Abstract

Purpose of Review

In countries such the USA, Iran, and Turkey, pistachio nut is considered one of the most economically valuable agricultural products. Pistachio production and related dehulling processes generate a large quantity of organic waste, containing green hull, cluster woody part, shells, and leaves. The inadequate conventional management of such wastes calls for sustainable and economical strategies not only to enhance resource efficiency but also to create value.

Recent Findings

Pistachio residues have a high content of total extractives and essential oils and a considerable amount of phenolic compounds that explain their good antioxidant activities and other potential human health benefits. Furthermore, considering the generation volume (about 660,000 tons) and lignocellulosic structure, pistachio residues can also be sustainably used to produce value-added products, such as biofuels, phytochemicals, activated carbon, and other potential bioproducts such as filamentous fungi as protein enriched biomass, single-cell protein (SCP), and volatile fatty acids. In general, recent studies have not comprehensively investigated all value-added potential products.

Summary

This review provides a thourough insight into the present pistachio processing industries, and pistachio waste chemical composition and characteristics. Furthermore, the applications of pistachio residues as a renewable source for the production of potential value-added products by various thermochemical (pyrolysis, gasification, and liquefaction), physicochemical (solvent extraction, ultrasound-assisted extraction (UAE), microwave-assisted extraction (MAE), and extraction by pressurized liquids (PLE)), and biological (anaerobic digestion (AD) and fermentation (solid-state and submerged)) processes are presented including an analysis of the advantages and disadvantages of such methods. In this regard, production of new products such as edible filamentous fungi and antioxidant, and their market appeal has been briefly considered.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

A growing number of clinical studies have revealed the potential health benefits of pistachio nuts based on their high content of potassium, phytosterols, vitamin K, g-tocopherol, and lutein compared to other nuts, their heart-healthy fatty-acids profile, protein, dietary fiber, and some phytochemicals, including phenolic acids and xanthophyll carotenoids [1,2,3,4]. Considering the aforementioned nutritional and health benefits, pistachios, consumption is increasing worldwide.

Based on the latest statistics, the USA and Iran are world leaders in the production and cultivation of pistachios with a sum of about 700,000 metric tons in 2019 (more than 70% of the world’s pistachio production) [5,6,7]. Figure 1 and Table 1 demonstrate the world’s top pistachio production and producing countries in 2019.

Distribution map of world’s top pistachio producing countries in 2019 adopted from [5]

Pistachio (Pistacia vera L.) contains an edible seed in the center protected by a hard lignified shell and a green hull [9]. After harvesting, dehulling and downstream process to obtain pistachio kernels, green hull, cluster woody part, shell, and leave are the most common types of waste generated. Pistachio by-product mixture (PBM), the largest portion of total pistachio residues, refers to a mixture of leaves, clusters, and green hulls resulting from the dehulling process [10].

PBM is biodegradable and prone to spoilable, turning black, and moldy in a matter of days if spread over land untreated. The molesting insects and extensive soil and water pollution, for example, increases the distribution of aflatoxin by overwintering spores of Aspergillus sp. around the pistachio orchard and terminals, are some issues associated with dumping PBM. Although some farmers and pistachio growers apply PBM as fertilizer without any treatment, increases in the amount of aflatoxin contamination in the pistachio production chain due to the movement of Aspergillus sp. spores [8,9,10]. Although a small portion of the green hull is used for animal feeding, tannins and polyphenolic compounds in the hulls reduce its acceptance and digestibility as animal feed [11•].

As above mentioned, Like most other agricultural wastes, pistachio wastes are not managed by circular bioeconomy approach which is proposed more efficient sustainable biobased renewable resource management [12, 13]. On the other hand, because of growing volume of these waste, limited fossil fuels, and chemical sources, sustainable management of agricultural wastes is a critical issue in the world which lead humans to find a sustainable manner for energy and biobased generation [14, 15]. For this purpose, the concept of biorefinery, thermochemical, and extraction methods is used to convert biomass to chemicals, energy, and other bio-based products [16, 17].

Hence, pistachio residues need to be considered potential raw materials for producing value-added products such as phytochemicals, biofuels, protein-rich food or feed, fungal biomass protein, bio-oil, and activated carbon rather than just excretion or feeding them, to avoid transmission of hazardous materials and environmental pollution [18, 19, 20••, 21].

The present study opens with a thorough review of pistachio composition, production and processing, and waste generation. The main attention was then focused on thermochemical, extractive, and biological production of value-added products from pistachio residues. There is a general lack of a comprehensive literature review in this area. Moreover, the potential of PBM as feedstock to waste-based biorefineries is investigated.

Pistachio Dehulling Process and Residues

In most countries, it is common practice that pistachios are harvested as mature (except in Turkey that pistachios are harvested as un-matured and matured) [22] by knocking them off the tree followed by shaking onto sheets or mechanical shakers. This process is called dehulling, through which the soft hull, leaves, and clusters are separated from nuts [23,24,25]. From 3 kg of pistachio harvested that enters the processing unit, 1 kg of dried nuts is produced, and about 66% ends as residuals [11•].

PBM forms more than 90% of total pistachio residues. Pistachio green hull (PGH), as a large portion of pistachio (approximately 33% of dry matter weight), is the main contributor to (about 59%) PBM [24, 25]. After dehulling in the pistachio terminals, separating unpeeled and unripe pistachios, washing, and drying to the appropriate moisture level are the following processes [11•].

Due to the high moisture content of PBM, its improper management results in environmental and ecological challenges [26]. However, based on the energy and nutrient content point of view, the pistachio dehulling residues is an ideal source for extracting or producing valuable products.

Pistachio Residues Composition and Usage

Pistachio nuts are a rich antioxidant and anti-inflammatory source due to their high content of phenolic compounds such as anthocyanins, flavonols, flavanones, cardioprotective constituents, and phytosterols tocopherols varying based on the species of pistachio [27, 28]. Similar to pistachio nuts specification, the composition of pistachio residues changes with the species of pistachio [29], variety of pistachio [30], and method of harvesting and storage [31]. Several studies have reported the chemical composition of various types of pistachio residues [10, 11•, 32•, 33]. As presented in Table 2, carbohydrate, phenolic compounds, and protein are the most important components found in different streams of pistachio residues.

In addition to the chemical composition listed in Table 2, there are other valuable minerals and vitamins in PGH such as phosphorus, nitrogen, potassium, sodium, calcium, magnesium, iron, manganese, zinc, and copper, which are generally less than 10% [11•, 33].

Dietary fiber is the portion of plant-derived food consisting of structural carbohydrates and lignin that cannot be completely broken down by human digestive enzymes or readily absorbed in the small intestine [26, 35]. These fibers form the major structure of lignocellulosic structure. Although dietary fibers are generally more slowly digested than non-fiber carbohydrate (NFC), they can potentially be converted into value-added products [36,37,38]. PBM can be considered lignocellulosic biomass [10]. Due to the lignocellulosic nature of pistachio residues and their rich organic matter content, their potential applications and products have been investigated. Biogas production [39], compost and fertilizer [40,41,42], animal feed [43], biosorbent [44, 45], phytochemicals [46], and pigments [28] from PGH, bio-oil [47], and activated carbon [48] from pistachio shell and also preparing the substrate for mushroom from the mixture of shells and PGH [49] are some of these studies which the valorization approaches discussed later.

Another use of pistachio waste is as animal feed. Paydaș et al. [50] investigated the effects of the addition of pistachio shells on different levels of corn silage. As a result, by ensiling up to 9% pistachio shells along with corn silage reduction in ruminal methane production in ruminants can be achieved. Although pistachio waste can be used as additive in conventional ruminant feed, the presence of high levels of copper and phenolic compounds restricts its inclusion proportions in ruminants’ diet. These by-products also contain tannins that limits pistachio waste application in ruminant feeding due to toxicity or undesirable interactions with protein, carbohydrates, minerals, or rumen microorganisms [51, 52]. Therefore, using other value creation approaches than application in animal feeding can be more promising.

PBM has a high content of total extractives, essential oils, and a considerable amount of phenolic compounds, tannin, and fatty acid that explain their good antioxidant, cytotoxicity, and anti-mutagenic activities, with human health benefits, such as prevention of hypertension and anti-diabetic effects [53,54,55,56,57,58]. Gallic acid, 2-methylphenol, 2,6-dimethoxy-4-(2-propenyl)-phenol, and catechin are some of the phenolic compounds in PGH [32•, 59]. Through comparing the phenolic compounds of pistachio hulls (such as gallic acid) and nuts, some studies have shown that pistachio hulls had better antioxidant activity than nuts [59]. Essential oils found in PGH are classified as monoterpene hydrocarbons, sesquiterpene hydrocarbons, oxygenated monoterpenes, oxygenated sesquiterpenes, and polyphenols, in order of the highest to lowest content. β-caryophyllene, myrcene, α-pinene, limonene, α-humulene, α-terpinolene, 4-carene, and β-citral are the most important compounds among the 90 compounds detected as PGH essential oil [60,61,62,63,64]. Furthermore, about 20 types of different aroma compounds, including acids, alcohols, and benzenes, were identified in PGH [65]. PGH also contains significant amounts of pectin compared to other sources such as apple pomace [66,67,68,69]. This uniqueness in variety and type of chemical compounds found in pistachio waste extract motivates further detailed studies in valorization of such waste.

Pistachio Dehulling Waste Valorization Approaches

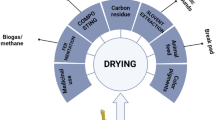

Based on the previously noted structural and compositional characteristics of pistachio dehulling waste, there are various methods which have the potential to convert these residues into valuable products bringing environmental and economic advantages while alleviating issues revolving around pistachio waste management. Considering Fig. 2, approaches of creating added value from pistachio wastes have been determined.

Thermochemical Methods

Thermochemical conversion biomass into fuels happens through chemically catalyzed thermal decomposition. Pyrolysis, gasification, and liquefaction are such thermochemical processes used in the valorization of waste. Pyrolysis is performed in the absence of oxygen at medium and high temperatures. Bio-oil, biochar, and some light gases such as hydrogen are the most common products of the pyrolysis process. The type and distribution of products vary depending on the operational conditions and the composition of the residues. For example, higher temperatures yield more gaseous products. Pyrolysis and gasification are significantly different in terms of yield type and the ratio of products. Although pyrolysis is an affordable technology, some pollutants such as SOx, NOx, hydrogen sulfide, and ammonia are produced during the process [70,71,72,73,74].

Okutucu et al. [75] investigated the feasibility of the application of pistachio shell as feedstock for the production of fungicidal oil (pyrolysis bio-oil) and a precursor for the production of activated carbon by pyrolysis at temperatures of 300–600 °C. Fungicidal activity of the bio-oil against four different types of fungi (T. viridae, A. niger, T. rubrum, and C. versicolor) was proven effective at concentration 10–50 mg.ml−1. Compared to the fungicidal activity of the bio-oil produced from peach stone, which only had acceptable activity against C. versicolor [76], the generated antifungal from pistachio shell has showed more efficiency. The surface area and micropore volume of the activated carbon produced from the char were found to be 708 m2.g−1 and 0.280 cm3.g−1, respectively. In addition, Yang et al. [77] investigated activated carbon production from pistachio shells by activating the resulting chars following pyrolysis. The pyrolysis temperature was 500 °C, and residence time at this temperature was 2 h. The aforementioned study also investigated the effects of CO2 flow and heating rates during activation. The surface area and micropore volume of the activated carbon prepared at 800 °C were found to be 1064.2 m2.g−1 and 0.210 cm3.g−1, respectively. Comparing the results of this study with other similar agricultural wastes, the surface area of biochar obtained from pistachio shell was much higher than that of walnut and hazelnut shell [78, 79]. In summary, pyrolysis chars of pistachio shells has a good potential for being used as a solid fuel or as raw material to produce activated carbon and adsorbent. Despite pyrolysis chars, gas products and bio-oil are not attractive as fuel due to the low calorific value and high oxygen content, respectively. In addition to the various studies on pistachio shell pyrolysis, some researchers have performed pyrolysis on PGH. Jalayeri et al. [80] investigated the use of biochar derived from PGH for Cu (II) removal from aqueous solutions. The PGH was pyrolyzed at 450 °C for 1 h in the absence of oxygen. The maximum amount of Cu (II) ions adsorbed by biochar was reported 19.84 mg.g−1.

Moreover, Karatas et al. [81] studied the gasification of walnut and pistachio shells. It was shown that the lower heating value of the pistachio shell is higher than that of the walnut shell by 8–12%, and it increases from 3.2 to 5.4 MJ.Nm−3 with the reduction in equivalence ratio from 0.4 to 0.2 for pistachio shell.

Besides the above methods, hydrothermal liquefaction has been used as a method for high biomass conversion yields in the production of bio-crudes [82]. Hongthong et al. [83] investigated co-processing of common plastics with pistachio hulls via hydrothermal liquefaction at 350 °C over 15 and 60 min time intervals in blends of up to 20 wt% plastic to pistachio hulls. Under optimal conditions, nylon-6 and PET broke down almost entirely, and high yields of up to 35% bio-crude were achieved.

Physicochemical Methods

Physical, chemical, or combination of these methods are used to produce valuable products from pistachio dehulling wastes. The products derived from pistachio dehulling wastes through these methods are highlighted in this section.

Among bioactive compunds in pistachio dehulling wastes, polyphenols have attracted special attention for their antioxidant, anti-inflammatory, and other biological activities. Liquid–solid extraction and liquid–liquid extraction (solvent extractions) are the main conventional extraction methods of different compounds from biomass. The extraction of phenolic and antioxidant compounds is commonly done using simple and traditional methods such as Soxhlet with organic solvents or conventional hydrodistillation. For example, Mohammadi et al. [84] investigated the extraction of essential oils from pistachio shells and clusters by the hydrodistillation method. Essential oils extraction efficiency from cluster and shells was 2.10% and 0.13%, respectively. The major compounds identified in shells were d-limonene, α-thujene, and terpinolene, while the major components of clusters were α-thujene and α-pinene. The total phenolic content in shells and clusters were 958 and 796 mg gallic acid (GA)/100 g dry material, respectively. In another study, the phenolic content of water extract of PGH was reported to contain about 197 mg GAE/g dry weight [85].

However, as presented in the literature, these methods have low extraction efficiency, long extraction time, and their high temperature leads to the degradations of the bioactive and unstable ingredients [86,87,88]. The enhancement of the extraction efficiency, reduction of solvent consumption, extraction time, and the use of greener solvents have led to modern or nonconventional techniques such as ultrasound-assisted extraction (UAE), microwave-assisted extraction (MAE), and extraction by pressurized liquids (PLE) [89, 90].

The MAE uses microwave energy that includes internal heating to provide faster extraction, lesser or no solvent consumption, and lower external temperature when compared to traditional heating [91, 92]. Özbek et al. [93] investigated the extraction of non-polar compounds from pistachio hulls by MAE and Soxhlet methods. The extraction yields were 9.81 and 9.50% for MAE and Soxhlet methods, respectively. The results revealed that the total phenolic compounds, antioxidant activity, and tocopherol content of the MAE extract were significantly higher than that of the Soxhlet extract. In another study, Özbek et al. [94] investigated the extraction of phenolic compounds from pistachio hull using microwave-assisted solvent extraction (MASE). In optimal conditions, 62.24 mg gallic acid equivalent (GAE).g−1 dry hull of total phenolic compounds was obtained. In addition, in this study, MASE was proven to give higher extraction yield, phenolic compounds, and antioxidant activity than conventional solvent extraction. Furthermore, pistachio shells have been evaluated for natural antioxidants extraction via various extraction methods and solvent such as methanol, ethanol, ethyl acetate, UAE, and MAE among which microwave-assisted ethanol extract turned out to be the most promising [95].

The UAE method is based on ultrasonic waves, which lead to acoustic cavitations production. Although UAE is known as a cheap and effective alternative method compared to MAE and conventional methods, its low efficiency has been claimed in some studies [96, 97]. For example, Mokhtarpour et al. [98] studied the phenolic profile and tannins from pistachio by-products by four different solvents and UAE methods. Using acetone resulted in higher total phenol compared to methanol, ethanol, and water. In addition, higher tannin content was extracted by ethanol compared to methanol and water. In another experiment, no difference was observed in the extraction of total phenols and tannins by UAE and 12 h solvent extraction without ultrasonic. Despite the results of the mentioned study, the findings of Rajaei et al. [57] indicated that the yield of phenolic compounds extracted by UAE was higher than maceration extraction and MAE methods. Generally, the amount of total phenolic content in pistachio dehulling waste, regardless of the extraction method, is much higher than some conventional agricultural wastes such as rice straw (486 mg (GA)/100 g dry material) [99] and many edible vegetables and fruits considered rich sources of phenolic compounds [100].

Pectin is another promising product which can be obtained from PGH by extraction. Pectin is widely used in food industry for gelling and as emulsifier. Based on the degree of esterification of pectin (high and low methoxyl pectin), PGH pectin obtained by acidic extraction method is classified as low methoxyl pectin, which can be applied as a food ingredient for gel formation in low calorie products [67]. In addition to the acid extraction method, UAE and MAE have also been investigated to extract pectin from PGH. In short, PGH is a good source of high purity pectin [66, 67, 100].

Biological Methods

Biological conversion methods are the cornerstone of waste biorefineries for wastes valorization. The waste-derived bioproducts like bio-fuels (biogas, bioethanol, bio-hydrogen, etc.), biomass, and secondary chemicals are mainly obtained through anerobic digestion, fermentation, composting, and enzymatic hydrolysis [101, 102•, 103].

Anaerobic digestion (AD) is the natural process in which bacterial consortia decompose organic materials in the absence of oxygen under controlled operational conditions. During AD, organic material is hydrolyzed into sugars, amino acids, and fatty acids resulting in the final main metabolites of methane and carbon dioxide called biogas as a renewable source of energy [104, 105••, 106]. In addition to biogas, a nutrient rich digestate is generated which has the potential to be used as fertilizer [107]. A few studies on biogas production from pistachio dehulling wastes show the possibility of biogas production as a renewable energy source. For example, Demirer [108] investigated the first report on biogas production potential of pistachio dehulling waste. The results showed that 134 mL of biogas (62.6 mL methane) was produced per gram of dehulling solid waste. In another study, Celik and Demirer [39] investigated the anaerobic treatment capability and potential of biogas production from pistachio residues. In this regard, thermal and chemical (acidic and alkaline) pretreatment methods were evaluated and applied to pistachio residues. Based on the acquired results, thermal pretreatment has shown the best performance and the highest methane yield with 213.4 ml CH4.g−1 COD.

By comparing the results of the AD of pistachio dehulling waste to other conventional agricultural wastes such as wheat and rice straw, it seems that pistachio wastes have less potential for biogas production. For example, Baetge et al. [109] investigated the production of biogas from rice straw generating 449 mL of biogas per gram of organic dry matter. Also Xi et al. [110] studied biogas production from wheat straw obtaining 337 ml biogas per gram of total solid. In orger to improve biogas production from pistachio waste, strategies such as co-digestion can be considered.

Similar to AD, aerobic fermentation converts lignocellulosic wastes such as pistachio residues into valuable metabolites. Fermentation of pistachio residues has been investigated in a few studies. Recently, Göncü et al. [111] evaluated the bioethanol production from pistachio shells by applying ozone, hot water, and combined (ozone and hot water) pretreatment. This study showed that combined pretreatment was more effective than single where through a post enzymatic hydrolysis, 1.21–2.33 g.L−1 ethanol was obtained at the end of the fermentation by Saccharomyces cerevisiae, which presents a fermentation efficiency of 42–55%. Pretreatment methods are usually applied for opening the lignocellulosic biomass structure and increasing the accessibility to the inner structure by enzymes and microorganisms during the AD or fermentation process by eliminating lignin or other structural components [112,113,114]. Physical (chipping, milling, cavitation, etc.) [115], chemical (alkaline, acidic, oxidizing agents, etc.) [116], physico-chemical (steam explosion, hydrothermal, etc.) [117], and biological (enzymatic, etc.) [118] approaches are some of the most common pretreatment methods with only a few practiced during bioconversion pistachio waste. Due to the composition of PBM, compounds such as furfural and 4-hydroxy-3,5-dimethoxybenzaldehyde, can be released during harsh pretreatment that acts as inhibitory products to fermentation [32•].

Solid-state fermentation (SSF) is a fermentation method by which the growth of microorganisms happens in the absence of free water [119]. In this case, Karimi et al. [120] and Abbasi et al. [121] determined the effect of SSF on pistachio hulls' antioxidant activity using fungi. It was claimed that SSF is not an effective method for improving the antioxidant activities of pistachio hulls.

Although the production of some bioproducts from pistachio residues has been investigated, there are various unexplored areas for pistachio residues bioconversions. Acetone-butanol-ethanol (ABE) [122], volatile fatty acids (VFAs) [123], bio-hydrogen [124], single-cell proteins [20••, 125], fungal biomass protein such as filamentous fungi [125,126,127], etc., are some of the potential bioproducts that can be considered when considering value creation from pistachio residues. One of the bioproducts that has recently received attention are edible filamentous fungi, that have the ability to produce a variety of enzymes that enable them to growth on various complex organic substrates. The product of such biological process is a protein-rich biomass that can be used as human food and animal feed. Fungal cultivation can also generate other products such as ethanol, chitin, chitosan, and pigment [126, 128••, 129]. According to the characteristics and chemical composition of pistachio waste, obtaining novel bioproducts as fungal biomass or antioxidants instead of conventional bio-based products can be considered an attractive alternative.

Comparative Evaluation of Valorization Approaches

It is known that biomass pretreatment considered in different valorization practices is the energy and cost hotspots of the system. Acidic or basic, advanced oxidation processes (AOPs) such as ozonolysis and Fenton, biological and organosolv pretreatment are some common examples of such pretreatment methods [130,131,132,133]. These methods have also been considered in industrial scale practices. For example, ethanol-based organosolv is used in Lignol Innovations in Canada, an integrated biorefinery producing ethanol, lignin, furfural, xylose, and acetic acid [134]. Regardless of the pretreatment stage, the main mentioned valorization approaches, i.e. thermochemical, physicochemical, and biological, are comparable to each other in terms of technical, economic, energy demand, and environmental aspects. These approaches can be used individually in an integrated approach in order to produce specific value-added products from pistachio waste. However, as summarized in Table 3, there are various advantages and disadvantages to each method.

Considering the generation volume of pistachio waste in specific areas, this waste can be considered one of the most abundant low-priced organic substrate for bioconversion purposes in a biorefinery concept fort the production of biofuels and other added value products [141]. However, if an integrated biorefinery concept is not considered, taking into account the benefits and shortcomings presented, and regardless of the specific cases where a unique product is aimed at, production of new products that open up new markerts and economical apportunities compared conventional well-established products should be more promising from dense agricultural wastes such as pistachio wastes. In this regard, production of single-cell protein (e.g. edible filamentous fungi), antioxidant, pigment, etc., may be more appealing as they can be produced on a small scale with rather small investment and low market rivalry as a green alternative products. In addition, considering the potential products, the negative or low value of the substrate, physicochemical and biological processes present a wider scope of products with considerably low processing cost.

Future Prospectives

Considering the trend in population growth and future demands for food, feed, and energy, production and application practices should be focused on the efficient use of resources and the recovery of nutrients from waste in a circular economy concept. When it comes to organic-rich waste streams, waste-based biorefineries are the true realization of such a goal through which nutrients are recovered into a range of value-added biochemicals and biomaterials.

About 1,000,000 metric tons of pistachio is produced per year around the world resulting in the generation of 660,000 metric tons of waste. Considering the rich dietary fiber, antioxidants, and phenolic compounds content of this residue, it has great potential to be used as feedstock for a waste-biorefinery. In order to have an efficient high-yielding conversion, a detailed understanding of pistachio residues characteristics is necessary. However, based on little information available on pistachio residues content and available state-of-the-art conversion processes, it can be predicted that pistachio residues can become a key player in providing antioxidants, phytochemicals, activated carbon, and biofuels. More detailed studies on the applications and processing of pistachio residues, on the other hand, are needed to demonstrate its potential and provide sufficient knowledge and feedback on the development of industrial-scale processes on a pistachio processing waste platform.

Although the potential for optimising the bioconversion of pistachio residues as lignocellulose biomass has been demonstrated in a few available literatures, further research into biological processes such as fermentation has yet to be conducted. Also, it can necessarily require pretreatment methods for improved digestibility. Therefore, further research into pretreatment methods is essential in order to evaluate more cost-effective options that lead to higher product yield and lower overall costs.

Conclusion

Pistachio residues and by-products such as dehulling waste or shells contain a significant amount of valuable chemical compounds and nutrients. Due to the high content of phenolic compounds and extractive in pistachio waste, production of antioxidant and other human health benefiting from such waste stream has attracted great research and industrial attention. Pistachio waste has great potential to be used as feedstock in biorefineries for the production of other value-added products such as biofuels, bio-oil, carbon active, and novel products such as edible fungal biomass and volatile fatty acids. Thermochemical, physicochemical, and biological valorization approaches have been considered in this regard. Although all applied pistachio waste management practices and products have certain degree of feasibility and appeal, considering the trade off between the advantages and shortcomings, novel products such as antioxidant and single-cell proteins have the potential to be further explored. Generally, the valorization of such an organic-rich resource, which is commonly regarded as an agricultural waste, will be a prizing resource recovery strategy not only to manage waste but also to create value. However, pistachio waste valorization methods practiced until the present are limited, leaving the field open for extended future research.

References

Papers of particular interest, published recently, have been highlighted as: • Of importance •• Of major importance

Bailey HM, Stein HH. Raw and roasted pistachio nuts (Pistacia vera L.) are ‘good’ sources of protein based on their digestible indispensable amino acid score as determined in pigs. Sci Food Agric. 2020.

Dreher ML. Pistachio nuts: composition and potential health benefits. Nutr Rev. 2012;70(4):234–40. https://doi.org/10.1111/j.1753-4887.2011.00467.x.

Nadimi AE, Ahmadi Z, Falahati-pour SK, Mohamadi M, Nazari A, Hassanshahi G, et al. Physicochemical properties and health benefits of pistachio nuts. Int J Vitam Nutr Res. 2020;90(5–6):564–74. https://doi.org/10.1024/0300-9831/a000529.

Noguera-Artiaga L, Pérez-López D, Burgos-Hernández A, Wojdyło A, Carbonell-Barrachina ÁA. Phenolic and triterpenoid composition and inhibition of α-amylase of pistachio kernels (Pistacia vera L.) as affected by rootstock and irrigation treatment. Food Chem. 2018;261:240–5. https://doi.org/10.1016/j.foodchem.2018.04.033.

Tridge: https://www.tridge.com/ (2021). Accessed 2021.

IPA: www.iranpistachio.org (2021). Accessed 2021.

APG: www.americanpistachios.org (2020). Accessed 2021.

Tridge: Tridge. https://www.tridge.com/ (2021). Accessed 5 January 2021.

Erşan S, Güçlü Üstündağ Ö, Carle R, Schweiggert RM. Identification of phenolic compounds in red and green pistachio (Pistacia vera L.) hulls (Exo- and Mesocarp) by HPLC-DAD-ESI-(HR)-MSn. J Agric Food Chem. 2016;64(26):5334–44. https://doi.org/10.1021/acs.jafc.6b01745.

Alkhtib A, Wamatu J, Kaysi Y, Mona M, Rischkowsky B. Pistachio (Pistacia vera) By-products as ruminant feed:a review on production, management and utiliztion in arid and semi-arid areas in the Middle East. J Exp Biol Agric Sci. 2017;5(6).

• Hokmabadi H. Pistachio Wastes in Iran and the Potential to Recapture them in Value Chain. Pistachio Health J. 2018;1(4):1–12. https://doi.org/10.22123/phj.2019.151263.1018. This article described value-added products which can be obtained from pistachio wastes.

Koul B, Yakoob M, Shah MP. Agricultural waste management strategies for environmental sustainability. Environ Res. 2022;206: 112285. https://doi.org/10.1016/j.envres.2021.112285.

Fermanelli CS, Chiappori A, Pierella LB, Saux C. Towards biowastes valorization: peanut shell as resource for quality chemicals and activated biochar production. Sust Environ Res. 2022;32(1):3. https://doi.org/10.1186/s42834-021-00112-9.

Lerdlattaporn R, Phalakornkule C, Trakulvichean S, Songkasiri W. Implementing circular economy concept by converting cassava pulp and wastewater to biogas for sustainable production in starch industry. Sust Environ Res. 2021;31(1):20. https://doi.org/10.1186/s42834-021-00093-9.

Viaggi D. Agricultural waste management and valorisation in the context of the circular bioeconomy: exploring the potential of biomass value webs. Curr Opin Environ Sci Health. 2022;27:100356. https://doi.org/10.1016/j.coesh.2022.100356

Hingsamer M, Jungmeier G. Chapter Five - Biorefineries. In: Lago C, Caldés N, Lechón Y, editors. The role of bioenergy in the bioeconomy. Academic Press; 2019. p. 179–222.

Liu S, Abrahamson LP, Scott GM. Biorefinery: ensuring biomass as a sustainable renewable source of chemicals, materials, and energy. Biomass Bioenerg. 2012;39:1–4. https://doi.org/10.1016/j.biombioe.2010.12.042.

Romaní A, Rocha CMR, Michelin M, Domingues L, Teixeira JA. Chapter 20 - Valorization of lignocellulosic-based wastes. In: Varjani S, Pandey A, Gnansounou E, Khanal SK, Raveendran S, editors. Current Developments in Biotechnology and Bioengineering. Elsevier; 2020. p. 383–410.

Rao P, Rathod V. Valorization of food and agricultural waste: a step towards greener future. Chem Rec. 2019;19(9):1858–71. https://doi.org/10.1002/tcr.201800094.

•• Ferreira JA, Mahboubi A, Lennartsson PR, Taherzadeh MJ. Waste biorefineries using filamentous ascomycetes fungi: present status and future prospects. Biores Technol. 2016;215:334–45. https://doi.org/10.1016/j.biortech.2016.03.018. This article shows capabilities of filamentous fungi in growing on various residualsand production of organic acids, ethanol, pigments, etc.

Taherzadeh M, Karimi K. Pretreatment of lignocellulosic wastes to improve ethanol and biogas production: a review. Int J Mol Sci. 2008;9:1621–51. https://doi.org/10.3390/ijms9091621.

Şahan A, Bozkurt H. Effects of harvesting time and irrigation on aroma active compounds and quality parameters of pistachio. Sci Hortic. 2020;261: 108905. https://doi.org/10.1016/j.scienta.2019.108905.

Omid M, Mahmoudi A, Omid M. An intelligent system for sorting pistachio nut varieties. Expert Syst Appl. 2009;36:11528–35. https://doi.org/10.1016/j.eswa.2009.03.040.

Whitehouse WE. The pistachio nut a new crop for the Western United States. Econ Bot. 2008;11:281–321.

Bloch F, John EB. Processing of pistachio nuts. Econ Bot. 1960;14(2):129–44.

Oladzad S, Fallah N, Mahboubi A, Afsham N, Taherzadeh MJ. Date fruit processing waste and approaches to its valorization: a review. Biores Technol. 2021;340: 125625. https://doi.org/10.1016/j.biortech.2021.125625.

Salvador MD, Ojeda-Amador RM, Fregapane G. Chapter 30 - Pistachio nut, its virgin oil, and their antioxidant and bioactive activities. In: Preedy VR, editor. Pathology. Academic Press; 2020. p. 309–20.

Kiumarsi A. Pistachio hulls, a new source of fruit waste for wool dyeing. J Text Sci Eng. 2015;05. https://doi.org/10.4172/2165-8064.1000185.

Bohluli A, Naserian A, Valizadeh R. The chemical composition and ruminal disappearance of pistachio by-product. Proc British Soc An Sci. 2007;2007:224-. https://doi.org/10.1017/S175275620002127X.

Boğa M, Güven İ, Atalay Ai̇, Kaya E. Effect of varieties on potential nutritive value of pistachio hulls. Kafkas Universitesi Veteriner Fakültesi Dergisi. 2013;19(4):699–703.

Bagheripour E, Rouzbehan Y, Alipour D. Chemical composition and digestibility of ensiled pistachio by-products. XVI. 2012:238.

• Elakremi M, Sillero L, Ayed L, Labidi J, Moussaoui Y. Chemical composition of leaves and hull from Pistacia Vera L. an evaluation of phenolic content and antioxidant properties of their extracts. 2020. (This article described the suitability of pistachio dehulling wastes as a source of biorenewable compounds, a chemical characterization of these wastes has been carried out, as well as the analysis of their extractives.)

Taghizadeh-Alisaraei A, Assar HA, Ghobadian B, Motevali A. Potential of biofuel production from pistachio waste in Iran. Renew Sustain Energy Rev. 2017;72:510–22. https://doi.org/10.1016/j.rser.2017.01.111.

Daneshmandi S. Application of pistachio waste as organic manure in sustainable agriculture. Sustainable Agriculture and Production Science. 2017;27:217–26.

Rezende ESV, Lima GC, Naves MMV. Dietary fibers as beneficial microbiota modulators: a proposed classification by prebiotic categories. Nutrition. 2021;89: 111217. https://doi.org/10.1016/j.nut.2021.111217.

Meenakshisundaram S, Fayeulle A, Leonard E, Ceballos C, Pauss A. Fiber degradation and carbohydrate production by combined biological and chemical/physicochemical pretreatment methods of lignocellulosic biomass – a review. Biores Technol. 2021;331: 125053. https://doi.org/10.1016/j.biortech.2021.125053.

Kover A, Kraljić D, Marinaro R, Rene ER. Processes for the valorization of food and agricultural wastes to value-added products: recent practices and perspectives. Systems Microbiology and Biomanufacturing. 2021. https://doi.org/10.1007/s43393-021-00042-y.

Haq Iu, Qaisar K, Nawaz A, Akram F, Mukhtar H, Zohu X, et al. Advances in valorization of lignocellulosic biomass towards energy generation. Catalysts. 2021;11(3):309.

Çelik İ, Demirer GN. Biogas production from pistachio (Pistacia vera L.) processing waste. Biocatal Agric Biotechnol. 2015;4(4):767–72. doi: https://doi.org/10.1016/j.bcab.2015.10.009.

Jalili M, Mokhtari M, Eslami H, Abbasi F, Ghanbari R, Ebrahimi AA. Toxicity evaluation and management of co-composting pistachio wastes combined with cattle manure and municipal sewage sludge. Ecotoxicol Environ Saf. 2019;171:798–804.

Doula M, Elaiopoulos K, Kouloumbis P, Zorpas A. In situ application of clinoptilolite to improve compost quality produced from pistachio bio-wastes. Fresenius Environ Bull. 2018;27:1312.

Malakootian M, Mobini M, Nekoonam GA. Evaluation of the compost produced from mixed sludge of municipal wastewater treatment plant and pistachio hull waste. Journal of Mazandaran University of Medical Sciences. 2014;24(116):172–83.

Paydaș E, Savrunlu Z, Savrunlu M, Denek N. Investigation of effect on silage quality and in vitro methane gas formation of pistachio (Pistacia vera L.) outer shell with additional at different levels in corn silage. Erciyes Üniversitesi Veteriner Fakültesi Dergisi. 2019;16(1):16–22.

Beidokhti MZ, Naeeni STO, AbdiGhahroudi MS. Biosorption of nickel (II) from aqueous solutions onto pistachio hull waste as a low-cost biosorbent. Civil Engineering Journal. 2019;5(2):447–57.

Moussavi G, Khosravi R. The removal of cationic dyes from aqueous solutions by adsorption onto pistachio hull waste. Chem Eng Res Des. 2011;89(10):2182–9.

Elhadef K, Akermi S, Ben Hlima H, Ennouri K, Fourati M, Ben Braïek O, et al. Tunisian pistachio hull extracts: phytochemical content, antioxidant activity, and foodborne pathogen inhibition. J Food Qual 2021;2021.

Apaydın-Varol E, Putun E, Putun A. Slow pyrolysis of pistachio shell. Fuel. 2007;86. https://doi.org/10.1016/j.fuel.2006.11.041.

Foo K, Hameed B. Preparation and characterization of activated carbon from pistachio nut shells via microwave-induced chemical activation. Biomass Bioenerg. 2011;35(7):3257–61.

Zweigle CA. Pistachio byproducts as substrate for shiitake mushrooms. Fresno: California State University; 2010.

Paydaș E, Savrunlu Z, Savrunlu M, Denek N. Investigation of effect on silage quality and in vitro methane gas formation of pistachio (Pistacia vera L.) outer shell with additional at different levels in corn silage. Erciyes Üniversitesi Veteriner Fakültesi Dergisi 2019;16:16–22.

Alkhtib A, Wamatu J, Kaysi Y, Mona M, Rischkowsky B. Pistachio (Pistacia vera) by-products as ruminant feed: a review of production, management and utilization in arid and semi-arid areas in the Middle East. Journal of Experimental Biology and Agricultural Sciences. 2017;5:718–29. https://doi.org/10.18006/2017.5(6).718.729.

Mokhtarpour A, Naserian AA, Valizadeh R, Mesgaran MD, Pourmollae F. Extraction of phenolic compounds and tannins from pistachio by-products. Ann Res Rev Biol. 2014:1330–8.

Noorolahi Z, Sahari MA, Barzegar M, Ahmadi GH. Tannin fraction of pistachio green hull extract with pancreatic lipase inhibitory and antioxidant activity. J Food Biochem. 2020;44(6): e13208. https://doi.org/10.1111/jfbc.13208.

Sadeghinejad N, Amini Sarteshnizi R, Ahmadi Gavlighi H, Barzegar M. Pistachio green hull extract as a natural antioxidant in beef patties: effect on lipid and protein oxidation, color deterioration, and microbial stability during chilled storage. LWT. 2019;102:393–402. https://doi.org/10.1016/j.lwt.2018.12.060.

Lalegani S, Ahmadi Gavlighi H, Azizi MH, Amini SR. Inhibitory activity of phenolic-rich pistachio green hull extract-enriched pasta on key type 2 diabetes relevant enzymes and glycemic index. Food Res Int. 2018;105:94–101. https://doi.org/10.1016/j.foodres.2017.11.003.

Sila A, Bayar N, Ghazala I, Bougatef A, Ellouz-Ghorbel R, Ellouz-Chaabouni S. Water-soluble polysaccharides from agro-industrial by-products: functional and biological properties. Int J Biol Macromol. 2014;69:236–43. https://doi.org/10.1016/j.ijbiomac.2014.05.052.

Rajaei A, Barzegar M, Mobarez A, Mohabati, Ali M, Esfahani ZH. Antioxidant, anti-microbial and antimutagenicity activities of pistachio (Pistachia vera) green hull extract. Food Chem Toxicol. 2010;48(1):107–12. https://doi.org/10.1016/j.fct.2009.09.023.

Goli AH, Barzegar M, Sahari MA. Antioxidant activity and total phenolic compounds of pistachio (Pistachia vera) hull extracts. Food Chem. 2005;92(3):521–5. https://doi.org/10.1016/j.foodchem.2004.08.020.

Tomaino A, Martorana M, Arcoraci T, Monteleone D, Giovinazzo C, Saija A. Antioxidant activity and phenolic profile of pistachio (Pistacia vera L., variety Bronte) seeds and skins. Biochimie. 2010;92(9):1115–22. https://doi.org/10.1016/j.biochi.2010.03.027.

Hasheminya S-M, Dehghannya J. Composition, phenolic content, antioxidant and antimicrobial activity of Pistacia atlantica subsp. kurdica hulls’ essential oil. Food Biosci. 2020;34:100510. https://doi.org/10.1016/j.fbio.2019.100510.

Taghizadeh SF, Davarynejad G, Asili J, Riahi-Zanjani B, Nemati SH, Karimi G. Chemical composition, antibacterial, antioxidant and cytotoxic evaluation of the essential oil from pistachio (Pistacia khinjuk) hull. Microb Pathog. 2018;124:76–81. https://doi.org/10.1016/j.micpath.2018.08.039.

Smeriglio A, Denaro M, Barreca D, Calderaro A, Bisignano C, Ginestra G, et al. In vitro evaluation of the antioxidant, cytoprotective, and antimicrobial properties of essential oil from Pistacia vera L. variety bronte hull. Int J Mol Sci. 2017;18(6):1212.

Chahed T, Dhifi W, Hosni K, Msaada K, Kchouk ME, Marzouk B. Composition of Tunisian pistachio hull essential oil during fruit formation and ripening. J Essent Oil Res. 2008;20(2):122–5. https://doi.org/10.1080/10412905.2008.9699971.

Chahed T, Dhifi W, Hamrouni I, Msaada K, Bellila A, Kchouk ME, et al. Comparison of pistachio hull essential oils from different Tunisian localities. Ital J Biochem. 2007;56(1):35–9.

Sonmezdag AS, Kelebek H, Selli S. Characterization and comparative evaluation of volatile, phenolic and antioxidant properties of pistachio (Pistacia vera L.) hull. J Essent Oil Res. 2017;29(3):262–70. https://doi.org/10.1080/10412905.2016.1216899.

Kazemi M, Khodaiyan F, Labbafi M, Saeid Hosseini S, Hojjati M. Pistachio green hull pectin: Optimization of microwave-assisted extraction and evaluation of its physicochemical, structural and functional properties. Food Chem. 2019;271:663–72. https://doi.org/10.1016/j.foodchem.2018.07.212.

Chaharbaghi E, Khodaiyan F, Hosseini SS. Optimization of pectin extraction from pistachio green hull as a new source. Carbohyd Polym. 2017;173:107–13. https://doi.org/10.1016/j.carbpol.2017.05.047.

Kulkarni SG, Vijayanand P. Effect of extraction conditions on the quality characteristics of pectin from passion fruit peel (Passiflora edulis f. flavicarpa L.). LWT - Food Sci Technol. 2010;43(7):1026–31. https://doi.org/10.1016/j.lwt.2009.11.006.

Wang S, Chen F, Wu J, Wang Z, Liao X, Hu X. Optimization of pectin extraction assisted by microwave from apple pomace using response surface methodology. J Food Eng. 2007;78(2):693–700. https://doi.org/10.1016/j.jfoodeng.2005.11.008.

Ngo TNLT, Chiang K-Y. Co-thermal degradation characteristics of rice straw and sewage sludge. Sustainable Environment Research. 2021;31(1):23. https://doi.org/10.1186/s42834-021-00096-6.

Ghosh P, Sengupta S, Singh L, Sahay A. Chapter 8 - Life cycle assessment of waste-to-bioenergy processes: a review. In: Singh L, Yousuf A, Mahapatra DM, editors. Bioreactors. Elsevier; 2020. p. 105–22.

Singh V, Das D. Chapter 3 - Potential of hydrogen production from biomass. In: de Miranda PEV, editor. Science and Engineering of Hydrogen-Based Energy Technologies. Academic Press; 2019. p. 123–64.

Neto JM, Komesu A, da Silva Martins LH, Gonçalves VOO, de Oliveira JAR, Rai M. Chapter 10 - Third generation biofuels: an overview. In: Rai M, Ingle AP, editors. Sustainable Bioenergy. Elsevier; 2019. p. 283–98.

Basu P. Chapter 5 - Pyrolysis. In: Basu P, editor. Biomass gasification, pyrolysis and torrefaction (Third Edition). Academic Press; 2018. p. 155–87.

Okutucu C, Duman G, Ucar S, Yasa I, Yanik J. Production of fungicidal oil and activated carbon from pistachio shell. J Anal Appl Pyrol. 2011;91(1):140–6. https://doi.org/10.1016/j.jaap.2011.02.002.

Uysal T, Duman G, Onal Y, Yasa I, Yanik J. Production of activated carbon and fungicidal oil from peach stone by two-stage process. J Anal Appl Pyrol. 2014;108:47–55. https://doi.org/10.1016/j.jaap.2014.05.017.

Yang T, Lua AC. Characteristics of activated carbons prepared from pistachio-nut shells by physical activation. J Colloid Interface Sci. 2003;267(2):408–17. https://doi.org/10.1016/S0021-9797(03)00689-1.

Alfattani R, Shah M, Siddiqui M, Ashraf M, Alnaser I. Bio-char characterization produced from walnut shell biomass through slow pyrolysis: sustainable for soil amendment and an alternate bio-fuel. Energies. 2021;15:1. https://doi.org/10.3390/en15010001.

Zhao C, Liu X, Chen A, Chen J, Lv W, Liu X. Characteristics evaluation of bio-char produced by pyrolysis from waste hazelnut shell at various temperatures. Energy Sources A: Recovery Util Environ Eff. 2020:1–11. https://doi.org/10.1080/15567036.2020.1754530.

Jalayeri H, Pepe F. Novel and high-performance biochar derived from pistachio green hull biomass: Production, characterization, and application to Cu(II) removal from aqueous solutions. Ecotoxicol Environ Saf. 2019;168:64–71. https://doi.org/10.1016/j.ecoenv.2018.10.058.

Karatas H, Akgun F. Experimental results of gasification of walnut shell and pistachio shell in a bubbling fluidized bed gasifier under air and steam atmospheres. Fuel. 2018;214:285–92. https://doi.org/10.1016/j.fuel.2017.10.061.

Peterson AA, Vogel F, Lachance RP, Fröling M, Antal MJ Jr, Tester JW. Thermochemical biofuel production in hydrothermal media: a review of sub-and supercritical water technologies. Energy Environ Sci. 2008;1(1):32–65.

Hongthong S, Raikova S, Leese HS, Chuck CJ. Co-processing of common plastics with pistachio hulls via hydrothermal liquefaction. Waste Manage. 2020;102:351–61. https://doi.org/10.1016/j.wasman.2019.11.003.

Mohammadi M, Ghorbani M, Beigbabaei A, Yeganehzad S, Sadeghi-Mahoonak A. Investigation effects of extracted compounds from shell and cluster of pistachio nut on the inactivation of free radicals. Heliyon. 2019;5(9): e02438. https://doi.org/10.1016/j.heliyon.2019.e02438.

Garavand F, Madadlou A, Moini S. Determination of phenolic profile and antioxidant activity of pistachio hull using high-performance liquid chromatography–diode array detector–electro-spray ionization–mass spectrometry as affected by ultrasound and microwave. Int J Food Prop. 2017;20(1):19–29. https://doi.org/10.1080/10942912.2015.1099045.

Zygler A, Słomińska M, Namieśnik J. 2.04 - Soxhlet Extraction and New Developments Such as Soxtec. In: Pawliszyn J, editor. Comprehensive sampling and sample preparation. Oxford: Academic Press. 2012. p. 65–82.

Routray W, Orsat V. Microwave-assisted extraction of flavonoids: a review. Food Bioprocess Technol. 2012;5(2):409–24. https://doi.org/10.1007/s11947-011-0573-z.

De Castro ML, Garcıa-Ayuso L. Soxhlet extraction of solid materials: an outdated technique with a promising innovative future. Anal Chim Acta. 1998;369(1–2):1–10.

Soural I, Vrchotová N, Tříska J, Balík J, Horník Š, Cuřínová P, et al. Various extraction methods for obtaining stilbenes from grape cane of Vitis vinifera L. molecules. 2015;20(4):6093–112.

Segneanu A-E, Cziple F, Vlazan P, Sfirloaga P, Grozescu I, Gherman VD. Biomass extraction methods. Biomass now-sustainable growth and use. 2013:390–9.

Sonar MP, Rathod VK. Microwave assisted extraction (MAE) used as a tool for rapid extraction of Marmelosin from Aegle marmelos and evaluations of total phenolic and flavonoids content, antioxidant and anti-inflammatory activity. Chemical Data Collections. 2020;30:100545. https://doi.org/10.1016/j.cdc.2020.100545.

Belwal T, Pandey A, Bhatt ID, Rawal RS. Optimized microwave assisted extraction (MAE) of alkaloids and polyphenols from Berberis roots using multiple-component analysis. Sci Rep. 2020;10(1):917. https://doi.org/10.1038/s41598-020-57585-8.

Özbek H, Yanık DK, Fadıloğlu S, Çavdar HK, Göğüş F. Microwave-assisted extraction of non-polar compounds from pistachio hull and characterization of extracts. Grasas y Aceites. 2018;69(3):e260-e.

Özbek HN, Yanık DK, Fadıloğlu S, Göğüş F. Optimization of microwave-assisted extraction of bioactive compounds from pistachio (Pistacia vera L.) hull. Sep Sci Technol. 2020;55(2):289–99. https://doi.org/10.1080/01496395.2019.1577444.

Cardullo N, Leanza M, Muccilli V, Tringali C. Valorization of agri-food waste from pistachio hard shells: extraction of polyphenols as natural antioxidants. Resources. 2021;10(5):45.

Pan G, Yu G, Zhu C, Qiao J. Optimization of ultrasound-assisted extraction (UAE) of flavonoids compounds (FC) from hawthorn seed (HS). Ultrason Sonochem. 2012;19(3):486–90. https://doi.org/10.1016/j.ultsonch.2011.11.006.

Vilkhu K, Mawson R, Simons L, Bates D. Applications and opportunities for ultrasound assisted extraction in the food industry — a review. Innov Food Sci Emerg Technol. 2008;9(2):161–9. https://doi.org/10.1016/j.ifset.2007.04.014.

Mokhtarpour A, Naserian AA, Valizadeh R, Mesgaran MD, Pourmollae F. Extraction of phenolic compounds and tannins from pistachio by-products. Annual Research & Review in Biology. 2014;4(8):1330–8. https://doi.org/10.9734/ARRB/2014/7793.

Freitas PA, González-Martínez C, Chiralt A. Application of ultrasound pre-treatment for enhancing extraction of bioactive compounds from rice straw. Foods. 2020;9(11):1657.

Arjeh E, Akhavan H-R, Barzegar M, Carbonell-Barrachina ÁA. Bio-active compounds and functional properties of pistachio hull: a review. Trends Food Sci Technol. 2020;97:55–64. https://doi.org/10.1016/j.tifs.2019.12.031.

Song B, Lin R, Lam CH, Wu H, Tsui T-H, Yu Y. Recent advances and challenges of inter-disciplinary biomass valorization by integrating hydrothermal and biological techniques. Renew Sustain Energy Rev. 2021;135: 110370. https://doi.org/10.1016/j.rser.2020.110370.

• Chen Z, Wan C. Biological valorization strategies for converting lignin into fuels and chemicals. Renew Sust Energy Rev. 2017;73:610–21. https://doi.org/10.1016/j.rser.2017.01.166. This review focuses on the studies concerning biological conversion of lignin by bacteria, fungi and enzymes into value-added products.

Mao C, Feng Y, Wang X, Ren G. Review on research achievements of biogas from anaerobic digestion. Renew Sustain Energy Rev. 2015;45:540–55.

Gopal PM, Sivaram NM, Barik D. Chapter 7 - Paper industry wastes and energy generation from wastes. In: Barik D, editor. Energy from Toxic Organic Waste for Heat and Power Generation. Woodhead Publishing; 2019. p. 83–97.

•• Gao M, Wang D, Wang Y, Wang X, Feng Y. Opportunities and challenges for biogas development: a review in 2013–2018. Curr Pollut Rep. 2019;5(2):25–35. https://doi.org/10.1007/s40726-019-00106-7. This study focus on the dynamic changes in the past 5 years, and the purpose is to provide reference for future biogas development.

Xu F, Khalaf A, Sheets J, Ge X, Keener H, Li Y. Chapter Three - Phosphorus removal and recovery from anaerobic digestion residues. In: Li Y, Ge X, editors. Advances in Bioenergy. Elsevier; 2018. p. 77–136.

Qi C, Yin R, Gao X, Chen J, Wang R, Xu Z, et al. Development of solid-state anaerobic digestion and aerobic composting hybrid processes for organic solid waste treatment and resource recovery: a review. Curr Pollut Rep. 2022;8(3):221–33. https://doi.org/10.1007/s40726-022-00223-w.

Demirer GN. Biogas production from pistachio (Pistaciavera L.) de-hulling waste. Int J Green Energy. 2016;13(13):1320–4. https://doi.org/10.1080/15435075.2016.1206001.

Baetge S, Kaltschmitt M. Rice straw and rice husks as energy sources—comparison of direct combustion and biogas production. Biomass Convers Biorefin. 2018;8(3):719–37. https://doi.org/10.1007/s13399-018-0321-y.

Xi Y, Liu Y, Ye X, Du J, Kong X, Guo D, et al. Enhanced anaerobic biogas production from wheat straw by herbal-extraction process residues supplementation. Front Bioeng Biotechnol. 2021;9. https://doi.org/10.3389/fbioe.2021.623594.

Göncü B, Gülşen H, Hoşgün EZ. Bioethanol production from pistachio (pistacia vera L.) shells applying ozone pretreatment and subsequent enzymatic hydrolysis. Environ Technol. 2021;42(15):2438–46. https://doi.org/10.1080/09593330.2021.1903565.

Poddar BJ, Nakhate SP, Gupta RK, Chavan AR, Singh AK, Khardenavis AA, et al. A comprehensive review on the pretreatment of lignocellulosic wastes for improved biogas production by anaerobic digestion. Int J Environ Sci Technol. 2021. https://doi.org/10.1007/s13762-021-03248-8.

Batista Meneses D, Montes de Oca-Vásquez G, Vega-Baudrit JR, Rojas-Álvarez M, Corrales-Castillo J, Murillo-Araya LC. Pretreatment methods of lignocellulosic wastes into value-added products: recent advances and possibilities. Biomass Convers Biorefin. 2020. https://doi.org/10.1007/s13399-020-00722-0.

Kumari D, Singh R. Pretreatment of lignocellulosic wastes for biofuel production: A critical review. Renew Sustain Energy Rev. 2018;90:877–91. https://doi.org/10.1016/j.rser.2018.03.111.

Senatore A, Corrente GA, Verteramo F, Dalena F. 2 - An overview on pretreatment processes for an effective conversion of lignocellulosic biomass into bioethanol. In: Rahimpour MR, Kamali R, Amin Makarem M, Manshadi MKD, editors. Advances in Bioenergy and Microfluidic Applications. Elsevier; 2021. p. 41–68.

Norrrahim MNF, Ilyas RA, Nurazzi NM, Rani MSA, Atikah MSN, Shazleen SS. Chemical pretreatment of lignocellulosic biomass for the production of bioproducts: an overview. Appl Sci Eng Prog. 2021;13:2971.

Kumari D, Jain Y. Enhanced biofuel production from lignocellulosic biomass: an overview of advanced physico-chemical and biological technologies. In: Verma P, editor. Biorefineries: A Step Towards Renewable and Clean Energy. Singapore: Springer Singapore; 2020. p. 151–72.

Liew YX, Chan YJ, Manickam S, Chong MF, Chong S, Tiong TJ, et al. Enzymatic pretreatment to enhance anaerobic bioconversion of high strength wastewater to biogas: a review. Sci Total Environ. 2020;713: 136373.

Pandey A. Recent process developments in solid-state fermentation. Process Biochem. 1992;27(2):109–17. https://doi.org/10.1016/0032-9592(92)80017-W.

Karimi E, Ehsan Oskoueian , Rudi Hendra, HZE J. Solid state fermentation effects on pistachio hulls antioxidant activities. Asia-Pac J Sci Technol (APST). 2010;15.

Abbasi S, Mehranian M, Vahabzadeh F. profile of phenolics and antioxidant activity of pistachio hulls during solid-state fermentation by phanerochaete chrysosporium- involvement of lignin peroxidase and manganese peroxidase. Sci Iran. 2007;14(4).

da Conceição Gomes A, Rodrigues MI, de França Passos D, Machado de Castro A, Maria Mello Santa Anna L, Pereira N. Acetone–butanol–ethanol fermentation from sugarcane bagasse hydrolysates: Utilization of C5 and C6 sugars. Electron J Biotechnol. 2019;42:16–22. https://doi.org/10.1016/j.ejbt.2019.10.004.

Sawatdeenarunat C, Sung S, Khanal SK. Enhanced volatile fatty acids production during anaerobic digestion of lignocellulosic biomass via micro-oxygenation. Biores Technol. 2017;237:139–45. https://doi.org/10.1016/j.biortech.2017.02.029.

Yadav M, Paritosh K, Vivekanand V. Lignocellulose to bio-hydrogen: an overview on recent developments. Int J Hydrogen Energy. 2020;45(36):18195–210. https://doi.org/10.1016/j.ijhydene.2019.10.027.

Gmoser R, Sintca C, Taherzadeh MJ, Lennartsson PR. Combining submerged and solid state fermentation to convert waste bread into protein and pigment using the edible filamentous fungus N. intermedia. Waste Manag. 2019;97:63–70. https://doi.org/10.1016/j.wasman.2019.07.039.

Uwineza C, Mahboubi A, Atmowidjojo A, Ramadhani A, Wainaina S, Millati R, et al. Cultivation of edible filamentous fungus Aspergillus oryzae on volatile fatty acids derived from anaerobic digestion of food waste and cow manure. Biores Technol. 2021;337:125410. https://doi.org/10.1016/j.biortech.2021.125410.

Mahboubi A, Ferreira JA, Taherzadeh MJ, Lennartsson PR. Value-added products from dairy waste using edible fungi. Waste Manage. 2017;59:518–25. https://doi.org/10.1016/j.wasman.2016.11.017.

•• Ferreira JA, Mahboubi A, Lennartsson PR, Taherzadeh MJ. Waste biorefineries using filamentous ascomycetes fungi: present status and future prospects. Bioresour Technol. 2016;215:334–45. https://doi.org/10.1016/j.biortech.2016.03.018. This study described the potential of the ascomycetes for production of organic acids, ethanol, cellulases, and xylanases.

Karimi S, Mahboobi Soofiani N, Lundh T, Mahboubi A, Kiessling A, Taherzadeh MJ. Evaluation of filamentous fungal biomass cultivated on vinasse as an alternative nutrient source of fish feed: protein, lipid, and mineral composition. Fermentation. 2019;5(4):99.

Barr MR, Forster L, D’Agostino C, Volpe R. Alkaline pretreatment of walnut shells increases pore surface hydrophilicity of derived biochars. Appl Surf Sci. 2022;571: 151253. https://doi.org/10.1016/j.apsusc.2021.151253.

M’Arimi MM, Mecha CA, Kiprop AK, Ramkat R. Recent trends in applications of advanced oxidation processes (AOPs) in bioenergy production: review. Renew Sustain Energy Rev. 2020;121: 109669. https://doi.org/10.1016/j.rser.2019.109669.

Martín C, Peinemann JC, Wei M, Stagge S, Xiong S, Jönsson LJ. Dilute-sulfuric acid pretreatment of de-starched cassava stems for enhancing the enzymatic convertibility and total glucan recovery. Ind Crops Prod. 2019;132:301–10. https://doi.org/10.1016/j.indcrop.2019.02.037.

Sindhu R, Binod P, Pandey A. Biological pretreatment of lignocellulosic biomass–an overview. Biores Technol. 2016;199:76–82.

Arato C, Pye EK, Gjennestad G. The lignol approach to biorefining of woody biomass to produce ethanol and chemicals. Appl Biochem Biotechnol. 2005;123(1):871–82. https://doi.org/10.1385/ABAB:123:1-3:0871.

Amran MA, Palaniveloo K, Fauzi R, Satar NM, Mohidin TBM, Mohan G, et al. Value-added metabolites from agricultural waste and application of green extraction techniques. Sustainability. 2021;13(20):11432.

Jha S, Nanda S, Acharya B, Dalai AK. A review of thermochemical conversion of waste biomass to biofuels. Energies. 2022;15(17):6352.

Nayak A, Bhushan B. An overview of the recent trends on the waste valorization techniques for food wastes. J Environ Manage. 2019;233:352–70. https://doi.org/10.1016/j.jenvman.2018.12.041.

Santolini E, Bovo M, Barbaresi A, Torreggiani D, Tassinari P. Turning agricultural wastes into biomaterials: assessing the sustainability of scenarios of circular valorization of corn cob in a life-cycle perspective. Appl Sci. 2021;11(14):6281.

Stąsiek J, Szkodo M. Thermochemical conversion of biomass and municipal waste into useful energy using advanced HiTAG/HiTSG technology. Energies. 2020;13(16):4218.

Walling E, Babin A, Vaneeckhaute C. Nutrient and carbon recovery from organic wastes. In: Bastidas-Oyanedel J-R, Schmidt JE, editors. Biorefinery: Integrated Sustainable Processes for Biomass Conversion to Biomaterials, Biofuels, and Fertilizers. Cham: Springer International Publishing; 2019. p. 351–73.

Bello S, Ríos C, Feijoo G, Moreira MT. Comparative evaluation of lignocellulosic biorefinery scenarios under a life-cycle assessment approach. Biofuels, Bioprod Biorefin. 2018;12(6):1047–64. https://doi.org/10.1002/bbb.1921.

Acknowledgements

The authors would like to express their gratitude to the Swedish Agency for Economic and Regional Growth (Tillväxtverket) through a European Regional Development Fund for providing financial support for this review paper.

Funding

Open access funding provided by University of Boras.

Author information

Authors and Affiliations

Contributions

J.T. wrote the main manuscript, A.M., N.F., M.T., N.A. and B.N. have reviewed, edited and revised the manuscript.

Corresponding author

Ethics declarations

Ethics Approval

The authors also certify that there are no ethical issues involved.

Conflict of Interest

The authors declare that there are no conflicts of interest.

Human and Animal Right and Informed Consent

In the current review no animal or human testing has been conducted. The information presented in this review present ways to reduce and manage organic waste to reduce human and animal health risks.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This article is part of the Topical Collection on Biology and Pollution

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Toghiani, J., Fallah, N., Nasernejad, B. et al. Sustainable Pistachio Dehulling Waste Management and Its Valorization Approaches: A Review. Curr Pollution Rep 9, 60–72 (2023). https://doi.org/10.1007/s40726-022-00240-9

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40726-022-00240-9