Abstract

Purpose of Review

Ground-based mechanized forest operations can cause severe soil disturbances that are often long lasting and detrimental to the health of forested ecosystems. To reduce these soil disturbances, focus is being increasingly directed at identifying and using appropriate mitigation techniques. This systematic review considered 104 scientific articles and reported the main findings according to four core themes: terrain-related factors, operational planning, machine modifications, and types of amendments used to mitigate machine-induced soil impacts.

Recent Findings

For terrain-related factors, most severe disturbances occur on machine operating trails exceeding 20% slope and that soil bulk density and rut depth show greater increases in fine-textured soils. When considering operational planning, trafficability maps proved to be helpful in reducing the frequency and magnitude of soil damages as well as the length of trails needed within harvest sites, especially if they are regularly updated with weather information. Machine modifications, through high flotation tires, use of extra bogie axle, lower inflation pressure, and use of steel flexibles tracks, are highly researched topics because of the considerable upside in terms of machine ground pressure distribution and increased traction. Two main types of amendments emerged to mitigate soil disturbances: brush mats and mulch cover. Brush mats created from harvesting debris can spread the load of a machine to a greater area thereby lowering peak loads transferred to the soil. Brush mats of 15–20 kg m−2 are being recommended for adequate soil protection from harvesting operations.

Summary

To conclude, we outline recommendations and strategies on the use of soil mitigation techniques within cut-to-length forest operations. New research opportunities are also identified and discussed. Considering single factors causing machine-induced soil disturbances remains important but there is a pressing need for having a multi-disciplinary approach to tackle the complex problems associated with machine/soil/plant interactions.

Similar content being viewed by others

Introduction

A higher share of forest mechanization has been needed to meet the growing needs of the world’s population for wood and wood-derived products [1, 2]. Despite some clear advantages of mechanized harvesting systems, such as higher productivity and improved safety, concerns surrounding the use of heavy machines on forest soils remain [3]. Forest machines are commonly operated on machine operating trails designed to allow machine movement in a stand. This off-road traffic can lead to significant environmental effects on forest ecosystems, particularly forest soils [4, 5]. From the perspective of sustainable forest management and the concept of sustainable forest operations [1], forest soils serve as one of the basic components assuring the sustainability and productivity of forest stands [6, 7].

Compaction, rutting, and displacement (a biproduct of rutting) are the main impacts caused to the soil by forest harvesting operations [2, 8, 9]. Compaction occurs when the mechanical forces exerted to the soil cause soil particles to be pushed closer together at the detriment of pore space, which leads to increased soil bulk density [6, 10]. During this process and when soil water content is high, soil deformation can occur through repeated machine passes [11–13]. Ground-based traffic of forest machines can adversely affect the following key functions of forest soils: increase soil strength and soil bulk density [14, 15], decrease macroporosity [16], infiltration [14], saturated hydraulic conductivity [17], and impede soil fauna colonization [14]. In turn, these effects can lead to decreased oxygen availability, increased surface waterflow [18], soil loss and sedimentation [19]. Ultimately, these adverse effects can hinder root and tree growth [20], and negatively affect site productivity [21]. The degree and extent of soil compaction and rutting during mechanized logging operations is often influenced by the type and characteristics of the harvesting system, number of machine passes, terrain slope, soil type, texture and water content as well as silvicultural treatments [2, 3, 22, 23].

The undesirable effects of machine traffic on forest soils can persist for a few years to several decades [24–26]. For example, DeArmond et al. [5] concluded that soil physical properties did not return to preharvest level 30 years after machine-induced compaction had occurred in the Amazon Basin. In the Hyrcanian forests, Jourgholami et al. [14] reported that soil compaction effects persisted over a 25-year period. Similarly, Ezzati et al. [27] found that soil bulk density and total porosity did not recover 20 years after ground-based machine traffic. In general, the implications to restore a compacted soil to a preharvest level are time-consuming and costly. Therefore, measures and strategies to control and minimize the negative effects of mechanized harvesting operations on forest soils should be properly planned and implemented [1, 2].

Many papers have dealt with the direct impact of forest operations on soils, water regime, vegetation, and forest growth. However, as forest mechanization is increasing, so is the need for appropriate and tailored mitigation techniques to reduce the environmental impacts of machines on the soil. The overall aim of this paper was to systematically review scientific literature concerning soil impact mitigation techniques used in a context of mechanized harvesting operations.

In addition to the overall aim, the paper also:

-

(1)

provides recommendations and strategies to mitigate machine-induced soil disturbances through terrain-related factors, operational planning, machine modifications, and types of amendments,

-

(2)

highlights key opportunities for future research.

Material and Methods

Databases and Search Strategy

A systematic review was performed in Scopus and Web of Science databases. After several iterations, the following search strings were used as they provided the most relevant results regarding soil mitigation techniques to reduce machine-induced soil disturbances. In Scopus, we searched for the terms ("forest* operations" OR "forest* harvesting" OR "forwarder*" OR "skidder*") ("soil mitigation" OR "soil disturbance" OR "soil protection" OR "ground protection" OR "rutting" OR "compaction") in the title, abstract and keywords. In Web of Science, the search was (forest* operations OR "forest* harvesting" OR “forwarder*” OR “skidder*”) AND ("soil mitigation" OR "soil disturbance" OR "soil protection" OR "ground protection" OR "rutting" OR "compaction") Refined by: WEB OF SCIENCE CATEGORIES: (FORESTRY). Indexes: SCI-EXPANDED, SSCI, CPCI-S, ESCI.

Studies were only considered if words used in the search string were present in the title, keywords or abstract and if they were:

-

published between 2010 and 2020, in order to reflect the actual state of the art and recent developments;

-

peer-reviewed scientific articles or conference proceedings;

-

written in English.

Search Query and Article Analysis

The search query resulted in a total of 273 articles of which 90 were reported by Scopus, 101 by WOS and an additional 82 articles common to both databases but only counted once (Fig. 1; black line). The number of published articles has been increasing in the past decade with two noticeable peaks occurring in 2015–2016 and from 2018 onwards with the highest frequency of 45 articles reported in 2020.

Each of the 273 articles resulting from the search queries were evaluated in a three-step process.

-

1.

Titles were first verified to make sure that the field of study was forestry,

-

2.

Abstracts and keywords were read and articles that did not refer to soil mitigation techniques were omitted,

-

3.

Full articles were read and inclusion rested on the use of techniques to mitigate machine-induced soil physical disturbances (primarily soil compaction and rutting).

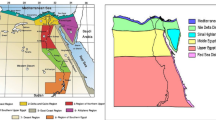

In total, 104 articles fulfilled all three criteria (Fig. 1; grey line) and are part of this review. To structure the main findings and associated recommendations, the articles were divided into four main themes: terrain-related factors, operational planning, machine modifications, and use of amendments as mitigation techniques (Fig. 2). These themes are then presented and assessed in a chronological order from the point of view of forest operations.

Results

Terrain-Related Factors

Terrain-related factors are normally inherent to a harvest site and are thereby difficult to adjust, particularly once operations are on-going. However, despite the reduced possibilities for alterations, factors such as slope [12, 23, 28–31], soil water content at the time of harvesting [9, 11, 13, 30], soil texture [23, 32], initial soil bulk density, relative bulk density [21], organic matter content, and duff thickness [31] can all play an important role in how a soil will physically respond to ground-based machine traffic (Table 1). In the context of this article, slope is referred to as the longitudinal incline or decline of the terrain located on machine operating trails.

Slope

Terrain slope often governs the trafficability of forest machines and can result in increased soil bulk density [12, 23, 28, 29, 31, 33, 38] due to an unbalanced load distribution during logging operations. Naghdi et al. [23] found that soil bulk density and rut depth increased as the slope of a machine trail increased. Conversely, Jankovský et al. [30] reported that trail slope had little to no effect on mean rut depth and the rehabilitation of rut depth five years following harvesting operations.

Sohrabi et al. [31] reported that, due to slippage of a wheeled skidder, soil bulk density and penetration resistance were higher on slopes exceeding 20% as compared to lower gradients (0–20%). These same authors also reported that the recovery rate of soil properties including bulk density, total porosity, and penetration resistance was slower in slopes exceeding 20%. Similarly, Naghdi et al. [33] determined that soil bulk density, porosity, and rut depth were significantly affected by trail slope.

According to the abovementioned results, several authors concluded that ground-based logging operations should be limited to machine operating trails with slopes below 25% [12, 23, 28, 29, 31, 33, 38]. However, in some instances, few machine passes can be allowed on trails steeper than 25% [12]. By considering two skidding directions through downhill slopes (i.e., -10%, -20%) and uphill slopes (10%), Majnounian and Jourgholami [38] and Jourgholami et al. [28] explained that soil bulk density showed substantial increases in uphill skidding as compared to downhill skidding direction. In uphill skidding, wheeled ground-based machines slipped on the surface soil, resulting in the exposure of mineral soil due to the applied vibration and shear strength [28, 38].

Soil Water Content

Soil water content plays a key role in soil consistency as soil changes from one state to another (i.e., Atterberg limits) [30]. Seasonal changes in rainfall and temperature have direct effects on soil water conditions that influence load bearing capacity, which in turn determines the degree of soil disturbance and compaction [11]. Normally, moist soils are more susceptible to compaction than dry soils [30]. Soil disturbances and average rut depth can effectively be predicted by soil water content [12, 13]. At a given compaction energy, increasing the soil water content will increase soil bulk density up to the maximum density, after this critical point, soil bulk density decreases as soil water content increases [30]. A strong correlation exists between soil water content and mean rut depth [11–13]. Allman et al. [13] found that when soil water content exceeded the plastic limit, an average rut depth > 16 cm occurred during logging operations. Jourgholami and Majnounian [11] concluded that average rut depth were 35 cm, 22 cm, and 17 cm on soils with gravimetric water contents of 40 − 50%, 30 − 40%, and 20 − 30%, respectively.

Studies also highlight that when soil water content exceeds the field capacity, an important measure to mitigate soil compaction and rutting is the cessation of harvesting activities until soil conditions improve (Table 1). Other implications include reducing the ground contact pressure, topsoil reinforcement (i.e., logging residues, mulching), and scheduling operations to dry period or on frozen soils [11–13, 30].

Soil Texture and Other Factors

Several studies focused on the effects of texture on soil compactibility [32, 39]. Naghdi et al. [23] concluded that soil bulk density and rut depth showed greater increases in clay loam soil than in a sandy loam soil during ground-based skidding. The content of fine-grained particles (silt and clay) is an important driver that determines the degree of soil compaction [9]. The resistance to compaction was higher in soils with low clay content [32]. Slesak et al. [39] stated that a well-structured loam soil was more susceptible to soil compaction. Martins et al. [32] found that higher levels of resistance to soil compaction were observed on soils with greater amount of sand content. Accordingly, Naghdi et al. [23] reported that rut depth on slopes exceeding 20% were 28.3 and 15.4 cm, on clay loam and sandy loam soils, respectively.

Soil structure, soil organic matter content, and initial bulk density were also crucial in assessing soil compaction caused by heavy forest machines [31]. Forest soils with an initial low (pre traffic) bulk density can be more easily compacted, at the same compaction energy, than a denser soil. However, a denser soil might require a lower compaction energy in order to trigger tree growth impediments [21].

Operational Planning

Decision Support for Predicting Trafficability and Route Planning

Theoretical Predictions of Machine Impact

In Russia, several studies have focused on predicting machine impact by theoretical mathematical models. Manukowskii [40], presented a model to calculate rutting by caterpillar forest machinery based on number of passes, subsoil and topsoil properties. Grigorev et al. [41] developed a model for dynamic soil compaction by wheeled forestry machines where the impact of topography, weight and type of wheel system could be studied. However, the model did not include parameters such as soil water content and soil type. A detailed study of the impact of logs on three different soils during skidding, by the same research group, was suggested to be used for drawing up a technological map for projecting a logging area based on skidding system specifics and soil type [42, 43]. The model results were compared with experimental studies in the laboratory and the differences were less than 10% [42]. Rudov et al. [44] studied the lifting capacity of frozen grounds of different textures, soil water contents and temperatures under the action of static loads and pointed out the increase in sensitivity of the soils between -1 and 0 °C and its dependence on soil salinity.

A decision support tool used in agriculture is the SoilFlex-model which was developed for predictions of tire/soil interactions: Goutal et al. [45] tested if it could also be used on forest soils in France. The predicted bulk densities after two passes with a forwarder were higher than the measured ones in the upper layer (0 − 10 cm) and the opposite but smaller differences in the deepest layers (20 − 35 cm). According to the authors, the overestimation in the upper layers could be due to the buffering effect of the forest floor due to the organic matter content and persistent root mat which is not present in agricultural soils. Goutal et al. [45] suggested that an increased rebound could improve the model performance and that this parameter depends on the soil organic carbon in the soil layer. They conclude that the model estimations well predicted the compaction range after forwarder traffic, even for forest soils with a non-negligible root and gravel content.

Trafficability Maps

Several trafficability maps have been developed and tested in the field in the recent years. In Finland, a static trafficability map was developed by Arbonaut OY and tested by Kankare et al. [46]. The model was based on topographic wetness index (TWI), amount of vegetation, ground water height and ditch depth. The main point was to provide information about in which season different areas may be harvested with standard machinery (harvesters and forwarders) with a 16 m × 16 m resolution. When the maps were used in thinning operations, ~ 70% of the evaluated stands were harvested without causing any damage if they were harvested in the correct season; the corresponding percentage for incorrect timing was ~ 40%. In Western Montana (US), Reeves et al. [47] developed a model based on landscape characteristics and the season of harvest that with local calibration can be used for prediction of detrimental soil disturbance and help adapt management strategies. Aspect, slope, land type and the interaction between harvest season (winter or non-winter) and land type were significant variables in the model. Another decision support tool for predicting forest harvesting impact on soil properties was developed by Shabani et al. [48] generating maps with susceptibility for either compaction, displacement or rutting. The model was based on GRASP (generalized regression analysis and spatial prediction) and included a.o. soil properties, slope, and forest type. It accurately predicted compaction, displacement and rutting with 97 − 98% in the test area in Iran.

In 2012, Mohtashami et al. [49] demonstrated a model in ArcGIS where elevation, slope, aspect and soil type were used to build up a cost-index surface, where trafficability was classified in five levels. In the case study presented, it was demonstrated that both time and money could be saved when using the model and building a corduroy road on a piece of wetland to reduce the forwarding distance and at the same minimize the disturbance on soils and waters for the entire extraction road network. Following this work, Mohtashami et al. [50] tested if depth-to-water maps alone or combined with other information such as soil type, could predict where ruts occurred during forest operations. The results pointed to that DTW-maps alone did not predict rut formation but combined with other information, their relevance increased. Slash reinforcement was used by the operators, when they found it necessary, at the 16 sites included in the inventory which may have influenced the results.

Whereas trafficability maps that are not modified over time despite changing weather can be referred to ‘static’, ‘dynamic’ trafficability maps are updated using weather data. In a study by Salmivaara [51], a dynamic map for rut depth or rolling resistance prediction was developed by using hydrological modelling to account for changing weather conditions. The map had a resolution of 16 × 16 m and a wide range of open-source spatial data was included, e.g. soil texture, a digital elevation model and stand characteristics from the Finnish forest inventory, as well as transported mass through a cell. In the same study, harvester CAN (Controlled Area Network)-bus data was pointed out as a useful tool to measure rolling resistance coefficient in the field [51].

Predicting Trafficability Based on Field Measurements

Cone penetrometers are popular and simple tools for measurements of bearing capacity in soil disturbance research, where Cone index is the penetrometer resistance at a given depth (average or maximum). Allman et al. [52] found that Cone index of the upper 30 cm of the mineral soil was a weak predictor of soil disturbance (rutting and soil compaction) in the temperate forests in the mountains of central Europe. There was a weak relationship between maximal rut depth and cone index for the eight harvested forest stands, but not between cone index and mean rut depth [52]. In a study in Croatia, both cone index and shear strength were found to following the same pattern over a year as the volumetric water content (VWC) measured by a portable TDR (time-domain reflectometry); high VWC resulted in low cone index and shear strength and vise verse [53]. All three parameters were related to precipitation and temperature and their fluctuations over the year.

Different soil properties can be measured and available inventory data used for predicting trafficability [54–56]. Uusitalo et al. [54] presented a model for predicting rut depth by an 8-wheeled forwarder in fine-grained boreal forest soil. The best predictors were VWC, the thickness of humus layer, cumulative mass of machine passes, and bulk density. For a forwarder on fine grained soil, rut depth was found to be related to total overdriven mass, VWC, cone penetration resistance and the harvester rut depth [56]. Five different models were tested, and the authors conclude that the model including harvester ruth depth and cumulative overdriven mass is a good predictor of rut depth. The impact of the harvester on the soil was a good predicter of the forwarder rut formation also on mid-grained soils [55]. Here, the number of machine passes, VWC in the mineral soil and depth of the organic layer was controlling factors for rut formation.

Route-Planning

A model called “Direct Skid Trail Pattern (DSTP) has been developed for planning skidding operations with farm tractors in Turkey [57]. The aims were to minimize skidding time, achieve a high extraction productivity and optimize the skid trail pattern in order to minimize spatial soil compaction and soil loss. Working time performance/productivity increased by 17% when the “Direct Skid Trail Pattern”-model was used compared to not using the model. At the same time, the average length of skid trails per hectare decreased by 33%, and thus the spatial area affected by soil compaction and the potential soil loss decreased accordantly [57].

Picchio et al. [58] demonstrated a method for strip road planning, where a digital elevation model (DEM) of 2 m resolution was used, together with data on no-go areas within the forest stands. Driving steeper than 45% forward-backwards or steeper than 25% sideways were not allowed (based on the tipping risk of the machine used). From each position of the forwarder, it was assumed that logs up to 12 m from the center of the strip-road could be reached. The harvested area was divided into pixels, based on the total harvested mass for the entire harvested area, where each pixel was one forwarder load (assuming that the harvested mass was evenly spread over the clearcut). The strip road pattern and routes were optimized with various GIS-tools to minimize surface impact of the operation. Finally, the routes were transferred to the machine and followed by the operator. When comparing the GIS-planned routes with the harvester strip road pattern, the area of impacted soil was reduced between 50 and 70% (three different stands).

Operational Methods

There are several means by which soil compaction and rutting can be minimized within an operational context. At the forefront, this includes improved planning and choice of harvesting method. In the literature there are examples of follow-up techniques and methods to counteract soil compaction by site preparation to enhance seedling growth. There are two main harvesting methods dominating; cut-to-length (CTL) and tree length (TL). The CTL method is normally performed with a harvester-forwarder system, while the TL method usually includes felling (by machine or manual) and skidders of different types. These differences can be considered when evaluating the results. Furthermore, differences in management strategies, final felling or thinnings could explain some of the results since transported volume per area differs.

Reduced Compaction by Improved Planning

The way harvesting operations are planned could have a large impact on soil damages. Improved planning could be done by a better distribution of machine operating trails [59], minimizing driving by optimizing distances between harvested trees [60] or establish permanent designated trails [61]. As presented in the results of the terrain-related factors, it is demonstrated that the direction uphill or downhill could affect soil disturbances. There are indications that driving downhill reduces the negative impacts on the soil [28, 62]. The extent of machine turning can also influence the severity of soil disturbances, particularly when the change in direction is pronounced [63]. Driving distances within a harvest site could also have an impact on the extent and severity of compaction or rather, that all traffic is funneled to landing sites leads to higher soil compaction at the perimeters of harvest sites [64].

Reduced Compaction by Logging Methods

Literature concerning reduced compaction by harvesting methods are quite diverse. A study from Poland reported of less damages on remaining trees and soil following CTL as compared to TL [65•]. Similar results were obtained from a study in Maine (USA) were the harvester-forwarder system had the lowest impact on soil bulk density compared to skidding with tractor, bulldozer, or skidder [66]. This is in contrast to a study by Dudakova et al. [67] in Slovakia where a harvester-forwarder system caused the largest damages. Cambi et al. [68] used a photogrammetry method to compare effect of forwarder traffic vs. skidder traffic and concluded that the forwarder caused more damages to the soil. In a Turkish study by Eroğlu et al. [69], four different extraction methods were compared: skyline, ground skidding by manpower, skidders and a chute system. The results imply that both ground-based system had an impact on soil permeability, bulk density and soil water balance. Marchi et al. [70] measured the difference between two carrying systems compared to two winching system and concluded that dragging the logs on the ground caused more severe disturbances.

Coppice Forestry

Coppice or short rotation forestry is a common forest management system in the Mediterranean area, where about 23 million ha are managed as coppice [71]. The coppice system is characterized by short rotation, 6–10 years between cutting meaning that the time for soil recovery is very short between operations. Spinelli et al. [72] published an extensive review covering 65 stands in central and Southern Italy and Laschi et al. [22] made a thorough Life Cycle Analysis (LCA) and concluded that the extraction phase had the largest impact on the end result. Venanzi et al. [71, 73] compared two skidder systems with light weight machines and a harvester/forwarder system and reported some soil recovery already one year after operations. In contrast, Naghdi et al. [74] found no sign of recovery during the first year after skidding. Paya et al. [71] found that following skidding operations, microporosity was reduced by 62.5 and 53.8% for 0–10 cm and 10–20 cm, respectively, in comparison to unaffected soil surfaces.

Site Preparation

In four cases of the articles in this review, site preparation has been reported to counteract soil compaction. Silveira França et al. [75] showed that planting in borehole through the compacted layer improved seedling growth. Following a wind throw event on a wet soil in South Carolina, long-term effects of different types of site preparation were studied [76, 77]. The result showed that so-called bedding (i.e., creating a string of soil on top of the soil surface for better aeration at wet sites) led to improved seedling growth. Long-term studies are rare, but Cerise et al. [78] sampled a 45-year old felling where different types of site preparation had been tested and could not detect any residual effects.

Machine Modifications

Twenty-seven articles investigated the effects of various machines operating in different conditions on their impacts on soils and identifying possible mitigation strategies linked to machine modifications. In fact, the use of machines in forest operations is the direct cause of impacts on soil. For this reason, many studies investigated different factors to find solutions to reduce the impacts, mainly in relation with soil compaction. In this context, machine size, traction type, tire size, axle load and the total number of passes (traffic) are the most important variables affecting soil compaction; the role and the effects of these factors can be increased or reduced depending on soil properties. In particular, slope, soil water content and soil texture are the most crucial. In this context, it is fundamental to choose appropriate machines considering local conditions in terms of logistics and soil properties [79–81]. Several studies investigated the use of machines applying different technological solutions to mitigate the negative effects on soil.

Technical Features

The reduction of ground pressure exerted to the soil is key in minimizing soil compaction and rutting [15]. For this reason, several strategies have been tested and reported in the literature. The addition of steel flexible tracks (SFT), created from steel cross-members joined by chain links that span the entire length of a bogie axle, are common for wheeled machines as they contribute to reduce soil compaction in many conditions by increasing the contact area between machines and soil surface [82–84]. In this context, Labelle and Jaeger [85] investigated the load distribution on a load test platform using a forwarder in different conditions (loaded/unloaded and with/without SFT). They assessed for the first time the dynamic load distribution below SFT, obtaining 30% lower values of dynamic peak loads mounting SFT than without SFT.

In another study, Haas et al. [82] compared three configurations of tires – 940 mm width, 710 mm with and without steel flexible tracks (SFT)- on an approx. 30 000 kg loaded forwarder to assess the effects of rutting. Results indicated that deeper ruts were caused by narrower tires and also higher lateral soil displacement, causing more consistent bulges than wider tires. The use of wider tires as mitigation strategy for soil compaction has also been confirmed by Cudzik et al. [83] and Solgi et al. [86], which found a positive effect in terms of tractive efficiency [83] and soil physical properties [86]. According to Starke et al. [84], reducing tire inflation pressure of a ten-wheeled forwarder caused lower rut depth. Moreover, authors evidenced the potential positive effects of an added bogie to reduce soil compaction, as suggested also by Solgi et al. [86], especially on soft soil conditions [84]. An interesting improvement on forwarders to reduce rutting has been tested in Sweden by applying a pendulum arm technology to a 6-wheel forwarder. It has been compared with a traditional 8-wheel forwarder; results of rutting measurements were not better than traditional technology, mainly due to the lower number of wheels, but the good potential of this technology was reported [87]. Furthermore, this potential was partially confirmed in another study comparing different forwarders equipped with standard wheels, SFT, rubber tracks, and pendulum arms. In fact, pendulum arm technology obtained promising results in terms of rutting, but rubber tracks obtained the most encouraging results. In fact, rubber tracks used under loaded conditions were able to lower rut depth by up to three times as compared to conventional tracks [88], highlighting the importance to distribute the applied load. In this context, the response of tracks in relation to wheels of crawler tractors on soils exposed to different conditions of slope and traffic, caused significantly lower increases of bulk density and rutting [79, 89–91]. In this sense, similar results were obtained by Cambi et al. [90] comparing the effects of a tracked and a wheeled agricultural forest tractor adapted for use in forestry on forest soil physical properties (bulk density, penetration resistance, porosity and shear resistance) at different soil water contents.

Solutions for Steep Terrains

Slope is one of the most important factors affecting the impacts of forest operations on soils. This is one of the reasons why, together with productivity and safety improvement, cable-assisted machines have been developed and increasingly used in the last years, and why this technology is considered as “one of the major innovations in steep terrain harvesting in the twenty-first century” [92••]. In fact, thanks to this technology, slip during machine traffic can be reduced [93], together with reducing maximum ground pressure [92••, 94]. Moreover, Garren et al. [94] in an experimental area in Brazil, found similar impacts of bulk density for both forwarding on gentle slope and cable-assisted forwarding on steep slope [94]. Furthermore, it could have positive effects also on flat terrains and soft soils [92••]. Finally, Green et al. [93] reported that cable-assisted machines maintain consistent travel paths concentrating the impacts on a smaller surface than non-tethered ones, confirming also a lower effect in terms of bulk density increase after traffic. Nevertheless, comparing tethered equipment and traditional systems for felling and extraction, Chase et al. [95] observed lower soil disturbance and stream-adjacent disturbance applying motor-manual felling and extraction by conventional cable yarder than using cable-assisted machines.

Machine Choice

Regarding machines, another important factor to mitigate the impacts on soil properties is strictly related with the importance in choosing the most suitable machine for specific worksite conditions [79, 80, 96, 97]. In this context, the debate on the best choice between traditional or mechanized harvesting systems is very active, where “traditional” means low mechanized systems including the use of chainsaw for felling and processing, and farm tractors adapted for forestry for bunching and extraction [97–99]. In some cases, mechanization is considered better than traditional systems in terms of impacts on soils; Rejšek et al. [98] applying a dynamic penetration test obtained lower effects operating with a three-axle harvester and four-axle forwarder than with a universal wheeled tractor. The main difference was identified as a poorer load distribution and higher ground pressure of the tractor. Other studies obtained different results, as reported in Solgi et al. [97], comparing skidding operations with a light farm tractor (3 100 kg) and a skidder (11 500 kg) in clay loam soil. In this case study, the negative effects of traffic on soil properties in terms of bulk density, porosity and rut depth after the same number of passes were higher for skidder than tractor [97]. Similar results and conclusions are reported in Nikooy et al. [99]. In general, the results obtained comparing different machines or solutions in terms of impacts on soils are strictly related to local conditions; this is also valid for comparing different harvesting systems as reported by Venanzi et al. [71], which obtained lower soil impacts by winching in comparison with forwarding in coppice.

Machines Use

Beyond the above-mentioned technical aspects, a strong influence on the effective impacts on soil derives from the proper or unproper use of machines, which is influenced by the workers’ experience and the operational conditions. In this sense, several authors have reported a series of recommendations to mitigate impacts on soil physical properties. Many authors agree on the fundamental need to have a correct and rational planning of forest roads and machine operating trails in particular [38, 87, 96, 100]. On the other hand, some authors recommend to reduce the number of trails in order to concentrate impacts on limited surfaces [38], while others suggest to limit the number of passes in a single trail recommending the creation of more trails to distribute soil compaction in the forest [100]. Solgi et al. [86] included both options suggesting to limit the number of passes in a trail up to 15, or to create high-traffic areas. Uusitalo et al. [101] suggested to create wider trails in peatlands to avoid to pass with wheels or tracks in the same area, thus distributing the traffic on a larger path. In any case, machines should avoid operating outside the planned trails [102]. It is important considering that the negative effects of traffic in terms of increased bulk density are extended up to 1 m far from tracks, enlarging the total damaged forest surface [15]. Moreover, trails must be maintained and restored to minimize erosion risks [79] and they should be used in dry conditions [15, 80, 96, 97, 102]. When it is not possible and work is necessary in wet conditions, the use of tracked tractors is recommended and preferred to wheeled [90]. However, to evaluate if soil water content allows forest operations, Allman et al. [103] suggest to test if Atterberg plasticity limits of soil are exceeded or not.

Use of Amendments as Mitigation Techniques

In total, 15 articles dealt directly with amendments that can be placed on the soil surface during or after harvesting operations to act as a protective layer against machine-induced soil disturbances (Table 2). From these articles, two main groups of amendments emerged: brush (12 articles) and mulch (3 articles). These amendments were tested to see how they could impact load distribution, bulk density, rut depth, penetration resistance, and total porosity following ground-based machine traffic. Brush is defined as harvesting debris (treetops, branches, and foliage) that originates from the processing phase and is placed on machine operating trails in order mitigate the effect of harvesting and forwarding machines on soils as they are being operated in a harvest block. The use of brush is more commonly linked to cut-to-length operations where harvesting debris remains in the stand. Once placed on a machine operating trail, harvesting debris forms a brush mat. When a machine is in direct contact with a brush mat, the friction between the pieces constituting the brush mat increases and creates a reinforced surface that can expand the contact area between a machine’s running gear and the soil surface [10]. The other main group of amendment, referred to as mulch, includes sawdust, straw and litter. Unlike brush, which is a direct raw biproduct of forest operations, mulch types are normally brought to the harvest site and originate from a secondary transformation.

Brush

As bioenergy markets are expanding, the competition between using harvesting debris as a soil protective layer during forest operations or for bioenergy operations is on the rise [15]. Finding a certain equilibrium between the two uses remains complicated and is normally a function of biomass markets and a site’s susceptibility to disturbances. The quantity and quality of brush available for soil protection is directly related to site quality, stand characteristics (species, age, diameter at breast height (dbh), and height), silvicultural treatment, and degree of tree removal [117].

Load Distribution and Bulk Density

Brush mats are able to distribute applied loads to a greater area below the mats and thus decrease peak pressures exerted to the soil [10, 109]. In a controlled test, Labelle and Jaeger [10] demonstrated that brush mats of ≥ 20 kg m−2 were able to statistically lower peak pressures exerted below an 8-wheel forwarder (30 180 kg loaded) as compared to a no brush scenario and that these thicker mats offered better protection against repeated forwarder passes as compared to lighter brush mats (< 20 kg m−2). Those tests were performed on a so-called load test platform equipped with high-capacity load cells. Beyond their capabilities of load distribution, brush mats can also mitigate the increase of soil bulk density during ground-based machine traffic [110]. Specifically, Labelle et al. [105], Solgi et al. [108], Agherkakli et al. [111], and Matangaran [112] all reported a reduction in the compaction rate (difference between pre- and post-impact soil bulk density) as brush amount increased. However, this finding was not supported by all studies as Parkhurst et al. [107] and Hashimoto et al. [114] were not able to report any clear trends as to the ability of brush mats to reduce soil bulk density increases as compared to a no brush scenario. Since the compaction rate is often linked to the initial (pre-harvest) state of the soil, the concept of relative bulk density has also been applied to obtain a qualitative assessment of the disturbance [15, 105]. In this context, relative bulk density is referred to as the ratio between field bulk density and maximum bulk density achieved by the standard Proctor test. A relative bulk density threshold of 0.8 has been linked to reduced growth of Norway spruce (Picea abies Karst) [21]. Using this relative bulk density concept, Labelle et al. [105] reported that 40.5%, 17.9%, 14.3%, 15.5%, and 3.6% of soil relative bulk density measurements covered with 0, 5, 10, 15, and 20 kg m–2 of brush, respectively, exceeded the 0.8 threshold when performing operations with a Timberjack 1110D 8-wheel forwarder (32 860 kg loaded) on silty soils.

Rut Depth and Penetration Resistance

As the distance between the point of impact (below the machine running gear) and the soil surface increases through the use of brush mats, rut depth caused by machine traffic can also be reduced [104, 106, 108, 111–113]. In a study performed in eastern Canada with a 35 800 kg loaded 8-wheel forwarder, brush mats of 5, 10, 15, and 20 kg m−2 offered reductions of indent areas (depression of the soil below the pre-impact level) of 0.0, 14.3, 71.4, and 90.5%, respectively, as compared to the no brush treatment [106]. Moreover, brush mats of 15 and 20 kg m −2 were able to statistically reduce rut depth as compared to when the forwarder was driven directly on the forest floor, a finding that was also supported by Ilintsev et al. [104] when using an 8-wheel John Deere 1210 (31 080 kg loaded). On highly susceptible soils (clayey silts), research by Matangaran et al. [112] showed that average rut depth created by a Valmet 860.1 forwarder weighing 29 900 kg decreased from 24 cm down to 0 cm when using 1 m thick brush mats composed of black wattle (Acacia mangium Willd.) as compared to no brush.

In addition to soil bulk density, penetration resistance measured pre and post harvest can also be used to gain further insight soil disturbances. According to Labelle et al. [105] who performed field trials with a Timberjack 1110D 8-wheel forwarder weighing 32 980 kg, soil penetration values > 3.0 MPa represented 23.7%, 15.0%, 9.4%, 4.6%, and 0.7% of all post-forwarding test plots that were covered by 0, 5, 10, 15, and 20 kg m–2 of brush, respectively. The penetration resistance threshold of 3.0 MPa was used since it has been linked interrupted root growth [118].

Mulch

Mulch has been used as a post-impact amendment to try and accelerate the rehabilitation of certain soil physical properties. Jourgholami et al. [115] tested the influence of straw and litter mulches applied to the machine operating trail at rates of 1.27 kg m−2 and 1.67 kg m−2, respectively, on the recovery of soil bulk density and penetration resistance measured three years after mechanized operations. Results indicate that both bulk density and penetration resistance values recovered at a faster rate with the use of litter mulch as compared to straw mulch but that both mulch types improved recovery as compared to the uncovered plots. Jourgholami et al. [116] reported that applying sawdust mulch (3.65 kg m−2) allowed for a faster recovery measured six years after harvesting operations of soil bulk density (8%), rut depth (13%) and penetration resistance (19%) as compared to untreated trails. It is important to note that these findings are for trails with a longitudinal gradient of 10%. In a study performed in Iran with a 4-wheel skidder operated on a silty loam, Solgi et al. [108] only reported statistical differences in soil bulk density when using the thicker 20 kg m−2 sawdust mat as compared to unprotected soil but statistical differences were noted when using the thicker 20 kg m−2 sawdust mats.

Discussion and Recommendations

Terrain-Related Factors

Terrain steepness was an important factor that influences the trafficability of ground-based machines on forest soils and has a direct impact on changes in soil physical properties (i.e., bulk density, porosity, perpetration resistance, rut depth) [23, 31, 37]. Both unbalanced load distribution and wheel slippage on the soil surface are the main contributors to excessive soil compaction on steeper terrains [34, 36]. Studies highlighted that ground-based harvesting operations should be planned whenever possible on slopes less than 20% with downhill directions [28, 30, 36, 38]. By increasing the slope of machine operating trails, environmental impacts on soils appeared to be intensified, thereafter; several studies concluded that a critical slope can be appointed coupled with soil texture and water content conditions [2, 31, 33].

Changes in soil water content during the year by seasonal alterations and precipitation has a significant effect on soil vulnerability to compaction and rut formation, especially in fine-textured soils [9, 13, 30]. Studies demonstrated that soil compaction and rut depth were significantly higher in moist soils as compared to drier soils [11, 17, 33]. In many regions, ground-based logging operations were conducted on frozen soils, a natural barrier that greatly reduces soil disturbances [2]. However, in changing climate that triggers highly variable weather conditions, forest operations can be presented with shortened windows of operations, particularly in sensitive areas of high water content [1, 104, 119]. In fact, studies revealed that fine-textured soils coupled with high water content are easily prone to soil compaction and rutting [23, 32, 39]. Forest soils with low intrinsic bulk density, well-structured, and high organic matter content might be more vulnerable to compaction and rutting, which appropriate measures should be applied to prevent the adverse effects on forest soil.

Operational Planning

The different theoretical mathematical models, described above, need to be incorporated in a user-friendly decision support tool to be of use for operational planning in forestry. The static and dynamic trafficability maps summarized in this paper appear to be useful tools for operational planning. However, their use may be limited to the region/country in which they were developed, as they are based on conditions and data availability in that region. As pointed out by some studies included in this review [55, 56], the rut depth of the harvester is a useful predictor of where more severe rutting is expected by the forwarder. There are several techniques of directly measuring the forwarder rut depth, but they all require additional sensors to be mounted at the rear of the harvester. A more cost-efficient method could be to use harvester CAN-bus data (i.e., data on the power used for driving) to predict trafficability of the forwarder, as tried by Salmivaara et al. [51]. This technique has been further tested by Ala-Ilomäki et al. [120•] and they found that the CAN-bus data was efficient for mapping site trafficability. In addition, assessments of harvester rolling resistance by using CAN-bus data has the potential to be used in a larger scale (Big Data), as indirect power recording is possible in all modern harvesters and the cost of automatically creating trafficability maps is negligible, according to Ala-Ilomäki et al. [120•].

A couple of tools for route-planning of an area to be harvested were within the search string of this review [57, 58]. However, there are other tools with high potential for efficient and gentle route-planning, where less soil disturbance could be an important biproduct. Rönnqvist et al. [121] demonstrated a decision support tool (BestWay) for primary extraction routes to minimize forwarding distance while avoiding steep terrain and wet areas. The input data in the optimization model were harvesting block perimeter, forest volume density (from LiDAR-data), a digital terrain model (2 m resolution), a depth-to-water map and no-go areas (e.g., historical or nature conservation areas). The BestWay tool has been developed to also suggest landings based on the forest road network, closeness to crossings, power lines, streams, and too steep areas for storage [122]. If wood can be extracted through shorter distances and transport times and at the same time with less impact on soils and waters, there is a high potential for acceptance and a smooth implementation in operational forestry.

Machine Modifications

The analysis of the wide existing literature in terms of impact on soils due to machine traffic highlighted how the different aspects are always directly or indirectly related with the pressure exerted on the ground. In fact, the mitigation techniques reported, such as wider tires, reduced tire inflation pressure, additional axles and wheels, steel flexible tracks, etc. are all systems aimed at reducing ground pressure and consequently the negative effects on soil physical properties. As reported, many factors affect the performances of the existing solutions limiting impacts on soil. In particular, soil texture, soil bearing capacity and terrain slope have to be considered as fundamental to choose the best technical solution. In this context, the right option is not certain, even if some solutions often resulted better than others. In general, harvester-forwarder are considered the least impactful machine-based forest operations [2]. Nevertheless, conflicting results emerged from some studies that compared traditional tractors with highly mechanized systems. In many cases, using traditional tractors resulted in lower forest soils disturbances than with highly mechanized systems. This result could be attributed to the fact that comparisons were made in terms of similar operational condition and comparing the same number of passes. To gain further insight, it would be interesting to compare the impacts on soil after the same wood quantity processed and transported by the two machines (and consequently a different number of passes). Moreover, it would be useful to investigate if workers’ level of both training and experience can affect the impacts on soil during operations. This is demonstrated in terms of productivity [123], but not in terms of efficiency to reduce impacts on soil, even if remarked in some studies as a factor to be considered [2, 124].

Use of Amendments as Mitigation Techniques

The frequency of partial harvests is on the rise as more forest operations are performed under close-to-nature/continuous cover forestry [125, 126]. During such operations, it might become more difficult to reach the suggested brush amounts for adequate soil protection [117]. However, it is not necessary to aim for a uniform distribution of brush on machine operating trails, at least not to the suggested extent, but rather try to reach the recommended targets (15–20 kg m−2) on sensitive areas (depressions, moist soils, fine-textured soils, high traffic areas, etc.) where soils are most susceptible. Most brush studies performed in a context of soil protection presented brush amounts in kg m−2. This unit is practical for scientific experiments but remains quite cumbersome to translate into an operational context. To circumvent this, Labelle et al. [10] determined that kg m−2 brush amounts can be converted to cm thickness by applying a factor of 2 or 2.5, hence, a 20 kg m−2 brush mat would approx. equal a 40 to 50 cm loose thickness.

Brush generally provided the highest protection against soil bulk density increases and rut depth as compared to the other reported mulch types. This is particularly the case when machine traffic is low. When brush is exposed to repeated machine passes, it compacts and a high proportion of branches are broken or sheared, which can in turn decrease the overall strength of the mat [10]. Despite this lowered strength, Labelle and Jaeger [10] reported that thicker brush mats of 15 and 20 kg m−2 still offered beneficial load distributing capabilities after 12 loaded passes. Another advantage of brush is that it is readily available at the harvest site, especially when no bioenergy markets are developed in the proximity to the harvest area.

General Management Recommendations and Strategies

Pre-harvest

Operational planning of forest operations is the key to avoiding severe soil disturbances, including which forest units to be cut in which season, which machine resources to be used (including machine modifications), and the planning of landings, main extraction routes (machine operating trails), no-go areas, and amendments to be used, such as portable bridges and brush. Following recommendations should be considered during planning:

-

Adapting the forest practice to local conditions and specific site characteristics with different soil types, hydrology, and slope.

-

Planning landings and forest road network in steep terrain in such a way that the timber extraction is done in downhill directions; upward movement of untethered loaded machines should be prevented as far as possible.

-

Limiting logging operations to gentle slopes, particularly < 25% appeared to be an effective way to minimize the degree and extent of soil compaction and rutting.

-

Lowering the ground pressure of the machines by using larger tires, reduced inflation pressure, additional axles and wheels, and/or bogie tracks.

-

Limiting logging operations on fine-textured soils to dry periods or frozen soil in addition to minimizing ground pressure.

-

Use route-planning tools based on various geo-data for finding potential landings and effective wood extraction routes to increase productivity (by shortening off-road transports) at the same time as soil disturbances are minimized.

-

Plan the operation beforehand as regards soil conditions and remaining trees to avoid turning.

During harvest

One of the most pivotal issue to minimize soil compaction and rutting is to prohibit machine entrance on wet soils.

-

Using real time mapping of sensitive soil based on local weather forecasts could be useful for help avoiding operations in areas where soil disturbances could be severe.

-

Measuring soil water content at the beginning of forest operations with some field methods could help machine operators to take decisions to concentrate the routes where high volume is extracted to drier areas and of increased use of amendments such as brush, mulch, corduroy mats in more sensitive areas.

-

With the increase of load capacity on new forwarder models, improved load distribution becomes paramount. In this context, the use of harvesting debris (brush mats) obtained from the processing phase, remains one of the most beneficial methods of distributing applied loads.

-

Applying between 15 and 20 kg m−2 of brush on machine operating trails to reduce soil bulk density increases and rut formation.

Post harvest

It is advisable to avoid rutting and soil compaction in the first place, but given that severe soil disturbances have occurred, there are some ways to try to mitigate the effect or speed up the recovery rate:

-

The usage of mulch types as a biproduct of a secondary transformation can help to accelerate the recovery of soil properties post harvest. One caveat is that is does require material to be brought to a harvest site and spread to machine operating trails post harvest, thus adding costs.

-

Mechanical site preparation could be used for loosening the topsoil after soil compaction and also backfill wheel ruts with the use of excavators. Such methods are normally applied in areas of high population (e.g., frequently accessed forest roads, areas of high visibility, etc.).

Further Research

Despite the wealth of published literature, it is clear that extensive research is still required in the field of soil mitigation techniques. The studies reviewed were wide ranging, both in terms of research scope and geographical location. The latter undoubtably influences the direction of the research through local policies and operational guidelines. Below is a list of selected research opportunities that either remain untapped or offer possibilities of expanded research.

-

Digital forestry provides almost endless possibilities of research. Now that trafficability maps are available, the challenge will be shifted to providing dynamic information to machine operators on where to travel, under which loading condition, and at which traffic frequency to minimize soil physical disturbances.

-

A lingering research question remains regarding the contrasting concepts of reducing the number of machine operating trails as much as possible via increased trail spacing, thus further concentrating machine-induced disturbances to a reduced surface or distributing the stress of machine passes over a larger area of a harvest site. This question is not trivial as the answer might be influenced by soil bearing capacity, operational considerations and machine use.

-

The presence of stones and boulders can increase soil bearing capacity but can also cause shifts in machine weight distribution if they are large enough, thereby increasing the exerted loads to certain wheels. We could not find studies that addressed this dual influence.

-

Consider new soil mitigation techniques that are in line with the effects of changing climate (increased calamities, insect outbreaks, draughts, etc.). For instance, a better understanding of how different mitigation techniques can be used simultaneously. Furthermore, the competition for use of brush between soil protection in forest stands and bioenergy operations as a source of biofuel should be studied further. Can an equilibrium be reached between the two uses? The answer probably rests on the status of biomass markets and the need to assign a value to the protection of forest soil.

-

Most studies have focused on quantifying one or two factors causing soil disturbances. There is a need for having a multi-disciplinary approach to tackle the complex problems associated with machine/soil/plant interactions. Certain relationships between mitigation techniques and their performance can only be fully understood through holistic projects.

References

Papers of particular interest, published recently, have been highlighted as: • Of importance •• Of major importance

Marchi E, Chung W, Visser R, Abbas D, Nordfjell T, Mederski PS, et al. Sustainable Forest Operations (SFO): A new paradigm in a changing world and climate. Sci Total Environ. 2018;634:1385–1397.

Picchio R, Mederski PS, Tavankar F. How and How Much, Do Harvesting Activities Affect Forest Soil, Regeneration and Stands? Curr For Rep. 2020;6:115–128.

Cambi M, Certini G, Neri F, Marchi E. The impact of heavy traffic on forest soils: A review. For Ecol Manag. 2015;338:124–138.

Picchio R, Neri F, Petrini E, Verani S, Marchi E, Certini G. Machinery-induced soil compaction in thinning two pine stands in central Italy. For Ecol Manag. 2012;285:38–43.

DeArmond D, Ferraz JBS, Emmert F, Lima AJN, Higuchi N. An Assessment of soil compaction after logging operations in central Amazonia. For Sci. 2020;66:230–41.

Picchio R, Mercurio R, Venanzi R, Gratani L, Giallonardo T, Lo Monaco A, Frattaroli A. Strip clear-cutting application and logging typologies for renaturalization of pine afforestation—A case study. Forests. 2018;9:366.

Schweier J, Magagnotti N, Labelle ER, Athanassiadis D. Sustainability impact assessment of forest operations: a Review. Curr For Rep. 2019;5:101–113.

Hansson LJ, Ring E, Franko MA, Gärdenäs AI. Soil temperature and water content dynamics after disc trenching a sub-xeric Scots pine clearcut in central Sweden. Geoderma. 2018;327:85–96.

Hansson LJ, Koestel J, Ring E, Gärdenäs AI. Impacts of off-road traffic on soil physical properties of forest clear-cuts: X-ray and laboratory analysis. Scand J For Res. 2018;33:166–77.

Labelle ER, Jaeger D. Quantifying the use of brush mats in reducing forwarder peak loads and surface contact pressures. Croat J For Eng. 2012;33:249–74.

Jourgholami M, Majnounian B. Effects of wheeled cable skidder on rut formation in skid trail - a case study in Hyrcanian forest. J Forestry Res. 2011;22:465–9.

Naghdi R, Solgi A, Zenner EK, Tsioras PA, Nikooy M. Soil disturbance caused by ground-based skidding at different soil moisture conditions in Northern Iran. Int J For Eng. 2016;27:169–78.

Allman M, Jankovský M, Messingerová V, Allmanová Z. Soil moisture content as a predictor of soil disturbance caused by wheeled forest harvesting machines on soils of the Western Carpathians. J For Res. 2017;28:283–9.

Jourgholami M, Ghassemi T, Labelle ER. Soil physio-chemical and biological indicators to evaluate the restoration of compacted soil following reforestation. Ecol Indic. 2019;101:102–10.

Labelle ER, Jaeger D. Soil compaction caused by cut-to-length forest operations and possible short-term natural rehabilitation of soil density. Soil Sci Soc Am J. 2011;75:2314–29.

Naghdi R, Solgi A, Zenner EK, Najafi A, Salehi A, Nikooy M. Compaction of forest soils with heavy logging machinery. Silva Balc. 2017;18:25–39.

Hansson L, Šimůnek J, Ring E, Bishop K, Gärdenäs AI. Soil compaction effects on root-zone hydrology and vegetation in boreal forest clearcuts. Soil Sci Soc Am J. 2019;83:105–15.

Jourgholami M, Fathi K, Labelle ER. Effects of foliage and traffic intensity on runoff and sediment in skid trails after trafficking in a deciduous forest. Eur J Forest Res. 2018;137:223–35.

Etehadi Abari M, Majnounian B, Malekian A, Jourgholami M. Effects of forest harvesting on runoff and sediment characteristics in the Hyrcanian forests, northern Iran. Eur J Forest Res. 2017;136:375–86.

Mariotti B, Hoshika Y, Cambi M, Marra E, Feng Z, Paoletti E, et al. Vehicle-induced compaction of forest soil affects plant morphological and physiological attributes- A meta-analysis. For EcolManag. 2020;462:118004.

Labelle ER, Kammermeier M. Above- and belowground growth response of Picea abies seedlings exposed to varying levels of soil relative bulk density. Eur J Forest Res. 2019;138:705–22.

Laschi A, Marchi E, González-García S. Forest operations in coppice: Environmental assessment of two different logging methods. Sci Total Environ. 2016;562:493–503.

Naghdi R, Solgi A, Labelle ER, Nikooy M. Combined effects of soil texture and machine operating trail gradient on changes in forest soil physical properties during ground-based skidding. Pedosphere. 2020;30:508–16.

Meyer C, Luscher P, Schulin R. Enhancing the regeneration of compacted forest soils by planting black alder in skid lane tracks. Eur J Forest Res. 2014;133:453–65.

Mohieddinne H, Brasseur B, Spicher F, Gallet-Moron E, Buridant J, Kobaissi A, et al. Physical recovery of forest soil after compaction by heavy machines, revealed by penetration resistance over multiple decades. For Ecol Manag. 2019;449:117472.

Sohrabi H, Jourgholami M, Jafari M, Shabanian N, Venanzi R, Tavankar F, et al. Soil recovery assessment after timber harvesting based on the Sustainable Forest Operation (SFO) perspective in Iranian temperate forests. Sustainability. 2020;12:2874.

Ezzati S, Najafi A, Rab M, Zenner E. Recovery of soil bulk density, porosity and rutting from ground skidding over a 20-year period after timber harvesting in Iran. Silva Fenn. 2012;46:521–38.

Jourgholami M, Majnounain B, Etehadi AM. Effects of tree-length timber skidding on soil compaction in the skid trail in Hyrcanian forests. For Syst. 2014;23:288–93.

Jourgholami M, Labelle E, Feghhi J. Response of runoff and sediment on skid trails of varying gradient and traffic intensity over a two-year period. Forests. 2017;8:472.

Jankovský M, Allman M, Allmanová Z, Ferenčík M, Vlčková M. Changes of key soil parameters five years after forest harvesting suggest slow regeneration of disturbed soil. J Sustain For. 2019;38:369–80.

Sohrabi H, Jourgholami M, Tavankar F, Venanzi R, Picchio R. Post-harvest evaluation of soil physical properties and natural regeneration gGrowth in steep-slope terrains. Forests. 2019;10(11):1034.

Martins PCC, Dias Junior M de S, Ajayi AE, Takahashi EN, Tassinari D. Soil compaction during harvest operations in five tropical soils with different textures under eucalyptus forests. Ciênc Agrotec. 2018;42:58–68.

Naghdi R, Solgi A, Labelle ER, Zenner EK. Influence of ground-based skidding on physical and chemical properties of forest soils and their effects on maple seedling growth. Eur J For Res. 2016;135:949–62.

Agherkakli B, Najafi A, Sadeghi SH. Ground based operation effects on soil disturbance by steel tracked skidder in a steep slope of forest. J For Sci. 2010;56:278–84.

Naghdi R, Bagheri I, Basiri R. Soil disturbances due to machinery traffic on steep skid trail in the north mountainous forest of Iran. J For Res. 2010;21:497–502.

Solgi A, Naghdi R, Tsioras PA, Nikooy M. Soil compaction and porosity changes caused during the operation of Timberjack 450C skidder in Northern Iran. Croat J For Eng. 2015;36:77–85.

Proto AR, Macri G, Sorgona A, Zimbalatti G. Impact of skidding operations on soil physical properties in southern Italy. Contemp Eng Sci. 2016;9:1095–104.

Majnounian B, Jourgholami M. Effects of rubber-tired cable skidder on soil compaction in Hyrcanian Forest. Croat J For Eng. 2013;34:123–35.

Slesak RA, Palik BJ, D’Amato AW, Kurth VJ. Changes in soil physical and chemical properties following organic matter removal and compaction: 20-year response of the aspen Lake-States Long Term Soil Productivity installations. For Ecol Manag. 2017;392:68–77.

Manukovskii AY, Grigorev IV, Ivanov VA, Gasparyan GD, Lapshina ML, Makarova JA, et al. Increasing the logging road efficiency by reducing the intensity of rutting: Mathemetical modeling. J Mech Eng Res Dev. 2018;41:35–41.

Grigorev I, Kunickaya O, Burgonutdinov A, Ivanov V, Shuvalova S, Shvetsova V, et al. Theoretical studies of dynamic soil compaction by wheeled forestry machines. Diagnostyka. 2020;21:3–13.

Grigorev I, Kunickaya O, Burgonutdinov A, Burmistrova O, Druzyanova V, Dolmatov N, et al. Modeling the effect of skidded timber bunches on forest soil compaction. J Def Model Simul. 2020;0:1–9.

Grigorev I, Kunickaya O, Burgonutdinov A, Burmistrova O, Druzyanova V, Dolmatov N, et al. Assessment the effect of skidding techniques on the ecological efficiency of the skidding tractor. Diagnostyka. 2020;21:67–75.

Rudov S, Shapiro V, Grigorev I, Kunitskaya O, Druzyanova V, Kokieva G, et al. Specific features of influence of propulsion plants of the wheel-tyre tractors upon the cryomorphic soils, soils, and soil grounds. Int J Civ Eng Technol. 2019;10:2052–71.

Goutal N, Keller T, Defossez P, Ranger J. Soil compaction due to heavy forest traffic: measurements and simulations using an analytical soil compaction model. Ann For Sci. 2013;70:545–56.

Kankare V, Luoma V, Saarinen N, Peuhkurinen J, Holopainen M, Vastaranta M. Assessing feasibility of the forest trafficability map for avoiding rutting – a case study. Silva Fenn. 2019;53:10197.

Reeves DA, Reeves MC, Abbott AM, Page-Dumroese DS, Coleman MD. A detrimental soil disturbance prediction model for ground-based timber harvesting. Can J For Res. 2012;42:821–30.

Shabani S, Najafi A, Majnonian B, Alavi J, Sattarian A. Spatial prediction of soil disturbance caused by forest logging using generalized additive models and GIS. Eur J For Res. 2019;138:595–606.

Mohtashami S, Bergkvist I, Lofgren B, Berg S. A GIS approach to analyzing off-road transportation: a case study in Sweden. Croat J For Eng. 2012;33:275–84.

Mohtashami S, Eliasson L, Jansson G, Sonesson J. Influence of soil type, cartographic depth-to-water, road reinforcement and traffic intensity on rut formation in logging operations: a survey study in Sweden. Silva Fenn. 2017;51:1–14.

Salmivaara A, Launiainen S, Perttunen J, Nevalainen P, Pohjankukka J, Ala-Ilomäki J, et al. Towards dynamic forest trafficability prediction using open spatial data, hydrological modelling and sensor technology. Forestry. 2020;93:662–74.

Allman M, Jankovský M, Allmanová Z. The cone index is a weak predictor of soil disturbance on forest soils of the Western Carpathians. J Sustain For. 2018;37:38–45.

Đuka A, Poršinsky T, Pentek T, Pandur Z, Janeš D, Papa I. Soil measurements in the context of planning harvesting operations and variable climatic conditions. South-east Eur For. 2017;9:61–71.

Uusitalo J, Ala-Ilomäki J, Lindeman H, Toivio J, Siren M. Predicting rut depth induced by an 8-wheeled forwarder in fine-grained boreal forest soils. Ann For Sci. 2020;77:1–10.

Sirén M, Ala-Ilomäki J, Lindeman H, Uusitalo J, Kiilo KE, Salmivaara A, et al. Soil disturbance by cut-to-length machinery on midgrained soils. Silva Fenn. 2019;53:10134.

Sirén M, Salmivaara A, Ala-Ilomäki J, Launiainen S, Lindeman H, Uusitalo J, et al. Predicting forwarder rut formation on fine-grained mineral soils. Scand J For Res. 2019;34:145–54.

Gumus S, Turk Y. A new skid trail pattern design for farm tractors using linear programing and geographical information systems. Forests. 2016;7:306.

Picchio R, Latterini F, Mederski PS, Tocci D, Venanzi R, Stefanoni W, et al. Applications of GIS-based software to improve the sustainability of a forwarding operation in central Italy. Sustainability. 2020;12:5716.

Bigelow SW, Jansen NA, Jack SB, Staudhammer CL. Influence of selection method on skidder-trail soil compaction in longleaf pine forest. For Sci. 2018;64:641–52.

Donagh PM, Rivero L, Garibaldi J, Alvez M, Cortez P, Marek M, et al. Effects of selective harvesting on traffic pattern and soil compaction in a subtropical forest in Guarani, Misiones. Argentine Sci For. 2010;38:12.

Page-Dumroese DS, Jurgensen M, Terry T. Maintaining soil productivity during forest or biomass-to-energy thinning harvests in the Western United States. West J Appl For. 2010;25:5–11.

Solgi A, Naghdi R, Tsioras PA, Ilstedt U, Salehi A, Nikooy M. Combined effects of skidding direction, skid trail slope and traffic frequency on soil disturbance in North mountainous forest of Iran. Croat J For Eng. 2017;38:97–106.

Solgi A, Naghdi R, Zenner EK, Tsioras PA, Hemmati V. Effects of ground-based skidding on soil physical properties in skid trail switchbacks. Croat J For Eng. 2019;40:341–50.

Rodrigues CK, Lopes E da S, Polizeli KMVC, Müller MML. Soil compaction due to wood harvesting traffic at different extraction distances. Floresta Ambient. 2018;25:e20160045.

• Cudzik A, Brennensthul M, Białczyk W, Czarnecki J. Damage to soil and residual trees caused by different logging systems applied to late thinning. Croat J For Eng. 2017;38:83–95.This paper is good example on comparing damages to soil and stand between different logging systems (cut-to-length vs. tree length) in late thinnings.

Bustos O, Egan A. A Comparison of soil compaction associated with four ground-based harvesting systems. North J Appl For. 2011;28:194–8.

Dudáková (Allmanová) Z, Allman M, Merganič J, Merganičová K. Machinery-induced damage to soil and remaining forest stands—Case study from Slovakia. Forests. 2020;11:1289.

Cambi M, Giannetti F, Bottalico F, Travaglini D, Nordfjell T, Chirici G, et al. Estimating machine impact on strip roads via close-range photogrammetry and soil parameters: a case study in central Italy. iForest. 2018;11:148–154.

Eroğlu H, Sariyildiz T, Küçük M, Sancal E. The effects of different logging techniques on the physical and chemical characteristics of forest soil. Balt For. 2016;22:9.

Marchi E, Picchio R, Spinelli R, Verani S, Venanzi R, Certini G. Environmental impact assessment of different logging methods in pine forests thinning. Ecol Eng. 2014;70:429–36.

Venanzi R, Picchio R, Spinelli R, Grigolato S. Soil disturbance and recovery after coppicing a mediterranean oak stand: The effects of silviculture and technology. Sustainability. 2020;12:4074.

Spinelli R, Magagnotti N, Nati C. Benchmarking the impact of traditional small-scale logging systems used in Mediterranean forestry. For Ecol Manag. 2010;260:1997–2001.

Venanzi R, Picchio R, Grigolato S, Latterini F. Soil and forest regeneration after different extraction methods in coppice forests. For Ecol Manag. 2019;454:117666.

Naghdi R, Solgi A, Zenner EK, Behjou FK. Soil physical properties degrade further on skid trails in the year following operations. J For Res. 2018;29:93–101.

SilveiraFrança J, Reichert JM, Holthusen D, Rodrigues MF, de Araújo EF. Subsoiling and mechanical hole-drilling tillage effects on soil physical properties and initial growth of eucalyptus after eucalyptus on steeplands. Soil Till Res. 2021;207:104860.

Neaves CM, Aust WM, Bolding MC, Berret S, Tretten C, Vance E. Soil properties in site prepared loblolly pine (Pinus taeda L.) stands 25 years after wet weather harvesting in the lower Atlantic coastal plain. For Ecol Manag. 2017;404:344–53.

Neaves CM, Aust WM, Bolding MC, Berret S, Tretten C, Vance E. Loblolly pine (Pinus taeda L.) productivity 23 years after wet site harvesting and site preparation in the lower Atlantic coastal plain. For Ecol Manag. 2017;401:207–14.

Cerise LM, Page-Dumroese DS, McDaniel P, Mayn C, Heinse R. Productivity and soil properties 45 years after timber harvest and mechanical site preparation in Western Montana. West J Appl For. 2013;28:158–65.

Bagheri I, Naghdi R. Effect of HSM 904 wheel skidder and Zetor crawler skidder on rutting and soil displacement. Silva Balc. 2011;12:113–20.

D’Acqui LP, Certini G, Cambi M, Marchi E. Machinery’s impact on forest soil porosity. J Terramechanics. 2020;91:65–71.

Martins PCC, de Souza Dias Junior M, da Silca Carvalho J, Silva AR, Fonseca SM. Levels of induced pressure and compaction as caused by forest harvesting operations. Cerne. 2013;19:83–91.

Haas J, Hagge Ellhöft K, Schack-Kirchner H, Lang F. Using photogrammetry to assess rutting caused by a forwarder-A comparison of different tires and bogie tracks. Soil Till Res. 2016;163:14–20.

Cudzik A, Brennensthul M, Bia\lczyk W, Czarnecki J. Tractive performance of tyres in forest conditions – Impact assessment of ground and tyres parameters. Croat J For Eng. 2018;39:85–96.

Starke M, Derron C, Heubaum F, Ziesak M. Rut depth evaluation of a triple-bogie system for forwarders-field trials with TLS data support. Sustainability. 2020;12:6412.

Labelle ER, Jaeger D. Effects of steel flexible tracks on forwarder peak load distribution: results from a prototype load test platform. Croat J For Eng. 2019;40:1–23.

Solgi A, Najafi A, Page-Dumroese DS, Zenner EK. Assessment of topsoil disturbance caused by different skidding machine types beyond the margins of the machine operating trail. Geoderma. 2020;367:114238.

Gelin O, Henriksen F, Volungholen R, Björheden R. Improved operator comfort and off-road capability through pendulum arm technology. J Terramechanics. 2020;90:41–8.

Gelin O, Björheden R. Concept evaluations of three novel forwarders for gentler forest operations. J Terramechanics. 2020;90:49–57.

Naghdi R, Mousavi SR. Impacts of rubber-tired skidder and crawler tractor on forest soil in the mountainous forests of Northern Iran. Balt For. 2016;22:375–81.

Cambi M, Certini G, Fabiano F, Foderi C, Laschi A, Picchio R. Impact of wheeled and tracked tractors on soil physical properties in a mixed conifer stand. iForest. 2016;9:89–94.

Yang D-L, Wang L-H, Ji, Shu-e, Lin W-S. Comparison of skidding performance of small track type experimental prototype skidder and J-50 skidding tractor. J Harbin Inst Technol. 2013;20:93–96.

•• Holzfeind T, Visser R, Chung W, Holzleitner F, Erber G. Development and benefits of winch-assist harvesting. Curr For Rep. 2020;6:201–209. This paper reviews the benefits related with the use of winch-assist systems, which is one of the most important innovations introduced in the last years in forest operations. The positive effects of winch-assist systems in terms of environmental impacts, operators’ safety and productivity are clearly reported.

Green PQ, Chung W, Leshchinsky B, Belart F, Sessions J, Fitzgerald SA, et al. Insight into the productivity, cost and soil impacts of cable-assisted harvester-forwarder thinning in Western Oregon. For Sci. 2020;66:82–96.

Garren AM, Bolding MC, Aust WM, Moura AC, Barrett SM. Soil disturbance effects from tethered forwarding on steep slopes in Brazilian eucalyptus plantations. Forests. 2019;10:1–21.

Chase CW, Reiter M, Homyack JA, Jones JE, Sucre EB. Soil disturbance and stream-adjacent disturbance from tethered logging in Oregon and Washington. For Ecol Manag. 2019;454:117672.

Tassinari D, Andrade M luiza de C, Dias Junior M de S, Martins RP, Rocha WW, Pais PSAM, et al. Soil compaction caused by harvesting, skidding and wood processing in eucalyptus forests on coarse-textured tropical soils. Soil Use Manag. 2019;35:400–411.

Solgi A, Naghdi R, Labelle ER, Tsioras PA, Nikooy M. Effect of varying machine ground pressure and traffic frequency on the physical properties of clay loam soils located in mountainous forests. Int J For Eng. 2016;27:161–8.

Rejšek K, Buchar J, Vaníec̀ek I, Hromádko L, Vranová V, Marosz J. Results of dynamic penetration test - An indicator of the compaction of surface soil horizons by forestry machinery. J For Sci. 2011;57:439–450.

Nikooy M, Ahrari S, Salehi A, Naghdi R. Effects of rubber-tired skidder and farm tractor on physical properties of soil in plantation areas in the north of Iran. J For Sci. 2015;61:393–8.

Varol T, Emir T, Akgul M, Ozel HB, Acar HH, Cetin M. Impacts of small-scale mechanized logging equipment on soil compaction in forests. J Soil Sci Plant Nutr. 2020;20:953–63.

Uusitalo J, Salomäki M, Ala-Ilomäki J. The effect of wider logging trails on rut formations in the harvesting of peatland forests. Croat J For Eng. 2015;36:125–30.

DeArmond D, Ferraz JBS, Emmert F, Lima AJN, Higuchi N. An assessment of soil compaction after logging operations in central Amazonia. For Sci. 2020;66:230–41.