Abstract

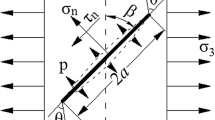

Pre-existing fractures in rock engineering significantly affect the entire structural stability. To deepen the understanding of the fracture mechanism of fractured rocks under shear loading, a numerical study based on the distinct element method was conducted to investigate the shear behaviors of rock fractures. A discrete element model with fractures of Barton's ten standard profiles was established, and shear simulations under different normal stresses and joint roughness coefficient (JRC) were carried out. The simulation results show that the shear stress–displacement curve can be divided into three stages: elastic loading stage, inelastic stage and stress drop stage. The shear strength, internal friction angle and cohesion increase with the increase of normal stress and JRC. These macroscopic mechanical characteristics are consistent with the results of previous experimental studies. Most of the microcracks generated during the shearing process are tensile microcracks, which are first formed at the steep position of the fracture profile line, and the proportion of shear microcracks is less than 10%. In addition, the contact force between particles is mainly compressive stress, which is greater in magnitude and density than tensile stress. As the shear proceeds, the displacement of the particles gradually changes from non-uniform distribution to uniform distribution.

Similar content being viewed by others

Data availability

Data will be made available on request.

References

Wang SY, Sloan SW, Sheng DC, Yang SQ, Tang CA (2014) Numerical study of failure behaviour of pre-cracked rock specimens under conventional triaxial compression. Int J Solids Struct 51(5):1132–1148. https://doi.org/10.1016/j.ijsolstr.2013.12.012

Zhao YL, Zhang CS, Wang YX, Lin H (2021) Shear-related roughness classification and strength model of natural rock joint based on fuzzy comprehensive evaluation. Int J Rock Mech Min Sci. https://doi.org/10.1016/j.ijrmms.2020.104550

Khosravi A, Serej AD, Mousavi SM, Haeri SM (2016) Effect of hydraulic hysteresis and degree of saturation of infill materials on the behavior of an infilled rock fracture. Int J Rock Mech Min Sci 88:105–114. https://doi.org/10.1016/j.ijrmms.2016.07.001

Jiang M, Liu J, Crosta GB, Li T (2017) DEM analysis of the effect of joint geometry on the shear behavior of rocks. CR Mécanique 345(11):779–796. https://doi.org/10.1016/j.crme.2017.07.004

Wu H, Fan A, Ma D, Spearing AJS, Zheng Z (2023) Fracturing process and initiation mechanism of hard rock tunnels with different shapes: particle flow modeling and analytical study. Comput Part Mech. https://doi.org/10.1007/s40571-023-00594-x

Li Y, Chen L, Wang Y (2005) Experimental research on pre-cracked marble under compression. Int J Solids Struct 42(9):2505–2516. https://doi.org/10.1016/j.ijsolstr.2004.09.033

Hoek E, Martin CD (2014) Fracture initiation and propagation in intact rock—A review. J Rock Mech Geotech 6(4):287–300

Zhang YC, Jiang YJ, Asahina D, Wang Z (2020) Shear behavior and acoustic emission characteristics of en-echelon joints under constant normal stiffness conditions. Theor Appl Fract Mec. https://doi.org/10.1016/j.tafmec.2020.102772

Wang JG, Schweizer D, Liu QB, Su AJ, Hu XL, Blum P (2021) Three-dimensional landslide evolution model at the Yangtze River. Eng Geol. https://doi.org/10.1016/j.enggeo.2021.106275

Indraratna B, Oliveira DAF, Brown ET (2010) A shear-displacement criterion for soil-infilled rock discontinuities. Geotechnique 60(8):623–633. https://doi.org/10.1680/geot.8.P.094

Indraratna B, Ranjith PG (2001) Laboratory measurement of two-phase flow parameters in rock joints based on high pressure triaxial testing. J Geotech Geoenviron 127(6):530–542. https://doi.org/10.1061/(asce)1090-0241(2001)127:6(530)

Indraratna B, Oliveira DAF, Brown ET, de Assis AP (2010) Effect of soil–infilled joints on the stability of rock wedges formed in a tunnel roof. Int J Rock Mech Min Sci 47(5):739–751. https://doi.org/10.1016/j.ijrmms.2010.05.006

Ellsworth WL (2013) Injection-induced earthquakes. Science 341(6142):142. https://doi.org/10.1126/science.1225942

Bao XW, Eaton DW (2016) Fault activation by hydraulic fracturing in western Canada. Science 354(6318):1406–1409. https://doi.org/10.1126/science.aag2583

Singh M, Seshagiri RK (2005) Empirical methods to estimate the strength of jointed rock masses. Eng Geol 77(1):127–137. https://doi.org/10.1016/j.enggeo.2004.09.001

Mohammadnejad M, Fukuda D, Liu HY, Dehkhoda S, Chan A (2020) GPGPU-parallelized 3D combined finite–discrete element modelling of rock fracture with adaptive contact activation approach. Comput Part Mech 7(5):849–867. https://doi.org/10.1007/s40571-019-00287-4

Han W, Jiang Y, Luan H, Du Y, Zhu Y, Liu J (2020) Numerical investigation on the shear behavior of rock-like materials containing fissure-holes with FEM-CZM method. Comput Geotech 125:103670. https://doi.org/10.1016/j.compgeo.2020.103670

Zou Z, Hameed M (2018) Combining interface damage and friction in cohesive interface models using an energy based approach. Compos Part A-appl S 112:290–298. https://doi.org/10.1016/j.compositesa.2018.06.017

Zhang JZ, Zhou XP, Zhou LS, Berto F (2019) Progressive failure of brittle rocks with non-isometric flaws: insights from acousto-optic-mechanical (AOM) data. Fatigue Fract Eng M 42(8):1787–1802. https://doi.org/10.1111/ffe.13019

Develi K (2020) Computation of direction dependent joint surface parameters through the algorithm of triangular prism surface area method: a theoretical and experimental study. Int J Solids Struct 202:895–911. https://doi.org/10.1016/j.ijsolstr.2020.06.038

Chen W, Wan W, Zhao Y, Peng W (2020) Experimental study of the crack predominance of rock-like material containing parallel double fissures under uniaxial compression. Sustainability 12(12):5188

Zhao YL, Tang JZ, Chen Y, Zhang LY, Wang WJ, Wan W et al (2017) Hydromechanical coupling tests for mechanical and permeability characteristics of fractured limestone in complete stress-strain process. Environ Earth Sci. https://doi.org/10.1007/s12665-016-6322-x

Agharazi A, Tannant D, Martin CD (2012) Characterizing rock mass deformation mechanisms during plate load tests at the Bakhtiary dam project. Int J Rock Mech Min Sci 49:1–11. https://doi.org/10.1016/j.ijrmms.2011.10.002

Sanei M, Faramarzi L, Fahimifar A, Goli S, Mehinrad A, Rahmati A (2015) Shear strength of discontinuities in sedimentary rock masses based on direct shear tests. Int J Rock Mech Min Sci 75:119–131. https://doi.org/10.1016/j.ijrmms.2014.11.009

Han G, Zhang C, Zhou H, Zhang C, Gao Y, Singh HK (2021) A new predictive method for the shear strength of interlayer shear weakness zone at field scales. Eng Geol 295:106449. https://doi.org/10.1016/j.enggeo.2021.106449

Wang YN, Bui HH, Nguyen GD, Ranjith PG (2019) A new SPH-based continuum framework with an embedded fracture process zone for modelling rock fracture. Int J Solids Struct 159:40–57. https://doi.org/10.1016/j.ijsolstr.2018.09.019

Wang J, Li JT, Shi ZM (2022) Crack evolution law and failure mode of red sandstone under fatigue-creep interaction. Fatigue Fract Eng M 45(1):270–284. https://doi.org/10.1111/ffe.13599

Zhou XP, Xia EM, Yang HQ, Qian QH (2012) Different crack sizes analyzed for surrounding rock mass around underground caverns in Jinping I hydropower station. Theor Appl Fract Mec 57(1):19–30. https://doi.org/10.1016/j.tafmec.2011.12.004

Goudie AS (2016) Quantification of rock control in geomorphology. Earth Sci Rev 159:374–387. https://doi.org/10.1016/j.earscirev.2016.06.012

Xie S, Lin H, Duan H (2023) A novel criterion for yield shear displacement of rock discontinuities based on renormalization group theory. Eng Geol. https://doi.org/10.1016/j.enggeo.2023.107008

Xie S, Lin H, Duan H, Chen Y (2023) Modeling description of interface shear deformation: A theoretical study on damage statistical distributions. Constr Build Mater 394:132052. https://doi.org/10.1016/j.conbuildmat.2023.132052

Barla G, Robotti F, Vai L, editors. (2011) Revisiting large size direct shear testing of rock mass foundations. 6th international conference on dam engineering, Lisbon, Portugal. LNEC, Lisbon

Vorobiev O (2008) Generic strength model for dry jointed rock masses. Int J Plast 24(12):2221–2247. https://doi.org/10.1016/j.ijplas.2008.06.009

Xie S, Lin H, Chen Y, Duan H, Liu H, Liu B (2023) Prediction of shear strength of rock fractures using support vector regression and grid search optimization. Mater Today Commun 36:106780. https://doi.org/10.1016/j.mtcomm.2023.106780

Muralha J, Grasselli G, Tatone B, Blümel M, Chryssanthakis P, Yujing J (2014) ISRM suggested method for laboratory determination of the shear strength of rock joints: revised version. Rock Mech Rock Eng 47(1):291–302

Patton FD, editor. Multiple modes of shear failure in rock. 1st ISRM Congress; 1966: OnePetro

Barton N (1973) Review of a new shear-strength criterion for rock joints. Eng Geol 7(4):287–332. https://doi.org/10.1016/0013-7952(73)90013-6

Isrm I (1978) Suggested methods for the quantitative description of discontinuities in rock masses. Int J Rock Mech Min Sci Geomech Abstr 15(6):319–368

Jafari MK, Amini Hosseini K, Pellet F, Boulon M, Buzzi O (2003) Evaluation of shear strength of rock joints subjected to cyclic loading. Soil Dyn Earthq Eng 23(7):619–630. https://doi.org/10.1016/S0267-7261(03)00063-0

Kleepmek M, Khamrat S, Thongprapha T, Fuenkajorn K (2016) Displacement velocity effects on rock fracture shear strengths. J Struct Geol 90:48–60. https://doi.org/10.1016/j.jsg.2016.07.007

Singh HK, Basu A (2018) Evaluation of existing criteria in estimating shear strength of natural rock discontinuities. Eng Geol 232:171–181. https://doi.org/10.1016/j.enggeo.2017.11.023

Barton N, Wang C, Yong R (2023) Advances in joint roughness coefficient (JRC) and its engineering applications. J Rock Mech Geotech. https://doi.org/10.1016/j.jrmge.2023.02.002

Barton N, Choubey V (1977) The shear strength of rock joints in theory and practice. Rock Mech 10(1–2):1–54. https://doi.org/10.1007/BF01261801

Wang G, Wu XL, Zhang XD, Zhang ZS, Zhao ZP, Han W et al (2020) Macro-microscopic study on the shear characteristics of filled joints with different roughnesses. Arab J Sci Eng 45(10):8331–8348. https://doi.org/10.1007/s13369-020-04705-1

Day JJ, Diederichs MS, Hutchinson DJ (2017) New direct shear testing protocols and analyses for fractures and healed intrablock rockmass discontinuities. Eng Geol 229:53–72. https://doi.org/10.1016/j.enggeo.2017.08.027

Xie S, Lin H, Chen Y (2022) New constitutive model based on disturbed state concept for shear deformation of rock joints. Arch Civ Mech Eng 23(1):26. https://doi.org/10.1007/s43452-022-00560-z

Fakhimi A, Norouzi S (2019) Dilation angle in bonded particle simulation of rock. Comput Part Mech 6(2):195–211. https://doi.org/10.1007/s40571-018-0208-5

Gong L, Nemcik J, Ren T (2018) Numerical simulation of the shear behavior of rock joints filled with unsaturated soil. Int J Geomech 18(9):04018112. https://doi.org/10.1061/(ASCE)GM.1943-5622.0001253

Li H, Wong LNY (2012) Influence of flaw inclination angle and loading condition on crack initiation and propagation. Int J Solids Struct 49(18):2482–2499

Zhou X, Chen J (2019) Extended finite element simulation of step-path brittle failure in rock slopes with non-persistent en-echelon joints. Eng Geol 250:65–88. https://doi.org/10.1016/j.enggeo.2019.01.012

Wang Y, Zhou X, Wang Y, Shou Y (2018) A 3-D conjugated bond-pair-based peridynamic formulation for initiation and propagation of cracks in brittle solids. Int J Solids Struct 134:89–115. https://doi.org/10.1016/j.ijsolstr.2017.10.022

Duriez J, Darve F, Donzé FV (2011) A discrete modeling-based constitutive relation for infilled rock joints. Int J Rock Mech Min Sci 48(3):458–468. https://doi.org/10.1016/j.ijrmms.2010.09.008

Lee H, Jeon S (2011) An experimental and numerical study of fracture coalescence in pre-cracked specimens under uniaxial compression. Int J Solids Struct 48(6):979–999. https://doi.org/10.1016/j.ijsolstr.2010.12.001

Cundall PA, Hart RD (1992) Numerical modelling of discontinua. Eng Computation.

Li Z, Rao QH (2021) Quantitative determination of PFC3D microscopic parameters. J Cent South Univ 28(3):911–925. https://doi.org/10.1007/s11771-021-4653-6

Zhou XP, Zhang JZ, Yang SQ, Berto F (2021) Compression-induced crack initiation and growth in flawed rocks: a review. Fatigue Fract Eng M 44(7):1681–1707. https://doi.org/10.1111/ffe.13477

Cundall PA (2000) Numerical experiments on rough joints in shear using a bonded particle model. In: Lehner FK, Urai JL, editors. Aspects of Tectonic Faulting: In Honour of Georg Mandl. Berlin, Heidelberg: Springer Berlin Heidelberg p. 1–9

Park J-W, Song J-J (2009) Numerical simulation of a direct shear test on a rock joint using a bonded-particle model. Int J Rock Mech Min Sci 46(8):1315–1328. https://doi.org/10.1016/j.ijrmms.2009.03.007

Bahaaddini M, Sharrock G, Hebblewhite BK (2013) Numerical direct shear tests to model the shear behaviour of rock joints. Comput Geotech 51:101–115. https://doi.org/10.1016/j.compgeo.2013.02.003

Shi C, Xu W (2015) Techniques and practice for numerical simulation of particle flow. China Building Construction Industry Press, Beijing, China

Xie S, Lin H, Cheng C, Chen Y, Wang Y, Zhao Y et al (2022) Shear strength model of joints based on Gaussian smoothing method and macro-micro roughness. Comput Geotech 143:104605. https://doi.org/10.1016/j.compgeo.2021.104605

Cundall PA, Strack OD (1979) A discrete numerical model for granular assemblies. Geotechnique 29(1):47–65

Tarokh A, Fakhimi A (2014) Discrete element simulation of the effect of particle size on the size of fracture process zone in quasi-brittle materials. Comput Geotech 62:51–60. https://doi.org/10.1016/j.compgeo.2014.07.002

Yue Z, Meng F, Zhou X, Wang X, Zhang L, Wang Z (2022) Influence of non-persistent joint aperture and inclination angle on the shear behavior and fracture mode of solid rock and concrete material. Constr Build Mater 316:125892. https://doi.org/10.1016/j.conbuildmat.2021.125892

Poulsen BA, Adhikary D, Guo H (2018) Simulating mining-induced strata permeability changes. Eng Geol 237:208–216. https://doi.org/10.1016/j.enggeo.2018.03.001

Li K, Han D, Fan X, Yang Y, Wang F (2022) Shear rupture behaviors of intact and granulated Wombeyan marble with the flat-jointed model. Arch Civ Mech Eng 22(1):51. https://doi.org/10.1007/s43452-022-00377-w

Itasca Consulting Group I (2014) PFC—Particle Flow Code, Ver. 5.0. Itasca Minneapolis

Coetzee CJ (2017) Calibration of the discrete element method. Powder Technol 310:104–142. https://doi.org/10.1016/j.powtec.2017.01.015

Sharrock B, Akram M, Mitra R (2009) Application of synthetic rock mass modeling to estimate the strength of jointed sandstone. 43rd US Rock Mechanics Symposium and 4th US-Canada Rock Mechanics Symposium

Ding X, Zhang L, Zhu H, Zhang Q (2014) Effect of model scale and particle size distribution on PFC3D simulation results. Rock Mech Rock Eng 47(6):2139–2156. https://doi.org/10.1007/s00603-013-0533-1

Bahaaddini M, Hagan PC, Mitra R, Khosravi MH (2016) Experimental and numerical study of asperity degradation in the direct shear test. Eng Geol 204:41–52. https://doi.org/10.1016/j.enggeo.2016.01.018

Xie SJ, Lin H, Chen YF, Yong R, Xiong W, Du SG (2020) A damage constitutive model for shear behavior of joints based on determination of the yield point. Int J Rock Mech Min Sci. https://doi.org/10.1016/j.ijrmms.2020.104269

Meng F, Wong LNY, Guo T (2022) Frictional behavior and micro-damage characteristics of rough granite fractures. Tectonophysics 842:229589. https://doi.org/10.1016/j.tecto.2022.229589

Nasir O, Fall M (2008) Shear behaviour of cemented pastefill-rock interfaces. Eng Geol 101(3):146–153. https://doi.org/10.1016/j.enggeo.2008.04.010

Xu W, Lin H, Cao R (2018) Simulation and macro-mesoscopic parameter analysis for direct shear of filled rough joints. J Southwest Jiaotong Univ 53(3):548–557

Gu Xue F, Seidel Julian P, Haberfield CM (2003) Direct shear test of sandstone-concrete joints. Int J Geomech 3(1):21–33. https://doi.org/10.1061/(ASCE)1532-3641(2003)3:1(21)

Jiang YJ, Wang YH, Yan P, Luan HJ, Chen YQ (2019) Experimental investigation on the shear properties of heterogeneous discontinuities. Geotech Geol Eng 37(6):4959–4968. https://doi.org/10.1007/s10706-019-00955-5

Yin T-B, Zhuang D-D, Li M-J, Li X-B (2022) Numerical simulation study on the thermal stress evolution and thermal cracking law of granite under heat conduction. Comput Geotech 148:104813. https://doi.org/10.1016/j.compgeo.2022.104813

Dang Y, Yang Z, Liu X, Lu C (2023) Numerical study on failure mechanism and acoustic emission characteristics of granite after thermal treatment. Comput Part Mech 10(5):1245–1266. https://doi.org/10.1007/s40571-023-00556-3

Eftekhari M, Baghbanan A, Hashemolhosseini H, Amrollahi H (2015) Mechanism of fracture in macro- and micro-scales in hollow centre cracked disc specimen. J Cent South Univ 22(11):4426–4433. https://doi.org/10.1007/s11771-015-2990-z

Acknowledgements

This paper gets its funding from Projects (42277175) supported by National Natural Science Foundation of China and the Postgraduate Research & Practice Innovation Program of Jiangsu Province (No. KYCX23_0276).

Author information

Authors and Affiliations

Contributions

SX: Methodology, Data curation, Writing—original draft. Hang Lin: Investigation, Supervision, Funding acquisition. HD: Conceptualization, Writing—original draft. HL: Investigation. BL: Writing—review & editing. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Xie, S., Lin, H., Duan, H. et al. Numerical study on cracking behavior and fracture failure mechanism of fractured rocks under shear loading. Comp. Part. Mech. 11, 903–920 (2024). https://doi.org/10.1007/s40571-023-00660-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40571-023-00660-4