Abstract

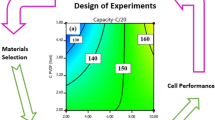

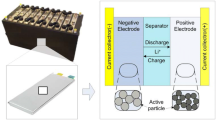

The effective electrical conductivity (EEC) and capacity of the electrodes are altered by the composition of electrode materials, leading to a significant impact on the performance of the Li-ion battery (LIB) cells. This study aims to develop a more efficient numerical optimization method that integrates hierarchical homogenization and feedforward neural networks (FNN) to identify the optimal composition of electrode materials. Currently, this determination heavily relies on conducting multiple experiments. The cathode's EEC, as per its formulation, is assessed through hierarchical homogenization of its components. The optimization is expedited using FNN in the homogenization. The LIB cell's performance is evaluated based on the cathode formulation via the hierarchical homogenization and the Doyle/Fuller/Newman model. The multi-objective optimization problem is formulated and solved using the modified NSGA-II. The resulting Pareto-optimal solutions identify the power optimized and energy optimized cells. The power density of the former is increased by 51% while maintaining the same energy density and the latter cell's energy density is increased by 68% while maintaining the same power density, as compared to the initial cell.

Similar content being viewed by others

Data Availability

All data generated during this study are open access data or included in this published article.

References

Ding, Y., Cano, Z. P., Yu, A., Lu, J., & Chen, Z. (2019). Automotive Li-ion batteries: Current status and future perspectives. Electrochemical Energy Reviews, 2, 1–28.

Li, J., Fleetwood, J., Hawley, W. B., & Kays, W. (2022). From materials to cell: State-of-the-art and prospective technologies for lithium-ion battery electrode processing. Chemical Reviews, 122, 903–956.

Newman, J. (1995). Optimization of porosity and thickness of a battery electrode by means of a reaction-zone model. Journal of The Electrochemical Society, 142, 97–101.

Srinivasan, V., & Newman, J. (2004). Design and optimization of a natural graphite/iron phosphate lithium-ion cell. Journal of The Electrochemical Society, 151, A1530.

Xue, N., Du, W., Gupta, A., Shyy, W., Sastry, A. M., & Martins, J. R. R. A. (2013). Optimization of a single lithium-ion battery cell with a gradient-based algorithm. Journal of The Electrochemical Society, 160, A1071–A1078.

Du, W., Xue, N., Gupta, A., Sastry, A. M., Martins, J. R. R. A., & Shyy, W. (2013). Optimization of LiMn2O4 electrode properties in a gradient- and surrogate-based framework. Acta Mechanica Sinica, 29, 335–347.

Liu, C., & Liu, L. (2015). Improving battery safety for electric vehicles through the optimization of battery design parameters. ECS Transactions, 69, 5–15.

Kim, J. S., Lee, D. C., Lee, J. J., & Kim, C. W. (2020). Optimization for maximum specific energy density of a lithium-ion battery using progressive quadratic response surface method and design of experiments. Scientific Reports, 10, 15586.

Lee, D. C., Lee, K. J., & Kim, C. W. (2020). Optimization of a lithium-ion battery for maximization of energy density with design of experiments and micro-genetic algorithm. International Journal of Precision Engineering and Manufacturing-Green Technology, 7, 829–836.

Liu, C., & Liu, L. (2017). Optimal design of Li-ion batteries through multi-physics modeling and multi-objective optimization. Journal of The Electrochemical Society, 164, E3254–E3264.

Hong, Y., & Lee, C. W. (2018). Pareto fronts for multiobjective optimal design of the lithium-ion battery cell. Journal of Energy Storage, 17, 507–514.

Zheng, H., Yang, R., Liu, G., Song, X., & Battaglia, V. S. (2012). Cooperation between active material, polymeric binder and conductive carbon additive in lithium ion battery cathode. The Journal of Physical Chemistry C., 116, 4875–4882.

Entwistle, J., Ge, R., Pardikar, K., Smith, R., & Cumming, D. (2022). Carbon binder domain networks and electrical conductivity in lithium-ion battery electrodes: A critical review. Renewable and Sustainable Energy Reviews., 166, 112624.

Liu, G., Zheng, H., Simens, A. S., Minor, A. M., Song, X., & Battaglia, V. S. (2007). Optimization of acetylene black conductive additive and PVDF composition for high-power rechargeable lithium-ion cells. Journal of The Electrochemical Society, 154, A1129.

Miranda, D., Gören, A., Costa, C. M., Silva, M. M., Almeida, A. M., & Lanceros-Méndez, S. (2019). Theoretical simulation of the optimal relation between active material, binder and conductive additive for lithium-ion battery cathodes. Energy, 172, 68–78.

Kondo, H., & Srinivasan, V. (2021). Simulation study of rate limiting factors of Li-ion batteries using experimental functions of electronic and ionic resistances. Electrochimica Acta, 371, 137834.

Mandal, S., Amarilla, J. M., Ibanez, J., & Rojo, J. M. (2001). The role of carbon black in LiMn2O4-based composites as cathodes for rechargeable lithium batteries. Journal of The Electrochemical Society, 148, A24.

Lestriez, B. (2010). Functions of polymers in composite electrodes of lithium ion batteries. Comptes Rendus Chimie, 13, 1341–1350.

Liu, G., Zheng, H., Song, X., & Battaglia, V. S. (2012). Particles and polymer binder interaction: A controlling factor in lithium-ion electrode performance. Journal of The Electrochemical Society, 159, A214–A221.

Kondo, H., Sawada, H., Okuda, C., & Sasaki, T. (2019). Influence of the active material on the electronic conductivity of the positive electrode in lithium-ion batteries. Journal of The Electrochemical Society, 166, A1285–A1290.

Vadakkepatt, A., Trembacki, B., Mathur, S. R., & Murthy, J. Y. (2015). Bruggeman’s exponents for effective thermal conductivity of lithium-ion battery electrodes. Journal of The Electrochemical Society, 163, A119–A130.

Birkholz, O., Gan, Y., & Kamlah, M. (2019). Modeling the effective conductivity of the solid and the pore phase in granular materials using resistor networks. Powder Technology, 351, 54–65.

Chen, Y. H., Wang, C. W., Zhang, X., & Sastry, A. M. (2010). Porous cathode optimization for lithium cells: Ionic and electronic conductivity, capacity, and selection of materials. Journal of Power Sources, 195, 2851–2862.

Gully, A., Liu, H., Srinivasan, S., Sethurajan, A. K., Schougaard, S., & Protas, B. (2014). Effective transport properties of porous electrochemical materials - A homogenization approach. Journal of The Electrochemical Society, 161, E3066–E3077.

Trembacki, B. L., Mistry, A. N., Noble, D. R., Ferraro, M. E., Mukherjee, P. P., & Roberts, S. A. (2018). Mesoscale analysis of conductive binder domain morphology in lithium-ion battery electrodes. Journal of the Electrochemical Society, 165, E725–E736.

Vierrath, S., Zielke, L., Moroni, R., Mondon, A., Wheeler, D. R., Zengerle, R., & Thiele, S. (2015). Morphology of nanoporous carbon-binder domains in Li-ion batteries - A FIB-SEM study. Electrochemistry Communications, 60, 176–179.

Hasanov, S., Gupta, A., Alifui-Segbaya, F., & Fidan, I. (2021). Hierarchical homogenization and experimental evaluation of functionally graded materials manufactured by the fused filament fabrication process. Composite Structures, 275, 114488.

Gupta, A., Hasanov, S., Fidan, I., & Zhang, Z. (2022). Homogenized modeling approach for effective property prediction of 3D-printed short fibers reinforced polymer matrix composite material. The International Journal of Advanced Manufacturing Technology, 118, 4161–4178.

Zheng, Y., Fu, Z., Wang, Y., Lu, X., Qu, J., & Zhang, C. (2022). Hierarchical design of material microstructures with thermal insulation properties. International Journal of Heat and Mass Transfer, 186, 122514.

MohdRadzuan, N. A., Sulong, A. B., & Sahari, J. (2017). A review of electrical conductivity models for conductive polymer composite. International Journal of Hydrogen Energy, 42, 9262–9273.

Ram, R., Soni, V., & Khastgir, D. (2020). Electrical and thermal conductivity of polyvinylidene fluoride (PVDF) - Conducting carbon black (CCB) composites: validation of various theoretical models. Composites Part B: Engineering, 185, 107748.

Kim, W. J., Taya, M., & Nguyen, M. N. (2009). Electrical and thermal conductivities of a silver flake/thermosetting polymer matrix composite. Mechanics of Materials, 41, 1116–1124.

Sanyal, J., Goldin, G. M., Zhu, H., & Kee, R. J. (2010). A particle-based model for predicting the effective conductivities of composite electrodes. Journal of Power Sources, 195, 6671–6679.

Nilsson, F., Krückel, J., Schubert, D. W., Chen, F., Unge, M., Gedde, U. W., & Hedenqvist, M. S. (2016). Simulating the effective electric conductivity of polymer composites with high aspect ratio fillers. Composites Science and Technology, 132, 16–23.

Kim, D. W., Lim, J. H., & Yu, J. (2019). Efficient prediction of the electrical conductivity and percolation threshold of nanocomposite containing spherical particles with three-dimensional random representative volume elements by random filler removal. Composites Part B: Engineering, 168, 387–397.

Mayer, J. K., Almar, L., Asylbekov, E., Haselrieder, W., Kwade, A., Weber, A., & Nirschl, H. (2020). Influence of the carbon black dispersing process on the microstructure and performance of Li-ion battery cathodes. Energy Technology, 8, 1900161.

Vaughan, T. J., & McCarthy, C. T. (2010). A combined experimental - numerical approach for generating statistically equivalent fibre distributions for high strength laminated composite materials. Composites Science and Technology, 70, 291–297.

Yang, L., Yan, Y., Ran, Z., & Liu, Y. (2013). A new method for generating random fibre distributions for fibre reinforced composites. Composites Science and Technology, 76, 14–20.

Bargmann, S., Klusemann, B., Markmann, J., Schnabel, J. E., Schneider, K., Soyarslan, C., & Wilmers, J. (2018). Generation of 3D representative volume elements for heterogeneous materials: A review. Progress in Materials Science, 96, 322–384.

Ismail, Y., Yang, D., & Ye, J. (2016). Discrete element method for generating random fibre distributions in micromechanical models of fibre reinforced composite laminates. Composites Part B: Engineering, 90, 485–492.

Li, G., Sharifpour, F., Bahmani, A., & Montesano, J. (2018). A new approach to rapidly generate random periodic representative volume elements for microstructural assessment of high volume fraction composites. Materials & Design, 150, 124–138.

Park, S. M., Lim, J. H., Seong, M. R., & Sohn, D. (2019). Efficient generator of random fiber distribution with diverse volume fractions by random fiber removal. Composites Part B-Engineering, 167, 302–316.

Bannerman, M. N., Sargant, R., & Lue, L. (2011). DynamO: A free O(N) general event-driven molecular dynamics simulator. Journal of Computational Chemistry, 32, 3329–3338.

Catalanotti, G. (2016). On the generation of RVE-based models of composites reinforced with long fibres or spherical particles. Composite Structures, 138, 84–95.

Puertolas, J. A., Garcia-Garcia, J. F., Pascual, F. J., Gonzalez-Dominguez, J. M., Martinez, M. T., & Anson-Casaos, A. (2017). Dielectric behavior and electrical conductivity of PVDF filled with functionalized single-walled carbon nanotubes. Composites Science and Technology, 152, 263–274.

Amin, R., Ravnsbaek, D. B., & Chiang, Y. M. (2015). Characterization of electronic and ionic transport in Li1-xNi0.8Co0.15Al0.05O2 (NCA). Journal of the Electrochemical Society, 162, A1163–A1169.

Cybenko, G. (1989). Approximation by superpositions of a sigmoidal function. Mathematics of Control, Signals and Systems, 2, 303–314.

Fuller, T. F., Doyle, M., & Newman, J. (1994). Simulation and optimization of the dual lithium ion insertion cell. Journal of The Electrochemical Society, 141, 1–10.

Uddin, K., Perera, S., Widanage, W. D., Somerville, L., & Marco, J. (2016). Characterising lithium-ion battery degradation through the identification and tracking of electrochemical battery model parameters. Batteries, 2, 13.

Lundgren, H., Behm, M., & Lindbergh, G. (2015). Electrochemical characterization and temperature dependency of mass-transport properties of LiPF6 in EC:DEC. Journal of The Electrochemical Society, 162(3), A413–A420.

Basu, S., Patil, R. S., Ramachandran, S., Hariharan, K. S., Kolake, S. M., Song, T., Oh, D., Yeo, T., & Doo, S. (2015). Non-isothermal electrochemical model for lithium-ion cells with composite cathodes. Journal of Power Sources, 283, 132–150.

Goren, A., Costa, C. M., Silva, M. M., & Lanceros-Mendez, S. (2015). State of the art and open questions on cathode preparation based on carbon coated lithium iron phosphate. Composites Part B: Engineering, 83, 333–345.

Acknowledgements

This work was supported by the National Research Foundation of Korea (NRF) grant funded by the Korea government (MSIT) (No. 2020R1A2C1102742). This study was supported by the BK21 funded by the Ministry of Education, Korea (No. 4199990314305).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Seo, B., Kim, C. New Numerical Approach to Determine the Optimum Mixing Ratio of Electrode Materials for Maximum Li-ion Battery Performance by the Hierarchical Homogenization and Feedforward Neural Networks. Int. J. of Precis. Eng. and Manuf.-Green Tech. (2024). https://doi.org/10.1007/s40684-024-00628-6

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40684-024-00628-6