Abstract

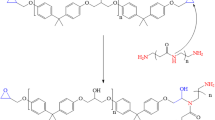

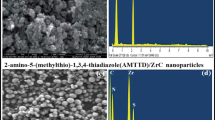

This study focused on developing an effective anticorrosive formulation for selected sulfo-tartaric anodized aluminium alloy (Al-alloy AA5086) to withstand harsh marine environment. The developed formulation was based on an epoxy resin bisphenol A diglycidyl ether (DGEBA) that is cured with polyaminoamide. Two sets of coated Al-alloy AA5086 samples were prepared using the epoxy resin formulation; a standard and ER–EZ. The formulation for making the ER samples included zinc phosphate (ER–ZP). Zinc phosphate was added to the formulation in about 5 wt%. The coated samples of Al-alloy AA5086 were evaluated by exposing them to a salt spray test chamber for various periods of time. The test was carried out according to an ISO 7253 standard test. The anticorrosive performance of the two epoxy coatings, the standard and ER–ZP were monitored by an electrochemical impedance spectroscopy (EIS). According to the EIS results, ER–ZP exhibited superior anticorrosive performance. The surface morphology analysis of the ER–ZP sample as shown by scanning electron microscopy with energy-dispersive spectroscopy (SEM/EDS) stayed smooth with minor roughness even after exposure to the harsh environments for 4392 h. The Bode and Nyquist plots showed that the ER–ZP coating has an outstanding barrier property in protecting Al-alloy AA5086 in marine environment against corrosion. The superior performance of the ER–ZP could be attributed to the presence of zinc phosphate which enhanced the adhesion properties of the coating and made it a more effective barrier.

Similar content being viewed by others

References

Zhu W, Li W, Mu S, Fu N, Liao Z (2017) Comparative study on Ti/Zr/V and chromate conversion treated aluminum alloys: anti-corrosion performance and epoxy coating adhesion properties. Appl Surf Sci 405:157–168

Golru SS, Attar M, Ramezanzadeh B (2015) Effects of surface treatment of aluminium alloy 1050 on the adhesion and anticorrosion properties of the epoxy coating. Appl Surf Sci 345:360–368

Li Y, Zhang P, Bai P, Wu L, Liu B, Zhao Z (2018) Microstructure and properties of Ti/TiBCN coating on 7075 aluminum alloy by laser cladding. Surf Coat Technol 334:142–149

Sabouri M, Khoei SM (2018) Plasma electrolytic oxidation in the presence of multiwall carbon nanotubes on aluminum substrate: morphological and corrosion studies. Surf Coat Technol 334:543–555

Sanaei Z, Bahlakeh G, Ramezanzadeh B (2017) Active corrosion protection of mild steel by an epoxy ester coating reinforced with hybrid organic/inorganic green inhibitive pigment. J Alloy Compd 728:1289–1304

Dagdag O, El Harfi A, Essamri A, El Bachiri A, Hajjaji N, Erramli H, Hamed O, Jodeh S (2018) Anticorrosive performance of new epoxy-amine coatings based on zinc phosphate tetrahydrate as a nontoxic pigment for carbon steel in NaCl medium. Arab J. Sci. Eng. https://doi.org/10.1007/s13369-018-3160-z

Alam MA, Samad UA, Khan R, Alam M, Al-Zahrani SM (2017) Anti-corrosive performance of epoxy coatings containing various nano-particles for splash zone applications. Korean J Chem Eng 34(8):2301–2310

Jiang M-Y, Wu L-K, Hu J-M, Zhang J-Q (2015) Silane-incorporated epoxy coatings on aluminum alloy (AA2024). Part 1: Improved corrosion performance. Corros Sci 92:118–126

Meis N, van der Ven L, van Benthem R (2014) Extreme wet adhesion of a novel epoxy-amine coating on aluminum alloy 2024-T3. Prog Org Coat 77(1):176–183

Živković LS, Bajat JB, Popić JP, Jegdić BV, Stevanović S, Mišković-Stanković VB (2015) Protective properties of cataphoretic epoxy coating on aluminium alloy AA6060 modified with electrodeposited Ce-based coatings: effect of post-treatment. Prog Org Coat 79:43–52

Saha R, Nandi R, Saha B (2011) Sources and toxicity of hexavalent chromium. J Coord Chem 64(10):1782–1806

Dey S, Chatterjee S, Singh BP, Bhattacharjee S, Rout TK, Sengupta DK, Besra L (2018) Development of superhydrophobic corrosion resistance coating on mild steel by electrophoretic deposition. Surf Coat Technol 341:24–30

Bajat J, Mišković-Stanković V, Kačarević-Popović Z (2008) Corrosion stability of epoxy coatings on aluminum pretreated by vinyltriethoxysilane. Corros Sci 50(7):2078–2084

Renaud A, Poorteman M, Escobar J, Dumas L, Bonnaud L, Dubois P, Olivier M-G (2017) A new corrosion protection approach for aeronautical applications combining a Phenol-paraPhenyleneDiAmine benzoxazine resin applied on sulfo-tartaric anodized aluminum. Prog Org Coat 112:278–287

García-Rubio M, De Lara M, Ocón P, Diekhoff S, Beneke M, Lavía A, García I (2009) Effect of postreatment on the corrosion behaviour of tartaric–sulphuric anodic films. Electrochim Acta 54(21):4789–4800

Chang C-H, Huang T-C, Peng C-W, Yeh T-C, Lu H-I, Hung W-I, Weng C-J, Yang T-I, Yeh J-M (2012) Novel anticorrosion coatings prepared from polyaniline/graphene composites. Carbon 50(14):5044–5051

Weng C-J, Huang J-Y, Huang K-Y, Jhuo Y-S, Tsai M-H, Yeh J-M (2010) Advanced anticorrosive coatings prepared from electroactive polyimide–TiO2 hybrid nanocomposite materials. Electrochim Acta 55(28):8430–8438

Vega J, Granizo N, Simancas J, Díaz I, Morcillo M, de la Fuente D (2017) Exploring the corrosion inhibition of aluminium by coatings formulated with calcium exchange bentonite. Prog Org Coat 111:273–282

Jadhav AJ, Holkar CR, Pinjari DV (2018) Anticorrosive performance of super-hydrophobic imidazole encapsulated hollow zinc phosphate nanoparticles on mild steel. Prog Org Coat 114:33–39

Naderi R, Attar M (2009) Electrochemical study of protective behavior of organic coating pigmented with zinc aluminum polyphosphate as a modified zinc phosphate at different pigment volume concentrations. Prog Org Coat 66(3):314–320

Behzadnasab M, Mirabedini S, Kabiri K, Jamali S (2011) Corrosion performance of epoxy coatings containing silane treated ZrO2 nanoparticles on mild steel in 3.5% NaCl solution. Corros Sci 53(1):89–98

Hao Y, Liu F, Han E-H, Anjum S, Xu G (2013) The mechanism of inhibition by zinc phosphate in an epoxy coating. Corros Sci 69:77–86

Rangari V, Bhuyan MS, Jeelani S (2011) Microwave curing of CNFs/EPON-862 nanocomposites and their thermal and mechanical properties. Compos A 42(7):849–858

Okabe T, Oya Y, Tanabe K, Kikugawa G, Yoshioka K (2016) Molecular dynamics simulation of crosslinked epoxy resins: curing and mechanical properties. Eur Polymer J 80:78–88

Ferdosian F, Zhang Y, Yuan Z, Anderson M, Xu CC (2016) Curing kinetics and mechanical properties of bio-based epoxy composites comprising lignin-based epoxy resins. Eur Polymer J 82:153–165

Jin F-L, Li X, Park S-J (2015) Synthesis and application of epoxy resins: a review. J Ind Eng Chem 29:1–11

Ferdosian F, Yuan Z, Anderson M, Xu CC (2015) Sustainable lignin-based epoxy resins cured with aromatic and aliphatic amine curing agents: curing kinetics and thermal properties. Thermochim Acta 618:48–55

Yahyaie H, Ebrahimi M, Tahami HV, Mafi ER (2013) Toughening mechanisms of rubber modified thin film epoxy resins. Prog Org Coat 76(1):286–292

Ding J, ur Rahman O, Peng W, Dou H, Yu H (2018) A novel hydroxyl epoxy phosphate monomer enhancing the anticorrosive performance of waterborne graphene/epoxy coatings. Appl Surf Sci 427:981–991

Rassouli L, Naderi R, Mahdavain M (2017) The role of micro/nano zeolites doped with zinc cations in the active protection of epoxy ester coating. Appl Surf Sci 423:571–583

Castela A, Simoes A (2003) An impedance model for the estimation of water absorption in organic coatings. Part I: a linear dielectric mixture equation. Corros Sci 45(8):1631–1646

Deflorian F, Rossi S, Fedel M, Motte C (2010) Electrochemical investigation of high-performance silane sol–gel films containing clay nanoparticles. Prog Org Coat 69(2):158–166

Montemor M, Snihirova D, Taryba M, Lamaka S, Kartsonakis I, Balaskas A, Kordas G, Tedim J, Kuznetsova A, Zheludkevich M (2012) Evaluation of self-healing ability in protective coatings modified with combinations of layered double hydroxides and cerium molibdate nanocontainers filled with corrosion inhibitors. Electrochim Acta 60:31–40

Ammar S, Ramesh K, Vengadaesvaran B, Ramesh S, Arof A (2016) Amelioration of anticorrosion and hydrophobic properties of epoxy/PDMS composite coatings containing nano ZnO particles. Prog Org Coat 92:54–65

Jalili M, Rostami M, Ramezanzadeh B (2015) An investigation of the electrochemical action of the epoxy zinc-rich coatings containing surface modified aluminum nanoparticle. Appl Surf Sci 328:95–108

Arman S, Ramezanzadeh B, Farghadani S, Mehdipour M, Rajabi A (2013) Application of the electrochemical noise to investigate the corrosion resistance of an epoxy zinc-rich coating loaded with lamellar aluminum and micaceous iron oxide particles. Corros Sci 77:118–127

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Dagdag, O., Hamed, O., Erramli, H. et al. Anticorrosive Performance Approach Combining an Epoxy Polyaminoamide–Zinc Phosphate Coatings Applied on Sulfo-tartaric Anodized Aluminum Alloy 5086. J Bio Tribo Corros 4, 52 (2018). https://doi.org/10.1007/s40735-018-0168-6

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40735-018-0168-6