Abstract

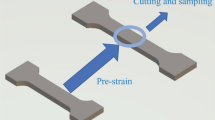

The microstructure and the mechanical properties of a super martensitic stainless steel (SMSS) were investigated in this study. Test specimens were taken from seamless tube generally used in oil and gas industries. The specimens were plastically deformed by tension from its as-received state to different levels of elongation at 2%, 10%, and 15%, respectively. The focus was to study the influence of plastic deformation on the tribological behavior against alumina balls in dry conditions and the corrosion resistance in 3.5% NaCl solution. Analysis results showed an abrasive wear as the main wear mechanism. Plastic deformation prior to sliding wear test increases wear resistance as the deformation rate increases. Based on the electrochemical experiments, all of the specimens showed an increase in their corrosion resistance i.e., the corrosion potential Ecorr (vs. Ag/AgCl) tends to move toward more noble values with respect to the initial potential. The greatest polarization resistance was displayed by the specimen with 10% of deformation rate.

Similar content being viewed by others

References

Ceschini L, Chiavari C, Lanzoni E, Martini C (2012) Low-temperature carburised AISI 316L austenitic stainless steel: wear and corrosion behaviour. Mater Des 38:154–160. https://doi.org/10.1016/j.matdes.2012.02.019

Liu Y, Zhu D, Pierre D, Gilbert JL (2019) Fretting initiated crevice corrosion of 316LVM stainless steel in physiological phosphate buffered saline: potential and cycles to initiation. Acta Biomater 97:565–577. https://doi.org/10.1016/j.actbio.2019.07.051

Turnbull A, Griffiths A (2003) Corrosion and cracking of weldable 13 wt-%Cr martensitic stainless steels for application in the oil and gas industry. Corros Eng Sci Technol 38(1):21–50. https://doi.org/10.1179/147842203225001432

Ye D, Li J, Jiang W, Su J, Zhao K (2012) Effect of Cu addition on microstructure and mechanical properties of 15%Cr super martensitic stainless steel. Mater Des 41:16–22. https://doi.org/10.1016/j.matdes.2012.04.036

Hill R, Perez AL (2017) New steels and corrosion-resistant alloys. In: El-Sherik AM (ed) Trends in oil and gas corrosion research and technologies: production and transmission, 1st edn. Woodhead Publishing, pp 613–626

Mabruri E, Anwar MS, Prifiharni S, Romijarso TB, Adjiantoro B (2016) Tensile properties of the modified 13Cr martensitic stainless steels. AIP Conf Proc 1725(1):020039-1-020039–5. https://doi.org/10.1063/1.4945493

Rodrigues CAD, Lorenzo PLD, Sokolowski A, Barbosa CA, Rollo JMDA (2007) Titanium and molybdenum content in supermartensitic stainless steel. Mater Sci Eng A 461:149–152. https://doi.org/10.1016/j.msea.2007.01.016

Liu YR, Ye D, Yong QL, Su J, Zhao KY, Jiang W (2011) Effect of heat treatment on microstructure and property of Cr13 super martensitic stainless steel. J Iron Steel Res Int 18(11):60–66. https://doi.org/10.1016/S1006-706X(11)60118-0

Ma X, Zhou C, Wang L, Liu C, Subramanian S, de Oliveira MP (2013) Role of Nb in 13Cr super-martensitic stainless steel. Rem Rev Esc Minas 66(2):179–185. https://doi.org/10.1590/s0370-44672013000200007

Zepon G, Kiminami CS, Filho WJB, Bolfarini C (2013) Microstructure and wear resistance of spray-formed supermartensitic stainless steel. Mater Res 16(3):642–646. https://doi.org/10.1590/S1516-14392013005000026

Barbosa C, Abud I (2013) Recent developments on martensitic stainless steels for oil and gas production. Recent Patents Corros Sci 3(1):27–38. https://doi.org/10.2174/22106839112029990004

Sun Y, Bell T, Wood G (1994) Wear behaviour of plasma-nitrided martensitic stainless steel. Wear 178(1–2):131–138. https://doi.org/10.1016/0043-1648(94)90138-4

Xi YT, Liu DX, Han D (2008) Improvement of corrosion and wear resistances of AISI 420 martensitic stainless steel using plasma nitriding at low temperature. Surf Coatings Technol 202(12):2577–2583. https://doi.org/10.1016/j.surfcoat.2007.09.036

Beliardouh NE, Tlili S, Oulabbas A, Ramoul CE, Meddah S, Kaleli H (2021) Investigation on dry sliding wear performance and corrosion resistance of 13Cr5Ni2Mo supermartensitic stainless steel. Tribol Ind 43(1):107–116. https://doi.org/10.24874/ti.970.09.20.11

Ramoul C, Beliardouh NE, Bahi R, Nouveau C, Djahoudi A, Walock MJ (2019) Surface performances of PVD ZrN coatings in biological environments. Tribol Mater Surfaces Interfaces 13(1):12–19. https://doi.org/10.1080/17515831.2018.1553820

Tlili S, Beliardouh NE, Ramoul CE, Bahi R, Abdullah OI, Kaleli H, Samad MA (2018) Thermal treatment effect on tribological and corrosion performances of 13Cr5Ni2Mo super-martensitic stainless steel. Tribol Ind 40(3):433–439. https://doi.org/10.24874/ti.2018.40.03.09

Oliveira MP, Calderón-Hernández JW, Magnabosco R, Hincapie-Ladino D, Alonso-Falleiros N (2017) Effect of niobium on phase transformations, mechanical properties and corrosion of supermartensitic stainless steel. J Mater Eng Perform 26(4):1664–1672. https://doi.org/10.1007/s11665-017-2610-1

Niessen F (2018) Austenite reversion in low-carbon martensitic stainless steels–a CALPHAD-assisted review. Mater Sci Technol 34(12):1401–1414. https://doi.org/10.1080/02670836.2018.1449179

Lacombe P, Baroux B, Béranger G (1990) Les aciers inoxydables. Les Ulis, Paris

Rodrigues CAD, Bandeira RM, Duarte BB, Tremiliosi-Filho G, Jorge AM (2016) Effect of phosphorus content on the mechanical, microstructure and corrosion properties of supermartensitic stainless steel. Mater Sci Eng A 650:75–83. https://doi.org/10.1016/j.msea.2015.10.013

Ma XP, Wang LJ, Liu CM, Subramanian SV (2012) Microstructure and properties of 13Cr5Ni1Mo0.025Nb0.09V0.06N super martensitic stainless steel. Mater Sci Eng A 539:271–279. https://doi.org/10.1016/j.msea.2012.01.093

Kang J, Li J, Zhao KY, Bai X, Yong QL, Su J (2015) Passivation behaviors of super martensitic stainless steel in weak acidic and weak alkaline NaCl solutions. J Iron Steel Res Int 22(12):1156–1163. https://doi.org/10.1016/S1006-706X(15)30127-8

Hamu GB, Eliezer D, Wagner L (2009) The relation between severe plastic deformation microstructure and corrosion behavior of AZ31 magnesium alloy. J Alloys Compd 468(1–2):222–229. https://doi.org/10.1016/j.jallcom.2008.01.084

Tiamiyu AA, Eduok U, Odeshi AG, Szpunar JA (2019) Effect of prior plastic deformation and deformation rate on the corrosion resistance of AISI 321 austenitic stainless steel. Mater Sci Eng A 745:1–9. https://doi.org/10.1016/j.msea.2018.12.093

Miyamoto H (2016) Corrosion of ultrafine grained materials by severe plastic deformation, an overview. Mater Trans 57(5):559–572. https://doi.org/10.2320/matertrans.M2015452

Acknowledgements

The authors are grateful to the Directorate-General for Scientific Research and Technological Development (DGRSDT) at the Algerian Ministry of Higher Education and Scientific Research (MESRS) for its support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ramoul, C.E., Ghelloudj, O., Gharbi, A. et al. Plastic Deformation Effect on Wear and Corrosion resistance of Super Martensitic Stainless Steel. J Bio Tribo Corros 7, 114 (2021). https://doi.org/10.1007/s40735-021-00553-0

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40735-021-00553-0