Abstract

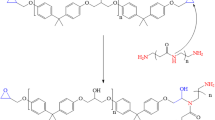

The protection properties of (3-aminopropyl)trimethoxysilane (APTMS) incorporated epoxy coating on aluminum alloy were studied by electrochemical techniques such as electrochemical impedance spectroscopy (EIS) and scanning electrochemical microscopy (SECM) analysis in seawater. The epoxy-APTMS coated Al alloy displayed higher charge transfer resistance (Rct) as well as film resistance (Rf) at 1 day immersion. However, both Rct anf Rf values decreased slowly compared to pure epoxy coated alloy which showed significant decrease in Rct and Rf values with increase in immersion time in chloride media. The released Al3+ ions were detected using SECM by applying the tip potential of –0.85 V. It was evident from the SECM measurement that the dissolution of Al3+ ions was impeded at the scratch of epoxy-APTMS coated Al alloy due to the presence of electron donating amino group in APTMS which inhibited Al alloy degradation. The enrichment of Mg, Mn, Si and Al at the scratch of epoxy-APTMS coated Al alloy was confirmed by Field emission-scanning electron microscopy/energy dispersive X-Ray spectroscopy (FE-SEM/EDX) analysis. Focused ion beam-transmission electron microscopy (FIB-TEM) analysis proved the presence of thin films of nano level oxide layers containing Mg, Mn, Si and Al in the coatings, which decreased the corrosion rate of Al alloy. The enhanced adherence of epoxy-APTMS coating to Al alloy was due to the strong chemical bonding between epoxy-APTMS and Al alloy. Therefore, the pronounced protection performance against corrosion and good adhesion strength was due to the incorporation of APTMS with epoxy coatings.

Similar content being viewed by others

REFERENCES

Forsgren, A., Corrosion Control through Organic Coatings, Boca Raton, FL: CRC, 2006.

Legghe, E., Aragon, E., Bélec, L., Margaillan, A., et al., Prog. Org. Coat., 2009, vol. 66, pp. 276–280.

Chrusciel, J.J. and Lesniak, E., Prog. Polym. Sci., 2015, vol. 41, pp. 67–121.

Queiroz, F.M., Magnani, M., Costa, I., and De Melo, H.G., Corros. Sci., 2008, vol. 50, pp. 2646–2657.

Boag, A., Hughes, A.E., Glenn, A.M., Muster, T.H., et al., Corros. Sci., 2011, vol. 53, pp. 17–26.

DeRose, J.A., Suter, T., Balkowiec, A., Michalski, J., et al., Corros. Sci., 2012, vol. 55, pp. 313–325.

Liu, J., Yu, Q., Yu, M., Li, S., et al., J. Alloys Compd., 2018, vol. 744, pp. 728–739.

Dezfuli, S.M., Shanaghi, A., and Baghshahi, S., Int. J. Miner. Metall. Mater., 2018, vol. 25, pp. 1344–1353.

Zhu, D. and van Ooij, W.J., Prog. Org. Coat., 2004, vol. 49, pp. 42–53.

Zhang, Y., Zhao, M., Zhang, J., Shao, Q., et al., J. Polym. Res., 2018, vol. 25, 130.

Brostow, W., Dutta, M., and Rusek, P., Eur. Polym. J., 2010, vol. 46, pp. 2181–2189.

Figueira, R.B., Silva, C.J.R., and Pereira, E.V., J. Coat. Technol. Res., 2015, no. 12, pp. 1–35. https://doi.org/10.1007/s11998-014-9595-6

Xavier, J.R., Int. J. Adhes. Sci. Technol., 2020, vol. 34, no. 2, pp. 115–134.

Echeverría, M., Abreu, C.M., Lau, K., and Echeverría, C.A., Prog. Org. Coat., 2016, vol. 92, pp. 29–43.

Diaz, I., Chico, B., de la Fuente, D., Simancas, J., et al., Prog. Org. Coat., 2010, vol. 69, pp. 278–286.

Brusciotti, F., Snihirova, D.V., Xue, H., Montemor, M.F., et al., Corros. Sci., 2013, vol. 67, pp. 82–90.

Pathak, S.S., and Khanna, A.S., Prog. Org. Coat., 2009, vol. 65, pp. 288–294.

Xue, D., and van Ooij, W.J., Prog. Org. Coat., 2013, vol. 76, pp. 1095–1102.

Montemor, M.F., Surf. Coat. Technol., 2014, vol. 258, pp. 17–37.

Zhang, Y., Shao, Y., Zhang, T., Meng, G., et al., Corros. Sci., 2011, vol. 53, pp. 3747–3755.

Deyab, M.A., Essehli, R., El Bali, B., and Lachkar, M., RSC Adv., 2017, vol. 7, pp. 55074–55080.

Xavier, J.R., Prot. Met. Phys. Chem., 2019, vol. 55, no. 1, pp. 80–88. https://doi.org/10.1134/S2070205119010167

Xavier, J.R., J. Appl. Polym. Sci., 2019, vol. 137, no. 5, 48323. https://doi.org/10.1002/APP.48323

Xavier, J.R., Nanjundan, S., and Rajendran, N., Ind. Eng. Chem. Res., 2012, vol. 51, pp. 30–43. https://doi.org/10.1021/ie1016464

Toorani, M., Aliofkhazraei, M., and Naderi, R., J. Alloys Compd., 2019, vol. 785, pp. 669–683.

Xavier, J.R., Anti-Corros. Method. Mater., 2018, vol. 65, no. 1, pp. 38–45. https://doi.org/10.1108/ACMM-04-2017-1784

Boomadevi Janaki, G. and Xavier, J.R., J. Bio- Tribo-Corros., 2020, vol. 6, 20. https://doi.org/10.1007/s40735-019-0316-7

ACKNOWLEDGMENTS

The author thanks Prof. Dr. A. Abudhahir, Prof. Dr. Koteswara Rao Anne, Prof. Dr. P. Sarasu, and the Management of Vel Tech Rangarajan Dr. Sagunthala R&D Institute of Science and Technology, Avadi, Chennai-600 062, Tamil Nadu, India, for their constant encouragement and constructive suggestions regarding this research.

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Joseph Raj Xavier Evaluation of Anticorrosion Properties of Epoxy-Silane Hybrid Nanocomposite Coating on AA6082 Aluminum Alloy. Surf. Engin. Appl.Electrochem. 56, 762–772 (2020). https://doi.org/10.3103/S1068375520060150

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1068375520060150