Abstract

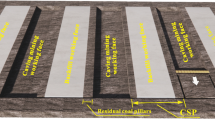

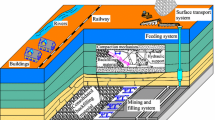

As a site for concentrated accumulation of slag, the waste slag yard is often large. Sliding can cause serious damage to nearby residents and infrastructure. In order to explore the law of sliding movement of the waste slag yard, the discrete element software PFC2D was used to study the blocking efficiency of the slag blocking walls in the waste slag yard. First, calibrate the meso-parameters of the slag material through a biaxial compression test of numerical simulation. Then, a numerical model of the waste slag yard is established, and four different slag blocking wall conditions are designed. Finally, the sliding simulation of the waste slag yard is carried out and the relevant data are monitored, the blocking efficiency of the slag blocking wall is analyzed from the aspects of particle displacement, particle velocity, and force and energy. The results show that the particle’s moving speed is greater and stable when there is no slag blocking wall. The entire movement process can be divided into four stages, i.e., rapid sliding, temporary stability, secondary sliding and stable. Among three different structures of slag blocking wall, the blocking efficiency of 90° slag blocking wall is the best, and the 45° slag blocking wall and the 60° slag blocking wall have different advantages. The sliding displacement of the 45° slag blocking wall is small, but the force is large. The sliding displacement of the 60° slag blocking wall is large, but the force is small.

Similar content being viewed by others

References

Behera PK, Sarkar K, Singh AK, Verma AK, Singh TN (2016) Dump slope stability analysis–a case study. J Geol Soc India 88:725–735. https://doi.org/10.1007/s12594-016-0540-4

Kainthola A, Verma D, Gupte SS, Singh TNJ (2011) A coal mine dump stability analysis–a case study. Geomaterials 1:1–13

Wang HB, Sun GH, Sui T (2021) Landslide mechanism of waste rock dump on a soft gently dipping foundation: a case study in China. Environ Earth Sci. https://doi.org/10.1007/s12665-021-09407-x

Yin YP, Li B, Wang WP, Zhan LT, Xue Q, Gao Y, Zhang N, Chen HQ, Liu TK, Li AG (2016) Mechanism of the december 2015 catastrophic landslide at the Shenzhen landfill and controlling geotechnical risks of urbanization. Engineering 2:230–249. https://doi.org/10.1016/j.Eng.2016.02.005

Cundall PA, Strack ODL (1979) A discrete numerical model for granular assemblies. Geotechnique 29:47–65

Gong SX, Zhao T, Zhao JD, Dai F, Zhou GGD (2021) Discrete element analysis of dry granular flow impact on slit dams. Landslides 18:1143–1152. https://doi.org/10.1007/s10346-020-01531-2

Zhou GGD, Sun QC (2013) Three-dimensional numerical study on flow regimes of dry granular flows by DEM. Powder Technol 239:115–127. https://doi.org/10.1016/j.powtec.2013.01.057

Li B, Gong WP, Tang HM, Zou ZX, Bowa VM, Juang CH (2021) Probabilistic analysis of a discrete element modelling of the runout behavior of the Jiweishan landslide. Int J Numer Anal Meth Geomech 45:1120–1138. https://doi.org/10.1002/nag.3199

Marchelli M, Leonardi A, Pirulli M, Scavia C (2020) On the efficiency of slit-check dams in retaining granular flows. Geotechnique 70:226–237. https://doi.org/10.1680/jgeot.18.P.044

Zhou GGD, Du JH, Song DR, Choi CE, Hu HS, Jiang CH (2020) Numerical study of granular debris flow run-up against slit dams by discrete element method. Landslides 17:585–595. https://doi.org/10.1007/s10346-019-01287-4

Qu TM, Feng YT, Wang M, Jiang SQ (2020) Calibration of parallel bond parameters in bonded particle models via physics-informed adaptive moment optimisation. Powder Technol 366:527–536. https://doi.org/10.1016/j.powtec.2020.02.077

Shi C, Yang WK, Yang JX, Chen X (2019) Calibration of micro-scaled mechanical parameters of granite based on a bonded-particle model with 2D particle flow code. Granul Matter. https://doi.org/10.1007/s10035-019-0889-3

Su H, Li HL, Hu BW, Yang JQ (2021) A research on the macroscopic and mesoscopic parameters of concrete based on an experimental design method. Materials. https://doi.org/10.3390/ma14071627

Yang BD, Jiao Y, Lei ST (2006) A study on the effects of microparameters on macroproperties for specimens created by bonded particles. Eng Comput 23:607–631. https://doi.org/10.1108/02644400610680333

Wang SQ, Zhuravkov M, Ji SY (2020) Granular flow of cylinder-like particles in a cylindrical hopper under external pressure based on DEM simulations. Soft Matter 16:7760–7777. https://doi.org/10.1039/c9sm02435b

Dai ZL, Huang Y (2016) A three-dimensional model for flow slides in municipal solid waste landfills using smoothed particle hydrodynamics. Environ Earth Sci. https://doi.org/10.1007/s12665-015-4923-4

Wang YK, Sun SW, Pang B, Liu L (2020) Base friction test on unloading deformation mechanism of soft foundation waste dump under gravity. Measurement. https://doi.org/10.1016/j.measurement.2020.108054

Teixeira MB, Nogueira CDL, de Oliveira WL (2012) Numerical simulation of hillside mine waste dump construction. Rem Rev Esc De Minas 65:553–559. https://doi.org/10.1590/s0370-44672012000400018

Hou J, Li H, Liu L, Wang SH, Teng YY, Bao SF (2021) A DEM analysis of geomembrane-lined landfill subject to vertical loading. Geotext Geomembr 49:369–375. https://doi.org/10.1016/j.geotexmem.2020.10.008

Cho N, Martin CD, Sego DC (2007) A clumped particle model for rock. Int J Rock Mech Min Sci 44:997–1010. https://doi.org/10.1016/j.ijrmms.2007.02.002

Manso J, Marcelino J, Caldeira L (2019) Effect of the clump size for bonded particle model on the uniaxial and tensile strength ratio of rock. Int J Rock Mech Min Sci 114:131–140. https://doi.org/10.1016/j.ijrmms.2018.12.024

Shen JY, Zhan SX, Karakus M, Zuo JP (2021) Effects of flaw width on cracking behavior of single-flawed rock specimens. Bull Eng Geol Env 80:1701–1711. https://doi.org/10.1007/s10064-020-02029-w

Ye Y, Thoeni K, Zeng YW, Buzzi O, Giacomini A (2019) A novel 3D clumped particle method to simulate the complex mechanical behavior of rock. Int J Rock Mech Min Sci 120:1–16. https://doi.org/10.1016/j.ijrmms.2019.06.002

Potyondy DO, Cundall PA (2004) A bonded-particle model for rock. Int J Rock Mech Min Sci 41:1329–1364. https://doi.org/10.1016/j.ijrmms.2004.09.011

Lin QW, Cheng QG, Xie Y, Zhang FS, Li K, Wang YF, Zhou YY (2021) Simulation of the fragmentation and propagation of jointed rock masses in rockslides: DEM modeling and physical experimental verification. Landslides 18:993–1009. https://doi.org/10.1007/s10346-020-01542-z

Group I.C. (2008) PFC2D-particle flow code in three-dimensions, in: I. C. G. I (Ed.), Minnesota.

Banton J, Villard P, Jongmans D, Scavia C (2009) Two-dimensional discrete element models of debris avalanches: parameterization and the reproducibility of experimental results. J Geophys Res Earth Surf. https://doi.org/10.1029/2008jf001161

Crosta GB, Imposimato S, Roddeman D (2016) Landslide spreading, impulse water waves and modelling of the vajont rockslide. Rock Mech Rock Eng 49:2413–2436. https://doi.org/10.1007/s00603-015-0769-z

Staron L (2008) Mobility of long-runout rock flows: a discrete numerical investigation. Geophys J Int 172:455–463. https://doi.org/10.1111/j.1365-246X.2007.03631.x

Tang CL, Hu JC, Lin ML, Yuan RM, Cheng CC (2013) The mechanism of the 1941 Tsaoling landslide, Taiwan: insight from a 2D discrete element simulation. Environ Earth Sci 70:1005–1019. https://doi.org/10.1007/s12665-012-2190-1

Yousefi A (2018) Size-dependent damping model for DEM: improved equilibrium compared with mass-damping at no extra computational cost. Granul Matter. https://doi.org/10.1007/s10035-018-0794-1

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sun, R., He, Y., Wang, Y. et al. The blocking efficiency of slag blocking wall of the waste slag yard based on PFC2D. Comp. Part. Mech. 10, 387–396 (2023). https://doi.org/10.1007/s40571-022-00503-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40571-022-00503-8