Abstract

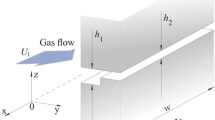

Supersonic gas–solid separation is a new dedusting concept, in which a de Laval nozzle is employed to accelerate a gas laden with solid particles to supersonic speeds. In the present work, a correction for the curved nature of the nozzle walls is implemented in the turbulent boundary layer model. A gas-particle coupled quasi-one-dimensional flow model is established based on an Eulerian–Lagrangian method. Combining the flux vector splitting of gas-phase equations, fifth-order weighted essentially non-oscillatory spatial discretization, and three-step third-order total variation diminishing Runge–Kutta time marching, we create a set of uniformly high-order accurate, stable, and efficient numerical methods. The validation against previous experiments demonstrates the validity and accuracy of the numerical model. The dependence of the flow fields on parameters including particle size and mass loading, nozzle inlet stagnation temperature and pressure, and nozzle expansion angle is numerically computed and analyzed. The results show that the decrease in particle size or mass loading and the increase in inlet stagnation temperature, pressure, or nozzle expansion angle facilitate an increase in exit particle velocity. The increase in particle size, inlet stagnation pressure, or nozzle expansion angle and the decrease in particle mass loading or inlet stagnation temperature increase the exit gas Mach number. In the current parametric study, particle size and mass loading have the largest effects on exit particle velocity and exit gas Mach number, respectively.

Similar content being viewed by others

Abbreviations

- A :

-

Cross-sectional area

- a :

-

Local sound speed

- \(a^\mathrm{gp}\) :

-

Drag force of gas flow per unit particle mass

- B :

-

Width

- \(B_\mathrm{e}\) :

-

Exit height

- \(B_\mathrm{i} \) :

-

Inlet height

- \(B_\mathrm{t}\) :

-

Throat height

- \(C_{1}\) :

-

Constant in the turbulent boundary layer model

- \(C_{2}\) :

-

Constant in the turbulent boundary layer model

- \(C_{3}\) :

-

Constant in the turbulent boundary layer model

- \(C_\mathrm{D} \) :

-

Drag coefficient

- \(C_\mathrm{f}\) :

-

Wall friction coefficient

- \(C_\mathrm{h}\) :

-

Stanton number

- \(c_\mathrm{p}\) :

-

Particle specific heat

- \(c_\mathrm{pg}\) :

-

Specific heat of a gas at constant pressure

- D :

-

Local equivalent diameter of the wetted perimeter

- \(d_\mathrm{p}\) :

-

Particle diameter

- \(E_\mathrm{r}\) :

-

Residual

- \(E_\mathrm{rp}\) :

-

Relative error function of pressure

- e :

-

Specific internal energy

- \(e^{*}\) :

-

Specific total energy

- \(\mathbf{F} \) :

-

Flux vector

- \(f^\mathrm{gp}\) :

-

Drag force of gas flow on a particle

- \(f^\mathrm{pp}\) :

-

Collision force between particles

- \(f_\mathrm{wf}\) :

-

Wall friction

- \(G^\mathrm{gp}\) :

-

Rate of work on a particle caused by gas flow force

- \(G^\mathrm{pg}\) :

-

Cell-volume averaged rate of work from particles to the gas

- \(G_\mathrm{w}\) :

-

Frictional rate of work by walls per unit cell volume

- g :

-

Gravitational acceleration

- \(h_\mathrm{g}\) :

-

Static specific enthalpy of the gas

- \(h_{\mathrm{g}0}\) :

-

Stagnation specific enthalpy of the gas

- \(h_\mathrm{w}\) :

-

Wall enthalpy

- J :

-

Maximum node or cell number

- \(\textit{JI}\) :

-

Cell number in which particle i resides

- Kn\(_\mathrm{p}\) :

-

Particle Knudsen number

- \(L_{1}\) :

-

Length of the convergent section

- \(L_{2}\) :

-

Length of the divergent section

- \(M_\mathrm{g}\) :

-

Gas Mach number

- \(M_\mathrm{p}\) :

-

Particle Mach number

- \(M_\mathrm{p,cr} \) :

-

Critical particle Mach number

- \(m^\mathrm{p}\) :

-

Mass of a single particle

- \(N_\mathrm{cp}\) :

-

Number of physical particles represented by a computational particle

- \(N_\mathrm{inj}\) :

-

Computational particle number injected every time step

- \(N_{JI}\) :

-

Total number of particles in cell j where particle iresides

- Nu:

-

Nusselt number

- Pr:

-

Prandtl number

- p :

-

Static pressure

- \(p_{\mathrm{c}i}\) :

-

Computational pressure at measurement point i

- \(p_{\mathrm{m}i}\) :

-

Measured pressure at measurement point i

- \(P_\mathrm{s}\) :

-

Constant in the collision force model

- \(Q^\mathrm{gp}\) :

-

Heat transfer rate from the gas to a particle

- \(Q^\mathrm{pg}\) :

-

Cell-volume averaged heat transfer rate from particles to the gas

- \(Q_\mathrm{w}\) :

-

Heat transfer rate from walls per unit cell volume

- \(q_\mathrm{mg}\) :

-

Gas mass flow rate

- \(q_\mathrm{mp}\) :

-

Particle mass flow rate

- R :

-

Gas constant

- \(R_{0}\) :

-

Transition arc radius

- \(\hbox {Re}_\mathrm{p}\) :

-

Particle Reynolds number

- \(\hbox {Re}_{x}\) :

-

Reynolds number at x position

- \(\mathbf{S} \) :

-

Source vector

- \(T_\mathrm{g}\) :

-

Gas temperature

- \(T_\mathrm{p}\) :

-

Particle temperature

- \(T_\mathrm{w}\) :

-

Wall temperature

- t :

-

Time

- \(\mathbf{U} \) :

-

Primitive vector of solution

- \(V_\mathrm{cell}\) :

-

Grid cell volume

- \(V_\mathrm{p}\) :

-

Volume of a single particle

- \(v_\mathrm{g}\) :

-

Gas velocity

- \(v_\mathrm{p}\) :

-

Particle velocity

- x :

-

Position along the nozzle axis

- \(x_\mathrm{p}\) :

-

Particle position

- \(\alpha \) :

-

Volume fraction of gas phase

- \(\beta \) :

-

Constant in the collision force model

- \(\gamma \) :

-

Ratio of specific heats of the gas

- \(\Delta t \) :

-

Time step

- \(\Delta x \) :

-

Spatial step

- \(\delta \) :

-

Nozzle expansion angle

- \(\varepsilon _\mathrm{r}\) :

-

Threshold value of residual

- \(\zeta \) :

-

Boundary layer correction factor

- \(\mu \) :

-

Dynamic viscosity of the gas

- \(\rho _\mathrm{g}\) :

-

Density of the gas

- \(\rho _\mathrm{p}\) :

-

Particle density

- \(\tau _\mathrm{v}\) :

-

Velocity relaxation time

- \(\varphi _{}\) :

-

Particle volume fraction

- \(\varphi _\mathrm{c}\) :

-

Particle volume fraction at close packing

- \(\varphi _{i}\) :

-

Local particle volume fraction in the grid cell where particle i resides

- \(\psi \) :

-

Particle mass loading

References

Xu, T.X., Zhang, L.T., Xin, Y.: New dedusting concept of high temperature and high pressure gases. J. Xi’an Jiaotong Univ. 38(7), 690–692, 745 (2004) (in Chinese). https://doi.org/10.3321/j.issn:0253-987X.2004.07.008

Gao, T.Y., Gong, J.Y., Wang, X.H.: Numerical and experimental study on a new separation device for gas–solid two-phase flows. Sep. Sci. Technol. 46, 2456–2464 (2011). https://doi.org/10.1080/01496395.2011.611210

Hu, Z.M., Myong, R.S., Nguyen, A.T., Jiang, Z.L., Cho, T.H.: Numerical analysis of the flowfield in a supersonic coil with an interleaved jet configuration and its effect on the gain distribution. Eng. Appl. Comput. Fluid Mech. 1(3), 207–215 (2007). https://doi.org/10.1080/19942060.2007.11015193

Guo, L., Yan, Y.Y., Maltson, J.D.: Performance of 2D scheme and different models in predicting flow turbulence and heat transfer through a supersonic turbine nozzle cascade. Int. J. Heat Mass Transf. 55, 6757–6765 (2012). https://doi.org/10.1016/j.ijheatmasstransfer.2012.06.083

Yu, Y., Xu, J.L., Mo, J.W., Wang, M.T.: Principal parameters in flow separation patterns of over-expanded single expansion RAMP nozzle. Eng. Appl. Comput. Fluid Mech. 8(2), 274–288 (2014). https://doi.org/10.1080/19942060.2014.11015513

Sudhan, K.H., Prasad, G.K., Kothurkar, N.K., Srikrishnan, A.R.: Studies on supersonic cold spray deposition of microparticles using a bell-type nozzle. Surf. Coat. Technol. 383, 125244 (2020). https://doi.org/10.1016/j.surfcoat.2019.125244

Balachandar, S., Eaton, J.K.: Turbulent dispersed multiphase flow. Annu. Rev. Fluid Mech. 42, 111–133 (2010). https://doi.org/10.1146/annurev.fluid.010908.165243

McGrath, T., Clair, J.S., Balachandar, S.: Modeling compressible multiphase flows with dispersed particles in both dense and dilute regimes. Shock Waves 2, 1–12 (2017). https://doi.org/10.1007/s00193-017-0726-8

Bhattacharya, S., Lutfurakhmanov, A., Hoey, J.M., Swenson, O.F., Mahmud, Z., Akhatov, I.S.: Aerosol flow through a converging-diverging micro-nozzle. Nonlinear Eng. 2, 103–112 (2013). https://doi.org/10.1515/nleng-2013-0020

Kudryavtsev, A., Shershnev, A., Rybdylova, O.: Numerical simulation of aerodynamic focusing of particles in supersonic micronozzles. Int. J. Multiph. Flow 114, 207–218 (2019). https://doi.org/10.1016/j.ijmultiphaseflow.2019.03.009

Molleson, G.V., Stasenko, A.L.: Acceleration of microparticles in a gasdynamic facility with high expansion of flow. High Temp. 46(1), 100–107 (2008). https://doi.org/10.1134/s10740-008-1014-1

Parmar, M., Haselbacher, A., Balachandar, S.: Improved drag correlation for spheres and application to shock-tube experiments. AIAA J. 48(6), 1273–1276 (2010). https://doi.org/10.2514/1.J050161

Bailey, A., Starr, R.: Sphere drag at transonic speeds and high Reynolds numbers. AIAA J. 14(11), 1631–1631 (1976). https://doi.org/10.2514/3.7262

Stewart, C., Balachandar, S., McGrath, T.P.: Soft-sphere simulations of a planar shock interaction with a granular bed. Phys. Rev. Fluids 3, 034308 (2018). https://doi.org/10.1103/PhysRevFluids.3.034308

Harris, S.E., Crighton, D.G.: Solitons, solitary waves, and voidage disturbances in gas-fluidized beds. J. Fluid Mech. 266, 243–276 (1994). https://doi.org/10.1017/S0022112094000996

Ling, Y., Wagner, J.L., Beresh, S.J., Kearney, S.P., Balachandar, S.: Interaction of a planar shock wave with a dense particle curtain: modeling and experiments. Phys. Fluids 24, 113301 (2012). https://doi.org/10.1063/1.4768815

Luo, X., Wang, G., Olivier, H.: Parametric investigation of particle acceleration in high enthalpy conical nozzle flows for coating applications. Shock Waves 17, 351–362 (2008). https://doi.org/10.1007/s00193-007-0116-8

Fu, D.X., Ma, Y.W., Li, X.L., Wang, Q.: Direct Numerical Simulation of Compressible Turbulent Flows, pp. 60–184. Science Press, Beijing (2010) (in Chinese)

Shershnev, A., Kudryavtsev, A.: Kinetic simulation of near field of plume exhausting from a plane micronozzle. Microfluid. Nanofluid. 19, 105–115 (2015). https://doi.org/10.1007/s10404-015-1553-9

Li, Z.J., Wang, H., Chen, J.W.: Ground effects on the hypervelocity jet flow and the stability of projectile. Eng. Appl. Comput. Fluid Mech. 12(1), 375–384 (2018). https://doi.org/10.1080/19942060.2018.1445034

Jiang, G.S., Shu, C.W.: Efficient implementation of weighted ENO schemes. J. Comput. Phys. 126, 202–228 (1996). https://doi.org/10.1006/jcph.1996.0130

Jones, J.B., Dugan, R.E.: Engineering Thermodynamics. Prentice Hall Inc., New Jersey (1996)

Snider, D.M., O’Rourke, P.J., Andrews, M.J.: Sediment flow in inclined vessels calculated using a multiphase particle-in-cell model for dense particle flows. Int. J. Multiph. Flow 24, 1359–1382 (1998). https://doi.org/10.1016/s0301-9322(98)00030-5

Drake, R.M.: Discussion on G.C. Vliet and G. Leppert: forced convection heat transfer from an isothermal sphere to water. J. Heat Transf. Trans. ASME 83, 170–172 (1961). https://doi.org/10.1115/1.3680507

Meyer, M., Caruso, F., Lupoi, R.: Particle velocity and dispersion of high Stokes number particles by PTV measurements inside a transparent supersonic cold spray nozzle. Int. J. Multiph. Flow 106, 296–310 (2018). https://doi.org/10.1016/j.ijmultiphaseflow.2018.05.018

Fang, D.Y.: Two-Phase Flow Dynamics, National University of Defense Technology Press, Changsha, pp. 153–240 (1988) (in Chinese)

Shu, C.W., Osher, S.: Efficient implementation of essentially non-oscillatory shock-capturing schemes. J. Comput. Phys. 77(2), 439–471 (1988). https://doi.org/10.1016/0021-9991(88)90177-5

Acknowledgements

The authors are grateful to the financial support from the Natural Science Foundation of Zhejiang Province (Grant No. LY17E060006), from the Fundamental Research Funds of Zhejiang Sci-Tech University (Grant No. 2019Q030), and from the National Natural Science Foundation of China (Grant No. 51876194).

Author information

Authors and Affiliations

Corresponding author

Additional information

Communicated by R. Bonazza.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix: Numerical methodology

Discretization methods for governing equations

In consideration of the prominently hyperbolic feature of the gas-phase conservation equations, a fifth-order WENO scheme [21] is employed to discretize the spatial derivative term of the flux vector (or convective term) on the left side of (1). However, it is necessary to conduct a characteristic splitting for the flux vector in advance. A modified Steger–Warming splitting method [18] is adopted in the present numerical model.

In order to make sure the spatial discretization for the gas-phase properties is at least third-order accurate, special treatments are required for grid nodes close to the nozzle inlet and exit boundaries. We combine a third-order upwind difference with a third-order upwind compact difference [18] to create the difference expressions for these nodes. Additionally, we adopt a simple third-order upwind difference approximation for the spatial derivatives such as the one of particle volume fraction in (19).

Shu and Osher’s [27] three-step third-order total variation diminishing Runge–Kutta (R–K) scheme is used for the difference approximation of the time derivatives.

Interpolation of the gas properties at particle locations

When we perform the calculations for the particle phase, the information of the gas phase should be provided in advance. However, the solution of the gas phase only provides the information at grid nodes. Therefore, we introduce a cubic polynomial interpolation for the properties of the gas phase at the particle positions.

Computational procedure of flow fields

The procedure for the present computations of the gas-particle two-phase flow is as shown in Fig. 14. The convergence criterion \(E_\mathrm{r}<\) \(\varepsilon _\mathrm{r}\) is adopted, where the residual of mass flow rate of the gas is defined by

and the threshold value \(\varepsilon _\mathrm{r} =\) 10\(^{-5}\). For clarity, we also list the bullet points as follows:

-

1.

Initialize the calculation with an isentropic gas flow.

-

2.

Calculate \(f_\mathrm{wf}\), \(Q_\mathrm{w}\), and \(G_\mathrm{w}\) at each node.

-

3.

Calculate \(v_\mathrm{g}\), p, \(T_\mathrm{g}\), and \(\rho _\mathrm{g}\) at the nozzle inlet.

-

4.

Calculate \(\rho _\mathrm{g}\), \(v_\mathrm{g}\), \(e^{*}\), e, \(T_\mathrm{g}\), and p at each node.

-

5.

Repeat (2)–(4) until the three-step R–K calculation is finished at this time step.

-

6.

Calculate \(E_\mathrm{r}\). If \(E_\mathrm{r} \ge \varepsilon _\mathrm{r}\), turn back to (5). Otherwise (i.e., \(E_\mathrm{r}<\) \(\varepsilon _\mathrm{r})\), if the current calculation is for gas-particle two-phase flow, terminate the calculation; if the current calculation is just for pure gas flow, proceed to the following steps.

-

7.

Inject particles by allocating \(x_\mathrm{p}\), \(v_\mathrm{p}\), and \(T_\mathrm{p}\).

-

8.

Reorder the new numbers for the remaining particles.

-

9.

Calculate \(N_{JI}\), \(\varphi \),and \(\alpha \) in each cell.

-

10.

Calculate \(\rho _\mathrm{g}\), p, and \(T_\mathrm{g}\) at particle locations.

-

11.

Calculate \(f^\mathrm{gp}\), \(f^\mathrm{pp}\), and \(Q^\mathrm{gp}\) for each particle.

-

12.

Calculate \(v_\mathrm{p}\), \(x_\mathrm{p}\), and \(T_\mathrm{p}\) for each particle.

-

13.

Calculate \(G^\mathrm{pg}\) and \(Q^\mathrm{pg}\) in each cell, and turn back to (5).

Rights and permissions

About this article

Cite this article

Zhang, L., Yu, Q., Liu, T. et al. Coupled modeling and numerical simulation of gas flows laden with solid particles in de Laval nozzles. Shock Waves 32, 213–230 (2022). https://doi.org/10.1007/s00193-021-01063-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00193-021-01063-1