Abstract

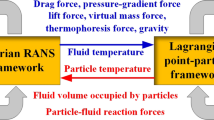

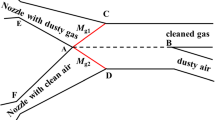

A unified second-order-moment (USM) two-phase turbulence model together with a kinetic theory of inter-particle collision (USM-θ), and combined with a frictional stress model, was used to simulate dense gas-particle flows in a downer reactor. The interaction between gas and particle turbulence is simulated by a transport equation of two-phase velocity correlation. The simulation results are in good agreement with experimental data reported by Wang et al. The typical dense ring of particles in the near-wall region was observed. It is found that the frictional stress affects the particle fluctuation energy dissipation, leading to the decrease of the particle pseudo-temperature. Because particles are not dense enough in the center region, the effect of inter-particle collision on particle fluctuation velocity, gas-particle velocity correlation, particle collision frequency, particle shear viscosity and particle effective thermal conductivity are not obvious.

Similar content being viewed by others

Abbreviations

- D :

-

Diffusion term

- e :

-

Coefficient of restitution particles

- e eff :

-

Effective coefficient of restitution

- et:

-

Tangential coefficient of restitution

- f :

-

Frequency

- g :

-

Gravitational force

- g 0 :

-

Radial distribution function

- k :

-

Kinetic energy

- G :

-

Production term

- P :

-

Pressure

- R :

-

Correlation term

- t :

-

Time

- V,v :

-

Velocity

- α :

-

Volume fraction

- β :

-

Drag coefficient

- δ :

-

Kronic-Delta unit tensor

- ε :

-

Dissipation term

- θ :

-

Particle temperature

- μ :

-

Dynamic viscosity

- ν :

-

Kinematic viscosity

- Π:

-

Pressure-strain term

- ρ :

-

Density

- τ :

-

Stress tensor

- i,j,k,l :

-

Coordinates directions

- coll:

-

Collision

- g :

-

Gas

- p:

-

Particle

- r :

-

Relaxation

- max:

-

Maximum

- min:

-

Minimum

References

Bolio EJ, Yasuna JA, Sinclair JL (1995) Dilute turbulent gas-solid flow in riser with particle-particle interactions. AIChE J 41:1375–1388

Cheng Y, Guo YC, Wei F (1999) Modeling the hydrodynamics of downer reactors based on kinetic theory. Chem Eng Sci 54:2019–2027

Ding J, Gidaspow D (1990) A bubbling fluidization model using kinetic theory of granular flow. AIChE J 36:523–538

Gidaspow D (1994) Multiphase flow and fluidization: continuum and kinetic theory description. Academic Press, New York, pp 65–78

Grace JR (2000) Reflection on turbulent fluidization and dense suspension. Powder Technol 113:242–248

Hunt ML (1997) Discrete element simulations for granular materials flows: effective thermal conductivity and self-diffusivity. Int J Heat Mass Transfer 40:3059–3068

Johnson PC, Nott P, Jackson R (1990) Frictional-collisional equations of motion for particles flows and their application to chutes. J Fluid Mech 210:501–535

Koch DL (1990) Kinetic theory for monodisperse gas-solids suspension. Phys Fluid A2:1711–1723

Lehner P, Wirth KE (1999) Characterization of the flow pattern in a downer reactor. Chem Eng Sci 54:5471–5483

Li SG, Lin WG, Yao JZ (2004) Modeling of the hydrodynamics of the fully developed region in a downer reactor. Powder Technol 145:73–81

Liu W, Luo KB, Zhu JX, Beeckmans JM (2001) Characterization of high-density gas–solids downward fluidized flow. Powder Technol 115:27–35

Lu XS, Li SG, Li HZ (2005) Flow structures in the downer circulating fluidized bed. Chem Eng J 112:23–31

Lu HL, Liu WT, Bie RS, Gidaspow D (2000) Kinetic theory of fluidized binary granular mixtures with unequal granular temperature. Phys A 284:265–276

Lu HL, Gidaspow D (2003) Hydrodynamics of binary fuidization in a riser: CFD simulation using two granular temperatures. Chem Eng Sci 58:3777–3792

Lun CK, Savage SB, Jeffrey DJ (1984) Kinetic theories for granular flow: inelastic particles in coquette flow and slightly inelastic particles in a general flow field. J Fluid Mech 140:223–256

Pantanker PV (1980) Numerical hear transfer and fluid flow. Hemisphere, New York

Savage SB (1998) Analyses of slow high-concentration flows of granular materials. J Fluid Mechanics 377:1–26

Sinclair JL, Jackson R (1989) Gas-particle flow in a vertical pipe with particle-particle interaction. AIChE J 35:1473–1486

Srivastava A, Agrawal K, Sundaresan S, Reddy SB (1998) Dynamics of gas-particle flow in circulating fluidized beds. Powder Technol 100:173–182

Sun J, Battaglia F (2006) Hydrodynamic modeling of particle rotation for segregation in bubbling gas-fluidized bed. Chem Eng Sci 61:1470–1479

Syamal M, Rogers WA, Brien O (1993) MFIX documentation and theory guide. DOE/METC94/1004, NTIS/DE940000087

Wang SY, Shen ZH, Lu HL (2008) Numerical predictions of flow behavior and cluster size of particles in riser with particle rotation model and cluster-based approach. Chem Eng Sci 63:4116–4125

Wang Y, Bai DR, Jin Y (1992) Hydrodynamics of cocurrent downflow circulating fluidized bed (CDCFB). Powder Technol 70:271–275

Wei F, Jin Y, Yu ZQ (1995) Gas mixing in cocurrent downflow circulating fluidized bed. Chem Engng Technol 18(1):59–62

Wei F, Ran X, Zhou RJ, Luo GH, Jin Y (1997) A dispersion model for catalytic cracking riser and downer reactors. Ind Engng Chem Res 36(12):5049–5053

Wei F, Wang ZW, Jin Y, Yu ZQ (1994) Dispersion of lateral and axial solids in a cocurrent downflow circulating fluidized bed. Powder Technol 81:25–31

Wu CN, Cheng Y, Jin Y (2008) Modeling the hydrodynamics in a coupled high density downer-to-riser reactor. Powder Technol 181:255–265

Yu Y, Zhou LX, Wang BT, Cai FP (2005) A USM-θ two-phase turbulence model for simulating dense gas-particle flows. Acta Mech Sinica 21:228–234

Zheng Y, Wan XT, Wei F, Jin Y (2001) Numerical simulation of the gas-particle turbulent flow in riser reactor based on k-ε-kp-εp-Θ two-fluid model. Chem Eng Sci 56:6813–6822

Zhou LX, Liao CM, Chen T (1994) A unified second-order-moment two-phase turbulence model for simulating gas-particle flows. ASME 185:307–313

Zhou LX, Chen T (2001) Simulation of strongly swirling gas-particle flows using USM and k-ε-kp two-phase turbulence models. Powder Technol 114:1–11

Zhou L (1993) Theory and numerical modeling of turbulent gas particle flows and combustion. Science Press, Beijing

Acknowledgements

This study was sponsored by the Projects of National Natural Science Foundation of China under the Grants nos: 50606026 and 50736006.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhou, L., Liu, Y. Simulation of dense gas-particle flow using a USM-θ model, combined with a frictional stress model. Comp. Part. Mech. 10, 1171–1180 (2023). https://doi.org/10.1007/s40571-023-00554-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40571-023-00554-5