Abstract

Purpose of the Review

The aim of the review was to better understand the impacts of the dominant harvesting systems in Europe, namely harvester-forwarder (HFW), chainsaw-skidder (CSK), and chainsaw-cable yarder (CCY). Furthermore, we aimed to learn how the impact categories environment, economy, ergonomics, people and society, and quality optimization are related to the European biogeographical regions Boreal, Continental, Alpine, and Mediterranean forests. Based on this, key drivers for the future development of forest operations were identified. It was specifically not the aim to develop models through the outcome of this study.

Recent Findings

HFW harvesting systems dominate in Boreal (99%) and Continental forests (72%). In Alpine forests the most relevant, even when not dominant, harvesting system is CCY (47%). CSK harvesting systems are applied in all biogeographical regions, with a focus on Mediterranean (70%), Alpine (50%) and Continental (22%) forests. Major drivers for harvesting system development were identified: (i) increased environmental constraints, (ii) increased complexity of harvesting caused by an increasing area of mixed-forest stands, (iii) increased resource efficiency fostered by a growing demand for wood products, (iv) a reduced available work force resulting from heightened competition for skilled worker and an aging population, and (v) more transparent work and material flows through the introduction of digitalization.

Summary

A literature review from 110 journal articles and 975 datasets from four biogeographical regions in Europe, specifically from Estonia, Germany, Spain and Switzerland was performed. Most of the reviewed papers included information about economic or environmental impacts, while ergonomics, quality optimization and societal aspects were less in focus. The impacts from the HFW, CSK and CCY harvesting systems were evaluated against regional conditions. Unfortunately, a common understanding of harvesting system evaluation is missing, which limits the comparability of results between different regions.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

In Europe, several harvesting systems with different degrees of mechanization are available. There are adaptations in forest operations to suit regional conditions and adjustments to meet the acceptance of local people in supplying wood for an emerging bioeconomy. The selection and application of a harvesting system depends on: (i) the site and terrain conditions, (ii) the preferred silvicultural management concepts, (iii) the tree species composition, in particular whether coniferous or deciduous species dominate, (iv) the tree size and correlated log volume, (v) the availability of machinery and working staff, (vi) the expected and accepted environmental impacts, (vii) the calculated costs and the economic conditions of the forest owner, and (viii) the tradition and individual preferences of the forest owner or the interest of the society in a certain region (e.g. citizens visiting the forest for recreation) [1,2,3,4,5,6].

The environmental, social and economic impacts of different harvesting systems have been studied extensively for decades [7]. However, under changing climate conditions and silvicultural management systems, in line with the continuous improvement of forest machinery, a significant transition of forest operation practices is likely but has yet to be described in the literature.

Sustainable supply chains, in the understanding of sustainable forest operations, need to: (i) safeguard environment conditions, (ii) consider operator safety and health, (iii) be economical within its work and wood supply, (iv) consider people’s expectations and acceptance, and (v) deliver the desired log quality and quantity on time [7, 8]. However, operational guidelines and research have focused on economic and environmental perspectives rather than ergonomics or resource efficiency [8]. In particular, the connection between strengthening forest biodiversity through considering forest operations within forest management decisions, forest operators’ role in the digitalization of forest work, and technological developments have rarely been discussed [compare e.g. 8, 9].

Forest operations are often associated with evidence of environmental impacts, such as carbon dioxide (CO2) emissions and soil disturbances of the selected harvesting system, in particular soil compaction caused by ground-based log extraction [9,10,11,12]. Together with the wood transport, these two processes essentially contribute to the carbon balance and costs of a wood product. Forest operations provide timber for people and industry, decent jobs, and income to local people, therefore contributing to the economy of a certain region. The question is how these impacts, which are well characterized by the definition of sustainable forest operations, will change in the near future.

The objective of this study is to compare the current impacts of forest operations in the areas of (i) environment, (ii) ergonomics, (iii) economics, (iv) people and society, and (v) product quality optimization with respect to the Boreal, Continental, Alpine and Mediterranean biogeographical regions (Table 1) based on existing data from the literature. The authors do not aim to provide specific numbers for modelling work productivity or harvesting costs, even when specific numbers are presented. Instead, the work is intended to illustrate differences and similarities between the biogeographical regions and the applied harvesting systems. Following this, drivers that will impact changes in forest operations in the near future are indicated. Based on this review, the authors then provide an outlook on potential or necessary developments of forest operations within the next decade. Developments in silvicultural management, industrial digitalization, and political strategies, such as the European Forest Strategy and the European Green Deal, are considered.

Material and Methods

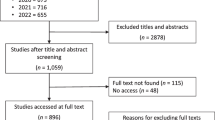

This review is based on a review of publications, reports and secondary literature on currently applied harvesting systems in Europe, as well as on available databases. The open-access web tool CADIMA [13] was used for the literature search and documentation, using the following keywords: forest operations, forest machine performance, harvesting impacts, mechanized thinning, thinning operations, forest work, socio-economic impacts of forest operations, soil-degradation from forest operations, harvesting assortments. The main search language was English, and national languages (German, Polish, Spanish) were only added to include relevant national studies from national forest research institutions that were not internationally published. In total, 1,063 records were identified through the database search, 938 of which were then excluded after the abstracts were checked (Fig. 1). The remaining 125 articles were considered for full-text reading and randomly distributed to the authors of this article. Via CADIMA, 10% of the articles were selected for double-reading from two of the co-authors to ensure the same understanding of the evaluation criteria.

In addition, 45 scientific publications were added based upon the knowledge of the authors, as well as one dataset from the Forest Science and Technology Centre of Catalonia (CTFC), 683 datasets from the Swiss National Forest Inventory (Swiss NFI) [14], and 336 datasets from the German Kuratorium für Waldarbeit und Forsttechnik e.V. (KWF) [15]. From all data sources, performance indicators of a predefined list were collected and processed using spreadsheets in Excel (Microsoft Corp., Redmond, WA, USA). As some of the articles provided more than one type of information, in sum 1,217 datasets were included in the analysis.

The considered literature was allocated to the defined biogeographical regions Boreal, Continental, Alpine and Mediterranean [16,17,18] and covered the case study regions of the ONEforest project. Therefore, the Atlantic biogeographical region was not considered in the analysis. These biogeographical regions were first defined in the framework of the Habitats Directive of the European Community and the Emerald network under the Bern Convention [17]. They were later extended to all European countries, and they are commonly used in the framework of Natura 2000, as well as in continuing scientific research and reporting [17, 18]. In the predefined biogeographical regions, focus countries based on their socio-economic situation were selected (underlined) for the literature research to ensure a more harmonized dataset (Table 1). Literature not referring to the focus countries was excluded from the detailed analysis.

As only some of the data assessed from the articles, Swiss NFI and KWF referred to complete harvesting systems, while most only referred to work activities, harvesting systems were defined based on the given data. All harvesting systems consist of the work activities felling, processing and extraction. Finally, for the purpose of presenting this work and being aware of variations between sources, three major harvesting systems were identified:

-

HFW – Harvester/Forwarder … felling and processing are done by a harvester and logs are extracted to the landing or main road by a forwarder; cut-to-length operations (CTL); fully-mechanized operations;

-

CSK – Chainsaw/Skidder … felling and processing are done with the help of a chainsaw and logs are skidded to the landing or main road by a skidder (grapple and winch assisted), farm tractor or forest tractor; tree-length operations; semi-mechanized operations;

-

CCY – Chainsaw/Cable Yarder … felling is done with the help of a chainsaw and logs are yarded to the landing or main road by a standard or mobile cable yarder or a tower yarder processor; whole tree / tree-length / cut-to-length operations; semi-mechanized operations.

For CCY, the extraction of whole trees, tree lengths or short logs were merged to increase the number of available data, as the authors were aware of differences in work processes and work productivity. Further, no distinction was made between different sizes of machines or between tracked and wheeled machines, though the authors are aware of the possible influence of these machines on the environment. For all harvesting systems, it was determined whether they were used in deciduous, coniferous or mixed forest stands.

Wood debris was taken into consideration for the three major harvesting systems and in respect to resource efficiency. It refers to logging residues, such as twigs, branches and small pieces of wood, that remain on site after harvesting to reduce the nutrient outtake or reduce soil compaction from machine driving (brush mats) [1, 20]. Studies in European forests have shown a correlation between wood debris volume, the chosen harvesting system and site conditions [1, 21, 22]. Even when most of the European countries defined parameters for wood debris, these vary strongly between the countries [1, 23, 24].

When breaking down values for each category considering the definition of sustainable forest operations and the biogeographical regions, data were not available in every case. Therefore, where data could not be assessed, impacts were described on a qualitative level based on the studied articles. Values for the harvesting systems always refer to all work activities from tree felling to extraction, unless it is specifically indicated otherwise.

Results

Dominant Silvicultural Management, Harvesting Systems and Forest Technology

Two silvicultural management principles dominate within Europe: Rotation forestry and continuous cover forestry. Rotation forestry is characterized by stands with even-aged tree structures, resulting from forest regeneration through clear cutting, usually followed by single species planting and by intermediate thinning from below. In contrast, with continuous cover forestry the aim is to maintain the forest cover during the regeneration phase, resulting in an uneven-aged tree structure [25]. This is realized through selective cuts, in which trees can be removed individually. A widespread focus on wood production in previous centuries has resulted in a simplification and homogenization of European forests in many regions, often exemplified by the creation of even-aged and single species stands. Today, three-quarters of European forests are managed as even-aged forests [26]. The proportion of forest area managed by continuous cover forestry varies considerably between the biogeographical regions and countries. The share of forests managed under principles of continuous cover forestry in Boreal forests, such as in Finland and Norway, is less than 10%, whereas clearcuts are forbidden e.g. in Switzerland. In Alpine forests, such as in Slovenia, continuous cover forestry dominates, with more than 90%, and in Continental forests, such as in Germany, continuous cover forestry contributes between 26 and 50% [27].

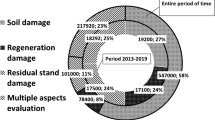

The silvicultural management concept is closely, but not exclusively, linked with the harvesting system. Within Boreal forests, only HFW harvesting systems were reported from four papers, and all referred to clear cuts [28,29,30,31] (Fig. 2). Harvesting systems in Continental forests are more diverse, taking different silvicultural management regimes and various level of mechanization into account. Ten papers involved analyses of HFW harvesting systems [4, 5, 28, 32,33,34,35,36,37,38], two papers included information on CCY harvesting systems [32, 39], and eight papers included references to CSK harvesting systems [28, 32, 33, 35, 36, 40,41,42]. Unsurprisingly, CCY harvesting systems are of high relevance for Alpine forestry [43, 44]; it is important to note that, besides the two papers cited, the dataset of the Swiss National Forest Inventory [14] was used for further analysis of this biogeographical region. Mediterranean forests again show a diverse range of harvesting systems, with the dominant system being CSK, with eleven papers cited [3, 45,46,47,48,49,50,51,52,53,54], followed by nine papers on HFW harvesting systems [3, 10, 28, 50, 53, 55,56,57,58] and one paper on CCY [59].

Relative distribution of the harvesting systems according to the number of papers (top row) and according to national inventory data of the state forest administrations in Estonia (Boreal forests), in Hesse and Thuringia, both in Germany (Continental forests), in the canton of Grisons, Switzerland (Alpine forests), and in Catalonia, Spain (Mediterranean forests) (bottom row). Harvesting systems: HFW = harvester-forwarder, CCY = chainsaw-cable yarder, CSK = chainsaw-skidder

In line with the reported harvesting systems, the level of mechanization decreases from north to south. No clear data were available on the age of the machines analysed within the papers; however, it is likely that more sophisticated forest technology (e.g. harvester and forwarder) is in operation in Boreal forests than in Mediterranean forests (including skidder and farm tractor).

Overview of Impacts Within the Four Biogeographical Regions

Environment

Even though the environmental impacts of forest operations have been studied for decades, most papers referred to either tree felling and processing or extraction, while only a few systematic datasets were available for complete harvesting systems. The greenhouse gas emissions from CCY were very unevenly distributed and ranged from 1.8 to 13.5 kg CO2_eq/m3. Reasons for this wide distribution could be the small number of references (Alpine n = 1; Continental n = 2; Mediterranean n = 2) and the inclusion of various cable yarder systems working under different conditions, in particular variation in the span of the yarding distance, which is directly correlated with the fuel consumption [44]. The analysis included mini-yarder systems (Savall 1500 and Maxwald, both standing skyline systems attached to a tractor [59]), medium cable yarders (e.g. Valentini V400 and V600 [44]), and cable yarders with an integrated processor [32]. Hybrid and full electric machines or machine equipment have not been studied in detail yet, even though this equipment is approaching the market [60, 61]. It is assumed that their implementation will lead to a large reduction in fossil fuel emissions. In the comparison of the harvesting systems, HFW generally shows lower emission rates per harvested cubic meter than those caused by CCY, except in Mediterranean forests, where CCY has the lowest emission rates.

The reviewed papers and database provide a good picture of the relative environmental impacts from various forest operations, although the patterns cannot be statistically proven, given the inhomogeneous site conditions of the studies, the missing information on data assessment and calculations within the studies, and the use of different reference units. Generally, forest operations in the Boreal region have lower CO2 emissions per m3 of harvested wood than those in the Continental and Mediterranean regions. Given the natural circumstances of steep terrain and unfavourable conditions for ground-based operations in the Alpine region, these forest operations emit four times the amount of CO2 compared with operations in the Boreal region. Particularly in the Italian and Slovenian Alps, small cable yarders without a processor are used, which surely contributes to a lower fuel consumption.

Surprisingly, the tree species that were harvested were not mentioned in each study. However, HFW operations dominated in coniferous stands and deciduous tree plantations, such as those with Eucalyptus spp. or Poplar spp., while CSK was applied in all forest stand types. A clear correlation between emission rates and tree species groups is not apparent with the studied data, even though there seems to be a slight trend towards higher emission rates for operations within deciduous and mixed forest stands compared with those in coniferous forest stands. For Continental forests, the emissions from HFW within operations involving coniferous trees (3.7 kg CO2_eq/m3) were half those within mixed forest stands (7.3 kg CO2_eq/m3), though again not taking different working conditions into account.

Soil damage, caused by ground-based operations, is typical and often an unavoidable environmental impact [62, 63]. The compacted soils are characterized by a reduced volume of macro and fine pores [12, 64], leading to a decrease in the oxygen (O2) and an increase in the CO2 concentration in the soil, often already after the first pass [65]. This could result in limited early-stage growth of the remaining trees [66].

To quantify the damage and to estimate the degree of disturbance to soils, to the regeneration potential, and to the remaining stand, several indicators and methods have been developed [67]. Due to these various indicators, a numerical analysis of soil impacts related to harvesting is still challenging. In some studies, the method applied for the soil impact assessment, such as penetration resistance or bulk density, was not defined. One of the documents summarizing soil disturbances as a results of various forest operations indicated that HFW can be the least impactful harvesting system, with CSK operations on the other end [67]. CCY harvesting systems can also cause sever soil disturbance, mainly because the logs are dragged across the ground [67].

A major drawback of the existing studies for this comparative review is that they provided either information on soil disturbance caused by heavy traffic [6, 14, 20,21,22,23,24] or data on machine performance, but seldom information on both aspects. Most of the reviewed papers on soil impacts involved analyses of the penetration resistance (n = 28), followed by an interpretation of disturbance as a percentage (n = 23) and bulk density measurements of disturbed vs undisturbed soils (n = 22) (Table 2).

Most of the included studies that considered soil impacts caused by forest operations focused on the direct and visible impacts, while long-term analyses are seldom done and often lead to contrary results. No recovery of soils was observed, even after 40 years, for sandy and loamy soils [74]. In contrast, for soils with a high clay content, significant recovery was measured after 20 years (with no differences at that point between traffic lines and the undisturbed soil) [74], and total recovery was reported for clay-loam sites after 20–30 years [75]. Fast recovery of physical soil characteristics (bulk density, shearing and penetration resistance) on sandy soils with sandy loam was observed within five years of the final felling of a Pinus pinea L. stand [10], while the soil mesofauna did not recover within this time [10]. The studies support the assumption that sandy soils are less prone to compaction than clay soils, even if the influence of the presence of organic matter remains unclear. In contrast, Ampoorter et al. reported no significance different between the compaction of sandy and clay soils [76].

The topic of soil damage caused by ground-based operations is a strong research area, and several studies were performed recently with the aim to reduce negative impacts on soils, for example considering the use of a tracked instead of a wheeled skidder to slightly lower soil compaction [71] or the use of a rubber-tracked forwarder [62] or wider tires [77].

Damage to the trees in the remaining stand were rarely assessed in the reviewed papers, except for thinning with HFW in a Scots pine (Pinus sylvestris L.) stand in Poland, where tree damage was between 4.62% and 6.24% across all age classes [78]. The probability of damage to the remaining stand increased with less favourable light conditions during the operations (night, fog), even when artificial light was available [78], while the degree of thinning preparation, in specific whether trees to be cut were marked and whether this decision was made by the operator or the forest manager, had no significant influence on the damage to the remaining stand [79].

The impact of forest harvesting systems on biodiversity, such as plant richness before and after harvesting/thinning, is rarely assessed. Only in a wider perspective of forest operations that includes cutting methods is biodiversity considered. A recent review concluded that there were no differences in plant richness after selective cuts compared with reference stands [80]. Generally, less intensive selective cuts tend to preserve biodiversity better, via differentiation within the forest stand, while (small scale) clear cuts provide more light for pioneer species, enhancing plant richness and supporting natural regeneration [80].

The support of vertical structures in forest stands by the harvesting system, a prominent indicator to assess biodiversity, was not specifically studied within the reviewed papers. However, the authors see a strong correlation of this indicator with the overall forest management concepts of rotation forestry and continuous cover forestry. In addition, harvesting systems can support vertical structures by causing less damage to the remaining stands, particularly young trees. HFW has a high potential in this respect, in that it involves felling and pre-extracting old trees, without damaging new saplings, before processing them on the skid road [81].

The location of tree processing is directly correlated with the amount of organic material available for nutrient recycling. While all non-merchantable wood is concentrated on the skid roads and serves to form brush mats with HFW, most non-merchantable organic material remains at the location of tree processing with CCY and CSK. The associated advantages (e.g. increased soil moisture, reduced soil erosion) and risks (e.g. increased fuel load, reduced natural regeneration potential) caused by a high organic material concentration on site are a heavily debated topic [82].

Ergonomics

The number of accidents within forest operations was reported in just one paper [32] from Germany, and from a dataset for Catalonia from the Forest Science and Technology Centre of Catalonia (CTFC). There seems to be a lack of analyses regarding operational risks in general and under changing management requirements (e.g. amount of dead wood on site) and site conditions (e.g. increase in mixed and deciduous forests) specifically. In the comparison of the harvesting systems, four times as many fatal accidents were reported for CSK and CCY operations (both 0.00045 accidents per 1,000 m3) compared with the small number of accidents for HFW (0.00010 accidents/1,000 m3), demonstrating the high degree of work safety in fully mechanized operations [32]. This is supported by the findings of Borchert et al. [83], who furthermore pointed out increased risks of accidents in forest stands with a large amount of young trees during the combined work of motor-manual felling trees into the harvester boom reach-distance for further processing.

Meanwhile, a time series of accidents in Catalonian forests indicated a slight decrease in the number of general accidents between 2007 and 2019, with a maximum of 0.7 accidents/1,000 m3 in 2009. The median of this time series was 0.42 accidents/1,000 m3/year [84].

Strong improvements to reduce noise (78%) and vibration exposure (45%) during motor-manual work can be realized by a shift from combustion-driven to battery-driven chainsaws [85]. In contrast to combustion-driven chainsaws, battery-driven chainsaws never run in idle mode (about one-third of the use time for combustion-driven chainsaws), which significantly reduces the duration of noise exposure [85, 86].

Economics

Productivity and cost analyses were identified as the most prominent research topic in all the biogeographical regions. In total, 708 datasets were incorporated into the analysis, most of which refer to the Swiss National Forest Inventory (NFI) data. The harvesting costs in the Alpine region were found to be at least twice as much as in all the other regions, independent of the harvesting system (Fig. 3). This finding is certainly influenced by the variation in wage level and operations costs between the biogeographical regions. In the Alpine region, CCY harvesting systems dominate; they are expensive in general due to steep terrain (mountains), and the numbers originated mainly from Switzerland, a region with high wage level. Harvesting in the Continental region seems to be more expensive than in the Mediterranean and Boreal regions. Reasons may be the different silvicultural management practices (clear cut vs. selective cut), varying wage levels, or operational restrictions.

On average, CCY is the most expensive harvesting system for the Alpine (mean 97.5 Euro/m3) and Continental forests (31.4 Euro/m3). Only in the Mediterranean forests (15.0 Euro/m3) are CCY harvesting systems slightly cheaper than CSK (17.8 Euro/m3), which might be related to machine age or harvested volume.

CCY harvesting systems were applied on steep and flat terrain with sensitive soils. On a test site in Germany, harvesting costs of 26.7 Euro/m3 on flat terrain were realized [39], i.e. comparable to the average skidding costs in the continental region (mean 25.2 Euro/m3).

Costs differed between tree species. For example, in the Mediterranean region, harvesting deciduous species was more cost efficient (mean 9.8 Euro/m3) [28, 50] than harvesting coniferous trees (mean 11.2 Euro/m3) [28, 56, 59]. Most information on harvesting costs in the Mediterranean region were available for plantation management; therefore, the numbers cannot directly be compared with those in other regions. For the Continental region harvesting costs were similar between coniferous (mean 10.2 Euro/m3) [28, 87] and deciduous trees (mean 11.0 Euro/m3) [28], but lower than harvesting operations within mixed forests (mean 14.4 Euro/m3) [32, 39,40,41]. The same applies to Boreal forests, where harvesting coniferous trees was cheaper (mean 8.2 Euro/m3) than operations in mixed forests (mean 11.1 Euro/m3) [28].

A trend in harvesting cost development was only detected for the Continental region, where CSK costs increased between 2012 and 2019, from 16.5 to 35.6 Euro/m3. Again, the reasons for this increase cannot be determined from the cited literature. In comparison, harvesting costs in Sweden (Boreal forests) remained constant between 2012 and 2017, analysed for the national market [88]. Currency exchange rates (SEK – EUR) impacted harvesting costs only when the logs were sold on international markets. In all regions, thinning costs were about two times higher (14–20 Euro/m3) [87, 88] than costs for final felling (7–10 Euro/m3) [50, 88].

Cut-to-length (CTL) technology, applied in the HFW system, turned out not only to be the most cost-efficient harvesting system, but also to reach the highest productivity (Fig. 4). A wide span within the data was observed, often owing to missing information on harvesting intensity, on whether operations involved thinning or final felling, and on the average volume of the harvested trees. Given these considerations, the span of harvesting system productivity of CTL was similar for the Boreal region (4.1–16.6 m3/pmh0 [29,30,31]) and Continental region (4.5–17.1 m3/pmh0 [4, 5, 36, 37]), even though the arithmetic mean was higher for the Continental region. Only the Mediterranean region had a mean harvesting system productivity and span that were higher than in the two other regions (15.9–23.5 m3/pmh0 [50, 53, 55]). These studies in the Mediterranean region involved cut-to-length operations by HFW in softwood plantations, which limits the comparability of the data. On the other hand, it underlines plantation management as the dominant use case for HFW in this region.

The harvesting system productivity for CCY and CSK were similar in the Continental and Mediterranean regions. In the Alpine region, CCY reached a productivity twice as high as in the Mediterranean region (Fig. 4), but varied widely, from 0.9 to 18.0 m3/pmh0 [43, 44].

Besides the assessed data, harvesting system productivity was modelled [89] by including studies on specific machine performance of the described harvesting systems in the review. Consequently, the number of available datasets increased markedly to 18 for Boreal forests, 317 for Continental forests, and 23 for Mediterranean forests. A comparison of productivity for felling and processing by harvester (across all tree species) yielded no clear differences between Boreal (20.7 m3/pmh0) [29,30,31, 90] and Continental regions (19.9 m3/pmh0) [15, 32, 40, 68, 87, 91,92,93,94,95], while productivity in the Mediterranean region was slightly lower (14.5 m3/pmh0) [45, 53, 56, 96,97,98]. As expected, the productivity for motor-manual felling and processing was about three times lower compared with that of mechanized felling. The productivity with motor-manual felling and processing was also lower for deciduous trees than for coniferous trees (Fig. 5).

The studied papers included both motor-manual felling on steep and accessible terrain and operations with different tree diameter classes. Consequently, the span of felling and processing productivity was wide, ranging from 0.6 to 16.0 m3/pmh0 [15] for the Continental region and, similarly, from 0.8 to 24.7 m3/pmh0 for the Mediterranean region [52, 59]. Considering the arithmetic mean only, the differences in productivity for motor-manual work were marginal between the Continental and Mediterranean regions [15, 32, 35, 45, 52, 59, 97, 99, 100].

Taking the reviewed papers as an indicator, a clear trend towards more heavy machines with a wider boom reach can be seen (Table 3, Fig. 6). A time series for harvesters operating in coniferous stands indicates a continuous increase of machine weight between 2008 and 2020. Mechanized deciduous tree harvesting was first studied in the early 1990s in France and Finland, but kept a niche application for the following years [37, 101, 102]. An increasing number of studies were conducted starting in 2015. Harvesters operating in deciduous forest stands were mainly of high weight, dominated by machines more than 20 tonnes, and reached peaks for the Impex Hanibal T40 and T50, weighing 51 and 54 tonnes, respectively [94].

Comparing the mean productivity of timber extracting only, a diverse picture can be observed between the biogeographical regions. Data on forwarder productivity within the Boreal region come from only one study on pulp- and energy-wood harvesting in early thinning; from the perspective of the authors of the present review, such data are not representative of forwarding within the Boreal region, and this partly explains the low forwarding productivity of 3.1 ± 0.5 m3/pmh0 [29]. Forwarder productivity within the Continental and Mediterranean regions is on a high level and comparable in the two regions (17.4 ± 5.3 m3/pm0 [38, 87, 103, 104] and 15.1 ± 12.7 m3/pm0 [60, 70, 100, 105, 106], respectively). Productivity is much higher than for skidder extraction, which was found to be, on average, 4.9 ± 0.7 m3/pmh0 in the Continental region, 10.6 ± 1.2 m3/pmh0 in the Boreal region, and 12.0 ± 14.2 m3/pmh0 in the Mediterranean region [32, 52, 69, 71, 107,108,109].

Cable yarding in Alpine regions seems to be very efficient when operated in both coniferous and mixed forest stands, reaching a mean productivity of 9.5 ± 8.0 m3/pmh0 [43, 44, 110]. In contrast, studies on cable yarding productivity in the Mediterranean region, with the extraction of young deciduous trees (age < 30 years), indicated a low mean productivity of 2.3 ± 0.6 m3/pmh0 [110].

The lowest unit costs were realized in Boreal and Mediterranean forests (11.5 Euro/m3 and 13.3 Euro/m3, respectively; Table 4). Here, both the cutting units and the harvested volumes were reported to be larger than in the other regions, with the exception of forest plantations in the Mediterranean region. Additionally, lower wage levels in the Mediterranean region compared with in the Continental or Alpine region contributed to low unit costs. In Continental forests, where harvesting is dominated by thinning and selective cuts, unit costs were found to be twice as high as in the Boreal and Mediterranean regions (25.1 Euro/m3). In the Alpine region, the average harvesting costs were 92.4 Euro/m3, with operations dominated by cable yarding operations. The high average harvesting costs were partly caused by high labour costs in Switzerland, while these costs were lower in other countries in the Alpine region (Fig. 7).

People and Society

Harvesting systems provide important jobs and income, particularly in rural areas, but information is rarely available on these aspects. Only one study indicated the job provision in Continental forests, where CSK provided 2,485 jobs per 10,000 m3 wood harvested, which was by far more than provided by CCY (753 jobs per 10,000 m3 wood harvested) and HFW (325 jobs per 10,000 m3 wood harvested) [32].

The dominant reason for harvesting differed among the biogeographical regions. Differences also existed between rural and conurbation areas and among types of forest owners. A clear picture could not be drawn from the included literature. Based on the authors’ experience, in Boreal forests management to produce wood dominates, in Continental forests combined management to promote resilient forests and to produce wood is mainly applied, in Alpine forests risk reduction of landslides and soil erosion is the focus of forest management, and in Mediterranean forests management to reduce fuel loads and risks of forest fires dominates.

Production Optimization

Besides optimizing the bucking process via on-board computers on the harvester, product-specific optimization is yet rarely applied in forestry. This is particularly true for motor-manual felling and processing, being part of CCY and CSK harvesting systems. For HFW, investigations were reported to better understand the accuracy of length measurements of the harvester bucking system under Continental conditions. While for coniferous trees the accuracy of log length measurement is precise (99%), an accuracy of only 91% was reached for deciduous trees [111, 112].

Log damage caused by delimbing with a harvester head was only considered in a few studies. Feed rollers can create major defects on the outer surface of logs, with a mean depth of 4.4 mm for coniferous trees and 2.6 mm for deciduous trees [113,114,115]. Damage caused by feed rollers was significantly deeper when harvesting was conducted in summer compared with operations in winter, although the average depth difference was only 1 mm [115]. The corresponding value loss depends strongly on the log assortment (e.g. logs for veneer, sawlogs, pulpwood, industrial roundwood, fuelwood) and cannot be generalized.

The resource efficiency during harvesting, defined here as the ratio between standing tree volume and volume of merchantable timber, surprisingly was not included in any of the studied papers. Only once did a study consider the share of the crown of deciduous trees that was used for logs (29.6%), illustrating that two-thirds of the crown remained on site [116]. In contrast, the share of merchantable timber from deciduous species that was not used for logs was only 9.3%, suggesting room for improvements [116].

The specific situation of current forest operations in the biogeographical regions

Boreal Forests

The majority of the Boreal forests are characterized by monocultural stands dominated by spruce (Picea spp.), pine (Pinus spp.) and/or birch (Betula spp.), but mixed stands featuring larch (Larix spp.) and poplar (Poplar spp.) are also common [19, 117]. The dominant management aim in European Boreal forests is timber production, while only mixed stands provide habitats that can enhance biodiversity and services for recreation [19, 117]. A few thinning events per rotation are conducted in Sweden and Finland, mostly performed as ‘thinning from below’, while in Norway thinning events are not common [118]. Besides thinning, salvage or sanitation cutting are applied in all mixtures, next to pruning or fertilization [19, 117]. In Sweden, clear cuts are a common method for final felling, also over larger areas of more than 20 ha [63]. The silvicultural management allows for rotation ages ranging from 70 to 120 years for pine and spruce, and 40 to 70 years for birch (Betula spp.), with the target diameter at breast height varying from 27 to 40 cm (pine and spruce) and from 16 to 31 cm (birch) [19].

Most of the area in Boreal forests is below 500 m above sea level and is relatively flat, with suitable accessibility for ground-based operations. Therefore, the dominant harvesting system is HFW (Nordic cut-to-length, CTL) with the combination of a harvester and forwarder operating in clear cuts of different sizes [117]. HFW is applied in both state and private forests. In Finland and Sweden, 66% of the forest land is privately owned, while in Latvia and Lithuania it is nearly 50% [119].

Common problems, often exacerbated by climate change, are windstorms, heavy snow loads (causing tree breakage), drought and forest fire, as well as biotic risks from insects (e.g. bark beetle) and pathogens (e.g. fungi). Other challenging issues are high game pressure, overly high rotation ages of spruce stands, and low success rates of natural regeneration of pine and artificial regeneration of spruce. Furthermore, a lack of knowledge and adequate management models exist for mixed forest stands [19, 117].

Continental Forests

Most of the Continental forests are characterized by a mixture of deciduous species (Quercus spp., Fagus spp., Fraxinus spp., Acer spp.) and coniferous species (Norway spruce (Picea abies), pine (Pinus spp.),) [19]. In Germany, Poland and France in particular, pine, spruce, beech and oak are the dominant tree species in forests. In some areas, short-rotation plantations, mainly of poplar, are becoming of increasing importance [120]. As the biogeographical region spans a large set of countries, the management aims are diverse. However, for most Continental forests the production of valuable timber is of high priority, together with the protection of soil, water and biodiversity [19].

A wide range of regeneration methods are applied, starting from e.g. shelterwood systems and small-scale clear-cuts and extending up to single-tree selection and coppice [19]. Given the many tree species and management methods, typical rotation ages range from 25 years (mostly coppice) to 240 years (in oak management) [19], and no general forest management system (Rotation Forestry or Continuous Cover Forestry) or strongly dominant harvesting system can be named. However, HFW is well represented in Continental forests, and only tree species composition (broadleaves), terrain conditions (mountains) and forest owners’ motivation limit wider HFW use. There are various sources confirming trials of HFW technology application in broadleaved or mixed stands in Central Europe to introduce fully mechanized operations beyond coniferous stands [63]. Strong motivations for this are increasing risks for forest worker resulting from grater shares of deadwood and deciduous trees, and difficulties in recruiting forestry workers. Difficulties for forest operations in general often apply mainly to steep terrain and the availabilities of machines and workers [19]. In addition, the wide range of tree species and different use applications (e.g. sawn wood, pulp wood, pallets, fibre-based material) strongly increases the number of assortments on site (up to 15 assortments per logging site), resulting in high effort for log extraction.

Recently, large areas have been and are still affected by bark beetle infestations, shifting the management focus of forest enterprises towards regeneration and planting activities. With the given lack of forest workers and technology, as well as the limited access to steep terrain, most replanting is done manually, further limiting the availability of workers for harvesting.

Alpine Forests

Most Alpine forests are described by horizontally and vertically structured and mixed forests with the main species spruce (Picea abies (L.) H.Karst), silver fir (Abies alba Mill.), European beech (Fagus sylvatica L.), and other species such as European larch (Larix decidua Mill.), Scots pine (Pinus silvestris), stone pine (Pinus cembra L.), and sycamore maple (Acer pseudoplatanus L.) [19]. As the European Alps are densely populated, in particular in Switzerland, Austria, Italy and Germany, forests play an important role in providing multiple ecosystem services and goods, in particular protecting infrastructure against gravitational natural hazards such as landslides, avalanches, flooding and rock fall [19, 121].

Selective cuts are mostly applied by thinning from above, and only in Austria is small-scale clear cutting applied for the regeneration of forests [19]. Cable-based technologies are often the only way of harvesting, i.e. when stands are located in steep terrain or the forest road infrastructure is insufficient [19, 122]. In the specific case of Switzerland and based on data from the Swiss National Forest Inventory [14], cable-based extraction methods are applied in 39% of the areas, whereas helicopter (30%) and ground-based methods (19%) are less frequently used and 12% of the forest areas are not accessed at all. Among the cable-based technologies, full tree extraction has a share of 60% (41% mobile tower yarder, 19% sledge winch cable yarders) and log/assortment yarding has a share of 40% (17% mobile tower yarder, 23% sledge winch yarder) [14].

Mediterranean Forests

In the Mediterranean biogeographical region, most forests are characterized by mixed tree species, particularly oak (Quercus spp.), pine (Pinus spp.) and hornbeam species (Carpinus spp.) and to a lesser extent beech (Fagus spp.), fir (Abies spp.), ceder (Cedrus spp.), ash (Fraxinus spp.) and chestnut (Castanea spp.) [19]. Forests are mainly managed for soil and water protection, and only secondarily for timber or production [19]. Naturally, the standing volume is lower than in the other biogeographical regions, and thinning intensity is low (10–15% of the standing volume). The target diameter at breast height for a rotation is diverse and strongly depends on the tree species, ranging from 10–15 cm to 50 cm [19]. Regarding forest operations, a small harvesting volume (from thinning) supports harvesting processes with low fixed costs, such as semi-mechanized forest operations with a large component of motor-manual work.

Major challenges are a gap of knowledge in managing mixed forest stands, a lack of technical and management guidelines, and the transformation from wood-oriented to protection-oriented (or integrated) forest management [19].

Besides the existing mixed forest stands, poplar (Populus spp.), pine (Pinus spp.) and eucalyptus (Eucalypt spp.) plantations represent a major source of wood in the Mediterranean region, in particular in France and Italy [123]. Plantations provide very easy access for any operation, with operations being prone to mechanization [124]. This largely explains the differences between the studied forest operation systems (semi-mechanized: CSK and CCY within forests; fully mechanized: HFW within plantations) and the strong deviations between the productivity or cost values (Fig. 8).

Discussion

Methods of the Review

To date, studies in different biogeographical regions or even between countries refer to different reference units, strongly limiting a cross-national analysis and results comparison. For that reason, it has been recommended that standards need to be set for a more holistic and comparable evaluation of forest operation impacts on the environment, suggested e.g. by Technodiversity [125].

This review of data on productivity and time consumption, as well as costs and impacts on the environment, was more challenging than expected. There are various studies available (the literature search returned 1,053 articles), but most were not considered suitable for this paper, for at least four reasons:

-

unclear description of the studied harvesting process;

-

focus on only one activity, while not providing data for the entire harvesting process;

-

concentration on either the environmental impacts of forest operations or the economic dimension;

-

use of several, sometime widely different, units, e.g. kg CO2_eq/m3 vs kg CO2_eq/odt; m3/smh vs odt/pmh0; percentage of disturbed area vs. number of trees with damage vs. increase in penetration resistance.

Therefore, a harmonization of data assessment and reporting is not only wishful, but strongly recommended. More data are required from harvesting systems to better understand their contribution, not only to the economic dimension of harvesting, but especially to the various indicators of the environmental dimension (e.g. contribution to biodiversity, net carbon storage). The benchmark systems developed within Tech4Effect (EU grant ID 720757) could potentially contribute in this respect, not only to improve the data quality and quantity, but also to ensure compatibility of the data.

Often, the reason for the publication of studies limits the reliability of review data, as specific cases or newly developed machines are studied and presented in articles. Such data are usually not representative of standard forest operations. More long-term empirical data are required and need to be collected in a database.

The future development of wood supply in general and forest operations in specific will be influenced by the willingness of cooperation between forest owners, forest companies and industry as well as the necessity for local adaptation of supply chains [126]. There is no ‘perfect solution’ in sight. Below, five main drivers that will lead to substantial changes in the conversion process are proposed, but a modelling or innovation approach, like in other published work (e.g. [127]) is not performed. The intention of this review was not to present specific productivity, cost or environmental impact data, nor to forecast them. Instead, the aim was to generally compare forest operations on a broader level of biogeographical regions, while being aware of the huge variation between these regions.

The performed review indicated that most of the publications present analyses of forest operations in a retrospective view aiming to precisely understand impacts of harvesting systems under current state. This approach is crucial to create a deep knowledge of complex systems, develop models for simulations and to build compromises among the pillars of sustainability. However, this sometimes hinders us to be creative and develop forward-looking operational solutions to reach a desired state of forest management. Today, we often focus on what is technically feasible by implementing innovative technology, rather on what is actual needed in a socio-economic and environmental context. A more holistic understanding of operations impact creation and harmonised assessment of these impacts is only the first step of modern forest operations. A sound definition of operational and forest management aims is required in a second step to engineer target-oriented solutions. In general, a comprehensive exchange of knowledge, not only across the biogeographical regions, but also between the humans involved, thus forest engineers and forest managers, is needed to define alternative operational solutions more precisely by using methodological approaches of e.g., clearing-house mechanism [128].

In line with other studies, we see a lack of finding worldwide valid solutions for forest operations and a great gap of models and approaches to compare harvesting systems [41, 129]. In times of big data and cloud computing this is not anymore acceptable.

Drivers that will Affect Forest Operations in the Near Future

It is widely understood that climate conditions will change within the next decades, with consequences for forestry and the forest-based sector in general. While in the last decades the main focus of forest management was on timber production [19, 130,131,132,133], including infrastructure provision (e.g. forest roads) and wood supply, various – partly competing – interests, such as increasing biodiversity, restoring forests, water retention and supporting bioeconomy strategies, have become more relevant today [134, 135]. This will have strong implications for forest operations, and strategic decisions on political, educational and operational levels will need to cope with the new expectations.

This study highlights the different situations of forest operations within the different forest biogeographical regions in Europe, representing starting points for potential developments in response to the upcoming challenges. The authors have chosen five major trends that strongly impact the development of forest operations to exemplify consequences for forest operations, based on the presented findings on the current forest operations. In particular, the major trends are: (i) increased environmental constraints, (ii) increased complexity of harvesting resulting from an increasing area of mixed forest stands, (iii) increased resource efficiency fostered by a growing demand for wood products, (iv) reduced available work force resulting from greater competition for skilled worker and an aging population, and (v) more transparent work and material flows through the introduction of digitalization.

(i) Increased Environmental Constraints

Biodiversity monitoring, including soil biodiversity monitoring, will become a more important indicator for forest operations. Particularly in mixed forest stands, it is essential to provide forest managers with this information to support management decision making [136]. So far this has hardly been addressed, and it will require closer trans- and interdisciplinary work involving e.g. the soil sciences, forest growth sciences and silviculture sciences [80]. From the reviewed literature it remains unclear how enhanced forest structure will influence operational efficiency and which harvesting system will be most suitable.

Higher precipitation and non-freezing weather conditions in autumn and winter will considerably reduce the bearing capacity of soils – a value that describes the resistance of soils against incoming forces, such as loads from forest machines [137, 138]. This will strongly limit ground-based wood extraction, due to the reduced technical accessibility of skid roads with forest machines. A single pass on forest soils can create severe compaction, in particular on wet soils [62, 63, 137, 139]. With reduced soil bearing capacity, even on a permanent skid road system where soil damage is accepted to a certain degree, technical accessibility cannot be ensured in any case. In return, the efficiency of harvesting will need to be increased in times of favourable operating conditions (in dry periods or under frozen soil conditions). This will require machines with a high productivity, generally those that are larger and more powerful. In this way, the number of passes could be reduced to avoid structural soil damage, although heavier machines also cause greater impacts, even after the first passage.

In most European regions the risk of forest fires will increase as a result of climate change, and even today forest operations are restricted during the summer. Using harvesting residues, such as branches, especially from deciduous trees, within the emerging bioeconomy or for energy recovery might reduce the fuel load within forests, but weather conditions are expected to more strongly influence forest fire risks [140]. However, the reduction of fuel loads by creating new assortments depends strongly on the chosen harvesting system, its economic performance, and the economic revenue of the product [140].

(ii) Increased Complexity of Harvesting Resulting From an Increasing Area of Mixed Forest Stands

Current silvicultural management concepts, as well as the aims formulated in the European Forest Strategy and several national forest policies, strongly promote mixed stands to increase biodiversity [141], support forest health, and reduce risks of large-scale diseases and consequently loss of forests, e.g. by storm events or bark beetle infestation [134]. The tree species composition, particularly coniferous and deciduous species, in turn directly determines the harvesting system.

With an increasing share of deciduous tree species and increasing distances between strip/skid roads, it is likely that HFW will be partly accompanied by semi-mechanized harvesting systems, such as the defined CSK, at least for trees of large dimensions. Besides terrain conditions, a major challenge for mechanization within forest harvesting is the presence of deciduous tree species [60]. Harvester heads enabling hardwood processing exist, but in practice they are dedicated mainly to processing small trees with small diameters [37]. Further advancements in the engineering of harvester heads are likely to happen, especially when the market demand increases. A new patent for harvester heads for broadleaved species has been published recently, proposing solutions for timber processing of broadleaved tree species, especially in Central Europe [37, 142].

For mixed forest stands managed under the principle of continuous cover forestry, a permanent skid road network typically exists in distances of 20 m (standard) up to 40 m or 60 m to reduce the compacted area caused by driving on forest soils [62]. Besides terrain conditions limiting driving on the ground, enhanced skid road distances lead to an increased application of motor-manual felling beyond the boom reach distance of the harvester [61, 64]. Today, only little information is available in this aspect; however, in Germany the share of motor-manual felling for following harvester processing is 1% in Hesse, 13% in Brandenburg, 27% in Rhineland-Palatinate, 32% in North Rhine-Westphalia, and 88% in Baden-Württemberg [143].

Forest operations are the essential component to enable the ecological transformation of forests towards resilient forests with enhanced biodiversity and a high potential to meet societal demands. There is a slight trend emerging that mixed forest stands, with a greater share of deciduous species, support motor-manual operations like those involved in CSK or HFW harvesting systems with supportive motor-manual felling. Technology for processing deciduous species with CTL technology is emerging in parallel.

(iii) Increased Resource Efficiency Fostered by a Growing Demand for Wood Products

It is highly likely that the realization of the European Green Deal and the European Bioeconomy Strategy, as well as national and regional initiatives to replace fossil energy and – more important – material sources with renewable material such as wood, will increase the wood demand. Besides activities to improve resource efficiency and yield in general, it is likely that resources that are currently unused in environmentally sensitive or difficult to reach occupy easily accessible terrain for food, animal feed and material production, pushing forestry to less attractive sites [144].

The percentage of merchantable timber in relation to the standing biomass volume (above ground biomass) is rarely considered, and harvested wood volumes are commonly firstly assessed by the harvester on-board computer, within wood stacks at the roadside or at the mill gate. However, in line with the European Bioeconomy Strategy and the European Forestry Strategy, it is an emerging aim to increase the overall resource efficiency of wood supply chains, including the yield of harvested trees. This refers to the degree of merchantable timber, as well as the parts of the tree that have been widely unused so far, such as non-merchantable timber (< 7 cm in diameter), bark and leaves. Studies modelling the utilization rate for different assortments (sawn wood, pulp wood, energy wood) against sorting criteria have demonstrated relevant changes in volume between material and non-material use paths, depending on the top end diameter of the pulp wood assortment [145]. In addition, the ratio of merchantable timber (excluding energy wood) of coniferous trees is about 1–21 percentage points higher than that of deciduous trees [116, 145]. Considering the transformation of forests towards resilient mixed forests by increasing the ratio of deciduous tree species, resource efficiency is becoming more important. Harvesting systems will need to intensify the output of merchantable timber per tree to reduce the overall number of harvested trees per site, and to compensate for forest areas that are excluded from wood harvesting for protection reasons. This aspect is becoming even more prominent in light of the European Forest Strategy, which fosters close-to-nature forest management with regard to value wood and non-wood products, as well as ecosystem services [134].

The mechanized processing of stems and branches from deciduous trees with harvesters or processors is often determined by the height/length of the harvester/processor head during delimbing (of deciduous tree species) and when holding the tree top while cross-cutting the last assortment with the bottom saw. A few harvester/processor heads with an additional top saw exist, but studies on their impact on yield are rare. On the other hand, the greater amount of slash biomass created by harvester technology can be used to form brush mats to reduce soil compaction or as energy wood stacks for renewable energy supply [20, 116].

Studies on the percentage of lost logs between tree felling and extraction with different harvestings systems are, to the best of the authors’ knowledge, nonexistent. However, it can be assumed that tree-length harvesting systems miss fewer logs than cut-to-length harvesting systems. As a consequence, cut-to-length operations require supportive technology to exchange digital information about logs (e.g. GNSS position, assortment, tree species) between the operator performing the work processes of tree felling and processing (delimbing and bucking) and the second operator extracting the logs. While brand-specific fleet-management systems are state-of-the-art for modern harvesters and forwarders (e.g. John Deere TimberMaticMaps, Komatsu Maxi-Fleet), capabilities are limited when it comes to connectivity between different brands and to chainsaws (e.g. Husqvarna Fleet Service). Hence, in HFW, CCY or HFW harvesting systems with supportive motor-manual felling, there is still room to increase resource efficiency.

Studies comparing volume creation through motor-manual and mechanized bucking did not indicate trends towards one technology [123, 146]. Obviously, the influence of the operator exceeds the impact of the bucking system [123]. In terms of value creation, spikes on feed rollers of the harvester head within the analysed HFW harvesting systems could damage the outer surface of veneer logs and therefore reduce the value of the logs [113]. In contrast, CSK harvesting systems tend to damage logs by extracting under rough conditions, which in return reduces the value of logs as well [45].

(iv) Reduced Available Work Force Resulting from Greater Competition for Skilled Worker and an Aging Population

The forest-based sector has a strong impact on the economy, providing people with basic-qualified and highly qualified jobs, particularly in rural areas. Highly or fully mechanized harvesting systems, such as HFW, logically provide fewer, but highly specified jobs with good income opportunities. It is known that machine work reduces the risk of accidents, but also increases the mental workload for the operator [147]. In addition, companies strongly compete for skilled worker with other industry sectors, such as the construction and automotive industries.

On the other hand, motor-manual work, being part of any semi-mechanized harvesting system, is often seen as less attractive, and there is a lack of young people interested in these positions. Today, the demand for workers often exceeds the number of candidates. The European forest sector is faced with a decline in available workers due to the aging population, a phenomenon especially apparent in rural areas as young people move towards urban areas [148].

Consequently, forest work will need to prioritize both processes that can be easily automated by machines and implemented work processes, such as harvesting, on the one hand, and those where machine alternatives are still rare or not available, such as planting and tending, on the other hand. A recent study indicated that 70.8% of the European area of forests available for wood supply is suitable for HFW operations [148]. In the context of reforesting damaged forests, the limited number of available forest workers will need to be assigned, with highest priority, tasks relating to replanting and restoring damaged ecosystems, such as areas attacked by bark beetles.

(v) More Transparent Work and Material Flows Through the Introduction of Digitalization

Several improvements in digitalization have been identified and are currently being studied, such as communication between machines or the visualization of maps within forest machines to reduce driving on sensitive forest soils or to increase efficiency [149, 150]. In particular, the use of GIS for skid road planning can contribute to reducing soil disturbances in thinning and final felling operations [58]. Furthermore, concepts for data provision from sensors and (freely) available satellite data to support management planning exist already, yet they have not been fully introduced into daily operations. Tracking and tracing of logs from the place of tree felling to the final product is another major research activity (e.g., EU project Sintetic) that will not only contribute to enhance sustainability of wood supply, but also will offer new business areas, such as carbon certificate trading.

Digitalization comes with impactful changes to work processes and routines, along with high costs for implementation. Therefore, it is often driven by major forest machine manufacturers. Harvesters and forwarders already assess and exchange a large set of digital data, which can serve to increase the efficiency of the machines or open new business opportunities. Near-time and precise planning and operational data will foster the concept of precision forestry. It will additionally encourage interdisciplinary work between forest management (inventory), forest operations and wood purchasing by applying Global Navigation Satellite System (GNSS) technology, GIS, on-board computers, and cloud solutions for both fully mechanized and semi-mechanized operations [58, 151, 152].

Conclusions

Both, environmental conditions and forest management aims differ between the biogeographical regions, and a comparison of the three selected harvesting systems in the sense of sustainable forest operations [7] is lacking. There is an emerging need to harmonize data assessment methodology across forest operations actors, publish research results and make data available for comparative studies, and strengthen a knowledge and data exchange. Second, we will need to better integrate forest operations into the description of a desired state of forest management by fostering trans- and interdisciplinary cooperations. Third, we will need to put people and people’s needs again into focus of forest engineering, where technology serves to reduce negative impacts and increase efficiency.

From the general trends for the biogeographical regions, based on the studied impacts of the currently applied harvesting systems and regarding the identified drivers that will likely affect forest operations in the future, general recommendations and future research topics can be made:

-

Operations within Boreal forests are already dominated by HFW harvesting systems, which were found to be the most cost-efficient harvesting system. It is likely that digitalization and automation, driven by the leading machine manufacturers, will happen first in Boreal forests before entering other biogeographical regions. Beside studied potential technical and economic gains, the interrelation between machine operator and new digital tools are widely not understood. Research on acceptance of digital tools by machine operator, impacts on mental stress, and required education concepts need to be conducted. Additionally, research is required on operations under changing climate conditions, parallel to increased knowledge exchange between Boreal and Continental regions.

-

For the widely applied integrative silvicultural management in Continental forests, it is difficult to predict changes in operational management. The authors assume that with the increasing complexity of forest management, fully mechanized operations provide the best economic solution, but research is still necessary on fully mechanized harvesting of deciduous tree species in mixed forest stands, particularly how horizontal and vertical forest structures affect economics. Fully mechanized operations also provide the highest safety level for forest workers. However, with increasing societal and legal restrictions on skid road driving, semi-mechanized operations or integrated motor-manual and machine work are on the rise as well. Further research should emphasise on the integration motor-manual work with machine work in adjusted harvesting systems. Specifically, questions of communication and data exchange are still unanswered. Continuing digitalization will help us to efficiently manage complex operations with various assortments and tree species on site. An integration of forest inventory and forest operations is essential to increase the effectiveness of the management of Continental forests for all demanded ecosystem services, parallel to wood supply.

-

Forests in steep terrain and with strong protective functions, particularly Alpine forests, will primarily provide ecosystem services rather than wood supply, due to the high operational effort, high CO2 emissions, and high supply costs. To maintain a sufficient and economically competitive wood supply, the existing forest road network will need to be optimized to allow winch-assisted HFW operations, which are much more cost efficient than CCY operations. Therefore, research on optimal layout of forest infrastructure is needed. Furthermore, investigations on the integration of CCY harvesting systems into digitalization processes, such as data-exchange by StanForD and visualization of cable-yarding lines by Augmented Reality, are desired.

-

Mediterranean forests can supply wood in a very efficient way with low costs and low environmental impacts. Semi-mechanized operations, like CSK, are still very present in Mediterranean forests. The authors assume that mechanization will continue for reasons of increasing wage levels, improved log quality and the reduced number of available workers. Machines and harvesting systems adjusted to mediterranean conditions and taking climate change into consideration, need to be investigated. Especially, research on small-scale operations under multiple management objectives need to be studied. In addition, digitalization will contribute to better integrate forest inventory, management decision making and forest operations, offering new possibilities, particularly for small-scale forest owners. Research should also focus on afforestation and reforestation with innovative planting and seeding techniques taking the application of soil conditioner and bio-based hydrogels into consideration.

References

Bessaad A, Bilger I, Korboulewsky N. Assessing biomass removal and woody debris in whole-tree harvesting system: Are the recommended levels of residues ensured? Forests. 2021;12:807. https://doi.org/10.3390/f12060807.

Mederski PS, Karaszewski Z, Rosińska M, Bembenek, M. Dynamika zmian liczby harwesterów w Polsce oraz czynniki determinujące ich występowanie. Sylwan. 2016;160:795–804 https://doi.org/10.26202/sylwan.2016030

Venanzi R, Picchio R, Grigolato S, Spinelli R. Soil disturbance induced by silvicultural treatment in chestnut (Castanea sativa Mill.) coppice and post-disturbance recovery. Forests. 2020;11:1053. https://doi.org/10.3390/f11101053.

Mederski PS. A comparison of harvesting productivity and costs in thinning operations with and without midfield. For Ecol Manage. 2006;224:286–96. https://doi.org/10.1016/j.foreco.2005.12.042.

Mederski PS, Borz SA, Đuka A, Lazdiņš A. Challenges in Forestry and Forest Engineering. Croat J For Eng (Online). 2021;42:117–34. https://doi.org/10.5552/crojfe.2021.838.

Bont LG, Fraefel M, Frutig F, Holm S, Ginzler C, Fischer C. Improving forest management by implementing best suitable timber harvesting methods. J Environ Manage. 2022;302:114099. https://doi.org/10.1016/j.jenvman.2021.114099.

Marchi E, Chung W, Visser R, Abbas D, Nordfjell T, Mederski PS, et al. Sustainable Forest Operations (SFO): A new paradigm in a changing world and climate. Sci Total Environ. 2018;634:1385–97. https://doi.org/10.1016/j.scitotenv.2018.04.084.

Abbas D, Di Fulvio F, Spinelli R. European and United States perspectives on forest operations in environmentally sensitive areas. Scand J For Res. 2018;33:188–201. https://doi.org/10.1080/02827581.2017.1338355.

Poltorak BJ, Labelle ER, Jaeger D. Soil displacement during ground-based mechanized forest operations using mixed-wood brush mats. Soil and Tillage Research. 2018;179:96–104. https://doi.org/10.1016/j.still.2018.02.005.

Cambi M, Paffetti D, Vettori C, Picchio R, Venanzi R, Marchi E. Assessment of the impact of forest harvesting operations on the physical parameters and microbiological components on a Mediterranean sandy soil in an Italian stone pine stand. Eur J Forest Res. 2017;136:205–15. https://doi.org/10.1007/s10342-016-1020-5.

Cambi M, Certini G, Fabiano F, Foderi C, Laschi A, Picchio R. Impact of wheeled and tracked tractors on soil physical properties in a mixed conifer stand. iForest-Biogeosci For. 2016;9:89–94. https://doi.org/10.3832/ifor1382-008.

Cambi M, Certini G, Neri F, Marchi E. The impact of heavy traffic on forest soils: A review. For Ecol Manage. 2015;338:124–38. https://doi.org/10.1016/j.foreco.2014.11.022.

Kohl C, McIntosh EJ, Unger S, Haddaway NR, Kecke S, Schiemann J, Wilhelm R. Online tools supporting the conduct and reporting of systematic reviews and systematic maps: a case study on CADIMA and review of existing tools. Environ Evid. 2018. https://doi.org/10.1186/s13750-018-0115-5.

Brändli U-B, Abegg M, Allgaier Leuch B, editors. Schweizerisches Landesforstinventar. Ergebnisse der vierten Erhebung 2009–2017. Birmensdorf. 2020. https://doi.org/10.16904/envidat.146

Kuratorium für Waldarbeit und Forsttechnik e.V. (KWF). Datenbasis Waldarbeit und Forsttechnik. 2020. https://dbwaldarbeit.kwf-online.de/. Accessed 22 July 2024.

European Environment Agency (EEA). Main biogeographical regions in Europe: Map. 2017. https://www.eea.europa.eu/ds_resolveuid/2d02c1c7c41f42d4a1fc113f5eff012b. Accessed 2 May 2022.

Roekaerts M. The biogeographical regions map of Europe. Basic principles of its creation and overview of its development. European Topic Centre Nature Protection and Biodiversity (EEA). 2002. https://www.eea.europa.eu/data-and-maps/data/biogeographical-regions-europe-2001/methodology-basic-principles-of-the-biogeographical-regions-map-creation-and-overview-of-its-development/methodology-basic-principles-of-the-biogeographical-regions-map-creation-and-overview-of-its-development/at_download/file. Accessed 2 May 2022

European Environment Agency (EEA). Europe’s environment: the third assessment. Luxembourg: Office for Official Publ. of the Europ. Communities; 2003.

Pach M, Sansone D, Ponette Q, Barreiro S, Mason B, Bravo-Oviedo A, et al. Silviculture of Mixed Forests: A European Overview of Current Practices and Challenges. In: Bravo-Oviedo A, Pretzsch H, Del Río M, editors. Dynamics, silviculture and management of mixed forests. Cham: Springer International Publishing; 2018. p. 185–253. https://doi.org/10.1007/978-3-319-91953-9_6.

Labelle ER, Jaeger D. Quantifying the use of brush mats in reducing forwarder peak loads and surface contact pressures. Croat J For Eng (Online). 2012;33:249–74.

Böhl J, Brändli U-B. Deadwood volume assessment in the third Swiss National Forest Inventory: methods and first results. Eur J Forest Res. 2007;126:449–57. https://doi.org/10.1007/s10342-007-0169-3.

Vítková L, Bače R, Kjučukov P, Svoboda M. Deadwood management in Central European forests: Key considerations for practical implementation. For Ecol Manage. 2018;429:394–405. https://doi.org/10.1016/j.foreco.2018.07.034.

Titus BD, Brown K, Helmisaari H-S, Vanguelova E, Stupak I, Evans A, et al. Sustainable forest biomass: a review of current residue harvesting guidelines. Energy Sustain Soc. 2021;11:1–32. https://doi.org/10.1186/s13705-021-00281-w.

Achat DL, Deleuze C, Landmann G, Pousse N, Ranger J, Augusto L. Quantifying consequences of removing harvesting residues on forest soils and tree growth – A meta-analysis. For Ecol Manage. 2015;348:124–41. https://doi.org/10.1016/j.foreco.2015.03.042.

Mason B, Kerr G, Simpson J. What is continous cover forestry? Forestry commission. Information Note 29. Edinburgh; 1999.

Forest Europe. State of Europe’s forests 2020; 2020. https://foresteurope.org/wp-content/uploads/2016/08/SoEF_2020.pdf. Accessed 10 Feb 2022.

Mason WL, Diaci J, Carvalho J, Valkonen S. Continuous cover forestry in Europe: usage and the knowledge gaps and challenges to wider adoption. Forestry. 2022;95:1–12. https://doi.org/10.1093/forestry/cpab038.

Berg S, Fischbach J, Brüchert F, Poissonnet M, Pizzirani S, Varet A, Sauter UH. Towards assessing the sustainability of European logging operations. Eur J Forest Res. 2012;131:81–94. https://doi.org/10.1007/s10342-011-0561-x.

Di Fulvio F, Bergström D. Analyses of a single-machine system for harvesting pulpwood and/or energy-wood in early thinnings. Int J For Eng. 2013;24:2–15. https://doi.org/10.1080/14942119.2013.798935.

Haavikko H, Kärhä K, Poikela A, Korvenranta M, Palander T. Fuel Consumption, Greenhouse Gas Emissions, and Energy Efficiency of Wood-Harvesting Operations. Croat J For Eng (Online). 2022;43:79–97. https://doi.org/10.5552/crojfe.2022.1101.

Stasys M, Liana S, Diana M. Productivity of Har vesting Machines and Costs of Mechanized Wood Harvesting: Lithuanian Case Study. Balt For. 2008;14:155–62.

Berg S, Schweier J, Brüchert F, Lindner M, Valinger E. Economic, environmental and social impact of alternative forest management in Baden-Württemberg (Germany) and Västerbotten (Sweden). Scand J For Res. 2014;29:485–98. https://doi.org/10.1080/02827581.2014.927913.

Cudzik A, Brennensthul M, Białczyk W, Czarnecki J. Damage to Soil and residual trees caused by different logging systems applied to late thinning. Croat J For Eng. 2017;38:83–95.

Kulak D, Sowa JM, Szewczyk G, Stańczykiewicz A. The Accessibility of Post-Fire Areas for Mechanized Thinning Operations. Forests. 2020;11:471. https://doi.org/10.3390/f11040471.

de La Fuente T, González-García S, Athanassiadis D, Nordfjell T. Fuel consumption and GHG emissions of forest biomass supply chains in Northern Sweden: a comparison analysis between integrated and conventional supply chains. Scand J For Res. 2017;32:568–81. https://doi.org/10.1080/02827581.2016.1259424.

Labelle ER, Lemmer KJ. Selected Environmental Impacts of Forest Harvesting Operations with Varying Degree of Mechanization. Croat J For Eng (Online). 2019;40:239–57. https://doi.org/10.5552/crojfe.2019.537.

Mederski PS, Schweier J, Đuka A, Tsioras P, Bont LG, Bembenek M. Mechanised Harvesting of Broadleaved Tree Species in Europe. Curr Forestry Rep. 2022;8:1–19. https://doi.org/10.1007/s40725-021-00154-7.

Ruch P, Montagny X, Bouvet A, Ulrich A, George P. Mechanized processing of big broadleaved crowns an operational reality. In: Gendek A, Moskalik T, editors. 49th Symposium on Forest Mechanization. Warsaw: Poland; 2016. p. 111–7.

Schweier J, Ludowicy C. Comparison of a cable-based and a ground-based system in flat and soil-sensitive area: A case study from southern Baden in Germany. Forests. 2020;11:611. https://doi.org/10.3390/f11060611.

Berendt F, Fortin M, Jaeger D, Schweier J. How climate change will affect forest composition and forest operations in Baden-Württemberg - A GIS-based case study approach. Forests. 2017;8:298. https://doi.org/10.3390/f8080298.

Schweier J, Magagnotti N, Labelle ER, Athanassiadis D. Sustainability impact assessment of forest operations: A review. Curr For Rep. 2019;5:101–13. https://doi.org/10.1007/s40725-019-00091-6.