Abstract

Increase in greenhouse gases, has made scientists to substitute alternative fuels for fossil fuels. Nowadays, converting biomass into liquid by Fischer–Tropsch synthesis is a major concern for alternative fuels (gasoline, diesel etc.). Selectivity of Fischer–Tropsch hydrocarbon product (green fuel) is an important issue. In this study, the experimental data has been obtained from three factors; temperature, H2/CO ratio and pressure in the fixed bed micro reactor. T = 543–618 (K), P = 3–10 (bar), H2/CO = 1–2 and space velocity = 4500 (1/h) were the reactor conditions. The results of product modeling for methane (CH4), ethane (C2H6), ethylene (C2H4) and CO conversion with experimental data were compared. The effective parameters and the interaction between them were investigated in the model. H2/CO ratio and pressure and interaction between pressure and H2/CO in ethane selectivity model and CO conversion and interaction between temperature and H2/CO ratio in methane selectivity model and ethylene gave the best results. To determine the optimal conditions for light hydrocarbons, ANOVA and RSM were employed. Finally, products optimization was done and results were concluded.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

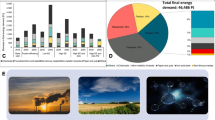

1 Introduction

From ancient time, energy has played an important role in human life. The supply of transport fuel is one of the most important issues that is at the forefront of attention. Considering that energy supply from fossil fuels cause serious damage to the environment, scientists are seeking ways for appropriate replacement (Tabrizi et al. 2015; Mishra et al. 2018). Agriculture and forestry residues, wood, municipal waste and any material which contains carbon, can be converted by various methods into useful products. Among these methods, the most alternative method is gasification, which through biomass can be converted into renewable and non-renewable products like transport fuels with high yields. Many communities are looking for clean and green energy to develop and solve a lot of problems (Sansaniwal et al. 2017; Cui et al. 2014; Knoope et al. 2013; Mi et al. 2015). Despite the waste, population growth and increase in transportation demand are factors which are important in the emission of greenhouse gases. To eliminate the waste, there are ways such as burying which poses a lot of risks for the environment, hence the method of gasification is very useful for environmental purpose.

By gasification, the diesel of Fischer–Tropsch is produced via biomass to liquid process. Fischer–Tropsch synthesis is an industrial technology which by using synthesis gas (that can be produced from gasification) produces liquid fuels such as gasoline, diesel etc. using a catalyst (Rafati et al. 2017; Sørum et al. 2001; Kim et al. 2013; Atashi and Rezaeian, 2017; Atashi and Veiskarami 2018; Zhang et al. 2018). Using the Fischer–Tropsch synthesis, a range of hydrocarbon products such as wax, liquid fuels, olefins and oxygenated hydrocarbons can be achieved by manipulating the process conditions and catalyst system. One of the great challenges of Fischer–Tropsch technology is manipulating the process conditions in order to minimize methane and maximize C2–C4 olefins (Botes et al. 2016). Certainly, the reaction performance of Fischer–Tropsch synthesis depends on operating conditions such as temperature, pressure, H2/CO feed ratio, and gas hour space velocity etc. Increase in temperature causes the products to shift to light hydrocarbons and C5+ products be to decrease and also increase methane (Todic et al. 2016). Cobalt catalyst produces hydrocarbon products only in a certain range of temperature and pressure, while the iron catalyst produces hydrocarbon in all ranges (Lari et al. 2017; Zhang et al. 2015). In commercial production, cobalt, iron, nickel, ruthenium which have catalytic properties are used. Ruthenium and cobalt have high catalytic activity and high heavy hydrocarbon selectivity and also, high stability at low temperatures, in high H2/CO feed ratio. But due to limited industrial applications (e.g. low price), the cobalt catalyst is used for C5+ hydrocarbons synthesis (Vosoughi et al. 2017). Cobalt catalyst has more activity, stability and selectivity compared to iron catalyst and also has less activity in water gas shift (WGS) reaction (Muleja et al. 2017). Many studies have been carried out on cobalt catalyst and to increase catalytic performance, different promoters have been investigated (Muleja et al. 2017; Sun et al. 2016). Taherzadeh believes that the distribution of hydrocarbon products is not only a function of process conditions but also depends on the type of catalyst. She also added that the activity and selectivity of bimetallic catalyst are higher than a single catalyst (Taherzadeh Lari et al. 2016). Nikparsa has investigated the reaction conditions on Co–Ni/Al2O3 and has also studied the kinetic of Fischer–Tropsch reaction (Nikparsaa et al. 2014). Xiaoping has investigated the effect of cerium promoters and concluded that the percentage of CO conversion and C5+ selectivity is increased (Xiaoping et al. 2006). Several studies were carried out on the effect of operating conditions in Fischer–Tropsch reaction which is evaluated qualitatively. Mandic et al. examined the process condition on catalyst and methane selectivity in Fischer–Tropsch reaction (Mandić et al. 2017). Krishnamoorthy et al. investigated the selectivity and the effect of water on Fischer–Tropsch synthesis which is studied qualitatively (Krishnamoorthy et al. 2002). Iglasia evaluated the selectivity of hydrocarbon products through the chain-growth using cobalt catalyst (Iglesia 1997).

As already mentioned, most of the Fischer–Tropsch product selectivity’s studies were assessed qualitatively and few number of researchers have provided a model by which selectivity of products can be obtained quantitatively. The aim of this paper is to obtain a model for Fischer–Tropsch products and using this model to select the effective parameter from temperature, pressure, H2/CO feed ratio and giving more attention to it. Through statistical models, the interaction between parameters was examine and finally, the optimum conditions which are very important for increase in the desirable product were evaluated.

2 Materials and methods

2.1 Catalyst preparation

In this study, Co–Ni–Ce/Al2O3 catalyst was prepared by incipient wetness impregnation method as follows: an appropriate amount of Y-Al2O3 as support was calcined at 873.15 K in flowing air for 4 h. The solution was prepared using Co(NO3)2·6H2O (99% Merck) and Ni(NO3)·H2O (99% Merck) and Ce(NO3)2·6H2O (99% Merck). The molar ratio of the salts used in the solution are equal to Co/Ni/Ce: 80/20/1. Support is suddenly placed in the solution for 1 h, then the filtered support is dried at 393.15 K for 6 h and calcined at 823.15 K for 10 h at the rate of 5 c/min.

2.2 Catalyst testing

Figure 1 shows the schematic diagram of the experimental setup in which all reactions were carried out with 1 g of catalyst in a fixed bed micro reactor. The flow channel control panel adjusted the flow rates of syngas by mass flow controller (MFC). The reactor was located in the middle of the furnace and the homogenized feed ratio passed the reactor bed. For the control of temperature and pressure, a thermocouple and a back pressure regulator were embedded, respectively. Before starting the reaction, the catalyst was reduced at 673.15 K in atmospheric pressure by hydrogen flow (30 ml/min) for 24 h. Then the temperature was reduced and hydrogenation of CO was done. The operating conditions rate are T = 543–618 K, P = 3–10 bar, H2/CO ratio = 1–2 and gas hourly space velocity = 4500 1/h. By using gas chromatography (Varian 3500 GC) equipment, the products were analyzed. In each run after stability of operating conditions, the feed and products were injected to the GC, separately. All results are presented in Table 1.

Experimental setup of fixed bed reactor (FBR) for Fischer–Tropsch synthesis: (1) gas cylinders, (2) pressure regulators, (3) mass flow controller (MFC), (4) pressure gages, (5) mixing chamber, (6) ball valves, (7) tubular furnace, (8) temperature controller (TC), (9) catalyst bed, (10) condenser, (11) liquid trap, (12) back pressure regulator (BPR), (13) dryer, (14) gas chromatograph, (15) hydrogen generator

The results are presented as CO conversion and hydrocarbon selectivity as follows:

where Pi represents the partial pressure of hydrocarbon products and \(\sum P_{i}\) is the total output of the carbon products partial pressure (e.g. methane, ethane, and ethylene) and \(x_{i}\) is molar ratio of products which is obtained through Gas Chromatography.

2.3 Response surface methodology

Selectivity of Fischer–Tropsch product depends on many factors, such as temperature, pressure, H2/CO ratio and space velocity etc. In this work, the effect of three parameters (temperature, pressure, H2/CO ratio) were investigated by Response Surface Methodology (RSM).

Response surface methodology is a statistical technique used to achieve a mathematical model which describes the main parameter and interactions that have the main effect on the process. In RSM, the regression of second order polynomial was employed. In this study, the model of regression can be written as follows:

where ‘y’ is the response, ‘a’ is the regression coefficient and ‘x’ is variables (e.g. temperature, pressure and H2/CO ratio) and ‘k’ shows the number of experiments (Zohdi-Fasaei et al. 2017; Razmjooie et al. 2017). The model regression accuracy can be obtained as shown in the following equations:

The amount of \(R^{2}\) and adjusted \(R^{2}\) must be close to 1. The Pvalue is used to evaluate the regression coefficients. Usually, the amount of Pvalue under 0.05 shows that the parameter has a significant effect on the response but Pvalue is not a necessary condition. The other item which is the same as Tvalue was used (Atashi et al. 2015). The test of lack of fit is an important item in choosing the model. The model with insignificant lack of fit is an appropriate model. For all the responses, the analysis showed that quadratic model is suitable. \(R^{2}\) and \(R^{2}\) adjusted for all models are close to 1 and lack of fit is insignificant due to this reason and the models are fitted well into the data. All statistical coefficient according to ANOVA are presented in Table 2.

3 Results and discussion

The selectivity model which is the primary key in industries that are significant for optimization of process and reactors via statistical method was studied. The RSM was employed to improve the selectivity model of products. The results have a good agreement between experimental data and predicted model. The results are presented in Table 3. Finally, the minimum amount of undesirable and maximum amount of desirable products are concluded from optimization process which are reported in Table 4. All analysis and calculations were performed with Minitab software.

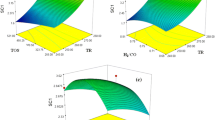

3.1 Selectivity model of methane

Figure 2 illustrates the surface and contour plot of methane selectivity that affects the operating conditions (e.g. temperature, pressure and H2/CO ratio). As can be seen, the methane selectivity decrease by increasing the temperature at constant pressure and H2/CO ratio but this increase is smooth at constant H2/CO ratio. The methane selectivity increases by increasing the H2/CO ratio. As it is clear for CH4 product, there is a minimum selectivity in the low H2/CO ratio. As can be seen, at high temperature and low H2/CO ratio, the amount of methane selectivity is reduced. CH4 selectivity varies parabolically with pressure. By increasing the pressure, the methane selectivity decreases and then increases. Therefore, the minimum amount of methane selectivity increases. The proposed selectivity model is as follows:

According to Eq. (7), H2/CO ratio has the most effect on the selectivity of methane. Also, the interaction between temperature and H2/CO ratio has an important effect. The effect of temperature can be ignored in methane selectivity because of low coefficient value.

3.2 Selectivity model for ethane

Figure 3 illustrates the surface and contour plot of ethane selectivity. As can be seen, the effect of temperature, pressure and H2/CO ratio are shown in Fig. 3. The selectivity of ethane increases with increase in pressure. By increasing the H2/CO ratio, the selectivity of ethane increases first and then decrease. As can be seen, at constant temperature and high pressure, the maximum amount of ethane was achieved. By increasing temperature, selectivity of ethane decreases and then increases. The ethane selectivity varies parabolically with temperature and H2/CO ratio. The selectivity model of ethane can be proposed as follows:

According to Eq. (8), H2/CO ratio has the most effect on the model because its coefficient is the most and has positive effect. Also, the important interaction between parameter belongs to pressure and H2/CO ratio.

3.3 Selectivity model for ethylene

Figure 4 illustrates the contour and surface plot of operating conditions effect on ethylene selectivity. As can be seen, the ethylene selectivity increased with increase in temperature but at high pressure, temperature has no effect on the ethylene selectivity therefore, the effect of temperature at high pressure can be neglected. By increasing H2/CO ratio, the selectivity increases, so the maximum amount of ethylene was achieved. The ethylene selectivity varies parabolically with pressure. The maximum selectivity of ethylene occurs at low pressure, but by increasing the pressure, ethylene selectivity decreases and then increases. The selectivity model of ethylene is given as follows:

As can be seen in Eq. (9), H2/CO ratio is the important parameter in the model because it has the most effect on the model. Also, an important interaction is T*H2/CO ratio and because of its negative coefficient, it has negative effect on the selectivity of ethylene.

3.4 The model for CO conversion

Figure 5 shows the effect of operating conditions such as temperature, pressure and H2/CO ratio on CO conversion model. The figures are in form of surface and contours. As can be seen in Fig. 5, at constant pressure, temperature has no effect on conversion but at constant H2/CO ratio, by increasing the temperature, the conversion decreases. This reduction at low pressure has great intensity, while at high pressure, increase in temperature has no effect on conversion. At high temperature and low H2/CO ratio, by increasing the pressure, CO conversion increases. By increasing the H2/CO ratio, the CO conversion decreases and then increases.

The model for CO conversion can be presented as follows:

In equation of CO conversion model, H2/CO ratio is the most effective parameter in the model. It has negative effect on the model. Also, the interaction between pressure and H2/CO ratio has the most effect on the model.

3.5 Optimization

To increase the desired product and decrease the undesired products, optimization is necessary. The RSM methodology is an appropriate method for creating the connection between inputs and outputs of process. Using RSM to optimize outputs of process, the operating cost can be reduced and plant profits can be increased. In this study, the optimization of products are done in two ways. As can be seen in Table 4, in three-objectives part, to increase the selectivity of ethylene (olefin) and decrease the selectivity of methane and ethane (paraffin), T = 600.49 K, P = 3.07 bar and H2/CO = 1 should be adjusted. In three single-objective part, to maximize the selectivity of ethylene as an olefin, the temperature, pressure and H2/CO ratio have been set at 618 K, 3 bar and 1.4848, respectively. Also, to decrease the selectivity of methane, the temperature, pressure and H2/CO ratio have been set at 618 K, 6.46 bar and 1, respectively. Figure 6 indicates the optimization plot in three objectives.

4 Conclusion

This work can be viewed as a roadmap which not only reduces undesirable products, but also increases the selectivity of desirable products by manipulating the process conditions. Generally, the fuels which are produced by this method, are very suitable for environmental purpose.

RSM and ANOVA were employed to study the Fischer–Tropsch synthesis product selectivity. The effect of temperature, pressure and H2/CO ratio on product selectivity of methane, ethane, ethylene and CO conversion model were investigated in fixed bed micro reactor. The presented mathematical models show that the response is affected by parameters. By using statistical analysis, the model is adequately significant. As shown in the ANOVA analysis and Figures, to decrease methane selectivity, the temperature must be high and H2/CO ratio must be low. However, by increasing the temperature and decreasing the pressure, the ethylene selectivity is increased. Also, by increasing the temperature and decreasing the H2/CO ratio, the CO conversion increases at high pressure. In optimization, the maximum desirable product (ethylene) was achieved at T = 618 K, P = 3 bar and H2/CO = 1.4848 while the minimum amount of undesirable product (methane) was achieved at T = 618 K, P = 6.4646 bar and H2/CO = 1. Also, to increase ethylene as an olefin product and decrease methane and ethane as a paraffin product in a coordinate manner, the temperature, pressure and H2/CO ratio have been set at 600.490 K, 3.0707 bar and 1, respectively. The equation of selectivity models of methane and ethylene shows that the interaction of H2/CO ratio and temperature has the most effect on the model, while the interaction of pressure and H2/CO in the model of CO conversion and ethane selectivity has the important effect. In all models, the main parameter is H2/CO ratio which has the most effect on the model.

References

Atashi H, Rezaeian F (2017) Modelling and optimization of Fischer–Tropsch products through iron catalyst in fixed-bed reactor. Int J Hydrogen Energy 42:15497–15506

Atashi H, Veiskarami S (2018) Green fuel from coal via Fischer–Tropsch process: scenario of optimal condition of process and modelling. Int J Coal Sci Technol 5:230–243

Atashi H, Razmjooei S, Khorashadizadeh M, Shiva M, Tabrizi FF, Mousavi SAHS (2015) Effects of operating conditions on selectivity of Fe–Co–Mn/MgO at high temperature CO hydrogenation. J Taiwan Inst Chem Eng 54:83–90

Botes GF, Bromfield TC, Coetzer RL, Crous R, Gibson P, Ferreira AC (2016) Development of a chemical selective iron Fischer Tropsch catalyst. Catal Today 275:40–48

Cui Y, Liang J, Wang Z, Zhang X, Fan C, Wang X (2014) Experimental forward and reverse in situ combustion gasification of lignite with production of hydrogen-rich syngas. Int J Coal Sci Technol 1:70–80

Iglesia E (1997) Design, synthesis, and use of cobalt-based Fischer–Tropsch synthesis catalysts. Appl Catal A 161:59–78

Kim K, Kim Y, Yang C, Moon J, Kim B, Lee J, Lee U, Lee S, Kim J, Eom W (2013) Long-term operation of biomass-to-liquid systems coupled to gasification and Fischer–Tropsch processes for biofuel production. Bioresour Technol 127:391–399

Knoope M, Meerman J, Ramírez A, Faaij A (2013) Future technological and economic performance of IGCC and FT production facilities with and without CO2 capture: combining component based learning curve and bottom-up analysis. Int J Greenh Gas Control 16:287–310

Krishnamoorthy S, Tu M, Ojeda MP, Pinna D, Iglesia E (2002) An investigation of the effects of water on rate and selectivity for the Fischer–Tropsch synthesis on cobalt-based catalysts. J Catal 211:422–433

Lari TT, Mirzaei AA, Atashi H (2017) Fischer–Tropsch synthesis: effects of aging time and operating temperatures on solvothermally prepared nanocatalyst for light olefin selectivity. Catal Lett 147:1221–1234

Mandić M, Todić B, Živanić L, Nikačević N, Bukur DB (2017) Effects of catalyst activity, particle size and shape, and process conditions on catalyst effectiveness and methane selectivity for Fischer–Tropsch reaction: a modeling study. Ind Eng Chem Res 56:2733–2745

Mi J, Wang N, Wang M, Huo P, Liu D (2015) Investigation on the catalytic effects of AAEM during steam gasification and the resultant char reactivity in oxygen using Shengli lignite at different forms. Int J Coal Sci Technol 2:223–231

Mishra A, Gautam S, Sharma T (2018) Effect of operating parameters on coal gasification. Int J Coal Sci Technol 5:113–125

Muleja AA, Yao Y, Glasser D, Hildebrandt D (2017) Variation of the short-chain paraffin and olefin formation rates with time for a cobalt Fischer–Tropsch catalyst. Ind Eng Chem Res 56:469–478

Nikparsaa P, Mirzaeia A, Atashib H (2014) Effect of reaction conditions and kinetic study on the Fischer–Tropsch synthesis over fused Co–Ni/Al2O3 catalyst. J Fuel Chem Technol 42:710–718

Rafati M, Wang L, Dayton DC, Schimmel K, Kabadi V, Shahbazi A (2017) Techno-economic analysis of production of Fischer–Tropsch liquids via biomass gasification: the effects of Fischer–Tropsch catalysts and natural gas co-feeding. Energy Convers Manag 133:153–166

Razmjooie A, Atashi H, Shahraki F (2017) Analysis of the effective operating factors of Fischer–Tropsch synthesis; Investigation of modeling and experimental data. J Nat Gas Sci Eng 40:72–78

Sansaniwal S, Pal K, Rosen M, Tyagi S (2017) Recent advances in the development of biomass gasification technology: a comprehensive review. Renew Sustain Energy Rev 72:363–384

Sørum L, Grønli M, Hustad J (2001) Pyrolysis characteristics and kinetics of municipal solid wastes. Fuel 80:1217–1227

Sun Y, Wei J, Zhang JP, Yang G (2016) Optimization using response surface methodology and kinetic study of Fischer–Tropsch synthesis using SiO2 supported bimetallic Co–Ni catalyst. J Nat Gas Sci Eng 28:173–183

Tabrizi FF, Mousavi SAHS, Atashi H (2015) Thermodynamic analysis of steam reforming of methane with statistical approaches. Energy Convers Manag 103:1065–1077

Taherzadeh Lari T, Mirzaei AA, Atashi H (2016) Influence of fabrication temperature and time on light olefin selectivity of iron–cobalt–cerium mixed oxide nanocatalyst for CO hydrogenation. Ind Eng Chem Res 55:12991–13007

Todic B, Nowicki L, Nikacevic N, Bukur DB (2016) Fischer–Tropsch synthesis product selectivity over an industrial iron-based catalyst: effect of process conditions. Catal Today 261:28–39

Vosoughi V, Badoga S, Dalai AK, Abatzoglou N (2017) Modification of mesoporous alumina as a support for cobalt-based catalyst in Fischer–Tropsch synthesis. Fuel Process Technol 162:55–65

Xiaoping D, Changchun Y, Ranjia L, Haibo S, Shikong S (2006) Role of CeO2 promoter in Co/SiO2 catalyst for Fischer–Tropsch synthesis. Chin J Catal 27:904–910

Zhang J, Lu S, Su X, Fan S, Ma Q, Zhao T (2015) Selective formation of light olefins from CO2 hydrogenation over Fe–Zn–K catalysts. J CO2 Util 12:95–100

Zhang H, Yu K, Zhu Z (2018) Steam gasification reactivity of a high-sodium coal fly ash obtained from a pilot scale CFB gasifier. Int J Coal Sci Technol 5:244–252

Zohdi-Fasaei H, Atashi H, Tabrizi FF, Mirzaei AA (2017) Modeling and optimization of Fischer–Tropsch synthesis over Co–Mn–Ce/SiO2 catalyst using hybrid RSM/LHHW approaches. Energy 128:496–508

Acknowledgements

The authors would like to thank and appreciate university of Sistan and Baluchestan and the Ministry of Science & Research for the financial assistance rendered to them. They are also grateful to the Iranian National Petrochemical Company (INPC) for their support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Atashi, H., Rezaeian, F. & Mirzaei, A.A. The green fuel from carbon waste: optimization and product selectivity model studies. Int J Coal Sci Technol 5, 399–410 (2018). https://doi.org/10.1007/s40789-018-0211-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40789-018-0211-8