Abstract

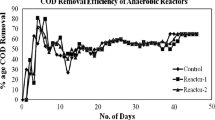

A sequential anaerobic-aerobic batch reactor was used to treat 3,6-dichloro-2-methoxybenzoic acid (dicamba) during a long operation period of 340 days in the presence of disodium anthraquinone-2,6-disulphonate (AQS) as redox mediator. The sludge activity was evaluated for different dosages of dicamba over constant hydraulic retention time (HRT), neutral pH (6.5–7.5) and at ambient reactor temperature. Effects of increased dicamba concentration, solids retention time (SRT) and oxidation reduction potential (ORP) on the biodegradation of dicamba was monitored and compared with control reactor containing no dicamba. Results revealed that long operation period, long SRT and ORP were playing important role in the breakdown of dicamba to its transformation products and subsequent removal in the system. The system was capable of degrading the compound completely during long operation period, long SRT and at low ORP in the presence of AQS. Reducing condition in the anaerobic reactor significantly contributed to the treatment process through demethylation, dehalogenation and dechlorination reactions in the presence of different reducing bacteria. The results of GC-HRMS identified the anaerobic transformation products of dicamba as oleic acid (C18H34O2), 9-Octadecenoic acid (Z), 2-hydroxy-1-(hydroxymethyl)ethyl ester (C21H40O4), trans-13-Ocatadecenoic acid (C18H34O2) compounds which were then oxidised in the aerobic reactor.

Similar content being viewed by others

References

Abiri F, Fallah N, Bonakdarpour B (2017) Sequential anaerobic–aerobic biological treatment of colored wastewaters: case study of a textile dyeing factory wastewater. Water Sci Technol 75(6):1261–1269. https://doi.org/10.2166/wst.2016.531

APHA (2016) Standard methods for the examination of water and wastewater. Washington, DC: American Public Health Association, 2012

Cervantes FJ, Vu-Thi-Thu L, Lettinga G, Field JA (2004) Quinone-respiration improves dechlorination of carbon tetrachloride by anaerobic sludge. Appl Microbiol Biotechnol 64:702–711. https://doi.org/10.1007/s00253-004-1564-z

Chin H, Elefsiniotis P, Singhal N (2005) Biodegradation of 2, 4-dicholophenoxyacetic acid using an acidogenic anaerobic sequencing batch reactor. J Environ Eng Sci 4(1):57–63. https://doi.org/10.1139/s04-044

Comfort SD, Inskeep WP, Macur RE (1992) Degradation and transport of dicamba in a clay soil. J Environ Qual 21(4):653–658. https://doi.org/10.2134/jeq1992.00472425002100040020x

Curtis GP, Reinhard M (1994) Reductive dehalogenation of hexachloroethane, carbon tetrachloride, and bromoform by anthraquinone disulfonate and humic acid. Environ Sci Technol 28:2393–3401. https://doi.org/10.1021/es00062a026

Da Silva MER, Firmino PIM, dos Santos AB (2012) Impact of the redox mediator sodium anthraquinone-2, 6-disulphonate (AQDS) on the reductive decolourisation of the azo dye reactive red 2 (RR2) in one-and two-stage anaerobic systems. Bioresour Technol 121(1–7):1–7. https://doi.org/10.1016/j.biortech.2012.06.099

Dos Santos AB, Traverse J, Cervantes FJ, Van Lier JB (2005) Enhancing the electron transfer capacity and subsequent color removal in bioreactors by applying thermophilic anaerobic treatment and redox mediators. Biotechnol Bioeng 89(1):42–52. https://doi.org/10.1002/bit.20308

Dutta A, Sarkar S (2015) Sequencing batch reactor for wastewater treatment: recent advances. Curr Pollut Rep 1(3):177–190. https://doi.org/10.1007/s40726-015-0016-y

Field JA, Brady J (2003) Riboflavin as a redox mediator accelerating the reduction of the azo dye mordant yellow 10 by anaerobic granular sludge. Water Sci Technol 48(6):187–193. https://doi.org/10.2166/wst.2003.0393

Field JA, Stams AJ, Kato M, Schraa G (1995) Enhanced biodegradation of aromatic pollutants in cocultures of anaerobic and aerobic bacterial consortia. J Microbiol 67(1):47–77. https://doi.org/10.1007/bf00872195

Ge T, Han J, Qi Y, Gu X, Ma L, Zhang C, Huang D (2017) The toxic effects of chlorophenols and associated mechanisms in fish. Aquat Toxicol 184:78–93. https://doi.org/10.1016/j.aquatox.2017.01.005

Ghoshdastidar AJ, Tong AZ (2013) Treatment of 2, 4-D, mecoprop, and dicamba using membrane bioreactor technology. Environ Sci Pollut Res 20(8):5188–5197. https://doi.org/10.1007/s11356-013-1498-z

González NV, Soloneski S, Larramendy ML (2006) Genotoxicity analysis of the phenoxy herbicide dicamba in mammalian cells in vitro. Toxicol in Vitro 20(8):1481–1487. https://doi.org/10.1016/j.tiv.2006.05.001

González-Cuna S, Galíndez-Mayer J, Ruiz-Ordaz N, Murugesan S, Piña-Escobedo A, García-Mena J, Santoyo-Tepole F (2016) Aerobic biofilm reactor for treating a commercial formulation of the herbicides 2, 4-D and dicamba: biodegradation kinetics and biofilm bacterial diversity. Int Biodeterior Biodegrad 107:123–131. https://doi.org/10.1016/j.ibiod.2015.11.014

Hamilton D, Crossley S (Eds.) (2004) Pesticide residues in food and drinking water: human exposure and risks. John Wiley and Sons. https://doi.org/10.1002/0470091614

Hamilton DJ, Ambrus A, Dieterle RM, Felsot AS, Harris CA, Holland PT, Wong SS (2003) Regulatory limits for pesticide residues in water (IUPAC technical report). Pure Appl Chem 75(8):1123–1155. https://doi.org/10.1351/pac200375081123

Kappler A, Haderlein SB (2003) Natural organic matter as reductant for chlorinated aliphatic pollutants. Environ Sci Technol 37:2714–2719. https://doi.org/10.1021/es0201808

Khan MZ, Khan SS (2011a) Aerobic granular treatment of 2, 4-dichlorophenol. Can J Chem Eng 89(4):914–920. https://doi.org/10.1002/cjce.20445

Khan MZ, Mondal PK, Sabir S, Tare V (2011b) Degradation pathway, toxicity and kinetics of 2, 4, 6-trichlorophenol with different co-substrate by aerobic granules in SBR. Bioresour Technol 102(13):7016–7021. https://doi.org/10.1016/j.biortech.2011.04.057

Khorsandi H, Ghochlavi N, Aghapour AA (2018) Biological degradation of 2, 4, 6-trichlorophenol by a sequencing batch reactor. Environ Process 5(4):907–917. https://doi.org/10.1007/s40710-018-0333-4

Koh YKK, Chiu TY, Boobis A, Cartmell E, Scrimshaw MD, Lester JN (2008) Treatment and removal strategies for estrogens from wastewater. Environ Technol 29(3):245–267. https://doi.org/10.1080/09593330802099122

Kuppusamy S, Jayaraman N, Jagannathan M, Kadarkarai M, Aruliah R (2017) Electrochemical decolorization and biodegradation of tannery effluent for reduction of chemical oxygen demand and hexavalent chromium. J Water Process Eng 20:22–28. https://doi.org/10.1016/j.jwpe.2017.09.008

Manu B, Chaudhari S (2002) Anaerobic decolorisation of simulated textile wastewater containing azo dyes. Bioresour Technol 82:225–231. https://doi.org/10.1016/S0960-8524(01)00190-0

Milligan PW, Häggblom MM (1999) Biodegradation and biotransformation of dicamba under different reducing conditions. Environ Sci Technol 33(8):1224–1229. https://doi.org/10.1021/es981117e

Mondal PK, Ahmad R, Usmani SQ (2010) Anaerobic biodegradation of triphenylmethane dyes in a hybrid UASFB reactor for wastewater remediation. Biodegradation 21(6):1041–1047. https://doi.org/10.1007/s10532-010-9364-x

Murphy CD, Clark BR, Amadio J (2009) Metabolism of fluoroorganic compounds in microorganisms: impacts for the environment and the production of fine chemicals. Appl Microbiol Biotechnol 84(4):617–629. https://doi.org/10.1007/s00253-009-2127-0

Navaratna D, Shu L, Baskaran K, Jegatheesan V (2012) Treatment of ametryn in wastewater by a hybrid MBR system: a lab-scale study. Water Sci Technol 66(6):1317–1324. https://doi.org/10.2166/wst.2012.318

Ratledge C (1992) Microbial oxidations of fatty alcohols and fatty acids. J Chem Technol Biotechnol 55(4):399–400. https://doi.org/10.1002/jctb.280550418

Rau J, Knackmuss HJ, Stolz A (2002) Effects of different quinoid redox mediators on the anaerobic reduction of azo dyes by bacteria. Environ Sci Technol 36(7):1497–1504. https://doi.org/10.1021/es010227+

Sangami S, Manu B (2017a) Fenton's treatment of actual agriculture runoff water containing herbicides. Water Sci Technol 75(2):451–461. https://doi.org/10.2166/wst.2016.538

Sangami S, Manu B (2017b) Optimization of Fenton’s oxidation of herbicide dicamba in water using response surface methodology. Appl Water Sci 7(8):4269–4280. https://doi.org/10.1007/s13201-017-0559-8

Shin EH, Choi JH, Abd El-Aty AM, Khay S, Kim SJ, Im MH, Shim JH (2011) Simultaneous determination of three acidic herbicide residues in food crops using HPLC and confirmation via LC-MS/MS. Biomed Chromatogr 25(1–2):124–135. https://doi.org/10.1002/bmc.1513

Speece RE (1996) Anaerobic biotechnology for industrial wastewaters. Archae Press, Nashville

Suflita JM, Horowitz A, Shelton D, Tiedje JM (1982) Dehalogenation: a novel pathway for the anaerobic biodegradation of haloaromatic compounds. Science 218(4577):1115–1117. https://doi.org/10.1126/science.218.4577.1115

Taraban RH, Berry DF, Berry DA, Walker HL (1993) Degradation of dicamba by an anaerobic consortium enriched from wetland soil. Appl Environ Microbiol 59(7):2332–2334. https://doi.org/10.1128/AEM.01201-16

Tratnyek PG, Scherer MM, Deng BL, Hu SD (2001) Effects of natural organic matter, anthropogenic surfactants, and model quinones on the reduction of contaminants by zero-valent iron. Water Res 35:4435–4443. https://doi.org/10.1016/S0043-1354(01)00165-8

Van der Zee FP, Cervante FJ (2009) Impact and application of electron shuttles on the redox (bio) transformation of contaminants: a review. Biotechnol Adv 27(3):256–277. https://doi.org/10.1016/j.biotechadv.2009.01.004

Weaver M, Zablotowicz RM, Locke MA (2004) Laboratory assessment of atrazine and fluometuron degradation in soils from a constructed wetland. Chemosphere 57(8):853–862. https://doi.org/10.1016/j.chemosphere.2004.08.013

Weinberg B, Teodosiu C (2012) Monitoring and assessment of herbicides removal by industrial wastewater treatment. Environ Eng Manag J 11(1):215–224. https://doi.org/10.30638/eemj.2012.028

William KV, Armbrust K (2002) Weed science Society of America. Herbicide handbook, Lawrence KS, USA

Yeruva DK, Jukuri S, Velvizhi G, Kumar AN, Swamy YV, Mohan SV (2015) Integrating sequencing batch reactor with bio-electrochemical treatment for augmenting remediation efficiency of complex petrochemical wastewater. Bioresour Technol 188:33–42. https://doi.org/10.1016/j.biortech.2015.02.014

Acknowledgments

The authors would like to thank MHRD, Government of India, for providing funds through institutional fellowship to carry out the research. We would also thank DST and SAIF, IIT Bombay, India, for providing the GC-HRMS analysis facility.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

• Sequential anaerobic-aerobic reactor was capable to mineralize dicamba

• Addition of AQS as redox mediator contributed to the enhanced methanogenic activity

• Increased anaerobic biotransformation of dicamba (70%) with high rate of biogas production

• System can remove 82% of dicamba (60 mg/L)

• Formation of aerobic granules and low effluent COD (<50 mg/L)

Electronic supplementary material

ESM 1

(JPG 220 kb)

Rights and permissions

About this article

Cite this article

Mahesh, G.B., Manu, B. Biological Treatment of 3,6-Dichloro-2-Methoxybenzoic Acid Using Anaerobic-Aerobic Sequential Batch Reactor. Environ. Process. 6, 493–509 (2019). https://doi.org/10.1007/s40710-019-00375-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40710-019-00375-w