Abstract

Benzene carboxylic acid (BCAs) are common and useful chemical blocks, which can be derived from the abundant low rank coals (LRCs) via oxidative degradation. In this work, we proposed a novel strategy to utilize BCAs as raw materials to prepare catalysts with transition metal zirconium, and the prepared catalysts were applied into the conversion of the renewable biomass resources. Typical model BCAs in the oxidative products of LRCs, including pyromellitic acid, trimesic acid (TMSA), trimellitic acid, and benzoic acid, were used as the block to construct the Zr-BCAs catalysts. The chemoselective conversion of furfural into furfuryl alcohol (FAL), an important reaction in the biomass conversion chain, is chosen to evaluate the activity of the catalysts. The preparation conditions of the catalysts and experiment factors during the reaction were systematically investigated. The prepared catalysts were characterized by SEM, TEM, XRD and TG-DTG. The results showed that the prepared catalysts were efficient for the conversion of furfural into FAL, among which Zr-TMSA gave the highest activity. Zr-TMSA could be recycled for ten times without obvious deactivation, indicating an excellent stability. The strategy proposed in this work may be beneficial for the value-added utilization of both LRCs and biomass resources.

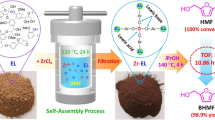

Graphical Abstract

Zr-BCAs catalysts prepared using benzene carboxylic acids and Zr are very efficient and stable for hydrogenation of biomass-derived furfural to furfuryl alcohol at mild conditions.

Similar content being viewed by others

Explore related subjects

Find the latest articles, discoveries, and news in related topics.Avoid common mistakes on your manuscript.

1 Introduction

Low rank coals (LRCs), with large abundance on earth, become important carbon resources especially with the fast depletion of high quality fossil resources. However, the LRCs have several disadvantages such as low calorific value, high oxygen and water content, and poor stability to air, which make LRCs not suitable for direct use as energy sources due to the low efficiency and serious pollution (Schobert and Song 2002; Gunka and Pyshyev 2014; Li et al. 2015). Therefore, exploring the clean and efficient utilization approach of LRCs is a critical issue for human beings (Li et al. 2015; Mi et al. 2015; Saikia et al. 2015; Liu et al. 2016). Although the low degree of coalification and the high content of oxygen result in the low calorific value of LRCs, on the other hand, these unique properties also lead to the higher reactivity of LRCs compared with the high rank coals, making it possible and facile to prepare value-added chemicals from LRCs (Shui et al. 2006, 2008; Wang et al. 2012; Li et al. 2015; Pan et al. 2017). Among the chemicals derived from LRCs, the organic acids, including the small-molecule fatty acids (SMFAs) and benzene carboxylic acids (BCAs), are important industrial blocks with wide applications (Wang et al. 2013a, b; Hu et al. 2016; Lv et al. 2016). Various oxidation approaches, including ruthenium ion-catalyzed oxidation (RICO),(Huang et al. 2008; Liu et al. 2016) oxidation with different oxidizing agents such as H2O2, ozone, oxygen (Mae et al. 2001; Yu et al. 2014), and alkali-oxygen oxidation (Wang et al. 2012, 2013a, b; Yang et al. 2015), were developed to produce organic acids from LRCs. High yields of the organic acids, including 18.4%–21.5% of BCAs and 39.8%–23.2% of SMFAs, have been achieved via alkali-oxygen oxidation (Wang et al. 2013a, b). After obtaining organic acids from LRCs, the next problem needing to be considered is that how to fulfill their efficient, facile, and value-added utilization. Therefore, exploring efficient utilizing approaches of organic acids, especially the BCAs, is of great importance to promote the clean and efficient utilization of LRCs.

In parallel with improving the utilization efficiency of fossil resources, it is essential to search sustainable and renewable resources for human beings in the long run (Beach et al. 2009; Shui et al. 2011; He et al. 2013). Biomass is believed to be green and renewable carbon resources with the advantages of large reserves, broad distribution, and abundance in varieties (Ruppert et al. 2012; Tuck et al. 2012). Catalytic conversion is an important way for the transformation and utilization of biomass resources (Zakzeski et al. 2010; Tao et al. 2011). Furfural, a typical representative of carbonyl compounds derived from biomass, could be converted into furfuryl alcohol (FAL) via chemoselective hydrogenation of carbonyl groups, and both furfural and FAL could be further converted into various useful chemicals (Bhogeswararao and Srinivas 2015; Chen et al. 2016). Zirconium (Zr) based catalysts are commonly used for the chemoselective conversion of carbonyl groups in the biomass conversion chain, such as ZrO2 (Miñambres et al. 2011), zirconium alkoxides (Zhu et al. 2003), Zr-containing zeolites (Wang et al. 2015), and Zr(OH)4 (Tang et al. 2014), etc. Recently, researchers pay more attention to explore new materials to construct Zr catalysts with novel structures and properties. For example, a natural source chemical, phytic acid, was used in our previous work to prepare Zr catalysts, and it was found that the prepared catalysts were highly efficient for the conversion of carbonyl compounds (Song et al. 2015a, b). Xue et al. applied cyanuric acid (CA), a nitrogen-containing functional chemical, to construct Zr catalysts, which were proved to be efficient for the conversion of biomass-derived esters levulinate (Xue et al. 2016). Very recently, we reported a novel Zr catalyst using the LRCs derived humic acids (HAs) as the building block, and the Zr-HAs catalysts were highly efficient for the production of gamma-valerolactone (GVL) from ethyl levulinate (EL) (Xiao et al. 2017). Although these reported catalysts are efficient for the hydrogenation of carbonyl groups, they also suffer some drawbacks, such as severe reaction conditions and limited sources of the skeleton materials used in the preparation. Therefore, it is still desirable to explore efficient, more common, and low-cost raw materials to construct Zr catalysts for the conversion of biomass-derived carbonyl compounds.

Carboxylic acids, especially the polycarboxylic acids, with high contents of acidic groups, are potential materials to synthesis functional materials and catalysts (Peng et al. 2012; Song et al. 2015a, b; Valekar et al. 2016). Using organic acids derived from the degradation of LRCs to construct catalysts and applying them into biomass conversion are a potential strategy for the utilization of both LRCs and the biomass resources. However, up to now, very few reports involved the use of polycarboxylic acids in constructing Zr catalysts, and only limited polycarboxylic acids were studied, such as 4-hydroxybenzoic acid, 1,4-benzenedicarboxylic acid, 1,2,4-benzenetricarboxylic acid, benzoic acid, etc (Song et al. 2015a, b; Valekar et al. 2016). Due to the fact that various polycarboxylic acids could be derived from LRCs, it is essential to conduct extensive work to construct catalysts using more polycarboxylic acids and studying their performances in biomass conversion reaction.

In this work, we constructed a novel Zr-based catalyst using different BCAs as the skeleton materials. The designed catalysts are intended to have the advantages of high efficiency under milder conditions with promising cost advantages because the raw materials (BCAs) can be derived from the abundant and low-cost LRCs. Several BCA model chemicals, which are common in the oxidative degradation derivatives from LRCs, were attempted to synthesize Zr-BCAs catalysts, including pyromellitic acid (PMA), trimesic acid (TMSA), trimellitic acid (TMLA), and benzoic acid (BA) (Scheme 1). The conversion of furfural into furfuryl alcohol (FAL) was applied to evaluate the performance of the prepared catalysts due to its importance in the reaction chain of biomass conversion. Furthermore, furfural is a typical representative with both C=C and C=O double bonds, which is often used to study the selective hydrogenation of the two different chemical bonds (Bhogeswararao and Srinivas 2015). The preparing conditions of the catalysts and the influences of the experimental factors on the reaction were systematically investigated. The obtained catalysts were characterized by SEM, TEM, XRD, and TG-DTG. A high FAL yield of 97% was achieved for Zr-TMSA catalyst under mild conditions. The catalyst could be recycled for ten times without obvious deactivation, showing an excellent stability. The proposed strategy is beneficial for both the efficient and clean utilization of LRCs and promoting the conversion of biomass-derived furfural.

2 Experimental

2.1 Materials

Pyromellitic acid (PMA, 96%), trimesic acid (TMSA, 99%),trimellitic acid (TMLA, 98%), benzoic acid (BA, 99%), furfural, furfuryl alcohol, and ZrOCl2·8H2O (AR) were provided by J&K Scientific Ltd. Isopropanol (AR), ethanol (AR), KOH (AR), decane (AR) and other chemicals were obtained from Beijing Institute of Chemical Reagent.

2.2 Preparation of catalysts

The catalysts constructed in this work were prepared as follows. In a typical procedure, 5 mmol (1.27 g) of PMA was dissolved in 50 mL alkali solution containing 20 mmol (1.12 g) of KOH under 80 °C for 5 h, forming Solution A. 5 mmol (1.61 g) of ZrOCl2·8H2O were dissolved in 50 mL distilled water, forming Solution B. Then Solution A was dropwise added into Solution B slowly under stirring. The mixture was maintained stirring under room temperature for 10 h to form the white gel. After this, the suspended slurry was separated by centrifugation or filtration to give white precipitate. Finally, the catalysts were obtained after the precipitate was thoroughly washed for five times with distilled water and two times with ethanol, dried in vacuum at 80 °C for 12 h, and then crowded into powders for use. The catalyst was denoted as Zr-PMA 1:4:1, the ratio representing the mole ratio of PMA:KOH:Zr. The ratios of KOH to BCAs linkers were varied to optimize the preparing conditions of the catalysts. Similarly, various catalysts were synthesized, denoted as Zr-PMA (1:4:1, 1:3:1, 1:2:1, 1:1:1), Zr-TMSA (1:3:0.75, 1:2:0.75), Zr-TMLA (1:3:0.75, 1:2:0.75), and Zr-BA (1:1:0.25), respectively.

2.3 Characterization of the catalyst

Scanning electron microscopy (SEM) measurements were performed on a Hitachi S-3400 N scanning electron microscope operated at 20 kV. Transmission electron microscopy (TEM) images were obtained using a TEM JEOL-1011 with an accelerating voltage of 120 kV. X-ray diffraction (XRD) were carried out on a XD8 Advance-Bruker AXS X-ray diffractometer using Cu-Kα radiation (λ = 532 nm) and Ni filter scanning at 2° per minute ranging 3°–80°. The tube voltage was 40 kV and the current was 40 mA. The thermogravimetric (TG) analysis of Zr-FA was performed on a thermogravimetric analysis system (Diamond TG/DTA6300, Perkin Elmer Instruments) under Ar atmosphere at a heating rate of 10 °C/min.

2.4 Reaction

The conversion of furfural into FAL was performed in a 10 mL Teflonlined stainless steel autoclave equipped with a magnetic stirrer. In a typical experiment, furfural (1 mmol), isopropanol (5 mL), and a certain amount of catalysts were introduced into the reactor. After sealing, the reaction mixture was stirred and allowed to react at suitable temperatures in oil bath for a desired time. After reaction, the reactor was cooled down in cold water to quench the reaction and the reaction solution was transferred and diluted by isopropanol. The samples were analyzed quantitatively by gas chromatography (GC, Shimadzu 2014) with a flame ionization detector using decane as the internal standard. Identification of the products and the reactant was fulfilled using a GC–MS (SHIMADZU-QP 2010) as well as by comparing the retention times with respective standards in GC traces.

Heterogeneity of Zr-BCAs catalysts were detected by removing the solid catalysts from the reaction mixture and the supernatant was allowed to react to check if the product could further increase without the presence of the solid catalysts. In the reusability experiments, the catalyst was separated by centrifugation, washed with fresh isopropanol for three times, and then reused for the next run without further treatments.

3 Results and discussion

3.1 Screening and characterization of the catalysts

The activities of the prepared catalysts for the conversion of furfural into FAL were shown in Table 1. For the conditions that all the carboxylic groups in BCA molecules were totally neutralized for the four kinds of BCAs, Zr-TMSA possessed the highest activity (Entries 1, 5, 7, 9). As regards each kind of BCAs, the activity of the catalysts varied with the usage of alkali. For PMA (Entries 1–4), TMSA (Entries 5–6), and TMLA (Entries 7–8), similar potentials could be found that the activity generally increased with the increasing of the usage of alkali, coming to the highest value when all the carboxylic groups in BCAs were totally neutralized. It could be speculated that the extent of neutralization of the carboxylic groups in BCAs molecules may have influences on the microstructures and spatial network between BCA skeleton and Zr4+ in the catalysts, resulting in different chemophysical properties and variation in activity. Among all the catalysts studied, Zr-TMSA (1:3:0.75) gave the highest conversion and yield, and thus it was chosen as a representative for further studies.

The performance of Zr-TMSA (1:3:0.75) catalyst was compared with other commonly reported Zr-based catalysts as well as some transition metal catalysts, including Fe, Ni, and Mg (Table 2). Among the studied catalysts in Table 2, Zr-based catalysts generally worked at the lower temperatures compared with Fe, Ni and Mg-based catalysts. Ni–Cu/Al2O3 gave the highest TOF value, which may be attributed to the higher reaction temperature and the co-catalytic effect of Cu (Kannapu et al. 2015). Compared with other catalysts, Zr-TMSA (1:3:0.75) prepared in this work exhibited high efficiency with almost similar level of TOF values, but the reaction temperature was lower and the required time was shorter at similar product yields. These results indicated that the prepared catalysts were highly efficient under mild conditions.

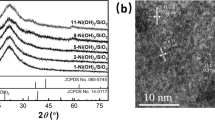

In order to understand well the structure of the catalyst, some characterizations were conducted. The morphology of Zr-TMSA (1:3:0.75) was characterized by SEM and TEM, showing that the catalyst was composed of particles with no uniform shapes (Fig. 1a, b). From Fig. 1c, one broad diffraction peak around 27° could be seen in XRD pattern, indicating that the as-prepared catalyst was amorphous (Song et al. 2015a, b). From TG-DTG results (Fig. 1d), there were two obvious DTG peaks around 110 and 590 °C, corresponding to two weight loss processes, respectively. The first weight loss (about 14%) could be assigned to the desorption of water and ethanol adsorbed on the catalyst during the preparation processes (Peng et al. 2012). The second weight loss from 500 to 650 °C could be attributed to the decomposition of the catalyst. TG results indicated that the catalyst had a good stability under reaction temperatures (below 100 °C).

3.2 Effects of the catalyst dosage

The effect of catalyst dosage on the conversion of furfural to FAL was studied with isopropanol as the hydrogen source (Fig. 2). It can be seen from the results that both the conversion and the yield increased significantly with the increasing of the dosage of the catalyst. The highest conversion of 78.5% and FAL yield of 74.6% with high selectivity of 95.0% were obtained when the catalyst dosage was 200 mg. Further increasing the catalyst dosage had a negative effect on the performance, which could be due to the fact that the large amount of the catalyst made the reaction slurry much thicker and the dispersion of the catalyst became poor, limiting the mass transfer during reaction. A catalyst dosage of 200 mg and furfural concentration of 0.2 mmol/mL were used in the following studies.

3.3 Influence of the reaction temperature

The effect of reaction temperature on the performance of the catalyst was studied and the results were shown in Fig. 3. It can be seen that reaction temperature had a dramatic influence on the performance of the catalyst. Within the whole temperature range studied from ambient temperature (25 °C) to 100 °C, both the conversion and the yield increased with the increasing of the temperatures, while the selectivity had a slight decrease in high temperature region (after 70 °C). Considering the reaction rate, product selectivity, and the energy consumption, we chose the moderate temperature 70 °C as a suitable temperature for the production of FAL from furfural under the present reaction condition.

3.4 Influence of the reaction time

On the basis of the above studies, the influence of reaction time was investigated (Fig. 4). The results showed that the reaction proceeded fast within the first 3 h and the FAL yield increased fast to 74.6%. The yield increased at a slower rate with prolonging the reaction time, and the final yield came to 97.0% with substrate conversion of 98.0% with high selectivity of 99.0% when the reaction time was 9 h. These results indicated that the prepared catalyst was highly efficient for the conversion of furfural to FAL under mild conditions.

3.5 The heterogeneity and reusability of the catalyst

To identify the heterogeneity of the catalyst, the reaction was stopped via removing the catalyst from the reaction slurry after the reaction was proceeded for 2 h, and the left solution was allowed to react under the same conditions to check if the FAL yield further increased without the solid catalyst (Song et al. 2015a, b). The results were given in Fig. 5a. It can be seen that there was no further increase in the FAL yield after the solid catalyst was removed, confirming that the active sites in the catalyst was not soluble in the reaction mixture and it was the solid catalyst to catalyze heterogeneously the reaction. The reusability of the catalyst was investigated under the experimental conditions that the conversion was controlled around 40%. The performances of the catalyst during ten repeated runs were shown in Fig. 5b. The results showed that there was no considerable decrease in the conversion, yield, and selectivity after ten cycles compared with the first use, indicating that the catalyst was very stable. The heterogeneity study together with the above TG-DTG analysis (Sect. 3.1, Fig. 1d) identified that the catalyst had good solvent and thermal stability, resulting in the excellent recycling performance under the studied reaction conditions.

3.6 Mechanism analysis

Based on the previous reports (Song et al. 2015a, b), the possible mechanism of Zr-BCAs catalyzed conversion of furfural into FAL was proposed (Scheme 2). For the transfer hydrogenation, both the acidic and basic sites in the catalyst were reported to be essential (Song et al. 2015a, b; Ikariya and Blacker 2007). In Zr-based catalysts, Zr4+ and O2− (carboxylate groups in BCAs) formed the acid and basic sites, respectively (Tang et al. 2013; Valvekens et al. 2014). Firstly, isopropanol was adsorbed onto the catalyst and interacted with the acid–base sites (Zr4+–O2−) on Zr-BCAs, resulting in its dissociation to the corresponding alkoxide. Meanwhile, the carbonyl groups in furfural molecules were adsorbed onto the adjacent sites on the catalyst. Then, hydrogen transfer took place between the dissociated alcohol and the activated furfural molecules via a concerted process involving a six-link intermediate to form the corresponding products. Furfural was converted into FAL while isopropanol converted into acetone.

4 Conclusions

A novel strategy to construct Zr-based catalyst for biomass conversion using BCAs was proposed in this work. Various Zr-BCAs catalysts were successfully prepared using BCAs with different structures, and the preparation conditions and experiment factors during the reaction were systematically studied. The catalyst was proved to be highly efficient for the conversion of biomass-derived furfural to FAL with high yield of 97% under mild temperature. The catalyst can be used at least ten times without obvious changes in performance, proving the excellent stability. Using BCAs potentially obtained from LRCs to construct catalysts and applying them in the biomass conversion is believed to be an efficient approach for the utilization of both LRCs and biomass resources.

References

Beach ES, Cui Z, Anastas PT (2009) Green chemistry: a design framework for sustainability. Energy Environ Sci 2:1038–1049

Bhogeswararao S, Srinivas D (2015) Catalytic conversion of furfural to industrial chemicals over supported Pt and Pd catalysts. J Catal 327:65–77

Biradar NS, Hengne AM, Sakate SS, Swami RK, Rode CV (2016) Single pot transfer hydrogenation and aldolization of furfural over metal oxide catalysts. Catal Lett 146:1611–1619

Chen XF, Zhang LG, Zhang B, Guo XC, Mu XD (2016) Highly selective hydrogenation of furfural to furfuryl alcohol over Pt nanoparticles supported on g-C3N4 nanosheets catalysts in water. Sci Rep 6:1–13

Gunka V, Pyshyev S (2014) Lignite oxidative desulphurization. Notice 1. Process condition selection. Int J Coal Sci Technol 1:62–69

He MY, Sun YH, Han BX (2013) Green carbon science: scientific basis for integrating carbon resource processing, utilization, and recycling. Angew Chem Int Ed 52:9620–9633

Hu JM, Guo R, Liu YG, Cui GH (2016) Four Co(II) coordination polymers based on 4,4′-bis(benzimidazol-1-ylmethyl)biphenyl and aromatic carboxylic acids co-ligands: synthesis, structures, and photocatalytic properties. Inorg Chim Acta 450:418–425

Huang YG, Zong ZM, Yao ZS, Zheng YX, Mou J, Liu GF, Cao JP, Ding MJ, Cai KY, Wang F, Zhao W, Xia ZL, Wu L, Wei XY (2008) Ruthenium ion-catalyzed oxidation of Shenfu coal and its residues. Energ Fuel 22:1799–1806

Iglesias J, Melero J, Morales G, Moreno J, Segura Y, Paniagua M, Cambra A, Hernández B (2015) Zr-SBA-15 Lewis acid catalyst: activity in Meerwein Ponndorf Verley reduction. Catalysts 5:1911–1927

Ikariya T, Blacker AJ (2007) Asymmetric transfer hydrogenation of ketones with bifunctional transition metal-based molecular catalysts. Acc Chem Res 40:1300–1308

Kannapu HPR, Mullen CA, Elkasabi Y, Boateng AA (2015) Catalytic transfer hydrogenation for stabilization of bio-oil oxygenates: reduction of p-cresol and furfural over bimetallic Ni–Cu catalysts using isopropanol. Fuel Process Technol 137:220–228

Li ZK, Wei XY, Yan HL, Wang YG, Kong J, Zong ZM (2015) Advances in lignite extraction and conversion under mild conditions. Energ Fuel 29:6869–6886

Li H, He J, Riisager A, Saravanamurugan S, Song BA, Yang S (2016a) Acid–base bifunctional zirconium N-alkyltriphosphate nanohybrid for hydrogen transfer of biomass-derived carboxides. ACS Catal 6:7722–7727

Li J, Liu JL, Zhou HJ, Fu Y (2016b) Catalytic transfer hydrogenation of furfural to furfuryl alcohol over nitrogen-doped carbon-supported iron catalysts. Chemsuschem 9:1339–1347

Liu FJ, Wei XY, Fan MH, Zong ZM (2016) Separation and structural characterization of the value-added chemicals from mild degradation of lignites: a review. Appl Energ 170:415–436

Lv LL, Zhang LJ, Zhao H, Wu BL (2016) Syntheses, structures and properties of nickel(II) and manganese(II) coordination polymers based on V-shaped bis-imidazole and aromatic carboxylate ligands. Polyhedron 115:204–211

Mae K, Shindo H, Miura K (2001) A new two-step oxidative degradation method for producing valuable chemicals from low rank coals under mild conditions. Energ Fuel 15:611–617

Mi JX, Wang NB, Wang MF, Huo PJ, Liu D (2015) Investigation on the catalytic effects of AAEM during steam gasification and the resultant char reactivity in oxygen using Shengli lignite at different forms. Int J Coal Sci Technol 2:223–231

Miñambres JF, Aramendía MA, Marinas A, Marinas JM, Urbano FJ (2011) Liquid and gas-phase Meerwein–Ponndorf–Verley reduction of crotonaldehyde on ZrO2 catalysts modified with Al2O3, Ga2O3 and In2O3. J Mol Catal A: Chem 338:121–129

Pan CX, Liu HL, Liu Q, Shui HF, Wang ZC, Lei ZP, Kang SG, Wei XY (2017) Oxidative depolymerization of Shenfu subbituminous coal and its thermal dissolution insoluble fraction. Fuel Process Technol 155:168–173

Peng L, Zhang JL, Li JS, Han BX, Xue ZM, Yang GY (2012) Surfactant-directed assembly of mesoporous metal-organic framework nanoplates in ionic liquids. Chem Commun (Camb) 48:8688–8690

Ruppert AM, Weinberg K, Palkovits R (2012) Hydrogenolysis goes bio: from carbohydrates and sugar alcohols to platform chemicals. Angew Chem Int Ed 51:2564–2601

Saikia BK, Khound K, Sahu OP, Baruah BP (2015) Feasibility studies on cleaning of high sulfur coals by using ionic liquids. Int J Coal Sci Technol 2:202–210

Schobert HH, Song C (2002) Chemicals and materials from coal in the 21st century. Fuel 81:15–32

Shui HF, Wang ZC, Wang GQ (2006) Effect of hydrothermal treatment on the extraction of coal in the CS2/NMP mixed solvent. Fuel 85:1798–1802

Shui H, Wang Z, Cao M (2008) Effect of pre-swelling of coal on its solvent extraction and liquefaction properties. Fuel 87:2908–2913

Shui HF, Shan CJ, Cai ZY, Wang ZC, Lei ZP, Ren SB, Pan CX, Li HP (2011) Co-liquefaction behavior of a sub-bituminous coal and sawdust. Energy 36:6645–6650

Song JL, Wu LQ, Zhou BW, Zhou HC, Fan HL, Yang YY, Meng QL, Han BX (2015a) A new porous Zr-containing catalyst with a phenate group: an efficient catalyst for the catalytic transfer hydrogenation of ethyl levulinate to γ-valerolactone. Green Chem 17:1626–1632

Song JL, Zhou BW, Zhou HC, Wu LQ, Meng QL, Liu ZM, Han B (2015b) Porous zirconium-phytic acid hybrid: a highly efficient catalyst for Meerwein–Ponndorf–Verley reductions. Angew Chem Int Ed 54:9399–9403

Tang X, Hu L, Sun Y, Zhao G, Hao WW, Lin L (2013) Conversion of biomass-derived ethyl levulinate into γ-valerolactone via hydrogen transfer from supercritical ethanol over a ZrO2 catalyst. RSC Adv 3:10277–10284

Tang X, Chen HW, Hu L, Hao WW, Sun Y, Zeng XH, Lin L, Liu SJ (2014) Conversion of biomass to γ-valerolactone by catalytic transfer hydrogenation of ethyl levulinate over metal hydroxides. Appl Catal B Environ 147:827–834

Tao F, Song H, Chou L (2011) Catalytic conversion of cellulose to chemicals in ionic liquid. Carbohydr Res 346:58–63

Tuck CO, Perez E, Horvath IT, Sheldon RA, Poliakoff M (2012) Valorization of biomass: deriving more value from waste. Science 337:695–699

Valekar AH, Cho K-H, Chitale SK, Hong D-Y, Cha G-Y, Lee UH, Hwang DW, Serre C, Chang J-S, Hwang YK (2016) Catalytic transfer hydrogenation of ethyl levulinate to γ-valerolactone over zirconium-based metal–organic frameworks. Green Chem 18:4542–4552

Valvekens P, Vandichel M, Waroquier M, Van Speybroeck V, De Vos D (2014) Metal-dioxidoterephthalate MOFs of the MOF-74 type: microporous basic catalysts with well-defined active sites. J Catal 317:1–10

Wang F, Zhang ZH (2017) Catalytic transfer hydrogenation of furfural into furfuryl alcohol over magnetic γ-Fe2O3@HAP catalyst. ACS Sustain Chem Eng 5:942–947

Wang WH, Hou YC, Wu WZ, Niu MG, Liu WN (2012) Production of benzene polycarboxylic acids from lignite by alkali-oxygen oxidation. Ind Eng Chem Res 51:14994–15003

Wang WH, Hou YC, Wu WZ, Niu MG (2013a) Simultaneous production of small-molecule fatty acids and benzene polycarboxylic acids from lignite by alkali-oxygen oxidation. Fuel Process Technol 112:7–11

Wang WH, Hou YC, Wu WZ, Niu MG, Wu T (2013b) High-temperature alkali-oxygen oxidation of lignite to produce benzene polycarboxylic acids. Ind Eng Chem Res 52:680–685

Wang J, Okumura K, Jaenicke S, Chuah G-K (2015) Post-synthesized zirconium-containing beta zeolite in Meerwein–Ponndorf–Verley reduction: pros and cons. Appl Catal A Gen 493:112–120

Xiao ZH, Zhou HC, Hao JM, Hong HL, Song YM, He RX, Zhi KD, Liu QS (2017) A novel and highly efficient Zr-containing catalyst based on humic acids for the conversion of biomass-derived ethyl levulinate into gamma-valerolactone. Fuel 193:322–330

Xue ZM, Jiang JY, Li GF, Zhao WC, Wang JF, Mu TC (2016) Zirconium–cyanuric acid coordination polymer: highly efficient catalyst for conversion of levulinic acid to γ-valerolactone. Catal Sci Technol 6:5374–5379

Yang F, Hou YC, Niu MG, Wu WZ, Sun DY, Wang Q, Liu ZY (2015) Production of benzene poly(carboxylic acid)s and small-molecule fatty acids from lignite by catalytic oxidation in NaVO3/H2SO4 aqueous solution with molecular oxygen. Ind Eng Chem Res 54:12254–12262

Yu JL, Jiang Y, Tahmasebi A, Han YN, Li XC, Lucas J, Wall T (2014) Coal oxidation under mild conditions: current status and applications. Chem Eng Technol 37:1635–1644

Zakzeski J, Bruijnincx PCA, Jongerius AL, Weckhuysen BM (2010) The catalytic valorization of ligin for the production of renewable chemicals. Chem Rev 110:3552–3599

Zhu YZ, Jaenicke S, Chuah GK (2003) Supported zirconium propoxide—a versatile heterogeneous catalyst for the Meerwein–Ponndorf–Verley reduction. J Catal 218:396–404

Acknowledgements

This work was supported by the National Natural Science Foundation of China (21606134, 21676149, 21566029, 21566028, and 21563022), the Natural Science Foundation of Inner Mongolia (2016BS0204, 2014MS0220), the Incentive Fund for the Scientific and Technology Innovation Program of Inner Mongolia, the Major Basic Research Open Programs of Inner Mongolia, the Startup Fund for New Teachers of Inner Mongolia University of Technology (IMUT), and the Science and Research Projects of IMUT (ZD201603).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Zhou, H., Sha, Y., Xiao, Z. et al. Using benzene carboxylic acids to prepare zirconium-based catalysts for the conversion of biomass-derived furfural. Int J Coal Sci Technol 5, 464–472 (2018). https://doi.org/10.1007/s40789-017-0181-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40789-017-0181-2