Abstract

The aim of this paper was to investigate the effectiveness of pyrolyzed low-cost food waste natural materials from the food industry on the removal of chlorine from water. Biochar was produced after pyrolysis at 850 oC from malt spent rootlets (MSR), walnut shells, and apricot, olive, carob and grape kernels. The biochars were characterized for their surface area, microporosity, functional groups and pH. Continuous flow column experiments were conducted at varying flow rates to evaluate the efficiency of biochars to remove free and total chlorine. The initial free and total chlorine concentrations in water fed to the columns were 2.0 and 2.2 mg/L, respectively. The chlorine removal of free and total chlorine of all materials tested ranged from 76 to 92% and 80 to 95%, respectively, with the MSR exhibiting the highest removal. MSR biochar was subjected to the highest cumulative water volume passed through the column (162 L/g) and exhibited the highest total chlorine removal capacity (6 to 330 mg/g). Olive kernel also reached high chlorine removal (99%), while apricot kernel, grape kernel, carob seed and pulp presented poor chlorine removals.

Highlights

• Biochar from food wastes is a promising option for chlorine removal from tap water.

• Malt spent rootlets (MSR) was the best material examined for removing chlorine.

• The highest total chlorine removal capacity of MSR was 330 mg/g.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Chlorination is the most common procedure for disinfection of water and wastewater. The main issue of chlorination is the oxidation reactions between chlorine and natural organic matter (NOM), which can result in the production of harmful by-products (Allard et al. 2013; Reguero et al. 2013; Liu et al. 2012; Bischel and Gunten 2000). NOM is a heterogeneous mixture of complex organic materials derived from both allochthonous and autochthonous sources, associated with many biotic and abiotic processes (da Costa Cunha et al. 2014; Zhao et al. 2016). In many cases, the protection of the distribution system is compulsory, and a minimum concentration of 0.5 mg Cl2/L is recommended with a minimum contact time of 30 min and a water turbidity of ideally less than 1 NTU (WHO 2011). The recommended chlorine residual, which is centrally treated at the point of delivery, is 0.2 to 0.5 mg/L for the protection of water in the distribution network (WHO 2011). The target of low chlorine residual dose (0.3 to 0.5 mg/L) leads to increase of the taste acceptability of chlorinated water and reduction in risk of waterborne diseases (Pickering et al. 2019). Free chlorine residual is sometimes more than the required level and its removal is recommended. Furthermore, chlorine-free water is required by many industries and chlorine removal is of great interest. There are many health concerns regarding the residual chlorine in water. The tolerable daily intake (TDI) of chlorine to humans is 150 µg/kg of body weight, which with an allocation of 100% of TDI to drinking water corresponds to a guideline value of 5 mg/L (WHO 2011).

Residual chlorine from water can be removed by various processes and the most common include sulfur compound or activated carbon (AC) (White 1999). Activated granular carbon, has been successfully used for the removal of chlorine from water (Magee 1956; Suidan et al. 1977; Suidan et al. 1980; Jaguaribe et al. 2005; Li et al. 2010), chlorine dioxide gas (Wood et al. 2010), and trihalomethanes (Rasheed et al. 2016). Chlorine removal by granular activated carbon is quite effective. It involves the reduction of free chlorine on the AC surface, and the production of chloride ion and of oxygen-containing organic compounds (Suidan et al. 1977; Suidan et al. 1980; Ogata et al. 2013). The main disadvantages of AC are its high production cost and the use of specific facilities for the carbon activation. Alternatively, char or biochar is produced by pyrolysis in an oxygen limited environment under a wide range of temperature (Manariotis et al. 2015). Biochar is a carbonaceous residue and has shown some significant potential for multiple applications (O’Connor et al. 2018; Lian and Xing 2017). These applications alongside with the large quantities of biochar in the natural water system may affect the disinfection byproducts, as biochar will react with various disinfectants. The usage of char is well known for centuries in order to purify water (Mason 1916) and is still widely used until today particularly in rural areas around the world for drinking water treatment (Kearns et al. 2015) due to its highly porous structure, large surface area and abundant O-functional groups (El-Nagar et al. 2018). Biochar is an emerging low-cost material, which has found wide application either for soil improvement, carbon sequestration and as sorbent for the removal of various organic (Valili et al. 2013; Manariotis et al. 2015) and inorganic pollutants (Boutsika et al. 2017). Biochar has been used to improve organoleptic properties, to remove organic contaminants and disinfection by-products (Kearns et al. 2015), and to study the catalytic dechlorination of chlorinated solvents (Ai et al. 2021).

The aim of this study was to evaluate the suitability of biochars derived from different food waste materials as low-cost materials for the removal of chlorine from tap water. Six easily available materials including malt spent rootlets (MSR), walnut shells, and apricot, olive, carob and grape kernels were examined. This paper presents the findings of an experimental study that investigated the use of biochar for the removal of chlorine from tap water using the above-mentioned materials. Column experiments were conducted and the performance of different biochars to remove free and total chlorine from tap water was evaluated under varying hydraulic loading conditions. According to the author’s knowledge no comparative work has been carried out for the evaluation of low-cost natural materials for the removal of chlorine from water.

2 Materials and Methods

2.1 Materials Used and Biochar Preparation

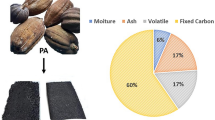

The raw materials in order to produce biochar were malt spent rootlets (MSR), walnut shells (WS), apricot kernel (AK), olive kernel (OK), carob pulp and seeds (CP and CS), and grape kernel (GK). The materials were obtained from local enterprises. The biochar of MSR was prepared in two batches. All the materials were dehydrated for 24 h at 60 oC and stored in a desiccator before pyrolysis. Each dried material was separately weighted and placed into quartz (18.6 and 137 mL volume) and ceramic vessels (249 and 728 mL volume) that were closed with their respective caps. The vessel with the material was placed in a gradient temperature furnace (LH 60/12, Nabertherm GmbH, Germany) and pyrolyzed at 850 oC for 1 h under a static atmosphere with a limited amount of air. Based on a detailed study on the effect of pyrolysis temperature on biochar surface area (Manariotis et al. 2015), pyrolysis at high temperature produces biochars with the highest surface area. The mass of each material was weighted before and after pyrolysis and the weight loss was calculated. The biochar was powdered in a mortar before sorption experiments and sieved and the fraction from 1.18 to 1.7 mm was used.

2.2 Biochar Characterization

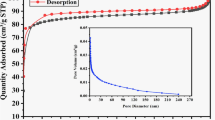

The surface area and the pore volume of each biochar were determined by nitrogen gas adsorption - desorption with the Tristar 3000 Analyzer (Micrometrics GA, USA) using the Brunauer, Emmett, and Teller (BET) equation. Attenuated total reflection (ATR) spectroscopy analysis was performed using an Equinox 55 spectrometer (Bruker Optik, GmbH, Germanry). Scanning Electron Microscope (SEM) (JEOL, 6300, JEOL Ltd.) was employed to visualize the macroscopic structure of the materials before and after chlorine contact. The microscope was equipped with spectrometer energy dispersion X-ray (EDS), wavelength dispersion X-ray (WDS), and Cryotrans. The pH of biochar suspension in distilled water was determined using a pH-meter (pH meter 310, Oakton Instruments, Singapore).

2.3 Column Experiments

Flow-through experiments were conducted in Plexiglas and glass columns. The Plexiglass columns had a packed length of 12 cm and internal diameters of 0.7 and 1.3 cm, while the glass column had length of 30 cm and internal diameter of 1.0 cm. Each column was carefully packed with biochar to minimize air entrapment. Fresh tap water was collected in a glass bottle before each experiment. The desired chlorine concentration in tap water was achieved by the addition of an appropriate volume of a household bleach, 4% sodium hypochlorite solution, to achieve concentration of free and total chlorine of 2.0 and 2.2 mg/L, respectively. The residual chlorine concentration of chlorine in tap water was quite low (< 0.2 mg/L). The biochar-packed columns were placed vertically and were fed with chlorinated tap water by a peristaltic pump (Masterflex, Cole Pamer Instrument, Co., Chicago, IL) in an upflow direction. All experiments were conducted at room temperature (~ 25 oC). The Experiments 5 (GK) and 6 (OK) were conducted in the 1.3-cm diameter column, the experiment 6 (OK1) with the 1.3-cm diameter column, the experiment 8 (OK2) in the 30-cm glass column, and the rest experiments in a 0.7-cm diameter column (Table 1).

2.4 Analytical Methods

The concentrations of free and total chlorine in the influent and effluent of the column were determined using the DPD (N, N-diethyl-p- phenylenediamine) colorimetric method (APHA, AWWA, WEF 2012) using a portable photometer (model HI96701, Hanna Instruments, Romania). A 10-mL sample volume was used for each determination. The uncertainty of measurement at a concentration of 0.5 mg/L, as it is reported by the manufacturer, is 0.03 mg/L for both total and free chlorine, respectively.

2.5 Statistical Analysis

Multiple regression analysis was used to determine the impact of different column dimensions, flow rates, and cumulative volume on the concentration of free and total chlorine. Apart of the aforementioned variables in the regression analysis, the interaction between column and flow rate was also included. For the cumulative volume variable, different transformations were tested to increase the coefficient of determination.

Post-hoc multiple comparisons of means were also conducted to quantify the differences between levels of the factors “Column” and “Flow rate” and determine which levels significantly differ from each other. More specifically, due to the unbalanced experimental design, the Tukey’s Honest Significant Differences (HSD) procedure was run to the two-way ANOVA without interactions by computing all possible pairwise combinations of levels to identify pairs with significant differences between their means according to the Bonferroni Adjusted p values.

3 Results and Discussion

3.1 Biochar Properties

The BET surface area, the pore volume, and the weight loss of the materials after pyrolysis are given in Table 1. The weight loss after pyrolysis ranged from 70 to 89%. OK exhibited the lowest BET surface area (73 m2/g) followed by the CP and CS (96 and 98 m2/g). On the other side, the material with the highest BET surface area was the grape kernel (560 m2/g) followed by the WS (536 m2/g). In this work it was found that the biochar with the highest pore volume was the WS (0.305 cm3/g), while the smallest pore volume was found in GK (0.024 cm3/g).

For better observation of the different ingredients on the surface of the biochars, ATR spectra were obtained (Fig. 1). The surface of all raw biochar materials contains much more functional groups than the biochars after the passage of chlorinated water (washed). More specifically, most of the materials demonstrate at least two or more of peaks at 3400 (O-H), 2900 (CH3), 1700 (C = O), 1400 (C-H), 1100 (O-H), and 830 (C-H) cm− 1 (Xu et al. 2013; Liu et al. 2015). This suggests that the surfaces of these materials, besides the aliphatic and aromatic C-H bonds, also contain polar groups with oxygen. The surface of the pyrolyzed materials contain less peaks with lower intensity or intensity that is considered insignificant. This suggests that the surfaces of the pyrolyzed materials contain less groups with most predominant peaks at 2900 (CH3) or 2300 (C-H) and 830 (C-H) cm− 1. The polar groups found on the raw material surfaces disappeared after pyrolysis.

All the materials were basic in nature, with pH values that ranged from 8.7 to 11 (Table 2). The difference of pH through time for most of the materials was between 0.1 and 0.5 pH units, except for AK, where an increase of 1.4 pH units was observed after 48 h. The material with the highest pH values was the MSR, which reached a value of 11 after 24 h.

SEM images were examined in biochar before and after the contact with chlorine (Supplementary Material (SM); Fig. SM1). As it can be seen, in carob seeds (CS) and apricot kernel (AK), the surface after the chlorination is smoother than before. Moreover, in malt spent rootlets (MSR1 and MSR2), in olive kernel (OK and OK’) and in grape kernel (GK) it is observed that there are sharper edges and more tough surface after the experiment. Finally, in the three samples, carob pulp (CP), walnut shell (WS) and olive kernel (OK2), no differences can be identified.

Free chlorine is removed in carbon filters by the following reaction (White 1999):

where C* is the active carbon and CO* is the surface oxide on carbon.

If significant amount of HOCl are allowed to react with the carbon some of the oxygen attached to the carbon surface may be emitted as CO or CO2 gas as shown in the following reaction:

A part of carbon is permanently destroyed during Reaction (2), and stoichiometrically one part of mass of carbon is destroyed by 11.8 parts of mass of chlorine. In the case of free chlorine, carbon is chemically exhausted and carbon should be replaced. Physical exhaustion of carbon occurs when chlorine is in the form of combined (i.e., chloramines), and in this case carbon can be regenerated (White 1999; Komorita and Snoeyink 1985).

3.2 Flow-Through Experiments

Νine experiments were conducted as it can be seen in Table 3. The influent and effluent chlorine concentration is graphically shown in Fig. 2. In column 1 (WS), the concentration of both free and total chlorine in the effluent ranged from 0 to 0.5 mg/L, throughout the experiment that lasted 2508 h and 29.15 L passed through the column. In column 2 (CP), free chlorine concentration started to rise from 0.5 to 1 mg/L after passing 30 L, and the flow rate was boosted from 4 to 8 mL/min. In column 3 (AK), free and total chlorine remained stable throughout the experiment, which lasted 298 h and 30.2 L passed. The effluent was around 0.3 and 0.6 mg/L for free and total chlorine, respectively. In column 4 (CS), free chlorine remained at about the same concentration, around 0.3 to 0.4 mg/L at a flow rate of 4 mL/min. The increase of flow rate to 8 mL/min resulted in higher free chlorine concentration above 1.5 mg/L. In column 5, GK was only tested for free chlorine. It can be seen that chlorine values had an increasing ratio from 0.4 to 1 mg/L after passing 5 L. The flow rate changed several times without any significant impact on the chlorine concentration. In column 6 (OK1), free chlorine concentration remained the same (0.3 to 0.4 mg/L) throughout the experiment after 298 h of operation and passing 34.1 L. On the contrary, total chlorine concentration was steadily above 0.5 mg/L, and when the flow rate increased from 4 to 8 mL/min, the concentration was over 1.2 mg/L. Furthermore, in the glass column, we used the higher biochar quantity from any other batch, 10.5 g of OK2 (Column 7), and the flow rate was changed many times from 2 to 32 mL/min in order to examine the behavior of biochar at varying loading conditions. Free and total chlorine concentrations in the effluent of the column surprisingly remained under 0.5 mg/L during the whole experiment after 198 h, and passing 87.38 L contrary to the rest of the columns, where the concentration of free and total chlorine raised after a specific time.

Finally, two different batches (Columns 8 and 9) were used for biochar from malt spent rootlets. The free chlorine concentration remained steadily under 0.4 mg/L in column 8 (MSR1), while total chlorine concentrations fluctuated around the limit of 0.5 mg/L, independently of the increase of the flow rate applied. In addition, in column 9 (MSR2) the free chlorine concentration decreased when the flow rate decreased from 4 to 2 mL/min and for the rest of the experiment remained at concentrations close to zero. In most columns, when the flow rate was increased from 4 to 8 mL/min, the concentration of the free and total chlorine were also increased, resulting in concentrations over 0.5 mg/L. The chlorine concentration was decreased when the flow rate dropped again to 4 mL/min. It must be noticed that when the flow rate decreased from 8 to 4 mL/min the concentration of free chlorine decreased too, since the contact time between the chlorine and the materials increased.

From the seven materials examined, the lowest efficiency of 80 and 75% for free and total chlorine, respectively, was observed for the carob seeds (CS). In contrast, the best material was the malt spent rootlets samples (MSR) with over 90% removal for both free and total chlorine. Giles and Danell (1983) reported that activated carbon reached a total chlorine concentration of 40 to 70 µg/L from an initial concentration of 80 to 530 µg/L for flow rates ranging from 5 to 271 L/min. The total volume of water that passed through the filter was 115 times the carbon bed volume.

3.3 Chlorine Mass Balance

The mass balance of free and total chlorine is shown in Tables 4 and 5, respectively. Throughout the experiment and for all the tested materials, the removal of the free chorine was higher in comparison with the total chlorine. Τhis result was observed in the MSR with values of 95.1 99.1% for MSR2 and MSR1, respectively. MSR2 and MSR1 exhibited the highest free chlorine mass retention capacity (308 and 76 mg/g, respectively). On the contrary, the lowest free chlorine mass retention was found for GK and OK (8.1 and 8.4 mg/g, respectively). Concerning the total chlorine, again MSR had the best efficiency with 330 and 73 mg/g for MSR2 and MSR1, respectively. In addition, MSR2 and WS exhibited the highest removal efficiency with 92.5 and 85%, respectively. On the other hand, the materials with the lower removal efficiency were OK1 and AK with 5.8 and 12.7 mg/g, respectively, whereas the least total chlorine removals of 75.5% and 79.3% were noticed for carob products (CS and CP). It must be mentioned that all materials achieved free and total chlorine removals over 80 and 75%, respectively.

Jaguaribe et al. (2005) investigated the performance of activated carbons prepared from different materials, i.e., sugarcane bagasse, babassu and coconut shells, in batch experiments. Sugarcane bagasse was capable to remove 100% the residual chlorine, while the other materials was around 40% for a contact time of 60 min. The iodine number of sugarcane was almost twice the value of the other two materials. Li et al. (2010) reported that coconut carbon, compared to coal and fruit nuts carbon, exhibited the highest sorption capacity. They also reported that phenol number compared to iodine number was better indicator for free chlorine sorption capacity. The iodine and phenol numbers are useful indicators for the effectiveness of carbons for the removal of low molecular weight compounds (around 1 nm) (Zhang et al. 2007). The iodine number is related to the capacity for small and/or non-polar molecules, while the phenol number for small polar and/or aromatic organic malecules (Li et al. 2010). A minimum value of 500 mg/g of the iodine number is recommended for powdered activated carbon for the removal of low molecular weight compounds (Jaguaribe et al. 2005).

3.4 Statistical Analysis Results

The ANOVA tables of the two multiple regression models are presented in Table SM1. For both models the transformation cumulative volume− 1/2 was adopted for the cumulative volume variable since this transformation presented the best fit to the data. For both models all variables were statistically significant for the total chlorine concentration at 0.001 level (p < 0.001) except cumulative volume− 1/2 variable, which was significant at 0.05 level (p = 0.012). The coefficient of determination for the free and total chlorine concentration models were 0.5133 and 0.5829, respectively, indicating a relatively strong linear association between the dependent and the explanatory variables.

Based on the interaction plot (Fig. 3) between the column and flow rate factors for the free (left plot) and total (right plot) chlorine concentrations, it seems that the minimum concertation for the free and total chlorine concentrations is obtained using Column 9 (packed with MSR), under all flow rates with an exception of a flow rate of 2 mL/min for the free chlorine. In this case, Column 9 (MSR2) presents the higher concentration of the free chlorine. Regarding the marginal grouping information as obtained by the Tukey’s HSD pair-wise comparisons test (with Bonferroni Adjusted p values) on the two-way ANOVA without interaction (Table 6) it seems that Column 9 (MSR2) presents again an overall better behavior. Regarding the flow rate, it seems that the best performance is observed when the flow rate is 4 mL/min. Based on the experimental results, no clear correlation was observed between the specific surface of the materials examined and their efficiency in removing chlorine. Meng et al. (2019) studied the removal of chlorine from water by activated carbons with similar surface and porosity. The differences found in chlorine removal were not attributed to the surface area, and most of the removal occurred in the micropores of activated carbon.

4 Conclusion

The usage of biochar from agro-industrial wastes in the removal of chlorine from tap water appears to be a highly promising option for replacing activated carbon in common filters. The low-cost materials associated with high capacity of removing chlorine can be proved useful. The use of six different types of wastes showed significant variation in terms of chlorine removal. The highest total chlorine removal capacities ranged from 6 to 330 mg/g, and malt spent rootlets was the best material compared to the others. Olive kernel was the second efficient material in removing total chlorine, whilst carob seeds and pulp had the lowest free and total chlorine removal. The results of the present study indicate the feasibility of pyrolyzed food waste residues to develop low-cost materials for the removal of chlorine from water and wastewater.

Data Availability

The authors confirm that the data supporting the findings of this study are available within the article and its supplementary materials.

References

Ai J, Lu C, van den Berg FWJ, Yin W, Strobel BW, Hansen HCB (2021) Biochar catalyzed dichlorination – which biochar properties matter? J Hazard Mater 406:124724. https://doi.org/10.1016/j.jhazmat.2020.124724

Allard S, Nottle CE, Chan A, Joll C, von Gunten U (2013) Ozonation of iodide-containing waters: selective oxidation of iodide to iodate with simultaneous minimization of bromate and I-THMs. Water Res 47(6):1953–1960. https://doi.org/10.1016/j.watres.2012.12.002

Bischel Y, Gunten U (2000) Formation of iodo-trihalomethanes during disinfection and oxidation of iodide-containing waters. Environ Sci Technol 34(13):2784–2791. https://doi.org/10.1021/es9914590

Boutsika LG, Karapanagioti HK, Manariotis ID (2017) Chloride and nitrate salts effect on hg(II) sorption by raw and pyrolyzed malt spent rootlets. J Chem Technol Biotechnol 92(8):1912–1918. https://doi.org/10.1002/jctb.5215

da Costa Cunha G, Romão LPC, Macedo ZS (2014) Production of alpha-alumina nanoparticles using aquatic humic substances. Powder Technol 254:344–351. https://doi.org/10.1016/j.powtec.2014.01.008

El-Nagar A, Lee SS, Awad YM, Yang X, Ryu C, Rizwan M, Rinklebe J, Tsang DCW, Ok YS (2018) Influence of soil properties and feedstocks on biochar potential for carbon mineralization and improvement of infertile soils. Geoderma 332:100–108. https://doi.org/10.1016/j.geoderma.2018.06.017

Giles MA, Danell R (1983) Water dechlorination by activated carbon, ultraviolet radiation and sodium sulphite. Water Res 17(6):667–676. https://doi.org/10.1016/0043-1354(83)90236-1

Jaguaribe EF, Medeiros LL, Barreto MCS, Araujo LP (2005) The performance of activated carbons from sugarcane bagasse, babassu, and coconut shells in removing residual chlorine. Braz J Chem Eng 22(1):41–47. https://doi.org/10.1590/S0104-66322005000100005

Kearns JP, Shimabuku KK, Mahoney RB, Knappe DRU, Summers RS (2015) Meeting multiple water quality objectives through treatment using locally generated char: improving organoleptic properties and removing synthetic organic contaminants and disinfection by-products. J Water Sanit Hyg Dev 5(3):359–372. https://doi.org/10.2166/washdev.2015.172

Komorita JD, Snoeyink VL (1985) Monochloramine removal from water by activated carbon. Am Water Works Assoc J 77(1):62–64

Li B, Zhang H, Zhang W, Huang L, Duan J, Hu J, Ying W (2010) Cost effective activated carbon treatment process for removing free chlorine from water. Asia-Pacific J Chem Eng 5:714–720. https://doi.org/10.1002/apj.396

Lian F, Xing B (2017) Black carbon (Biochar) in water/soil environments: molecular structure, sorption, stability, and potential risks. Environ Sci Technol 51:13517–13532. https://doi.org/10.1021/acs.est.7b02528

Liu X, Chen Z, Wang L, Shen J (2012) Effects of metal ions on THMs and HAAs formation during tannic acid chlorination. Chem Eng J 211–212:179–185. https://doi.org/10.1016/j.cej.2012.09.014

Liu Y, He Z, Uchimiya M (2015) Comparison of biochar formation from various agricultural by-products using FTIR spectroscopy. Mod Appl Sci 9(4):246–253. https://doi.org/10.5539/mas.v9n4p246

Magee V (1956) The application of granular active carbon for dechlorination of water supplies. Proc Soc Water Treat Exam 5:17–40

Manariotis ID, Fotopoulou KN, Karapanagioti HK (2015) Preparation and characterization of biochar sorbents produced from malt spent rootlets. Ind Eng Chem Res 54(39):9577–9584. https://doi.org/10.1021/acs.iecr.5b02698

Mason WP (1916) Water-supply: considered principally from a sanitary standpoint. Forgotten Books. 4th edn. Wiley, Reproduction from Forgotten Books, 2015, London

Meng F, Li G, Zhang B, Guo J (2019) Chemical kinetics and particle size effects on activated carbon for free chlorine removal from drinking water. Water Pract Technol 14(1):19–26. https://doi.org/10.2166/wpt.2018.092

O’Connor D, Peng T, Xhang J, Tsang DCW, Alessi DS, Shen Z, Bolan NS, Hou D (2018) Biochar application for the remediation of heavy metal polluted land: a review of in situ field trials. Sci Total Environ 619–620:815–825. https://doi.org/10.1016/j.scitotenv.2017.11.132

Ogata F, Tominaga H, Ueda A, Tanaka V, Iwata Y, Kawasaki N (2013) Application of activated carbons from coal and coconut shell for removing free residual chlorine. J Oleo Sci 62(4):241–244. https://doi.org/10.5650/jos.62.241

Pickering AJ, Crider Y, Sultana S, Swarthout J, Goddard FGB, Islam SA, Sen S, Ayyagari R, Luby SP (2019) Effect of in-line drinking water chlorination at the point of collection on child diarrhea in urban Bangladesh: a double-blind, cluster-randomised controlled trial. Lancet Glob Health 7:e1247–e1256. https://doi.org/10.1016/S2214-109X(19)30315-8

Rasheed S, Campos LC, Kim JK, Zjou Q, Hashmi I (2016) Optimization of total trihalomethanes’ (TTHMs) and their precursors’ removal by granulated activated carbon (GAC) and sand dual media by response surface methodology (RSM). Water Supply 16(3):783–793. https://doi.org/10.2166/ws.2015.175

Reguero V, López-Fernández R, Fermoso J, Prieto O, Pocostales P, González R, Irusta R, Villaverde S (2013) Comparison of conventional technologies and a submerged membrane photocatalytic Reactor (SMPR) for removing trihalomethanes (THM) precursors in drinking water treatment plants. Desalination 330:28–34. https://doi.org/10.1016/j.desal.2013.09.014

Suidan MT, Snoeyink VL, Schmitz RA (1977) Reduction of aqueous free chlorine with granular activated carbon-pH and temperature effects. Environ Sci Technol 11(8):785–789. https://doi.org/10.1021/es60131a013

Suidan M, Cross WH, Chacey K (1980) Extended dichlorination studies with granular activated carbon filters. J Water Pollut Control Fed 52(11):2634–2646

Valili S, Siavalas G, Karapanagioti HK, Manariotis ID, Christanis Κ (2013) Phenanthrene removal from aqueous solutions using well-characterized, raw, chemically treated, and Charred Malt Spent Rootlets. J Environ Manage 128:252–258. https://doi.org/10.1016/j.jenvman.2013.04.057

WEF (2012) Standard methods for the examination of water and wastewater, 22nd edn. American Public Health Association/American Water Works Association/Water Environment Federation, Washington DC

WHO (2011) Guidelines for drinking-water quality, 4th edn. World Health Organization, Geneva

White GC (1999) Handbook of chlorination and alternative disinfectants, 4th edn. Wiley-Interscience, New York

Wood JP, Ryan S, Snyder EG, Serre SD, Touati A, Clayton MJ (2010) Adsorption of chlorine dioxide gas on activated carbons. Air Waste Manag Assoc 60:898–606. https://doi.org/10.3155/1047-3289.60.8.898

Xu F, Yu JM, Tesso T, Dowell F, Wang DH (2013) Qualitative and quantitative analysis of lignocellulosic biomass using infrared techniques: a mini-review. Appl Energy 104:801–809. https://doi.org/10.1016/j.apenergy.2012.12.019

Zhang W, Chang QG, Liu WD, Li BJ, Jiang WX, Fu LJ, Ying WC (2007) Selecting activated carbon for water and wastewater treatability studies. Environ Prog 26(3):289–298. https://doi.org/10.1002/ep.10222

Zhao Y, Yang HW, Liu ST, Tang S, Wang XM, Xie YF (2016) Effects of metal ions on disinfection byproduct formation during chlorination of natural organic matter and surrogates. Chemosphere 144:1074–1082. https://doi.org/10.1016/j.chemosphere.2015.09.095

Acknowledgements

The authors would like to thank: PhD candidate Ekavi Isari of the Hellenic Open University for her help in BET and ATR analysis; the Associate Professor Kuriakos Bourikas from the Department of Chemistry of the University of Patras, and the PhD Candidate Nikolaos Mourgkogiannis from the Laboratory of Electron Microscopy and Microanalysis of the University of Patras; and Dr Andreas Seferlis, operator of the Scanning Electronic Microscope.

Funding

Open access funding provided by HEAL-Link Greece.

Author information

Authors and Affiliations

Contributions

HK Karapanagioti and ID Manariotis designed the research work. LN Sklivaniotis conducted the experimental and wrote the first draft of the manuscript. P Economou conducted statistical analysis. All authors contributed editing and completion to the final draft.

Corresponding author

Ethics declarations

Competing Interests

The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

ESM 1

(DOCX 1.02 MB)

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Sklivaniotis, L.N., Economou, P., Karapanagioti, H.K. et al. Chlorine Removal from Water by Biochar Derived from Various Food Waste Natural Materials. Environ. Process. 10, 4 (2023). https://doi.org/10.1007/s40710-022-00617-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40710-022-00617-4