Abstract

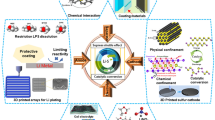

The year 1975 can be claimed to be the year of inception for the research and development of solid polymer electrolytes (SPEs) for Lithium-Ion Batteries (LIB), when the ionic conductivity of polyethylene oxide–alkaline metal ion complex was found by Peter Wright from the University of Sheffield. However, SPE research has undergone a leapfrog development, with conductivity values improving from 1 × 10–7 S·cm−1 to 1 × 10–1 S·cm−1. The seed of development of SPEs spurs from the need for introducing design freedom to battery structures as well as the need for leak-proof electrolytes, greater operational safety, higher energy density, and other considerations. While the benefits of SPEs are evident, poor interfacial contact is a major factor limiting their application. This review presents the history of SPEs and shows how the additive manufacturing (AM) could prove beneficial for the improvement of performance and the functional implementation of SPEs. While the article articulates a technical review of additively manufactured SPEs, it also provides a lab-to-market perspective that could aid in shaping the future of green technology in energy storage. It also aims to provide an overall picture about the evolution and diversity of research advances in the development of greener SPEs through AM technology.

Similar content being viewed by others

Data availability

Not available.

References

Masias, A., Marcicki, J., & Paxton, W. A. (2021). Opportunities and challenges of Lithium ion batteries in automotive applications. ACS Energy Letters, 6(2), 621–630. https://doi.org/10.1021/acsenergylett.0c02584

Li, M., Lu, J., Chen, Z., & Amine, K. (2018). 30 Years of Lithium-ion batteries. Advanced Materials, 30(33), 1800561. https://doi.org/10.1002/adma.201800561

He, W., Guo, W., Wu, H., Lin, L., Liu, Q., Han, X., & Peng, D. L. (2021). Challenges and recent advances in high capacity Li-rich cathode materials for high energy density lithium-ion batteries. Advanced Materials, 33(50), 2005937. https://doi.org/10.1002/adma.202005937

Emon, M. O. F., & Choi, J. W. (2017). Flexible piezoresistive sensors embedded in 3D printed tires. Sensors (Switzerland), 17(3), 656. https://doi.org/10.3390/s17030656

Jo, Y., Park, H. J., Kim, Y. B., Lee, S. S., Lee, S. Y., Kim, S. K., & Jeong, S. (2020). Form-factor free 3D copper circuits by surface-conformal direct printing and laser writing. Advanced Functional Materials, 30(45), 2004659. https://doi.org/10.1002/adfm.202004659

Ponnada, S., Babu Gorle, D., Chandra Bose, R. S., Sadat Kiai, M., Devi, M., Raju, C. V., Baydogan, N., Nanda, K. K., Marken, F., & Sharma, R. K. (2022). Current insight into 3d printing in solid-state lithium-ion batteries: a perspective. Batteries & Supercaps, 5(8), e202200223. https://doi.org/10.1002/batt.202200223

Zhang, B., Guo, Y. X., Sun, H., & Wu, Y. (2017). Metallic, 3D-printed, K-band-stepped, double-ridged square horn antennas. Applied Sciences (Switzerland), 8(1), 33. https://doi.org/10.3390/app8010033

Sverdrup, H. U., Olafsdottir, A. H., & Ragnarsdottir, K. V. (2019). “On the long-term sustainability of copper, zinc and lead supply, using a system dynamics model”, resources. Conservation and Recycling: X. https://doi.org/10.1016/j.rcrx.2019.100007

Cong, L., Zhao, F., & Sutherland, J. W. (2017). Integration of dismantling operations into a value recovery plan for circular economy. Journal of Cleaner Production, 149, 378–386. https://doi.org/10.1016/j.jclepro.2017.02.115

Royo, P., Ferreira, V. J., Ure, Z., Gledhill, S., López-Sabirón, A. M., & Ferreira, G. (2020). Multiple-criteria decision Analysis and haracterization of phase change materials for waste heat recovery at high temperature for sustainable energy-intensive industry. Materials and Design. https://doi.org/10.1016/j.matdes.2019.108215

Opatokun, S. A., Lopez-Sabiron, A. M., Ferreira, G., & Strezov, V. (2017). Life cycle analysis of energy production from food waste through anaerobic digestion, pyrolysis and integrated energy system. Sustainability (Switzerland), 9(10), 1804. https://doi.org/10.3390/su9101804

López-Sabirón, A. M., et al. (2015). Refuse derived fuel (RDF) plasma torch gasification as a feasible route to produce low environmental impact syngas for the cement industry. Waste Management and Research, 33(8), 715–722. https://doi.org/10.1177/0734242X15586476

Kim, T., Song, W., Son, D. Y., Ono, L. K., & Qi, Y. (2019). Lithium-ion batteries: Outlook on present, future, and hybridized technologies. Journal of Materials Chemistry A, 7(7), 2942–2964. https://doi.org/10.1039/C8TA10513H

Winter, M., Barnett, B., & Xu, K. (2018). “Before Li Ion Batteries”, chemical reviews. American Chemical Society. https://doi.org/10.1021/acs.chemrev.8b00422

Masias, A. (2018). Lithium-Ion Battery Design for Transportation. Behaviour of Lithium-Ion Batteries in Electric Vehicles: Battery Health, Performance, Safety, and Cost, 1–33. Doi: https://doi.org/10.1007/978-3-319-69950-9.

European Council for Automotive R&D, “Battery requirements for future automotive applications EG BEV&FCEV,” 2019. [Online]. Available: https://www.dke.de/resource/blob/933404/ fa7a24099c84ef613d8e7afd2c860a39/haracteri-li-ionen

United States Advanced Battery Consortium (USABC). Development of Lithium Electrode Based Cell and Manufacturing for Automotive Traction Applications: Appendix A – Lithium Electrode Based Cell Goals, April 2020. Retrieved from https://uscar.org/usabc/.

United States Advanced Battery Consortium (USABC). Goals for advanced high performance batteries for electric vehicle applications. April 2020. Retrieved from: https://uscar.org/usabc/

Tan, M. Y., Safanama, D., Goh, S. S., Lim, J. Y., Lee, C. H., Yeo, J. C. C., & Fam, D. W. H. (2022). Concepts and emerging trends for structural battery electrolytes. ChemistryAn Asian Journal, 17(21), e202200784.

Myung, S. T., Maglia, F., Park, K. J., Yoon, C. S., Lamp, P., Kim, S. J., & Sun, Y. K. (2017). Nickel-rich layered cathode materials for automotive lithium-ion batteries: Achievements and perspectives. ACS Energy Letters, 2(1), 196–223. https://doi.org/10.1021/acsenergylett.6b00594

Thackeray, M. M., Kang, S. H., Johnson, C. S., Vaughey, J. T., Benedek, R., & Hackney, S. A. (2007). Li2MnO3-stabilized LiMO2 (M = Mn, Ni, Co) electrodes for lithium-ion batteries. Journal of Materials Chemistry, 17(30), 3112–3125. https://doi.org/10.1039/b702425h

Chen, S., Dai, F., & Cai, M. (2020). Opportunities and challenges of high-energy Lithium metal batteries for electric vehicle applications. ACS Energy Letters, 5(10), 3140–3151. https://doi.org/10.1021/acsenergylett.0c01545

Choi, J. W., & Aurbach, D. (2016). Promise and reality of post-lithium-ion batteries with high energy densities. Nature Reviews Materials. https://doi.org/10.1038/natrevmats.2016.13

Shen, X., Tian, Z., Fan, R., Shao, L., Zhang, D., Cao, G., & Bai, Y. (2018). Research progress on silicon/carbon composite anode materials for lithium-ion battery. Journal of Energy Chemistry, 27(4), 1067–1090. https://doi.org/10.1016/j.jechem.2017.12.012

Salah, M., Murphy, P., Hall, C., Francis, C., Kerr, R., & Fabretto, M. (2019). Pure silicon thin-film anodes for lithium-ion batteries: a review. Journal of Power Sources, 414, 48–67. https://doi.org/10.1016/j.jpowsour.2018.12.068

Wold, J., Marcicki, J., & Masias, A. (2017). Derived Quantities uncertainty propagation in high precision battery testing. Journal of the Electrochemical Society, 164(9), A2131–A2137. https://doi.org/10.1149/2.1461709jes

Belt, J., Utgikar, V., & Bloom, I. (2011). Calendar and PHEV cycle life aging of high-energy, lithium-ion cells containing blended spinel and layered-oxide cathodes. Journal of Power Sources, 196(23), 10213–10221. https://doi.org/10.1016/j.jpowsour.2011.08.067

Smith, A. J., Burns, J. C., Xiong, D., & Dahn, J. R. (2011). Interpreting high precision coulometry results on Li-ion Cells. Journal of the Electrochemical Society, 158(10), A1136–A1142. https://doi.org/10.1149/1.3625232

Burns, J. C., Kassam, A., Sinha, N. N., Downie, L. E., Solnickova, L., Way, B. M., & Dahn, J. R. (2013). Predicting and extending the lifetime of Li-ion batteries. Journal of The Electrochemical Society, 160(9), A1451. https://doi.org/10.1149/2.060309jes

Ma, X., Harlow, J. E., Li, J., Ma, L., Hall, D. S., Buteau, S., & Dahn, J. R. (2019). Hindering rollover failure of Li [Ni0. 5Mn0. 3Co0.2] O2/graphite pouch cells during long-term cycling. Journal of The Electrochemical Society. https://doi.org/10.1149/2.0801904jes

Burns, J. C., Stevens, D. A., & Dahn, J. R. (2015). In-situ detection of lithium plating using high precision coulometry. Journal of the Electrochemical Society, 162(6), A959–A964. https://doi.org/10.1149/2.0621506jes

Bach, T. C., Schuster, S. F., Fleder, E., Müller, J., Brand, M. J., Lorrmann, H., & Sextl, G. (2016). Nonlinear aging of cylindrical lithium-ion cells linked to heterogeneous compression. Journal of Energy Storage, 5, 212–223. https://doi.org/10.1016/j.est.2016.01.003

Sauerteig, D., Hanselmann, N., Arzberger, A., Reinshagen, H., Ivanov, S., & Bund, A. (2018). Electrochemical-mechanical coupled modeling and parameterization of swelling and ionic transport in lithium-ion batteries. Journal of Power Sources, 378, 235–247. https://doi.org/10.1016/j.jpowsour.2017.12.044

Spingler, F. B., Wittmann, W., Sturm, J., Rieger, B., & Jossen, A. (2018). Optimum fast charging of lithium-ion pouch cells based on local volume expansion criteria. Journal of Power Sources, 393, 152–160. https://doi.org/10.1016/j.jpowsour.2018.04.095

Severson, K. A., Attia, P. M., Jin, N., Perkins, N., Jiang, B., Yang, Z., Chen, M. H., Aykol, M., Herring, P. K., Fraggedakis, D., Bazant, M. Z., Harris, S. J., Chueh, W. C., & Braatz, R. D. (2019). Data-driven prediction of battery cycle life before capacity degradation. Nature Energy, 4(5), 383–391. https://doi.org/10.1038/s41560-019-0356-8

Attia, P. M., Grover, A., Jin, N., Severson, K. A., Markov, T. M., Liao, Y. H., & Chueh, W. C. (2020). Closed-loop optimization of fast-charging protocols for batteries with machine learning. Nature. https://doi.org/10.1038/s41586-020-1994-5

Yen. T. Teh, Aubrey Demaray, Kent Griffith, Charlie Parker, Josh Stilling, Sriram Bharath, Andrew Weng, Eric Zheng, Jeffrey Bell, Mouda Abusukheila, Nick Albanese, Nicholas Yu, Katherine He, Rohit Kumar, & Jhalak Sharma. (2023). The battery Report 2022. https://www.volta.foundation/annual-battery-report

Duffner, F., Wentker, M., Greenwood, M., & Leker, J. (2020). Battery cost modeling: A review and directions for future research. Renewable and Sustainable Energy Reviews. https://doi.org/10.1016/j.rser.2020.109872

J. Frith, “Battery Price Declines Slow Down in Latest Pricing Survey,” Bloomberg Finance, Nov. 30, 2021. https://www.bloomberg.com/news/articles/2021-11-30/battery-price-declines-slow-down-in-latest-pricing-survey#xj4y7vzkg

Ahmed, S., Nelson, P. A., Gallagher, K. G., Susarla, N., & Dees, D. W. (2017). Cost and energy demand of producing nickel manganese cobalt cathode material for lithium ion batteries. Journal of Power Sources, 342, 733–740. https://doi.org/10.1016/j.jpowsour.2016.12.069

Schmuch, R., Wagner, R., Hörpel, G., Placke, T., & Winter, M. (2018). Performance and cost of materials for lithium-based rechargeable automotive batteries. Nature Energy, 3(4), 267–278. https://doi.org/10.1038/s41560-018-0107-2

Turcheniuk, K., Bondarev, D., Amatucci, G. G., & Yushin, G. (2021). Battery materials for low-cost electric transportation. Materials Today, 42, 57–72. https://doi.org/10.1016/j.mattod.2020.09.027

Chen, M., Ma, X., Chen, B., Arsenault, R., Karlson, P., Simon, N., & Wang, Y. (2019). Recycling end-of-life electric vehicle lithium-ion batteries. Joule, 3(11), 2622–2646. https://doi.org/10.1016/j.joule.2019.09.014

Borlaug, B., Salisbury, S., Gerdes, M., & Muratori, M. (2020). Levelized cost of charging electric vehicles in the United States. Joule, 4(7), 1470–1485. https://doi.org/10.1016/j.joule.2020.05.013

Kim, H. C., Wallington, T. J., Arsenault, R., Bae, C., Ahn, S., & Lee, J. (2016). Cradle-to-gate emissions from a commercial electric vehicle Li-Ion battery: a comparative analysis. Environmental Science and Technology, 50(14), 7715–7722. https://doi.org/10.1021/acs.est.6b00830

Tong, F., & Azevedo, I. M. L. (2020). “What are the best combinations of fuel-vehicle technologies to mitigate climate change and air pollution effects across the United States. Environmental Research Letters. https://doi.org/10.1088/1748-9326/ab8a85

Wu, D., Guo, F., Field, F. R., III., De Kleine, R. D., Kim, H. C., Wallington, T. J., & Kirchain, R. E. (2019). Regional heterogeneity in the emissions benefits of electrified and lightweighted light-duty vehicles. Environmental science & technology, 53(18), 10560–10570. https://doi.org/10.1021/acs.est.9b00648

Liu, X., Stoliarov, S. I., Denlinger, M., Masias, A., & Snyder, K. (2015). Comprehensive calorimetry of the thermally-induced failure of a lithium ion battery. Journal of Power Sources, 280, 516–525. https://doi.org/10.1016/j.jpowsour.2015.01.125

Liu, X., Wu, Z., Stoliarov, S. I., Denlinger, M., Masias, A., & Snyder, K. (2018). A Thermo-kinetic model of thermally-induced failure of a lithium ion battery: development, validation and application. Journal of the Electrochemical Society, 165(11), A2909–A2918. https://doi.org/10.1149/2.0111813jes

Sahraei, E., Meier, J., & Wierzbicki, T. (2014). Characterizing and modeling mechanical properties and onset of short circuit for three types of lithium-ion pouch cells. Journal of Power Sources, 247, 503–516. https://doi.org/10.1016/j.jpowsour.2013.08.056

Sahraei, E., Hill, R., & Wierzbicki, T. (2012). Calibration and finite element simulation of pouch lithium-ion batteries for mechanical integrity. Journal of Power Sources, 201, 307–321. https://doi.org/10.1016/j.jpowsour.2011.10.094

B. Xia, Z. Chen, C. Mi, and B. Robert, “External short circuit fault diagnosis for lithium-ion batteries,” in 2014 IEEE Transportation Electrification Conference and Expo: Components, Systems, and Power Electronics – From Technology to Business and Public Policy, ITEC 2014, Jul. 2014 https://doi.org/10.1109/itec.2014.6861806.

B. Xia, C. Mi, Z. Chen, and B. Robert, “Multiple cell lithium-ion battery system electric fault online diagnostics,” in 2015 IEEE Transportation Electrification Conference and Expo, ITEC 2015, Jul. 2015. https://doi.org/10.1109/ITEC.2015.7165777.

A. Masias, “Ford Safety Performance of Rechargeable Energy Storage Systems (RESS),” Report No. DOT HS 812 756. Final report. Washington, D.C.: National Highway Traffic Safety Administration. July 2019. [Online]. Available: www.ntis.gov.

Deng, J., Bae, C., Marcicki, J., Masias, A., & Miller, T. (2018). Safety modelling and testing of lithium-ion batteries in electrified vehicles. Nature Energy, 3(4), 261–266. https://doi.org/10.1038/s41560-018-0122-3

United Nations, “Uniform provisions concerning the approval of vehicles with regard to specific requirements for the electric power train, Addendum 99: Regulation No. 100, rev. 2, New York: United Nations, Aug 12, 2013.

H. Jung, B. Moon, S. Lee, and J. Bae, “A STUDY ON THERMAL ENERGY AT FIRE RESISTANCE TEST FOR REESS.” 25th International Technical Conference on the Enhanced Safety of Vehicles (ESV), Detroit, Michigan. 2017.

United Nations Economic commission for Europe, “Manual of Tests and Criteria” Seventh revised edition. December 2019. https://doi.org/10.18356/390e2d1a-en

United Nations Economic Commission for Europe, “Global Technical Regulation on the Electric Vehicle Safety (EVS)” ECE/TRANS/180/Add.20. In: 1998 Agreement on Global Technical Regulations Addendum 20, 1998. https://unece.org/transport/standards/transport/vehicle-regulations-wp29/global-technical-regulations-gtrs

Wu, X., Song, K., Zhang, X., Hu, N., Li, L., Li, W., & Zhang, H. (2019). Safety issues in lithium ion batteries: Materials and cell design. Frontiers in Energy Research, 7, 65. https://doi.org/10.3389/fenrg.2019.00065

Liu, X., Ren, D., Hsu, H., Feng, X., Xu, G. L., Zhuang, M., Gao, H., Lu, L., Han, X., Chu, Z., Li, J., He, X., Amine, K., & Ouyang, M. (2018). Thermal runaway of lithium-ion batteries without internal short circuit. Joule, 2(10), 2047–2064. https://doi.org/10.1016/j.joule.2018.06.015

Liu, K., Liu, Y., Lin, D., Pei, A., & Cui, Y. (2018). Materials for lithium-ion battery safety. Science Advances. https://doi.org/10.1126/sciadv.aas9820

Ahmed, S., Bloom, I., Jansen, A. N., Tanim, T., Dufek, E. J., Pesaran, A., & Zhang, J. (2017). Enabling fast charging–A battery technology gap assessment. Journal of Power Sources. https://doi.org/10.1016/j.jpowsour.2017.06.055

Bommier, C., Chang, W., Lu, Y., Yeung, J., Davies, G., Mohr, R., & Steingart, D. (2020). In operando acoustic detection of lithium metal plating in commercial LiCoO2/graphite pouch cells. Cell Reports Physical Science. https://doi.org/10.1016/j.xcrp.2020.100035

Amici, J., Asinari, P., Ayerbe, E., Barboux, P., Bayle-Guillemaud, P., Behm, R. J., & Edström, K. (2022). A roadmap for transforming research to invent the batteries of the future designed within the european large scale research initiative battery 2030+. Advanced Energy Materials, 12(17), 2102785. https://doi.org/10.1002/aenm.202102785

Clean Energy Materials Innovation Challenge Expert Workshop. (2020). Materials Acceleration Platform Accelerating Advanced Energy Materials Discovery by Integrating High-Throughput Methods with Artificial Intelligence. UC Office of the President: UC-Mexico Initiative. Retrieved from https://escholarship.org/uc/item/3926s13w

Vegge, T., Tarascon, J. M., & Edström, K. (2021). Toward better and smarter batteries by combining ai with multisensory and self-healing approaches. Advanced Energy Materials, 11(23), 2100362. https://doi.org/10.1002/aenm.202100362

Seifrid, M., Hickman, R. J., Aguilar-Granda, A., Lavigne, C., Vestfrid, J., Wu, T. C., & Aspuru-Guzik, A. (2022). Routescore: punching the ticket to more efficient materials development. ACS Central Science, 8(1), 122–131. https://doi.org/10.1021/acscentsci.1c01002

Atkins, D., Ayerbe, E., Benayad, A., Capone, F. G., Capria, E., Castelli, I. E., Cekic-Laskovic, I., Ciria, R., Dudy, L., Edstrom, K., Johnson, M. R., Li, H., Lastra, J. M. G., De Souza, M. L., Meunier, V., Morcrette, M., Reichert, H., Simon, P., Rueff, J. P., … Grimaud, A. (2022). Understanding battery interfaces by combined characterization and simulation approaches: challenges and perspectives. Advanced Energy Materials, 12(17), 2102687. https://doi.org/10.1002/aenm.202102687

Philippot, M., Alvarez, G., Ayerbe, E., van Mierlo, J., & Messagie, M. (2019). Eco-efficiency of a lithium-ion battery for electric vehicles: Influence of manufacturing country and commodity prices on GHG emissions and costs. Batteries, 5(1), 23. https://doi.org/10.3390/batteries5010023

Narayan, R., Laberty-Robert, C., Pelta, J., Tarascon, J. M., & Dominko, R. (2022). Self-healing: an emerging technology for next-generation smart batteries. Advanced Energy Materials, 12(17), 2102652. https://doi.org/10.1002/aenm.202102652

Senyshyn, A., Mühlbauer, M. J., Nikolowski, K., Pirling, T., & Ehrenberg, H. (2012). ‘In-operando’ neutron scattering studies on Li-ion batteries. Journal of Power Sources, 203, 126–129. https://doi.org/10.1016/j.jpowsour.2011.12.007

Bergman, S. D., & Wudl, F. (2008). Mendable polymers. Journal of Materials Chemistry, 18(1), 41–62. https://doi.org/10.1039/b713953p

Wang, H., Wang, P., Feng, Y., Liu, J., Wang, J., Hu, M., & Huang, Y. (2019). Recent advances on self-healing materials and batteries. ChemElectroChem, 6(6), 1605–1622. https://doi.org/10.1002/celc.201801612

Kwon, T. W., Choi, J. W., & Coskun, A. (2019). Prospect for supramolecular chemistry in high-energy-density rechargeable batteries. Joule, 3(3), 662–682. https://doi.org/10.1016/j.joule.2019.01.006

Sharpe, R., van Lopik, K., Neal, A., Goodall, P., Conway, P. P., & West, A. A. (2019). An industrial evaluation of an Industry 4.0 reference architecture demonstrating the need for the inclusion of security and human components. Computers in Industry, 108, 37–44. https://doi.org/10.1016/j.compind.2019.02.007

Negri, E., Fumagalli, L., & Macchi, M. (2017). A review of the roles of digital Twin in CPS-based production systems. Procedia Manufacturing, 11, 939–948. https://doi.org/10.1016/j.promfg.2017.07.198

Liu, K., Wei, Z., Yang, Z., & Li, K. (2021). Mass load prediction for lithium-ion battery electrode clean production: a machine learning approach. Journal of Cleaner Production. https://doi.org/10.1016/j.jclepro.2020.125159

The European Parliament And The Council Of The Euro-Pean Union. (2006). DIRECTIVE 2006/66/EC OF THE EUROPEAN PARLIAMENT AND OF THE COUNCILof 6 September 2006on batteries and accumulators and waste batteries and accumulators and repealing Directive91/157/EEC. http://data.europa.eu/eli/dir/2006/66/oj

Yao, W., Zhang, Z., Gao, J., Li, J., Xu, J., Wang, Z., & Yang, Y. (2009). Vinyl ethylene sulfite as a new additive in propylene carbonate-based electrolyte for lithium ion batteries. Energy & Environmental Science, 2(10), 1102–1108. https://doi.org/10.1039/b905162g

Wang, R., Li, X., Wang, Z., & Zhang, H. (2017). Electrochemical analysis graphite/electrolyte interface in lithium-ion batteries: p-Toluenesulfonyl isocyanate as electrolyte additive. Nano Energy, 34, 131–140. https://doi.org/10.1016/j.nanoen.2017.02.037

Ushirogata, K., Sodeyama, K., Okuno, Y., & Tateyama, Y. (2013). Additive effect on reductive decomposition and binding of carbonate-based solvent toward solid electrolyte interphase formation in lithium-ion battery. Journal of the American Chemical Society, 135(32), 11967–11974. https://doi.org/10.1021/ja405079s

Leggesse, E. G., & Jiang, J. C. (2012). Theoretical study of the reductive decomposition of ethylene sulfite: a film-forming electrolyte additive in lithium ion batteries. Journal of Physical Chemistry A, 116(45), 11025–11033. https://doi.org/10.1021/jp3081996

Goodenough, J. B., & Kim, Y. (2010). Challenges for rechargeable Li batteries. Chemistry of Materials, 22(3), 587–603. https://doi.org/10.1021/cm901452z

Armand, M. B. (1986). Polymer electrolytes. Ann Rev Mater. https://doi.org/10.1146/annurev.ms.16.080186.001333

Scrosati, B. (1995). Challenge of portable power. Nature, 373, 557–558. https://doi.org/10.1038/373557a0

Behera, Ajit, and Ajit Behera. “Energy Harvesting and Storing Materials.” Advanced Materials: An Introduction to Modern Materials Science (2022): 507–555.

Boz, B., Ford, H. O., Salvadori, A., & Schaefer, J. L. (2021). Porous polymer gel electrolytes influence lithium transference number and cycling in lithium-ion batteries. Electronic Materials, 2(2), 154–173. https://doi.org/10.3390/electronicmat2020013

Fenton, D. E. (1973). Complexes of alkali metal ions with poly (Haracte oxide). Polymer, 14, 589.

Armand, M. B., Chabagno, J. M., & Duclot, M. J. (1979). Fast ion transport in solids. Electrodes and Electrolytes, 131.

Bouchet, R., Maria, S., Meziane, R., Aboulaich, A., Lienafa, L., Bonnet, J. P., & Armand, M. (2013). Single-ion BAB triblock copolymers as highly efficient electrolytes for lithium-metal batteries. Nature materials, 12(5), 452–457. https://doi.org/10.1038/nmat3602

Imanishi, N., & Yamamoto, O. (2013). Polymer electrolytes for Lithium-air batteries. Lithium Batteries Advanced Technologies and Applications. https://doi.org/10.1002/9781118615515.ch10

Meyer, W. H. (1998). Polymer electrolytes for lithium-ion batteries. Advanced Materials, 10(6), 439–448. https://doi.org/10.1002/(SICI)1521-4095(199804)10:6%3c439::AID-ADMA439%3e3.0.CO;2-I

Yue, L., Ma, J., Zhang, J., Zhao, J., Dong, S., Liu, Z., & Chen, L. (2016). All solid-state polymer electrolytes for high-performance lithium ion batteries. Energy Storage Materials, 5, 139–164. https://doi.org/10.1016/j.ensm.2016.07.003

Ahmad, S. (2009). Polymer electrolytes: Characteristics and peculiarities. Ionics (Kiel), 15(3), 309–321. https://doi.org/10.1007/s11581-008-0309-x

Hallinan, D. T., & Balsara, N. P. (2013). Polymer electrolytes. Annual Review of Materials Research. https://doi.org/10.1146/annurev-matsci-071312-121705

D. E. Fenton, M. Parker, and P. v Wright, “A-l) 1966, 4, 1563,” 1964.

Scrosati, B., & Vincent, C. A. (2000). Polymer electrolytes: the key to lithium polymer batteries. Mrs Bulletin, 25(3), 28–30.

G. G. Cameron, “Polymer electrolyte reviews-l edited by J. R. MacCallum and C. A. Vincent, Elsevier Applied Science Publishers, London, 1987. Pp. x + 351, price £48.00. ISBN 1–85166–07 1–2,” British Polymer Journal, 20 (3) 299–300, 1988

Ib, I., Olsen, R. K., & Skou, E. (1995). Transference Number Measurements on a Hybrid Polyer Electrolyte. Electrochimica Acta, 40(11), 1701–1706.

Agrawal, R. C., & Pandey, G. P. (2008). Solid polymer electrolytes: materials designing and all-solid-state battery applications: an overview. Journal of Physics. D. Applied Physics. https://doi.org/10.1088/0022-3727/41/22/223001

Echeverri, M., Kim, N., & Kyu, T. (2012). Ionic conductivity in relation to ternary phase diagram of poly(ethylene oxide), succinonitrile, and lithium bis(trifluoromethane)sulfonyl imide blends. Macromolecules, 45(15), 6068–6077. https://doi.org/10.1021/ma3008509

Scorsati, B. (2000). Polymer electrolytes: the key to Lithiumpolymer batteries. MRS Bulletin. https://doi.org/10.1557/mrs2000.15

Petersen, G., Jacobson, P., & Torell, L. M. (1992). A raman study interactions of Ion-polymer and Ion-Ion interactions in low molecular weight polyether–LiCF3SO3 complexes. Electrochimica Acta, 37(9), 1495–1497.

Bruce, P. G., & Vincent, C. A. (1989). Effect of Ion association on transport in polymer electrolytes. Faraday Discussions of the Chemical Society, 88, 43–54. https://doi.org/10.1039/DC9898800043

Lightfoot, P., Mehta, M. A., & Bruce, P. G. (1993). Crystal structure of the polymer electrolyte poly (ethylene oxide) 3: LiCF3SO3. Science, 262(5135), 883–885.

Benrabah, D., Baril, D., Sanchez, J.-Y., Armand, M., & Gard, G. G. (1993). Comparative electrochemical study of new poly(oxyethy1ene)-Li salt complexes. Faraday Discussions of the Chemical Society, 89, 355–359. https://doi.org/10.1039/FT9938900355

Wilson, D. J., Nicholas, C. V., Mobbs, R. H., Booth, C., & Giles, J. R. M. (1990). “Synthesis of block copolymers based on oxyethylene chains and their use as polymer electrolytes. British Polymer Journal. https://doi.org/10.1002/pi.4980220206

Chintapalli, S., & Frech, R. (1996). Effect of plasticizers on Ionic association and conductivity in the (PEO) 9 LiCF3SO3 system. Macromolecules, 29(10), 3499–3506. https://doi.org/10.1021/ma9515644

Kim, Y.-T., & Smotkin, E. S. (2002). The effect of plasticizers on transport and electrochemical properties of PEO-based electrolytes for lithium rechargeable batteries. Solid State Ionics, 149(1–2), 29–37.

Das, S., & Ghosh, A. (2015). Ionic conductivity and dielectric permittivity of PEO-LiClO4 solid polymer electrolyte plasticized with propylene carbonate. AIP Advances. https://doi.org/10.1063/1.4913320

Frech, R., & Chintapalli, S. (1996). Effect of propylene carbonate as a plasticizer in high molecular weight PEO LiCF3SO3 electrolytes. Solid State Ionics, 85(1–4), 61–66. https://doi.org/10.1016/0167-2738(96)00041-0

Kelly, I. E., Owen, J. R., & Steele, B. C. H. (1985). Poly (ethylene oxide) electrolytes for operation at near room temperature. Journal of Power Sources, 14(1–3), 13–21. https://doi.org/10.1016/0378-7753(85)88004-6

Wang, C., Liu, Q., Cao, Q., & Meng, Q. (1992). Investigation on the structure and the conductivity of plasticized polymer electrolytes. Solid State Ionics. https://doi.org/10.1016/0167-2738(92)90298-4

Porcarelli, L., Gerbaldi, C., Bella, F., & Nair, J. R. (2016). Super Soft All-ethylene oxide polymer electrolyte for safe all-solid lithium batteries. Science and Reports, 6, 19892. https://doi.org/10.1038/srep19892

Michael, M. S., Jacob, M. M. E., Prabaharan, S. R. S., & Radhakrishna, S. (1997). Enhanced lithium-ion transport in PEO-based solid polymer electrolytes employing a novel class of plasticizers. Solid State Ionics, 98(3–4), 167–174. https://doi.org/10.1016/S0167-2738(97)00117-3

Nicotera, I., Ranieri, G. A., Terenzi, M., Chadwick, A. V., & Webster, M. I. (2002). A study of stability of plasticized PEO electrolytes. Solid State Ionics, 146(1–2), 143–150. https://doi.org/10.1016/S0167-2738(01)01003-7

Angell, C. A., Liu, C., & Sanchez, E. (1993). Rubbery solid electrolytes with dominant cationic transport and high ambient conductivity. Nature, 362(6416), 137–139.

Ferry, A., Edman, L., Forsyth, M., MacFarlane, D. R., & Sun, J. (1999). Connectivity, ionic interactions, and migration in a fast-ion-conducting polymer-in-salt electrolyte based on poly(acrylonitrile) and LiCF3SO3. Journal of Applied Physics, 86(4), 2346–2348. https://doi.org/10.1063/1.371053

Bushkova, O. V., Zhukovsky, V. M., Lirova, B. I., & Kruglyashov, A. L. (1999). Fast ionic transport in solid polymer electrolytes based on acrylonitrile copolymers. Solid State Ionics, 119(1–4), 217–222. https://doi.org/10.1016/S0167-2738(98)00506-2

Mishra, R., Baskaran, N., Ramakrishnan, P. A., & Rao, K. J. (1998). Lithium-ion conduction in extreme polymer in salt regime. Solid State Ionics, 112(3–3), 261–273. https://doi.org/10.1016/S0167-2738(98)00209-4

Croce, F., Appetecchi, G. B., Persi, L., & Scrosati, B. (1998). Nanocomposite polymer electrolytes for lithium batteries. Nature, 394(6692), 456–458.

Appetecchi, G. B., Scaccia, S., & Passerini, S. (2000). Investigation on the stability of the lithium-polymer electrolyte interface. Journal of the Electrochemical Society, 147(12), 4448–4452. https://doi.org/10.1149/1.1394084

Bronstein, L. M., Karlinsey, R. L., Ritter, K., Joo, C. G., Stein, B., & Zwanziger, J. W. (2004). Design of organic-inorganic solid polymer electrolytes: synthesis, structure, and properties. Journal of Materials Chemistry, 14(12), 1812–1820. https://doi.org/10.1039/b401826e

Itoh, T., Miyamura, Y., Ichikawa, Y., Uno, T., Kubo, M., & Yamamoto, O. (2003). Composite polymer electrolytes of poly(ethylene oxide)/BaTiO3/Li salt with hyperbranched polymer. Journal of Power Sources, 119–121, 403–408. https://doi.org/10.1016/S0378-7753(03)00261-1

Skaarup, S., West, K., & Zachau-Christiansen, B. (1988). Mixed phase solid electrolytes. Solid State lonics. https://doi.org/10.1016/0167-2738(88)90314-1

Wieczorek, W. (1992). Temperature dependence of conductivity of mixed-phase composite polymer solid electrolytes. Materials Science and Engineering B, 15(2), 108–114. https://doi.org/10.1016/0921-5107(92)90041-7

Capuano, F., Croce, F., & Scrosati, B. (1991). Composite polymer electrolytes. Journal of the Electrochemical Society, 138(7), 1918.

Forsyth, M., MacFarlane, D. R., Best, A., Adebahr, J., Jacobsson, P., & Hill, A. J. (2002). The effect of nano-particle TiO2 fillers on structure and transport in polymer electrolytes. Solid State Ionics, 147(3–4), 203–211. https://doi.org/10.1016/S0167-2738(02)00017-6

Liu, Y., Lee, J. Y., & Hong, L. (2002). Functionalized SiO2 in poly(ethylene oxide)-based polymer electrolytes. Journal of Power Sources, 109(2), 507–514. https://doi.org/10.1016/S0378-7753(02)00167-2

Croce, F., Settimi, L., & Scrosati, B. (2006). Superacid ZrO2-added, composite polymer electrolytes with improved transport properties. Electrochemistry Communications, 8(2), 364–368. https://doi.org/10.1016/j.elecom.2005.12.002

Croce, F., Sacchetti, S., & Scrosati, B. (2006). Advanced, lithium batteries based on high-performance composite polymer electrolytes. Journal of Power Sources, 162(1), 685–689. https://doi.org/10.1016/j.jpowsour.2006.07.038

Xi, J., Qiu, X., Zheng, S., & Tang, X. (2005). Nanocomposite polymer electrolyte comprising PEO/LiClO4 and solid super acid: Effect of sulphated-zirconia on the crystallization kinetics of PEO. Polymer (Guildf), 46(15), 5702–5706. https://doi.org/10.1016/j.polymer.2005.05.051

S. Abbrent, S. Greenbaum, E. Peled, and D. Golodnitsky, “Polymer Electrolytes.” In: Handbook of Solid State Batteries, 2nd ed. N.J. Dudney, W.C. West, and J. Nanda (eds.). Singapore: World Scientific. 2015 https://doi.org/10.1142/9789814651905_0016.

Varzi, A., Raccichini, R., Passerini, S., & Scrosati, B. (2016). Challenges and prospects of the role of solid electrolytes in the revitalization of lithium metal batteries. J Mater Chem A Mater, 4(44), 17251–17259. https://doi.org/10.1039/c6ta07384k

Bocharova, V., & Sokolov, A. P. (2020). Perspectives for polymer electrolytes: a view from fundamentals of ionic conductivity. Macromolecules, American Chemical Society. https://doi.org/10.1021/acs.macromol.9b02742

Strauss, E., Menkin, S., & Golodnitsky, D. (2017). On the way to high-conductivity single lithium-ion conductors. Journal of Solid State Electrochemistry, 21(7), 1879–1905. https://doi.org/10.1007/s10008-017-3638-8

Kerman, K., Luntz, A., Viswanathan, V., Chiang, Y.-M., & Chen, Z. (2017). Review—practical challenges hindering the development of solid state Li Ion batteries. Journal of the Electrochemical Society, 164(7), A1731–A1744. https://doi.org/10.1149/2.1571707jes

Golodnitsky, D., Ardel, G., Strauss, E., Peled, E., Lareah, Y., & Rosenberg, Y. (1997). Conduction mechanisms in concentrated Lu-polyethylene Oxide-A1203-based solid electrolytes. Journal of the Electrochemical Society, 144(10), 3484–3491. https://doi.org/10.1149/1.1838037

Wang, Y., Fan, F., Agapov, A. L., Saito, T., Yang, J., Yu, X., & Sokolov, A. P. (2014). Examination of the fundamental relation between ionic transport and segmental relaxation in polymer electrolytes. Polymer, 55(16), 4067–4076. https://doi.org/10.1016/j.polymer.2014.06.085

Golodnitsky, D., Strauss, E., Peled, E., & Greenbaum, S. (2015). Review—on order and disorder in polymer electrolytes. Journal of the Electrochemical Society, 162(14), A2551–A2566. https://doi.org/10.1149/2.0161514jes

Blanga, R., Burstein, L., Berman, M., Greenbaum, S. G., & Golodnitsky, D. (2015). Solid polymer-in-ceramic electrolyte formed by electrophoretic deposition. Journal of the Electrochemical Society, 162(11), D3084–D3089. https://doi.org/10.1149/2.0221511jes

Menkin, S., Lifshitz, M., Haimovich, A., Goor, H., Blanga, R., Greenbaum, S. G., & Golodnitsky, D. (2019). Evaluation of ion-transport in composite polymer-in-ceramic electrolytes. case study of active and inert ceramics. Electrochimica Acta, 304, 447–455. https://doi.org/10.1016/j.electacta.2019.03.006

Kumar, B., & Scanlon, L. G. (1994). Polymer-ceramic composite electrolytes. Journal of Power Sources, 52(2), 261–268. https://doi.org/10.1016/0378-7753(94)02147-3

Abraham, K. M. (1993). Highly conductive polymer electrolytes. Applications of electroactive polymer. https://doi.org/10.1007/978-94-011-1568-1_3

Dai, Y., Wang, Y., Greenbaum, S. G., Bajue, S. A., Golodnitsky, D., Ardel, G., & Peled, E. (1998). Electrical, thermal and NMR investigation of composite solid electrolytes based on PEO, LiI and high surface area inorganic oxides. Electrochimica acta, 43(10–11), 1557–1561. https://doi.org/10.1016/S0013-4686(97)10053-6

Horowitz, Y., Lifshitz, M., Greenbaum, A., Feldman, Y., Greenbaum, S., Sokolov, A. P., & Golodnitsky, D. (2020). polymer/ceramic interface barriers: the fundamental challenge for advancing composite solid electrolytes for Li-ion batteries. Journal of The Electrochemical Society. https://doi.org/10.1149/1945-7111/abcd12

Tang, S., Guo, W., & Fu, Y. (2021). Advances in composite polymer electrolytes for lithium batteries and beyond. Advanced Energy Materials, 11(2), 2000802. https://doi.org/10.1002/aenm.202000802

Appetecchi, G. B., Croce, F., & Scrosati, B. (1995). Kinetics and stability of the lithium electrode in poly(methylmethacrylate)-based gel electrolytes. Electrochimica Acta, 40(8), 991–997. https://doi.org/10.1016/0013-4686(94)00345-2

Ahmed, H. T., Jalal, V. J., Tahir, D. A., Mohamad, A. H., & Abdullah, O. G. (2019). Effect of PEG as a plasticizer on the electrical and optical properties of polymer blend electrolyte MC-CH-LiBF4 based films. Results Phys. https://doi.org/10.1016/j.rinp.2019.102735

Verdier, N., Lepage, D., Zidani, R., Prebe, A., Ayme-Perrot, D., Pellerin, C., & Rochefort, D. (2019). Cross-linked polyacrylonitrile-based elastomer used as gel polymer electrolyte in Li-Ion battery. ACS Applied Energy Materials, 3(1), 1099–1110. https://doi.org/10.1021/acsaem.9b02129

Tseng, Y. C., Hsiang, S. H., Lee, T. Y., Teng, H., Jan, J. S., & Kyu, T. (2021). In Situ polymerized electrolytes with fully cross-linked networks boosting high ionic conductivity and capacity retention for lithium Ion batteries. ACS Applied Energy Materials, 4(12), 14309–14322. https://doi.org/10.1021/acsaem.1c03011

Watanabe, M., Thomas, M. L., Zhang, S., Ueno, K., Yasuda, T., & Dokko, K. (2017). Application of ionic liquids to energy storage and conversion materials and devices. Chemical Reviews, 117(10), 7190–7239. https://doi.org/10.1021/acs.chemrev.6b00504

X. He, Y. Ni, Y. Hou, Y. Lu, S. Jin, H. Li, Z. Yan, K. Zhang, J. Chen, “Insights into the Ionic Conduction Mechanism of Quasi-Solid Polymer Electrolytes through Multispectral Characterization,” Angewandte Chemie – International Edition, 2021 https://doi.org/10.1002/anie.202107648.

Tripathi, A. K. (2021). Ionic liquid–based solid electrolytes (ionogels) for application in rechargeable lithium battery. Materials Today Energy. https://doi.org/10.1016/j.mtener.2021.100643

Li, W., Pang, Y., Liu, J., Liu, G., Wang, Y., & Xia, Y. (2017). A PEO-based gel polymer electrolyte for lithium ion batteries. RSC Advances, 7(38), 23494–23501. https://doi.org/10.1039/c7ra02603j

Zuo, X., Ma, X., Wu, J., Deng, X., Xiao, X., Liu, J., & Nan, J. (2018). Self-supporting ethyl cellulose/poly (vinylidene fluoride) blended gel polymer electrolyte for 5 V high-voltage lithium-ion batteries. Electrochimica Acta, 271, 582–590. https://doi.org/10.1016/j.electacta.2018.03.195

Zhang, M. Y., Li, M. X., Chang, Z., Wang, Y. F., Gao, J., Zhu, Y. S., & Huang, W. (2017). A sandwich PVDF/HEC/PVDF gel polymer electrolyte for lithium ion battery. Electrochimica acta, 245, 752–759. https://doi.org/10.1016/j.electacta.2017.05.154

Zhou, L., Wu, N., Cao, Q., Jing, B., Wang, X., Wang, Q., & Kuang, H. (2013). A novel electrospun PVDF/PMMA gel polymer electrolyte within situ TiO2 for Li-ion batteries. Solid State Ionics, 249, 93–97. https://doi.org/10.1016/j.ssi.2013.07.019

Kufian, M. Z., Aziz, M. F., Shukur, M. F., Rahim, A. S., Ariffin, N. E., Shuhaimi, N. E. A., & Arof, A. K. (2012). PMMA–LiBOB gel electrolyte for application in lithium ion batteries. Solid State Ionics, 208, 36–42. https://doi.org/10.1016/j.ssi.2011.11.032

Deng, X., Huang, Y., Song, A., Liu, B., Yin, Z., Wu, Y., & Cao, H. (2019). Gel polymer electrolyte with high performances based on biodegradable polymer polyvinyl alcohol composite lignocellulose. Materials Chemistry and Physics, 229, 232–241. https://doi.org/10.1016/j.matchemphys.2019.03.014

J. Thornton, “Environmental Impacts of Polyvinyl Chloride (PVC) Building Materials A briefing paper for the Healthy Building Network.” Available at: http://mts.sustainableproducts.com/ SmaRT/ThorntonRevised.pdf

Huang, X. (2013). Cellular porous polyvinylidene fluoride composite membranes for lithium-ion batteries. Journal of Solid State Electrochemistry, 17(3), 591–597. https://doi.org/10.1007/s10008-012-1891-4

Gong, W., Wei, S., Ruan, S., & Shen, C. (2019). Electrospun coaxial PPESK/PVDF fibrous membranes with thermal shutdown property used for lithium-ion batteries. Materials Letters, 244, 126–129. https://doi.org/10.1016/j.matlet.2019.02.009

Sun, X., Liu, G., Li, R., Meng, Y., & Wu, J. (2021). Polyporous PVDF/TiO2 photocatalytic composites for photocatalyst fixation, recycle, and repair. Journal of the American Ceramic Society, 104(12), 6290–6298. https://doi.org/10.1111/jace.18034

Zhao, Y., Fang, L. Z., Kang, Y. Q., Wang, L., Zhou, Y. N., Liu, X. Y., & Li, B. H. (2021). A novel three-step approach to separate cathode components for lithium-ion battery recycling. Rare Metals, 40, 1431–1436. https://doi.org/10.1007/s12598-020-01587-y

Xu, P., Chen, H., Zhou, X., & Xiang, H. (2021). Gel polymer electrolyte based on PVDF-HFP matrix composited with rGO-PEG-NH2 for high-performance lithium ion battery. J Memb Sci. https://doi.org/10.1016/j.memsci.2020.118660

Hosseinioun, A., Nürnberg, P., Schönhoff, M., Diddens, D., & Paillard, E. (2019). Improved lithium ion dynamics in crosslinked PMMA gel polymer electrolyte. RSC Advances, 9(47), 27574–27582. https://doi.org/10.1039/c9ra05917b

Kaminsky, W., & Franck, J. (1991). Monomer recovery by pyrolysis of poly( methyl methacrylate) (PMMA). Journal of Analytical and Applied Pyrolysis, 19, 311–318. https://doi.org/10.1016/0165-2370(91)80052-A

Chiellini, E., Corti, A., D’Antone, S., & Solaro, R. (2003). Biodegradation of poly (vinyl alcohol) based materials. Progress in Polymer science, 28(6), 963–1014.

Alipoori, S., Mazinani, S., Aboutalebi, S. H., & Sharif, F. (2020). Review of PVA-based gel polymer electrolytes in flexible solid-state supercapacitors: Opportunities and challenges. Journal of Energy Storage. https://doi.org/10.1016/j.est.2019.101072

Piątek, J., Afyon, S., Budnyak, T. M., Budnyk, S., Sipponen, M. H., & Slabon, A. (2021). Sustainable Li-Ion batteries: chemistry and recycling. Advanced Energy Materials, 11(43), 2003456. https://doi.org/10.1002/aenm.202003456

Han, Y. H., Han, S. O., Cho, D., & Kim, H. I. L. (2007). Kenaf/polypropylene biocomposites: Effects of electron beam irradiation and alkali treatment on kenaf natural fibers. Composite Interfaces. https://doi.org/10.1163/156855407781291272

Wohlert, M., Benselfelt, T., Wågberg, L., Furó, I., Berglund, L. A., & Wohlert, J. (2022). Cellulose and the role of hydrogen bonds: not in charge of everything. Cellulose, 29, 1–23. https://doi.org/10.1007/s10570-021-04325-4

Du, Z., Su, Y., Qu, Y., Zhao, L., Jia, X., Mo, Y., Yu, F., Du, J., & Chen, Y. (2019). A mechanically robust, biodegradable and high performance cellulose gel membrane as gel polymer electrolyte of lithium-ion battery. Electrochimica acta, 299, 19–26. https://doi.org/10.1016/j.electacta.2018.12.173

Chun, S. J., Lee, S. Y., Doh, G. H., Lee, S., & Kim, J. H. (2011). Preparation of ultrastrength nanopapers using cellulose nanofibrils. Journal of Industrial and Engineering Chemistry, 17(3), 521–526. https://doi.org/10.1016/j.jiec.2010.10.022

Leo Edward, M., Dharanibalaji, K. C., Kumar, K. T., Chandrabose, A. R. S., Shanmugharaj, A. M., & Jaisankar, V. (2022). Preparation and haracterization of chitosan extracted from shrimp shell (Penaeus monodon) and chitosan-based blended solid polymer electrolyte for lithium-ion batteries. Polymer Bulletin. https://doi.org/10.1007/s00289-020-03472-1

Xu, D., Jin, J., Chen, C., & Wen, Z. (2018). From nature to energy storage: a novel sustainable 3D cross-linked chitosan-PEGGE-based gel polymer electrolyte with excellent lithium-ion transport properties for lithium batteries. ACS Applied Materials & Interfaces, 10(44), 38526–38537. https://doi.org/10.1021/acsami.8b15247

Osinska-Broniarz, M., Gieparda, W., Wesolek, D., Martyla, A., Przekop, R., & Sierczynska, A. (2015). Preparation and characterization of gel polymer electrolytes based on electrospun PLA/PHB membranes for Lithium-Ion batteries. ECS Transactions, 70(1), 79–88. https://doi.org/10.1149/07001.0079ecst

Zhu, M., Lan, J., Tan, C., Sui, G., & Yang, X. (2016). Degradable cellulose acetate/poly-l-lactic acid/halloysite nanotube composite nanofiber membranes with outstanding performance for gel polymer electrolytes. J Mater Chem A Mater, 4, 12136–12143. https://doi.org/10.1039/c6ta05207j

Piana, G., Ricciardi, M., Bella, F., Cucciniello, R., Proto, A., & Gerbaldi, C. (2020). Poly(glycidyl ether)s recycling from industrial waste and feasibility study of reuse as electrolytes in sodium-based batteries. Chemical Engineering Journal. https://doi.org/10.1016/j.cej.2019.122934

Kim, S. K., Yoon, Y., Ryu, J. H., Kim, J. H., Ji, S., Song, W., Myung, S., Lim, J., Jung, H. K., Lee, S. S., Lee, J., & An, K. S. (2020). Recyclable high-performance polymer electrolyte based on a modified methyl cellulose-lithium Trifluoromethanesulfonate salt composite for sustainable energy systems. Chemsuschem, 13(2), 376–384. https://doi.org/10.1002/cssc.201902756

Tenhaeff, W. E., & Kalnaus, S. (2015). Designing solid polymer composite electrolytes for facile lithium transport and mechanical strength. Handbook of Solid State Batteries. https://doi.org/10.1142/9789814651905_0007

Judez, X., Zhang, H., Li, C., Eshetu, G. G., González-Marcos, J. A., Armand, M., & Rodriguez-Martinez, L. M. (2017). Solid electrolytes for safe and high energy density lithium-sulfur batteries: Promises and challenges. Journal of The Electrochemical Society, 165(1), A6008. https://doi.org/10.1149/2.0041801jes

Huang, X., Liu, C., Lu, Y., Xiu, T., Jin, J., Badding, M. E., & Wen, Z. (2018). A Li-Garnet composite ceramic electrolyte and its solid-state Li-S battery. Journal of Power Sources, 382, 190–197. https://doi.org/10.1016/j.jpowsour.2017.11.074

Doux, J. M., Nguyen, H., Tan, D. H., Banerjee, A., Wang, X., Wu, E. A., & Meng, Y. S. (2020). Stack pressure considerations for room-temperature all-solid-state lithium metal batteries. Advanced Energy Materials, 10(1), 1903253. https://doi.org/10.1002/aenm.201903253

Doux, J. M., Yang, Y., Tan, D. H., Nguyen, H., Wu, E. A., Wang, X., & Meng, Y. S. (2020). Pressure effects on sulfide electrolytes for all solid-state batteries. Journal of Materials Chemistry A, 8(10), 5049–5055. https://doi.org/10.1039/c9ta12889a

Chen, A., Qu, C., Shi, Y., & Shi, F. (2020). Manufacturing strategies for solid electrolyte in Batteries. Frontiers in Energy Research. https://doi.org/10.3389/fenrg.2020.571440

Appetecchi, G. B., Alessandrini, F., Carewska, M., Caruso, T., Prosini, P. P., Scaccia, S., & Passerini, S. (2001). Investigation on lithium–polymer electrolyte batteries. Journal of power sources, 97, 790–794. https://doi.org/10.1016/S0378-7753(01)00609-7

Nguyen, H., Banerjee, A., Wang, X., Tan, D., Wu, E. A., Doux, J. M., Stephens, R., Verbist, G., & Meng, Y. S. (2019). Single-step synthesis of highly conductive Na3PS4 solid electrolyte for sodium all solid-state batteries. Journal of Power Sources. https://doi.org/10.1016/j.jpowsour.2019.05.031

Hafner, S., Guthrey, H., Lee, S. H., & Ban, C. (2019). Synchronized electrospinning and electrospraying technique for manufacturing of all-solid-state lithium-ion batteries. Journal of Power Sources, 431, 17–24. https://doi.org/10.1016/j.jpowsour.2019.05.008

Commarieu, B., Paolella, A., Daigle, J. C., & Zaghib, K. (2018). Toward high lithium conduction in solid polymer and polymer–ceramic batteries. Current Opinion in Electrochemistry. https://doi.org/10.1016/j.coelec.2018.03.033

Tan, S. J., Zeng, X. X., Ma, Q., Wu, X. W., & Guo, Y. G. (2018). Recent advancements in polymer-based composite electrolytes for rechargeable lithium batteries. Electrochemical Energy Reviews, 1(2), 113–138. https://doi.org/10.1007/s41918-018-0011-2

Li, S., Zhang, S. Q., Shen, L., Liu, Q., Ma, J. B., Lv, W., & Yang, Q. H. (2020). Progress and perspective of ceramic/polymer composite solid electrolytes for lithium batteries. Advanced Science, 7(5), 1903088. https://doi.org/10.1002/advs.201903088

Cavaliere, S., Subianto, S., Savych, I., Jones, D. J., & Rozière, J. (2011). Electrospinning: designed architectures for energy conversion and storage devices. Energy and Environmental Science, 4(12), 4761–4785. https://doi.org/10.1039/c1ee02201f

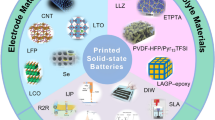

Pang, Y., Cao, Y., Chu, Y., Liu, M., Snyder, K., MacKenzie, D., & Cao, C. (2020). Additive manufacturing of batteries. Advanced Functional Materials, 30(1), 1906244. https://doi.org/10.1002/adfm.201906244

Strauss, E., Menkin, S., & Golodnitsky, D. (2018). Polymer electrolytes for printed batteries. Printed Batteries: Materials, Technologies and Applications, 80–111. DOI: https://doi.org/10.1002/9781119287902.ch4

Oliveira, J., Costa, C. M., & Lanceros-Méndez, S. (2018). Printed batteries: an overview printed batteries: materials. Technologies and Applications. https://doi.org/10.1002/9781119287902.ch1

Cheng, M., Jiang, Y., Yao, W., Yuan, Y., Deivanayagam, R., Foroozan, T., Huang, Z., Song, B., Rojaee, R., Shokuhfar, T., Pan, Y., Lu, J., & Shahbazian-Yassar, R. (2018). Elevated-temperature 3D printing of hybrid solid-state electrolyte for Li-ion batteries. Advanced Materials, 30(39), 1800615. https://doi.org/10.1002/adma.201800615

Yang, Y., Yuan, W., Zhang, X., Yuan, Y., Wang, C., Ye, Y., & Tang, Y. (2020). Overview on the applications of three-dimensional printing for rechargeable lithium-ion batteries. Applied Energy. https://doi.org/10.1016/j.apenergy.2019.114002

Costa, C. M., Gonçalves, R., & Lanceros-Méndez, S. (2020). Recent advances and future challenges in printed batteries. Energy Storage Mater, 28, 216–234. https://doi.org/10.1016/j.ensm.2020.03.012

Tehrani, Z., Korochkina, T., Govindarajan, S., Thomas, D. J., O’Mahony, J., Kettle, J., & Gethin, D. T. (2015). Ultra-thin flexible screen printed rechargeable polymer battery for wearable electronic applications. Organic Electronics, 26, 386–394. https://doi.org/10.1016/j.orgel.2015.08.007

Kim, S. H., Choi, K. H., Cho, S. J., Choi, S., Park, S., & Lee, S. Y. (2015). Printable Solid-state lithium-ion batteries: a new route toward shape-conformable power sources with aesthetic versatility for flexible electronics. Nano Letters, 15(8), 5168–5177. https://doi.org/10.1021/acs.nanolett.5b01394

D. Steingart, C. C. Ho, J. Salminen, J. W. Evans, and P. K. Wright, “Dispenser Printing of Solid Polymer-Ionic Liquid Electrolytes for Lithium Ion Cells,” 6th International Conference on Polymers and Adnesives in Microelectronics and Photonics, Tokyo, Japan. 15–18 January, 2007. Doi: https://doi.org/10.1109/POLYTR.2007.4339179.

Cheng, M., Deivanayagam, R., & Shahbazian-Yassar, R. (2020). 3D Printing of electrochemical energy storage devices: a review of printing techniques and electrode/electrolyte architectures. Batteries and Supercaps, 3(2), 130–146. https://doi.org/10.1002/batt.201900130

Ponnada, S., Babu Gorle, D., Chandra Bose, R. S., Sadat Kiai, M., Devi, M., Venkateswara Raju, C., Baydogan, N., Nanda, K. K., Marken, F., & Sharma, R. K. (2022). Current insight into 3D printing in solid-state lithium-Ion batteries: a perspective. Batteries & Supercaps. https://doi.org/10.1002/batt.202200223

Shinde, V. V., Wang, Y., Salek, M. F., Auad, M. L., Beckingham, L. E., & Beckingham, B. S. (2022). Material design for enhancing properties of 3D printed polymer composites for target applications. Technologies (Basel). https://doi.org/10.3390/technologies10020045

Zhu, C., Liu, T., Qian, F., Chen, W., Chandrasekaran, S., Yao, B., Song, Y., Duoss, E. B., Kuntz, J. D., Spadaccini, C. M., Worsley, M., & Li, Y. (2017). 3D printed functional nanomaterials for electrochemical energy storage. Nano Today, 15, 107–120. https://doi.org/10.1016/j.nantod.2017.06.007

Ngo, T. D., Kashani, A., Imbalzano, G., Nguyen, K. T. Q., & Hui, D. (2018). Additive manufacturing (3D printing): a review of materials, methods, applications and challenges. Composites Part B: Engineering, 143, 172–196. https://doi.org/10.1016/j.compositesb.2018.02.012

Chu, T., Park, S., & Fu, K. (2021). 3D printing-enabled advanced electrode architecture design. Carbon Energy, 3(3), 424–439. https://doi.org/10.1002/cey2.114

Kiran, A. S. K., Veluru, J. B., Merum, S., Radhamani, A. V., Doble, M., Kumar, T. S., & Ramakrishna, S. (2018). Additive manufacturing technologies: an overview of challenges and perspective of using electrospraying. Nanocomposites, 4(4), 190–214. https://doi.org/10.1080/20550324.2018.1558499

Pei, M., Shi, H., Yao, F., Liang, S., Xu, Z., Pei, X., & Hu, Y. (2021). 3D printing of advanced lithium batteries: a designing strategy of electrode/electrolyte architectures. Journal of Materials Chemistry A, 9(45), 25237–25257. https://doi.org/10.1039/d1ta06683h

McOwen, D. W., Xu, S., Gong, Y., Wen, Y., Godbey, G. L., Gritton, J. E., Hamann, T. R., Dai, J., Hitz, G. T., Hu, L., & Wachsman, E. D. (2018). 3D-printing electrolytes for solid-state batteries. Advanced materials, 30(18), 1707132. https://doi.org/10.1002/adma.201707132

Zhou, S., Usman, I., Wang, Y., & Pan, A. (2021). 3D printing for rechargeable lithium metal batteries. Energy Storage Materials, 38, 141–156. https://doi.org/10.1016/j.ensm.2021.02.041

Lewis, J. A. (2006). Direct ink writing of 3D functional materials. Advanced Functional Materials, 16(17), 2193–2204. https://doi.org/10.1002/adfm.200600434

Matsuzaki, R., Kanatani, T., & Todoroki, A. (2019). Multi-material additive manufacturing of polymers and metals using fused filament fabrication and electroforming. Additive Manufacturing. https://doi.org/10.1016/j.addma.2019.100812

Medellin, A., Du, W., Miao, G., Zou, J., Pei, Z., & Ma, C. (2019). Vat photopolymerization 3d printing of nanocomposites: A literature review. Journal of Micro and Nano-Manufacturing. https://doi.org/10.1115/1.4044288

Deiner, L. J., & Reitz, T. L. (2017). Inkjet and aerosol jet printing of electrochemical devices for energy conversion and storage. Advanced Engineering Materials, 19(7), 1600878. https://doi.org/10.1002/adem.201600878

He, Y., Chen, S., Nie, L., Sun, Z., Wu, X., & Liu, W. (2020). Stereolithography three-dimensional printing solid polymer electrolytes for all-solid-state lithium metal batteries. Nano Letters, 20(10), 7136–7143. https://doi.org/10.1021/acs.nanolett.0c02457

Chen, Q., Xu, R., He, Z., Zhao, K., & Pan, L. (2017). Printing 3D gel polymer electrolyte in Lithium-Ion microbattery using stereolithography. Journal of the Electrochemical Society, 164(9), A1852–A1857.

M. F. Norjeli, N. Tamchek, Z. Osman, I. S. Mohd Noor, M. Z. Kufian, and M. I. B. M. Ghazali, “Additive Manufacturing Polyurethane Acrylate via Stereolithography for 3D Structure Polymer Electrolyte Application,” Gels, 2022 https://doi.org/10.3390/gels8090589.

Deiner, L. J., Jenkins, T., Howell, T., & Rottmayer, M. (2019). Aerosol Jet Printed Polymer Composite Electrolytes for Solid-State Li-Ion Batteries. Advanced Engineering Materials, 21(12), 1900952. https://doi.org/10.1002/adem.201900952

Blake, A. J., Kohlmeyer, R. R., Hardin, J. O., Carmona, E. A., Maruyama, B., Berrigan, J. D., Huang, H., & Durstock, M. F. (2017). 3D printable ceramic–polymer electrolytes for flexible high-performance li-ion batteries with enhanced thermal stability. Advanced energy materials, 7(14), 1602920. https://doi.org/10.1002/aenm.201602920

Kohlmeyer, R. R., Buskohl, P. R., Deneault, J. R., Durstock, M. F., Vaia, R. A., & Chen, J. (2014). Shape-reprogrammable polymers: Encoding, erasing, and re-encoding. Advanced Materials, 26(48), 8114–8119. https://doi.org/10.1002/adma.201402901

Fu, K., Wang, Y., Yan, C., Yao, Y., Chen, Y., Dai, J., & Hu, L. (2016). Graphene oxide-based electrode inks for 3D-printed lithium-ion batteries. Advanced Materials. https://doi.org/10.1002/adma.201505391

Wei, T. S., Ahn, B. Y., Grotto, J., & Lewis, J. A. (2018). 3D Printing of customized Li-Ion batteries with thick electrodes. Advanced Materials, 30(16), 1703027. https://doi.org/10.1002/adma.201703027

Muench, S., Burges, R., Lex-Balducci, A., Brendel, J. C., Jäger, M., Friebe, C., Wild, A., & Schubert, U. S. (2020). Printable ionic liquid-based gel polymer electrolytes for solid state all-organic batteries. Energy Storage Materials, 25, 750–755. https://doi.org/10.1016/j.ensm.2019.09.011

Cheng, M., Ramasubramanian, A., Rasul, M. G., Jiang, Y., Yuan, Y., Foroozan, T., Deivanayagam, R., Saray, M. T., Rojaee, R., Song, B., Yurkiv, V. R., Pan, Y., Mashayek, F., & Shahbazian-Yassar, R. (2021). Direct ink writing of polymer composite electrolytes with enhanced thermal conductivities. Advanced Functional Materials, 31(4), 2006683. https://doi.org/10.1002/adfm.202006683

Gambe, Y., Kobayashi, H., Iwase, K., Stauss, S., & Honma, I. (2021). A photo-curable gel electrolyte ink for 3D-printable quasi-solid-state lithium-ion batteries. Dalton Transactions, 50(45), 16504–16508. https://doi.org/10.1039/D1DT02918E

Cho, K. G., Jang, S. S., Heo, I., Kyung, H., Yoo, W. C., & Lee, K. H. (2022). 3D printed solid-state composite electrodes and electrolytes for high-energy-density flexible microsupercapacitors. J Energy Storage. https://doi.org/10.1016/j.est.2022.105206

Jackson, S., & Dickens, T. (2021). Rheological and structural characterization of 3D-printable polymer electrolyte inks. Polymer Testing. https://doi.org/10.1016/j.polymertesting.2021.107377

Thakur, A., & Dong, X. (2020). Printing with 3D continuous carbon fiber multifunctional composites via UV-assisted coextrusion deposition. Manuf Lett, 24, 1–5. https://doi.org/10.1016/j.mfglet.2020.02.001

Thakur, A., & Dong, X. (2020). Additive manufacturing of 3D structural battery composites with coextrusion deposition of continuous carbon fibers. Manuf Lett, 26, 42–47. https://doi.org/10.1016/j.mfglet.2020.09.007

Seeba, J., Reuber, S., Heubner, C., Müller-Köhn, A., Wolter, M., & Michaelis, A. (2020). Extrusion-based fabrication of electrodes for high-energy Li-ion batteries. Chemical Engineering Journal. https://doi.org/10.1016/j.cej.2020.125551

Cook, J. A., Park, G. B., & McLoughlin, R. (1989). MATERIALS FOR ELECTRICAL DEVICES (Patent No. 4818643). United States Patent Office.

Duval, M., & Quebec, H. (1993). Process of coating by melt extrusion a solid polymer electrolyte on positive electrode of lithium battery (patent no. 5348824). united states patent office.

Reyes, C., Somogyi, R., Niu, S., Cruz, M. A., Yang, F., Catenacci, M. J., & Wiley, B. J. (2018). Three-dimensional printing of a complete lithium ion battery with fused filament fabrication. ACS Applied Energy Materials, 1(10), 5268–5279. https://doi.org/10.1021/acsaem.8b00885

Maurel, A., Grugeon, S., Fleutot, B., Courty, M., Prashantha, K., Tortajada, H., Armand, M., Panier, S., & Dupont, L. (2019). Three-dimensional printing of a LiFePO4/graphite battery cell via fused deposition modeling. Scientific reports, 9(1), 1–14. https://doi.org/10.1038/s41598-019-54518-y

Vinegrad, A., Ragones, H., Jayakody, N., Ardel, G., Goor, M., Kamir, Y., Dorfman, M. M., Gladkikh, A., Burstein, L., Horowitz, Y., Greenbaum, S., & Golodnitsky, D. (2021). Plasticized 3D-printed polymer electrolytes for lithium-ion batteries. Journal of The Electrochemical Society. https://doi.org/10.1149/1945-7111/ac39d5

Ragones, H., Menkin, S., Kamir, Y., Gladkikh, A., Mukra, T., Kosa, G., & Golodnitsky, D. (2018). Towards smart free form-factor 3D printable batteries. Sustainable Energy & Fuels, 2(7), 1542–1549. https://doi.org/10.1039/c8se00122g

Ragones, H., Vinegrad, A., Ardel, G., Goor, M., Kamir, Y., Dorfman, M. M., Gladkikh, A., & Golodnitsky, D. (2019). On the road to a multi-coaxial-cable battery: development of a novel 3D-printed composite solid electrolyte. Journal of The Electrochemical Society. https://doi.org/10.1149/2.0032007jes

Katcharava, Z., Marinow, A., Bhandary, R., & Binder, W. H. (1859). 3D Printable composite polymer electrolytes: influence of SiO2 nanoparticles on 3D-printability. Nanomaterials, 12(11), 2022. https://doi.org/10.3390/nano12111859

Maurel, A., Armand, M., Grugeon, S., Fleutot, B., Davoisne, C., Tortajada, H., Courty, M., Panier, S., & Dupont, L. (2020). Poly (ethylene oxide)− LiTFSI solid polymer electrolyte filaments for fused deposition modeling three-dimensional printing. Journal of The Electrochemical Society. https://doi.org/10.1149/1945-7111/ab7c38

Verdier, N., Foran, G., Lepage, D., Prébé, A., Aymé-Perrot, D., & Dollé, M. (2021). Challenges in solvent-free methods for manufacturing electrodes and electrolytes for lithium-based batteries. Polymers, 13(3), 323. https://doi.org/10.3390/polym13030323

Jung, K. N., Shin, H. S., Park, M. S., & Lee, J. W. (2019). Solid-state lithium batteries: bipolar design, fabrication, and electrochemistry. ChemElectroChem, 6(15), 3842–3859. https://doi.org/10.1002/celc.201900736

Brown, E., Yan, P., Tekik, H., Elangovan, A., Wang, J., Lin, D., & Li, J. (2019). 3D printing of hybrid MoS2-graphene aerogels as highly porous electrode materials for sodium ion battery anodes. Materials & Design. https://doi.org/10.1016/j.matdes.2019.107689

Down, M. P., Martínez-Periñán, E., Foster, C. W., Lorenzo, E., Smith, G. C., & Banks, C. E. (2019). Next-generation additive manufacturing of complete standalone sodium-ion energy storage architectures. Advanced Energy Materials, 9(11), 1803019. https://doi.org/10.1002/aenm.201803019

Schwaar, C. (2023, January 31). Additive manufacturing for batteries of the future: Will 3D printing transform battery making? Forbes. Retrieved April 12, 2023, from https://www.forbes.com/sites/carolynschwaar/2023/01/30/additive-manufacturing-for-batteries-of-the-future-will-3d-printing-transform-battery-making/?sh=5bb74f063795

Vlad Khaustovich, “3D Printing & Rapid Prototyping Services Breaking the mold: Developing technologies and a growing customer base are expected to boost revenue,” 2023.,Report no.: OD 4581.

Arielle Rose, “Battery Manufacturing in the US,” IBIS World, September 2022., Report No.: 33591.

Matt Pantalon, “Lithium Battery Manufacturing. In the US”, IBIS World, January 2023, OD4499.

Schmaltz, T., Wicke, T., Weymann, L., Voß, P., Neef, C., & Thielmann, A. (2022). Solid-State Battery Roadmap 2035+.

Sakuu to become publicly traded company Via Business Combination with plum acquisition corp.. I. Business Wire. (2023, March 2). Retrieved April 12, 2023, from https://www.businesswire.com/news/home/20230302005883/en/

Blackstone's major milestone in 3D-printing solid-state batteries. Business Wire. (2021, April 12). Retrieved April 12, 2023, from https://www.businesswire.com/news/home/20210412005715/en/Blackstone%E2%80%99s-major-milestone-in-3D-printing-solid-state-batteries

Arielle Rose, “Battery Recycling in the US.”, IBIS World, November 2022, Report No; OD4511

Kunz, T. (2019). DOE launches its first lithium-ion battery recycling R&D center: ReCell. Retrieved April 12, 2023, from Argonne National Laboratory. Available at https:// www. anl. gov/article/doe-launches-its-first-lithiumion-battery-recycling-rd-center-recell.

Cong, L., Liu, W., Kong, S., Li, H., Deng, Y., & Ma, H. (2021). A review on end-of-use management of spent lithium-ion batteries from sustainability perspective. Journal of Manufacturing Science and Engineering, 1–35. DOI: https://doi.org/10.1115/1.4050925

Cong, L., Zhou, K., Liu, W., & Li, R. (2023). Retired lithium-ion battery pack disassembly line balancing based on precedence graph using a hybrid genetic-firework algorithm for remanufacturing. Journal of Manufacturing Science and Engineering. https://doi.org/10.1115/1.4056572

Li, H., Cong, L., Ma, H., Liu, W., Deng, Y., & Kong, S. (2022). Screening of retired lithium-Ion batteries using incremental capacity charging curve-based residual capacity estimation method for facilitating sustainable circular lithium-ion battery system. Journal of Manufacturing Science and Engineering. https://doi.org/10.1115/14051677

Cong, L., Zhao, F., & Sutherland, J. W. (2019). A design method to improve end-of-use product value recovery for circular economy. Journal of Mechanical Design, 10(1115/1), 4041574.

Acknowledgements

This work was supported by a National Science Foundation PFI project (#2214006).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This paper is an invited paper (Invited Review).

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Alandur Ramesh, B.R., Basnet, B., Huang, R. et al. The Promise of 3D Printed Solid Polymer Electrolytes for Developing Sustainable Batteries: A Techno-Commercial Perspective. Int. J. of Precis. Eng. and Manuf.-Green Tech. 11, 321–352 (2024). https://doi.org/10.1007/s40684-023-00541-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40684-023-00541-4