xie HP (2017) Research framework and anticipated results of deep rock mechanics and mining theory. Adv Eng Sci 49(2):1–16 (in Chinese)

Xie HP, Peng SP, He MC (2005) Basic theory and engineering practice in deep mining. Science Press, Beijing (in Chinese)

Xie HP, Gao F, Ju Y (2015a) Research and development of rock mechanics in deep ground engineering. Chin J Rock Mech Eng 34(11):2161–2178 (in Chinese)

Xie HP, Gao F, Ju Y (2015b) Quantitative definition and investigation of deep mining. J China Coal Soc 40(1):1–10 (in Chinese)

Yang L, Dai HY (2016) Thoughts of calculation method of coal mining subsidence in home. Coal Min Technol 21(2):7–9 (in Chinese)

Yang HQ, Liu JF, Zhou XP (2017) Effects of the loading and unloading conditions on the stress relaxation behavior of pre-cracked granite. Rock Mech Rock Eng 50(5):1157–1169

Zhang N, Gao MS (2004) High-strength and pretension bolting support of coal roadway and its application. J China Univ Min Technol 33(5):524–527 (in Chinese)

Zhang QB, Zhao J (2013) Effect of loading rate on fracture toughness and failure micromechanisms in marble. Eng Fract Mech 102:288–309

Zhang ZX, Kou SQ, Jiang LG, Lindqvist PA (2000) Effects of loading rate on rock fracture: fracture characteristics and energy partitioning. Int J Rock Mech Min Sci 37:745–762

Zhang H, Kang HP, Xu YL (2013) Study on rapid reinforced technology with pre-stressed anchor for deep mine. Coal Sci Technol 41(4):16–19 (in Chinese)

Zhang N, Han CL, Kan JG, Zheng XG (2014) Theory and practice of surrounding rock control for pillarless gob-side entry retaining. J China Coal Soc 39(8):1635–1641 (in Chinese)

Zhou HW, Xie HP, Zuo JP (2005) Development in researches on mechanical behaviors of rocks under the condition of high ground pressure in the depths. Adv Mech 35(1):91–99 (in Chinese)

Zhou HW, Zuo JP, Wang J, Liu YM (2008) Experimental researches on meso-scale failure of Beishan granite under thermal–mechanical coupling. In: The second waste underground disposal symposium, pp 257–266 (in Chinese)

Zhou HW, Hu B, Zuo JP (2010) Mesostructure-based numerical researches on deformation and failure of Beishan granite under thermal–mechanical coupling. In: The third waste underground disposal symposium, pp 217–229 (in Chinese)

Zuo JP (2006) Sandstone failure mechanism at the meso-scale and its strength characteristics under the thermal–mechanical action. Dissertation, China University of Mining and Technology, Beijing (in Chinese)

Zuo JP, Chen Y (2017) Investigation on crack recovery effect of coal–rock combined body under the influence of unloading. J China Coal Soc 42(12):3142–3148 (in Chinese)

Zuo JP, Xie HP, Zhou HW (2005) Study on failure behavior of rock under coupling effects of temperature and confining pressure. Chin J Rock Mech Eng 24(16):2917–2921 (in Chinese)

Zuo JP, Xie HP, Zhou HW, Peng SP (2007a) Experimental research on thermal cracking of sandstone under different temperature. Chin J Geophys 50(4):1150–1155 (in Chinese)

Zuo JP, Xie HP, Zhou HW, Fang Y, Fan X (2007b) Fractography of sandstone failure under temperature-tensile stress coupling effects. Chin J Rock Mech Eng 26(12):2444–2457 (in Chinese)

Zuo JP, Xie HP, Zhou HW, Peng SP (2007c) Thermal–mechanical coupled effect on fracture mechanism and plastic characteristics of sandstone. Sci China Ser E: Technol Sci 50(6):833–843

Zuo JP, Li HT, Xie HP, Ju Y, Peng SP (2008a) A nonlinear strength criterion for rock-like materials based on fracture mechanics. Int J Rock Mech Min Sci 45(4):594–599

Zuo JP, Xie HP, Zhou HW, Wang HW, Fang Y (2008b) Meso-failure of sandstone under temperature effects and DSCM study on deformation field. Chin J Theor Appl Mech 40(6):786–794 (in Chinese)

Zuo JP, Man K, Cao H, Yang GX, Hu CP (2008c) Study on constitutive equation of rock rheological model with thermos-mechanical coupling effects. Chin J Rock Mech Eng 27(s1):2610–2616 (in Chinese)

Zuo JP, Xie HP, Zhou HW (2009) Experimental determination of coupled thermal–mechanical effects on fracture toughness of sandstone. J Test Eval 37(1):48–52

Zuo JP, Xie HP, Zhou HW, Peng SP (2010a) SEM in situ investigation on thermal cracking behaviour of Pingdingshan sandstone at elevated temperatures. Geophys J Int 181(2):593–603

Zuo JP, Xie HP, Liu YJ, Hu B, Lu JF (2010b) Investigation on fracture characteristics of sandstone after thermal effects through three-bending point experiments. Chin Jo Solid Mech 31(2):119–126 (in Chinese)

Zuo JP, Zhou HW, Liu YJ (2010c) Research on characteristics parameters of sandstone three-point bending failure under different temperatures. Chin J Rock Mech Eng 29(4):705–712 (in Chinese)

Zuo JP, Chai NB, Zhou HW (2011a) Study on the effect of buried depth on failure and energy characteristics of the basalt. Chin J Undergr Space Eng 07(6):1174–1180 (in Chinese)

Zuo JP, Zhou HW, Fang Y, Meng BB, Peng RD (2011b) Experimental research on thermal cracking of deep granite in Beishan region, Gansu province. Chin J Rock Mech Eng 30(6):1107–1115 (in Chinese)

Zuo JP, Zhao Y, Chai NB, Wang HW (2011c) Measuring micro/meso deformation field of geo-materials with SEM and digital image correlation method. Adv Sci Lett 4(4):1556–1560

Zuo JP, Pei JL, Liu JF, Peng RD, Li YC (2011d) Investigation on acoustic emission behavior and its time-space evolution mechanism in failure process of coal–rock combined body. Chin J Rock Mech Eng 30(8):1564–1570 (in Chinese)

Zuo JP, Xie HP, Zhou HW (2012a) Investigation of meso-failure behavior of rock under thermal–mechanical coupled effects based on high temperature SEM. Sci China: Phys Mech Astron 55(10):1855–1862

Zuo JP, Zhou HW, Fang Y, Huang YM (2012b) Experimental research on fracture characteristics of double-notched Beishan granite under thermal–mechanical coupling effects. Chin J Rock Mech Eng 31(4):738–745 (in Chinese)

Zuo JP, Liu LF, Zhou HW, Huang YM (2013a) Deformation failure mechanism and analysis of rock under different mining condition. J China Coal Soc 38(8):1319–1324 (in Chinese)

Zuo JP, Chai NB, Zhou HW (2013b) Investigation on failure behavior of basalt form different depths based on three-point bending meso-experiments. Chin J Rock Mech Eng 32(4):689–695 (in Chinese)

Zuo JP, Huang YM, Liu LF (2013c) Investigation on meso-fracture mechanism of basalt with offset notch based on in-situ three-point bending tests. Chin J Rock Mech Eng 32(4):740–746 (in Chinese)

Zuo JP, Zhou HW, Fan X, Ju Y (2013d) Research on fracture behavior of Beishan granite after heat treatment under three-point bending. Chin J Rock Mech Eng 32(12):2422–2430 (in Chinese)

Zuo JP, Huang YM, Xiong GJ, Liu J, Li MM (2014a) Study of energy-drop coefficient of brittle rock failure. Rock Soil Mech 35(2):321–327 (in Chinese)

Zuo JP, Liu LF, Chen SJ, Chen LJ (2014b) Investigation on constitutive model of rock failure under mining unloading and its experimental validation. Chin J Undergr Space Eng 10(5):1002–1009 (in Chinese)

Zuo JP, Wang XS, Mao DQ (2014c) SEM in-situ study on the effect of offset-notch on basalt cracking behavior under three-point bending load. Eng Fract Mech 131:504–513

Zuo JP, Xie HP, Dai F, Ju Y (2014d) Three-point bending test investigation of the fracture behavior of siltstone after thermal treatment. Int J Rock Mech Min Sci 70(9):133–143

Zuo JP, Wen X, Yang SL et al (2014e) The mechanism of progressive rock failures and plastic hinges at great depth. In: ICGCM China 2014 proceedings (English volume), pp 112–115

Zuo J, Liu H, Li H (2015a) A theoretical derivation of the Hoek–Brown failure criterion for rock materials. J Rock Mech Geotech Eng 7(4):361–366

Zuo JP, Chai NB, Zhao C, Liu M (2015b) Investigation on the relationship between of micro/meso mineral composition and macro mechanical behavior of Moutougou basalt. J Basic Sci Eng 23(5):942–951 (in Chinese)

Zuo J, Wei X, Pei JL, Zhao XP (2015c) Investigation of meso-failure behaviors of Jinping marble using SEM with bending loading system. J Rock Mech Geotech Eng 7(5):593–599

Zuo JP, Wang XS, Mao DQ, Wang CL, Jiang GL (2016a) T-M coupled effects on cracking behaviors and reliability analysis of double-notched crustal rocks. Eng Fract Mech 158:106–115

Zuo JP, Cao GM, Sun YJ, Wang JT, Chen Y (2016b) Failure mechanics for mining surrounding rock and practice of full space coordinative control. Science Press, Beijing (in Chinese)

Zuo JP, Sun YJ, Wang JT, Chen Y, Jiang GH (2016c) Study on full space truss and anchor coordinative support of mine large cross section broken roadway. Coal Sci Technol 44(3):1–6 (in Chinese)

Zuo JP, Wang JT, Sun YJ, Chen Y, Jiang GH, Li YH (2017a) Effects of thermal treatment on fracture characteristics of granite from Beishan, a possible high-level radioactive waste disposal site in China. Eng Fract Mech 182:425–437

Zuo JP, Chen Y, Wang C (2017b) Failure mechanics and model for deep coal–rock combined bodies. Science Press, Beijing (in Chinese)

Zuo JP, Chen Y, Song HQ, Wei X (2017c) Evolution of pre-peak axial crack strain and nonlinear model for coal–rock combined body. Chin J Geotech Eng 39(9):1609–1615 (in Chinese)

Zuo JP, Sun YJ, Qian MG (2017d) Movement mechanism and analogous hyperbola model of overlying strata with thick alluvium. J China Coal Soc 42(6):1372–1379 (in Chinese)

Zuo JP, Sun YJ, Li YC, Wang JT, Wei X, Fan L (2017e) Rock strata movement and subsidence based on MDDA, an improved discontinuous deformation analysis method in mining engineering. Arab J Geosci 10(18):395

Zuo JP, Chen Y, Cui F (2018a) Investigation on mechanical properties and rock burst tendency of different coal–rock combined bodies. J China Univ Min Technol 47(1):81–87 (in Chinese)

Zuo JP, Wei X, Wang J, Liu DJ, Cui F (2018b) Investigation of failure mechanism and model for rocks in deep roadway under stress gradient effect. J China Univ Min Technol 47(3):478–485 (in Chinese)

Zuo JP, Wen JH, Hu SY, Zhao SK (2018c) Theoretical model and simulation study of uniform strength beam support in deep coal mine roadway. J China Coal Soc 43(S1):1–11 (in Chinese)

Acknowledgements

This study was financially supported by the National Natural Science Foundation of China (51622404, 11572343 and 41877257), the Yueqi outstanding scholar of CUMTB, Outstanding Young Talents of “Ten Thousand People Plan (W02070044)” and Beijing Excellent Young Scientists.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Zuo, J., Wang, J. & Jiang, Y. Macro/meso failure behavior of surrounding rock in deep roadway and its control technology. Int J Coal Sci Technol 6, 301–319 (2019). https://doi.org/10.1007/s40789-019-0259-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40789-019-0259-0