Abstract

The cleavage of the aliphatic chain or ether bond connecting the polycyclic aromatic hydrocarbons in coal can be achieved by not only hydrogenation reduction but also oxidative acid treatment. In this paper, coal samples from Wucaiwan in Xinjiang were pretreated with HNO3 followed by mixed acids/ultrasound treatment. The depolymerized coal samples obtained under different pH conditions were then separated by fractional washing. The structures and properties of the resulting coal samples were studied by elemental analysis, FT-IR, XRD, TG–DTA, TEM, UV–Vis, and PL. The results showed that when pH = 0.012, the obtained coal samples were fragments stripped off from the raw coal samples by ultrasound in strong acid conditions, aliphatic hydrocarbons linked with oxygen-containing groups such as nitro group, a small amount of small aromatic molecules and mineral salts; when pH = 1.99–4.09, the obtained coal samples were polycyclic aromatic hydrocarbons linked with oxygen-containing groups such as nitro group,possessing the annulus wall of multilayer graphene fragment structures built up by sp2 carbons, and they are typical fluorescent substances of carbon nanoparticle structure. The former has no solubility in organic solvents, while the latter can be well dissolved in polar solvents such as acetone. All the depolymerized coal samples obtained under different pH conditions exhibited good absorption and ability of fluorescence emission.

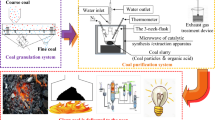

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

During the coal gasification and liquefaction processes, hydrogen can cleave the alkane chain or ether bond between the macromolecules in coal structures in the presence of catalyst to obtain liquid hydrogenated products (Chen et al. 2015; Li et al. 2015; Guo et al. 2015). The cleavage of these weak bonds can be achieved by not only hydrogenation reduction but also acid oxidation. For instance, Zhao et al. treated Dahuangshan bituminous coal samples with H2SO4/HNO3 (3:1) mixed acids and solubilized the treated samples in N, N-dimethylformamide (DMF) and mixed them with polyacrylonitrile (PAN) as spinning solution and produced coal-based carbon fibres by using electrospinning technique (Zhao et al. 2014); Hu et al. used Shanxi bituminous coal as carbon source and treated them with nitric acids and prepared coal-based fluorescent carbon dots (Hu et al. 2014). Undoubtedly, treating coal with oxidative acids to destroy the macromolecular structures of coal and break down particular chemical bonds and further prepare coal-based high value-added products is an effective way of realizing efficient utilization of coal resources (Hu et al. 2016). However, in terms of current research status, the main purpose of acid treatment of coal is to remove the minerals and sulfur in coal and loosen the cross-linked structure of coal so that the conversion processes of coal such as pyrolysis, gasification, liquefaction, and solvent extraction can proceed efficiently (Soneda et al.1998; Li et al. 2004a; Zhang et al. 2007; Izquierdo et al. 2011; Manoj and Narayanan 2013; Li et al. 2004b), and little has been reported on the preparation of specific products from acid treated coal.

Therefore, aiming at preparing coal-based carbon nanoparticles via depolymerizing coal, our research group treated Xinjiang Wucaiwan coal samples with a mixed acids/ultrasound method and found for the first time that varying the system pH values during the washing step can result in different depolymerization degree, product structure, product dispersity in organic solvents, and optical property of product aqueous dispersion. Our results not only presented a method for the preparation of coal-based carbon nanoparticles, but also aid in revealing the coal structures on a molecular level, at the same time, it can provide useful information for the developing technique of mild conversion of coal.

2 Experimental

2.1 Materials and reagents

Coal sample was collected from Wucaiwan coal mine in Zhundong coal field in Xinjiang, China. It was ground to pass a 200 mesh screen and dried at 105 °C for 4 h before use. Dialysis bag (Spectrumlabs, molecular weight cut off 100–500) was purchased from Shanghai Toscience Biotechnology Co., Ltd. H2SO4, HNO3, DMSO, DMF, acetone, and chloroform (CHCl3) are of analytical grade and commercially available.

2.2 Depolymerization of coal samples

A weighed amount of coal sample powder passing through 200 mesh screen was added into 2.6 M of HNO3 aqueous solutions. The mixture was stirred at room temperature for 24 h and refluxed for another 24 h and then cooled to room temperature. The remaining solid was separated from the mixture by centrifugation and air dried. A weighed amount of the dried solid was transferred into a flask and soaked in a certain amount of mixed acids of H2SO4/HNO3 (3:1 volume ratio) and sonicated at 60 °C for 12 h. Then the solid/acid mixture was transferred into a centrifuge tube with some distilled water added. Centrifugation was carried out at a rate of 10,000 rpm. The supernatant was labeled as No. 1. Distilled water was added into the centrifuge tube. After the precipitation was well dispersed by shaking the tube by hand, centrifugation was carried out again and the supernatant was labeled as No. 2. Repeat the steps until the precipitation was completely depolymerized. No. 1, 2, and 3 supernatants were transferred into dialysis bags with corresponding number and dialyzed in water for 72 h, during which water was constantly refreshed, until the pH was neutral. The solutions in the dialysis bags were the depolymerization products of Wucaiwan coal sample under different pH conditions. They were dried under nitrogen flow and then weighed.

2.3 Structural characterization

A variety of instruments were used to characterize three batches of coal samples: the raw coal sample, the coal sample pretreated with HNO3, and the depolymerized coal samples obtained under different pH conditions. The content of element C, H, O, N, and S in all three coal samples was determined by FLASHEA-PE2400 elemental analyzer. The ash content in all three samples was estimated by analyzing the weight changes of the samples during the programmed temperature using Kaiyuan 5E-MAG6700 industrial analyzer. FT-IR and XRD characterizations of all three samples were performed by Bruker-EQUINOX 55 Fourier Transform Infrared Spectrometer and MAC-M18XHF22-SRA X-Ray Diffractometer, respectively. The thermal properties of the three samples were determined by PE-DTA/1700 thermal analyzer. The aqueous dispersions of depolymerized coal samples obtained under different pH conditions were diluted and dropped onto copper grid and dried to allow observation of the morphology and structure of all sample particles using Japan Hitachi H-600 Transmission Electron Microscope (TEM). The particle sizes of the aqueous dispersion were measured by using NANO- S90laser particle size analyzer.

2.4 Properties of depolymerized coal samples

Depolymerized coal samples obtained under different pH conditions were dispersed in water and then diluted. The aqueous dispersions were transferred into cuvettes and measured by Japan Hitachi UV 3900H UV–Vis spectrophotometer for UV–Vis adsorption spectra and by France Horiba Fluorolog-3 fluorescence spectrometer for emission spectra at different excitation wavelengths, respectively. The solubility of depolymerized coal samples in organic solvents was observed by dispersing the samples into DMSO, DMF, acetone, and CHCl3.

3 Results and discussion

3.1 HNO3 pretreatment of coal samples

Table 1 lists the pretreatment method for Wucaiwan coal sample, yield, and elemental and ash analysis results of the treated sample.

Elemental analysis results showed that after pretreatment with HNO3, ash in the coal was removed and the content of S decreased while the content of both O and N increased.

To study the structure change of the coal sample before and after the pretreatment by HNO3, FT-IR, XRD, and TG-DTG analysis were performed on three samples in Table 1 and the results are shown in Fig. 1, 2.

Figure 1a shows that the FT-IR spectrum (curve 1) of Wucaiwan coal sample is consistent with that of other coal samples (Saikia et al. 2008; Manoj and Elcey 2010; Balachandran 2014). Three types of peaks were found: (1) the peaks at 2923 and 1376 cm−1 correspond to the aliphatic structure; (2) the peaks at 3050, 1585, 826, and 763 cm−1 are the characteristic peaks of aromatic ring; (3) the peaks at 3350, 1715, 1250 cm−1 are assigned to the oxygen-containing functional groups. The band between 400 and 600 cm−1 relates to the ash. Curve 2 represents the FT-IR spectrum of the coal sample after HNO3 treatment at 25 °C for 24 h. The shape of curve 2 is almost the same as that of curve 1 except the decrease of the band between 400 and 600 cm−1 and the increase of the peaks at 1715 and 1250 cm−1, indicating that treating raw coal sample with HNO3 at room temperature aided in the removal of ash and the increase of oxygen-containing functional groups in the structure of coal. Curve 3 is the FT-IR spectrum of the coal sample after 24 h of reflux. It shows that the intensities of the adsorption at 1715 and 1250 cm−1 further increase for sample 3. Besides that, a weak band appeared between 3000 and 2500 cm−1 and a single peak showed up at 1538 cm−1, corresponding to the adsorption of COOH and C–NO2 group, respectively. In addition, both the peak of O–H group at 3350 cm−1 and the peak of aliphatic structure at 2923 cm−1 decrease, and the peak at 1376 cm−1 assigned to the aliphatic structure disappeared, and also the band between 400 and 600 cm−1 associated with the ash almost disappeared. The results of ultimate analysis and FT-IR demonstrate that treating Wucaiwan coal sample with HNO3 under reflux condition not only was efficient in removing the ash in the coal but also introduced oxygen-containing groups such as nitro group into the organic structure of coal and reduced the content of aliphatic structure relatively.

Figure 1b shows that all three samples exhibited two distinct peaks at 26° and 43° in their X-ray diffraction (XRD) pattern, corresponding to the (002) plane of graphite (JCPDS 26-1079) (Hu et al. 2014). After treatment with HNO3, the peak for the (002) plane of sample 2 and 3 slightly shifted to higher degree compared with raw coal sample (sample 1), and gradually approached the (002) plane of graphite at 26.6°, but the peak width and height showed a significant difference, i.e., the peak of sample 2 which was only treated at 25 °C became wider and shorter while the peak of sample 3 which was treated with HNO3 under reflux became narrower and higher. The results reveal that HNO3 treatment under reflux condition can not only lower the ash content in the coal structure but also reduce the content of aliphatic structure, thereby increasing the relative content of polycyclic aromatic rings (Taylor and Bell 1980; Takagi et al. 2004). The XRD results are consistent with the FT-IR results, which may be attributed to the partial breakdown of the aliphatic chains linking the aromatic units by HNO3 under reflux condition.

It has been reported that the weight loss of coal sample under 150 °C is due to the vaporization of water; the weight loss between 150 and 300 °C corresponds to the volatilization of light component and the decomposition or dehydration condensation of reactive groups such as carboxyl and hydroxyl groups; the weight loss between 300 and 500 °C is mainly the pyrolysis of active bridge bonds in the coal, which is a devolatilization process and tar is produced; a second pyrolysis occurs between 600 and 800 °C, which is mainly a process of condensation of aromatic structures and dehydrogenation to produce semicoke (Shi et al. 2013). Therefore, the first weight loss peak at 75 °C of raw coal sample (Fig. 2a) is generated by the loss of water, and the second peak at 445 °C is the weight loss peak of devolatilization during pyrolysis. As the temperature increases, especially above 600 °C, polycondensation dominates and the weight loss becomes more gradual.

As seen in Figs. 2b, c, first of all, sample 2 obtained by HNO3 treatment at 25 °C and sample 3 obtained by HNO3 treatment under reflux condition, both showed peaks of loss of water at 82 and 69 °C, which is similar to the behavior of raw coal sample. Second, sample 2 and 3 showed a major weight loss peak at 284 and 293 °C, respectively, corresponding to the volatilization of small molecular compounds and the decomposition or dehydration condensation of oxygen-containing groups such as carboxyl and hydroxyl groups, this is distinctly different from the weight loss behavior of raw coal sample, it indicates that by treatment with oxidative HNO3, a large number of active oxygen-containing functional groups appeared in the coal structure. Noted that within this range sample 3 has lower temperatures for water loss peak and decomposition peak of oxygen-containing groups than that of sample 2, demonstrating that the content of oxygen-containing groups in sample 3 is higher than that in sample 2, because the existent of oxygen-containing groups can not only facilitate the decomposition and dehydration condensation of coal but also induce the pyrolysis of organic matter and decrease the pyrolysis temperature (Fletcher et al. 2007; Ruiz et al. 2006). Moreover, the oxygen-containing groups in sample 2 and 3 were basically removed by the first pyrolysis, resulting in higher dehydrogenation condensation coking temperature than that of raw coal sample during the second pyrolysis; therefore, both sample 2 and 3 exhibited weight loss peaks between 500 and 600 °C. In addition, the weight loss ratio of sample 2 within the 0–1000 °C temperature range is higher than that of sample 3, which is mainly caused by initial loss of water.

3.2 Depolymerization of pretreated coal samples by mixed acids/ultrasound

A certain proportion of mixed acids H2SO4/HNO3 (3:1 volume ratio) were added into the coal sample pretreated with HNO3 and the mixture was sonicated at 60 °C for 12 h. After sonication, the acid/coal mixture was washed by purified water for several times. Figure 3 are the photos of the washing solution obtained by washing the above sample (first treated with HNO3 and then by mixed acids/ultrasound for 12 h) with 100 mL of purified water for 10 times (a), and the aqueous dispersion of the depolymerized coal samples after acid removal by dialysis (b). Both photos were taken under visible light. It can be inferred by the color of the washing solution in Fig. 3 that when washing the mixture to different pH conditions, the amount and structure of depolymerized coal samples dispersing in water may be different.

FT-IR, fluorescent spectroscopy, and particle size distribution measurement, etc., were performed on group (b) aqueous dispersions with darker colors (1′, 4′–8′). The results showed that samples 4′–8′ had similar particle sizes and structures, and also their luminescence behaviors were basically the same, while the FT-IR spectrum, the particle size, and the luminescence behavior of sample 1′ were distinctly different from that of samples 4′–8′. Therefore, we grouped samples 4′–8′ for analysis and compared the results with sample 1′.

Table 2 lists the yield of the water soluble depolymerized coal samples (labeled as sample 4 and 5) obtained by air drying sample 1′ and the collected solution of samples 4′–8′ and their elemental analysis results.

The results in Table 2 showed that 56.1% of the coal sample pretreated with HNO3 and sonicated in mixed acids for 12 h depolymerized when washed for the first time (pH of the washing solution was 0.012). However, after dialysis, the color of the washing solution became significantly lighter, and the yield of the water soluble product obtained by air drying of the washing solution was quite low, only 18.7%. The elemental analysis results indicated that the carbon content of this depolymerized coal sample was relatively low, meaning that 81.3% of the depolymerized product of the coal samples obtained under strong acid condition are low-molecular-weight fluidic substance, or short chain small molecules and carbonaceous gas obtained from disruption of the aliphatic structures by strong acid. With the increase of the washing time, the system pH gradually increased, and the depolymerization degree of the coal sample changed from almost zero at pH = 0.85–1.21 to substantial depolymerization at pH = 1.99–4.09, and the amount of the product to remove by dialysis was not much, the yield of the water soluble product reached 64.6% (the color of the washing solution obtained at this pH turned slightly lighter, but it was caused by the penetration of water into the dialysis bag diluting the solution during the dialysis process). Moreover, the content of carbon in the product increased, indicating the content of aromatic structures in the depolymerized coal samples obtained at pH = 1.99–4.09 is relatively high.

3.3 Structures of depolymerized coal samples obtained under different pH conditions

To identify the structures of the depolymerized coal samples obtained under different pH conditions, we analyzed the two samples in Table 2 by means of FT-IR, XRD, TG-DTG, and TEM, etc., and the results are shown in Figs. 4, 5 and 6.

It can be seen from Fig. 4a that the depolymerized product obtained under the strongest acid condition (curve 4) showed characteristic peaks of several functional groups besides the peaks at 3050, 1587, 824, and 779 cm−1 corresponding to the adsorption band of aromatic structure: the peak at 2921 cm−1 corresponds to the adsorption band of aliphatic structure; the peaks at 1536, 1341, 634, and 607 cm−1 are attributed to the bending vibration bands of C–NO2 and C–N=O groups and cis- and trans- O–N=O group that link the aromatic compounds; the adsorption band of COOH group appeared between 3000 and 2100 cm−1; the two peaks at 1214 and 1073 cm−1 are indicative of the C–O–C unsymmetric and symmetric stretching vibration band; the shoulder at 1720 cm−1 is associated with the adsorption band of C=O group; the peak at 1410 cm−1 corresponds to the adsorption band of the sulfate group R–O–SO2–OR′; the adsorption band of Si–O group showed up as a strong peak at 1073 cm−1; the bands at 1000–900 and 506–424 cm−1 are assigned to the adsorption band of SO4 2−. These results reveal that the depolymerized product obtained under the strongest acid condition contains not only aromatic compounds linked with oxygen-containing groups including carboxyl, nitro, carbonyl, and sulfate groups and aliphatic compounds, but also mineral salts such as sulfate salts and silicon oxides which may be produced by the reaction of the minerals in the coal structure with the mixed acids. Curve 5 is the FT-IR spectrum of the depolymerized product obtained at pH = 1.99–4.09, the characteristic peaks of which are summarized: the peaks at 3076 and 740 cm−1 correspond to the adsorption band of the –CH group in aromatic compounds; the in-plane bending vibration band of the –CH group in aromatic ring appeared at 1223 cm−1; the adsorption band of COOH group showed up between 3000 and 2300 cm−1; the peak at 3371 cm−1 is assigned to the adsorption band of –OH group; the peak at 1725 cm−1 is the characteristic peak of the carbonyl group C=O; the peak at 1612 cm−1 is attributed to the adsorption band of aryl ketone group; the two peaks at 1538 and 1345 cm−1 correspond to the unsymmetric and symmetric stretching vibration band of the nitro group linking the aromatic compounds, respectively; the peaks at 667 and 600 cm−1 are associated with the bending vibration band of the O–N=O group in aromatic compounds; the adsorption band of sulfur containing groups appeared at 909, 536, and 467 cm−1. The results indicate that the depolymerized product obtained at pH = 1.99–4.09 is aromatic compound linked with more oxygen-containing groups including hydroxyl, carboxyl, ester, carbonyl, nitro, and sulfonic groups.

It can be seen from Fig. 4b that both samples exhibited diffraction peaks between 15° and 40° corresponding to the (002) plane of graphite, among which the peak of sample 4 is wider with a lot of unidentified peaks, indicating that the content of aliphatic structure and minerals in the depolymerized product obtained at pH = 0.012 is high (Taylor and Bell 1980; Takagi et al. 2004). However, the (002) plane of sample 5 is higher and narrower than that of sample 4 and most of the unidentified peaks disappeared, indicating that the content of aromatic structure in the depolymerized product obtained at pH = 1.99–4.09 increases, and the molecular orientation between aromatic planes is more ordered, i.e., the coal structure is gradually graphitized (Zou et al. 2008).

The weight losses of the depolymerized coal samples obtained at pH = 0.012 and pH = 1.99–4.09 at 1000 °C are 72.1% and 52.0%, respectively, as shown in Fig. 5, and weight loss of the latter was largely caused by the loss of water at low temperature, indicating that the depolymerized coal samples obtained at pH = 1.99–4.09 are structurally more stable. In addition, the maximum weight loss of sample 4 (Fig. 5a) basically occurred in the temperature range below 290 °C, i.e., when the temperature was above 290 °C, the curve smoothed and the weight loss ratio lowered. According to the statement of the reference mentioned above (Shi et al. 2013), weight loss below 290 °C corresponds to the volatilization of small molecular compounds and the decomposition or dehydration condensation of oxygen-containing groups such as carboxyl and hydroxyl groups, demonstrating that the depolymerized coal samples obtained under the strongest acid condition mainly consist of small molecular substances linked with oxygen-containing groups, and the content of aromatic structure is relatively low. For sample 5 (Fig. 5b) besides the weight loss peak at 291 °C indicative of the decomposition or condensation of the oxygen-containing groups such as carboxyl and hydroxyl groups, the weight loss peak appeared corresponding to the condensation of aromatic structure and the production of semicoke by dehydrogenation between 500 and 600 °C, indicating again that the depolymerized coal samples obtained at pH = 1.99–4.09 are mostly aromatic substance linked with oxygen-containing groups.

Particles of all sizes and shapes were obtained after dialysis of the depolymerized coal samples obtained under strong acid condition (pH = 0.012) to remove acid and low-molecular-weight fluidic substance (Fig. 6a) and the particle size distribution (Fig. 6c) is between 1 and 100 nm. It can be seen from its High Resolution TEM (HRTEM) images that the majority of the depolymerized coal sample particles obtained under strong acid condition possess irregular structures similar to that of amorphous carbon.

Sphere particles with uniform shapes were obtained after dialysis of the depolymerized coal samples obtained at pH = 1.99–4.09 (Fig. 6b) and the percentage of the particles with a size distribution (Fig. 6d) between 2 and 10 nm is as high as 79.15%. HRTEM images further show that these sphere particles are annulations, the annulus walls of which have lattice fringes similar to graphite structure (see inset), and the lattice spacing is 0.32 nm and 0.21 nm, corresponding to the (002) and (100) plane of graphite, respectively (Zhao et al. 2008).

Coal is a natural polymer. The two-phase model proposed by Marzec et al. stated that there are a large number of polycyclic aromatic hydrocarbons in coal molecules which are linked by aliphatic chains or ether bonds, forming the macromolecular phase of the coal molecules; the second phase is composed of smaller aromatic molecules which are distributed between the gaps of the first phase (Marzec 1986). This is extremely similar to the coal structure model raised by Shinn in 1986 through the products from the first and second stage liquefaction of coal (Shinn 1984). This type of structure explains the phenomena of organic solvents extracting small molecules from coal and the phenomena of coal swelling in certain organic solvents, thus it is the most authoritative theory for coal structure. Taking the two-phase model as the initial coal structure studied in this paper and combining the results from FT-IR, XRD, TG-DTG, TEM and particle size distribution analysis, we consider that the process of depolymerization of coal under the action of mixed acid and ultrasound as Fig. 7.

Under the action of mixed acid and ultrasound, the raw coal sample was shattered and the aliphatic structures or ether bonds of coal was disrupted at first. Then, the aliphatic hydrocarbons linked with oxygen-containing groups such as nitro group, mineral salts, and small aromatic molecules distributed between the gaps of the first phase was dissolved in water phase when washing the system to pH = 0.012. As the washing number increase (pH = 1.99–4.09), the rest of the sediment depolymerized, and the depolymerized coal samples are composed of only aromatic compound linked with more oxygen-containing groups including hydroxyl, carboxyl, ester, carbonyl, nitro, and sulfonic groups, possessing the annulus wall of multilayer graphene fragment structures built up by sp2 carbons, as the polycyclic aromatic hydrocarbons lost aliphatic chains or ether bonds is easier to oxidation when the proportion of mixed acid and the water reached to a certain value (Ross et al. 1986). They are typical fluorescent substances of carbon nanoparticle structure (Eda et al. 2010).

3.4 Properties of depolymerized coal samples

Figure 8 shows the absorption and fluorescence emission spectra for sample 1′ (Fig. 8a) and the collected solutions of samples 4′–8′ (Fig. 8b).It can be seen from Fig. 8 that the depolymerized coal samples obtained by mixed acids/ultrasound treatment all exhibited good absorption and emission ability.

The UV–Vis absorbance spectra show that sample 1′ has broad absorption bands in the ultraviolet–visible light region with a shoulder appearing at 340 nm, which may be related to the incorporation of aliphatic structures and small aromatic molecules linked with oxygen-containing groups such as nitro group, and complex compositions including raw coal fragments and minerals in sample 1′, as well as the uneven distributions of particle sizes. When sample 1′ was excited by the light of 340–440 nm wavelength, two maxima showed up in its fluorescence emission spectrum. The first one is between 416 and 506 nm, the peak shifted to longer wavelength and the intensity decreased gradually as the excitation wavelength increased. The second emission peak is located at around 550 nm, and the maximum wavelength did not shift with the change of the excitation wavelength, but the peak intensity first increased then decreased. When the excitation wavelength is longer than 440 nm, the fluorescence emission peak became a single one, red shift occurred with the increase of the excitation wavelength, and the peak intensity first increased then decreased. The optimal excitation wavelength reached at around 500 nm, where the strongest emission peak appeared at around 550 nm.

The collected solution of samples 4′–8′ contains mainly polycyclic aromatic hydrocarbons with large π bonds, and they are linked with more heteroatom chromophores including C=O, C=N, C=S, N=N, N=O, and –NO2, etc., which may result in π → π* and n → π* transitions simultaneously (Shull 1964); therefore, they have broad adsorption bands in the ultraviolet and visible light region. When the collected solution of samples 4′–8′ was excited with the light of 360–540 nm wavelength, there was a single peak in the fluorescence emission spectrum, the intensity of which first increased then decreased, red shift occurred with the increase of the excitation wavelength, and the optimal excitation wavelength reached at around 520 nm, where the strongest emission peak appeared at around 560 nm. The fluorescence property is basically the same as other typical luminescent carbon nanoparticles, depending on excitation wavelengths and having multiple excitation and multiple emission (Hana et al. 2009; Zhu et al. 2012; Liu et al. 2012).

In addition, upon exposure to the light of 365 nm wavelength from portable UV lamp, sample 1′ exhibited blue-green fluorescence and the collected solution of samples 4′–8′ exhibited blue fluorescence (inset in Fig. 8). Meanwhile, we used quinine sulfate as reference and measured the fluorescence quantum yields of sample 1′ and the collected solution of samples 4′–8′ to be 6.79 and 17.32%, respectively, based on the reference method. 17.32% is higher than the quantum yield of any other coal-based carbon dots ever reported (Hu et al. 2014).

The solubility of the depolymerized coal samples obtained at pH = 0.012 (sample 4) and pH = 1.99–4.09 (sample 5) in DMSO, DMF, acetone, and CHCl3 were measured as shown in Table 3.

Coal molecules are composed of large aromatic building blocks linked by aliphatic chains or ether bonds, thus coal is considered cross-linked polymer, which can only swell in organic solvents but cannot dissolve (Bazylyak et al. 2007). From the structural characterization results above, we know that the coal structure has undergone a fundamental change after the mixed acids/ultrasound treatment. First of all, under the action of ultrasound in mixed acids, the ether bonds in the structure of HNO3 pretreated coal sample may be protonated and ruptured by the attack from nucleophiles such as nitro group. Second, strong oxidative mixed acids may directly destroy the aliphatic chains that link the aromatic building blocks with the help of ultrasound, making the aromatic building blocks no longer cross-linked and separate from each other. Third, oxidative groups may be produced on the edge of the aromatic building blocks due to the strong oxidative effect on the aromatic hydrocarbons in the coal structure. The subsequence of the changes above apparently can make the coal sample depolymerize and dissolve in organic solvents. However, in terms of the experimental results, only the depolymerized coal samples obtained at pH = 1.99–4.09 have good solubility in DMSO, DMF and acetone, and the depolymerized coal samples obtained at pH = 0.012 can’t dissolve in those solvent (Table 3). Therefore, taking the characterization results of the depolymerized coal samples above into consideration, it was concluded that only when the pH of the coal-acid system was 1.99–4.09 can the oxygen-containing aromatic building blocks in the treated coal samples be disintegrated into independent aromatic units, while when the pH of the coal-acid system was 0.012, the obtained depolymerized coal samples mainly contain destroyed small molecular aliphatic chains, coal fragments and minerals.

In addition, oxygen-containing groups make the aromatic fragments very polar; therefore, the depolymerized coal samples obtained at pH = 1.99–4.09 can be well dissolved in polar solvents such as DMSO, DMF and acetone, but cannot be dissolved in low polarity solvents such as CHCl3.

4 Conclusions

Under the action of mixed acid and ultrasound, 56.1% of the coal samples pretreated with HNO3 depolymerized (pH of the coal-acid system was 0.012), among which 81.3% of the depolymerized coal samples are low-molecular-weight fluidic substances, or short chain small molecules and carbonaceous gas obtained from disruption of the aliphatic structures by strong acid, and 18.7% are aliphatic compounds linked with oxygen-containing groups including carboxyl, nitro, carbonyl, sulfate groups and small aromatic molecules, and minerals such as sulfate salts and silicon oxides. Continue to wash the sediment haven’t depolymerization to pH = 0.85–1.21, it basically did not depolymerize; when washing to pH = 1.99–4.09, a large number of the coal samples depolymerized, and the yield for the water soluble substances reached 64.6%. it is found by analysis that the depolymerized coal samples obtained at pH = 1.99–4.09 have single component consisting of polycyclic aromatic hydrocarbons linked with oxygen-containing groups such as nitro group, can be well dissolved in polar solvents such as acetone, and its aqueous solution exhibited good absorption and ability of fluorescence emission, they are typical graphitized fluorescent substances of carbon nanoparticle structure.

Through the study of the paper, we not only confirmed the structure model of coal put forward by Marzec, but also believe that it is feasible treating coal with oxidative acids to destroy the macromolecular structures of coal and break down particular chemical bonds and further prepare coal-based high value-added products.

References

Balachandran M (2014) Role of infrared spectroscopy in coal analysis—an investigation. Am J Anal Chem 5:367–372

Bazylyak LI, Bryk DV, Makitra RG, Prystansky RE, Zaikov GE (2007) Generalisation of data concerning coal swelling in organic solvents and their extraction using linear multiparametric equations. J Balk Tribol Assoc 13:182–196

Chen B, Diao ZJ, Zhao YL, Ma XX (2015) A ReaxFF molecular dynamics (MD) simulation for the hydrogenation reaction with coal related model compounds. Fuel 154:114–122

Eda G, Lin Y, Mattevi C, Yamaguchi H, Chen HA, Chen IS, Chen CW, Chhowalla M (2010) Blue photoluminescence from chemically derived graphene oxide. Adv Mater 22:505–509

Fletcher AJ, Uygur Y, Thomas KM (2007) Role of surface functional groups in the adsorption kinetics of water vapor on microporous activated carbons. J Phys Chem C 111:8349–8359

Guo BF, Zhou W, Liu S, Liu Y, Wang J, Yin R (2015) Effect of γ-ray irradiation on the structure and electrochemical liquefaction of Shenhua coal. Fuel 143:236–243

Hana Ž, Církva V, Hájek M (2009) Microwave synthesis of fluorescent carbon nanoparticles with electrochemiluminescence properties. Chem Commun 103:5118–5120

Hu C, Yu C, Li MY, Wang X, Yang J, Zhao Z, Eychmüller A, Sun YP, Qiu J (2014) Chemically tailoring coal to fluorescent carbon dots with tuned size and their capacity for Cu(II) detection. Small 10:4926–4933

Hu SL, Wei ZJ, Chang Q, Trinchi A, Yang J (2016) A facile and green method towards coal-based fluorescent carbon dots with photocatalytic activity. Appl Surf Sci 378:402–407

Izquierdo MT, Rubio B, Yuso AMD, Ballestero D (2011) Enhancement of nitric oxide removal by ammonia on a low-rank coal based carbon by sulphuric acid treatment. Fuel Process Technol 92:1362–1367

Li C, Takanohashi AT, Saito I, Aoki H, Mashimo K (2004a) Elucidation of mechanisms involved in acid pretreatment and thermal extraction during ashless coal production. Energy Fuels 18:97–101

Li C, Takanohashi T, Yoshida T, Ikuo S, Aoki H, Mashimo K (2004b) Effect of acid treatment on thermal extraction yield in ashless coal production. Fuel 83:727–732

Li XH, Xue YL, Feng J, Yi Q, Li W, Guo X, Liu K (2015) Co-pyrolysis of lignite and Shendong coal direct liquefaction residue. Fuel 144:342–348

Liu S, Tian J, Wang L, Zhang Y, Qin X, Luo Y, Asiri AM, Al-Youbi AO, Sun X (2012) Hydrothermal treatment of grass: a low-cost green route to nitrogen-doped carbon-rich photoluminescent polymer nanodots as an effective fluorescent sensing platform for label-free detection of Cu(II) ions. Adv Mater 24:2037–2041

Manoj B, Elcey CD (2010) Demineralization of coal by stepwise bioleaching: a study of sub-bituminous Indian coal by FTIR and SEM. J Univ Chem Technol Metall 45:385–390

Manoj B, Narayanan P (2013) Study of changes to the organic functional groups of a high volatile bituminous coal during organic acid treatment process by FTIR spectroscopy. J Miner Mater Charact Eng 01:39–43

Marzec A (1986) Macromolecular and molecular model of coal structure. Fuel Process Technol 14:39–46

Ross DS, Gu CL, Hum GP, Malhotra R (1986) Oxidation of benzyl alcohols by nitrous and nitric acids in strong sulfuric acid media. Int J Chem Kinet 18:1277–1288

Ruiz B, Parra JB, Pajares JA, Pis JJ (2006) Effect of coal pre-oxidation on the optical texture and porosity of pyrolysis chars. J Anal Appl Pyrol 75:27–32

Saikia BK, Boruah RK, Gogoi PK (2008) FT-IR and XRD analysis of coal from Makum coalfield of Assam. J Earth Syst Sci 116:575–579

Shi L, Liu QY, Guo XJ, Wu W, Liu Z (2013) Pyrolysis behavior and bonding information of coal—a TGA study. Fuel Process Technol 108:125–132

Shinn JH (1984) From coal to single-stage and two-stage products: a reactive model of coal structure. Fuel 63:1187–1196

Shull H (1964) Electronic Spectra and quantum chemistry. J Am chem Soc 26:5371–5372

Soneda Y, Makino M, Yasuda H, Yamada O, Kobayashi M, Kaiho M (1998) The effect of acid treatment of coal on H2S evolution during pyrolysis in hydrogen. Fuel 77:907–911

Takagi H, Maruyama K, Yoshizawa N, Yamada Y, Sato Y (2004) XRD analysis of carbon stacking structure in coal during heat treatment. Fuel 83:2427–2433

Taylor ND, Bell AT (1980) Effects of Lewis acid catalysts on the cleavage of aliphatic and aryl-aryl linkages in coal-related structures. Fuel 59:499–506

Zhang B, Wu D, Wang C, He S, Zhang Z, Kong H (2007) Simultaneous removal of ammonium and phosphate by zeolite synthesized from coal fly ash as influenced by acid treatment. J Environ Sci 19:540–545

Zhao QL, Zhang ZL, Huang BH, Peng J, Zhang M, Pang DW (2008) Facile preparation of low cytotoxicity fluorescent carbon nanocrystals by electrooxidation of graphite. Chem Commun 41:5116–5118

Zhao HY, Wang LX, Jia DZ, Xia W, Li J, Guo ZP (2014) Coal based activated carbon nanofibers prepared by electrospinning. J Mater Chem 2:9338–9344

Zhu CZ, Zhai JF, Dong SJ (2012) Bifunctional fluorescent carbon nanodots: green synthesis via soy milk and application as metal-free electrocatalysts for oxygen reduction. Chem Commun 48:9367–9369

Zou L, Kang FY, Li XL, Zheng YP, Shen W, Zhang J (2008) Investigations on the modified natural graphite as anode materials in lithium ion battery. J Phys Chem Solids 69:1265–1271

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Zhang, B., Maimaiti, H., Zhang, Y. et al. Effect of pH conditions on the depolymerization of Wucaiwan coal by mixed acids/ultrasound method and the product structures and performance. Int J Coal Sci Technol 4, 342–353 (2017). https://doi.org/10.1007/s40789-017-0183-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40789-017-0183-0