Abstract

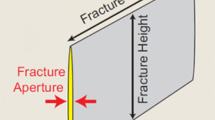

A numerical technique based on a CFD-DEM method is presented for the analysis of particle impact drilling (PID) systems. The method is built from a preexisting finite element Navier–Stokes solver for the fluid phase and a discrete element method module for the steel particles which this drilling technology utilizes to enhance the penetration rate. We provide a detailed description of the most relevant implementation issues, including our choice of the hydrodynamic forces appropriate for power-law fluids. We also discuss several critical aspects related to the validity of the simplifying assumptions that will be helpful to simulation engineers. We apply our simple, one-way coupled approach on designs provided by an industrial partner to illustrate its potential as an analysis tool for this promising drilling technology. The goal of this work is, on the one hand, to provide evidence for the usefulness of the numerical approach as a design tool for PID systems, as well as a detailed discussion of the different aspects to be assessed for an effective simulation campaign. On the other hand, a series of modeling aspects that require further work are identified. The focus of the simulation campaign presented is on the particles and fluid flow characteristics within the drill bit.

Similar content being viewed by others

References

Ron L (2006) Bit technology keeps pace with operator activity. World Oil 227(11):71–80

Zhao J, Yiji X (2014) The technical development for increasing ROP with particle impact drilling in China. Adv Mater Res 904:292–295

Rach NM (2007) Particle-impact drilling blasts away hard rock. Oil Gas J 105(6):43–48

Tibbitts GA, Galloway GG (2008) Particle drilling alters standard rock-cutting approach: drilling/completions. World Oil 229(6):37–44

l Yan T, Li J, Zhao L (2016) Numerical simulation on flow field of particle impact drilling in different drilling parameters. DEStech Trans Comput Sci Eng, (Icte):1–5. https://doi.org/10.12783/dtcse/icte2016/4801

Zhao J, Yiji X, Ren J, Hou D (2014) Numerical simulation of the bottom hole flow field of particle impact drilling. Adv Petrol Explor Dev 8(2):18–23

Ren FS, Ma RX, Cheng XZ (2014) Simulation of particle impact drilling nozzles based on fluent. Adv Mater Res 988:475–478

Lingbi JGWHW, Rongchao CMC (2012) Numerical simulation research on the bit nozzle flow field of particle impact drilling. China Petrol Mach, (10):6. https://en.cnki.com.cn/Article_en/CJFDTotal-SYJI201210006.htm

Zhou W, Huang J, Li L (2018) Numerical simulation of bottomhole flow field structure in particle impact drilling. E&ES 108(3):032080

Meng C, Ying-hu Z, Guo-dong J (2011) Experimental study of rock breaking effect of steel particles. J Hydrodyn Ser B 23(2):241–246

Kuerten JGM (2016) Point-particle DNS and les of particle-laden turbulent flow-a state-of-the-art review. Flow, Turbul Combus 97(3):689–713

Subramaniam S (2013) Lagrangian-Eulerian methods for multiphase flows. Prog Energy Combus Sci 39(2–3):215–245

Cleary PW (2004) Large scale industrial DEM modelling. Eng Comput 21(2-4):169–204. https://doi.org/10.1108/02644400410519730

Guo Yu, Curtis JS (2015) Discrete element method simulations for complex granular flows. Ann Rev Fluid Mech 47(1):21–46

Samiei K, Peters B, Bolten M, Frommer A (2013) Assessment of the potentials of implicit integration method in discrete element modelling of granular matter. Comput Chem Eng 49:183–193

Lichtenheldt R (2017) A stable, implicit time integration scheme for discrete element method and contact problems in dynamics. In: PARTICLES V: proceedings of the V international conference on particle-based methods: fundamentals and applications, pp. 297–308. CIMNE

Richardson DC, Walsh KJ, Murdoch N, Michel P (2011) Numerical simulations of granular dynamics: I. hard-sphere discrete element method and tests. Icarus 212(1):427–437

Williams JR, O’Connor R (1995) A linear complexity intersection algorithm for discrete element simulation of arbitrary geometries. Eng Comput 12(2):185–201

Santasusana M, Irazábal J, Oñate E, Carbonell JM (2016) The double hierarchy method. A parallel 3D contact method for the interaction of spherical particles with rigid FE boundaries using the DEM. Comput Part Mech 3(3):407–428

Wensrich CM, Katterfeld A (2012) Rolling friction as a technique for modelling particle shape in dem. Powder Technol 217:409–417

Loth E(2010) Particles drops and bubbles: Fluid dynamics and numerical methods

Ayala O, Grabowski WW, Wang LP (2007) A hybrid approach for simulating turbulent collisions of hydrodynamically-interacting particles. J Comput Phys 225(1):51–73

Rosa B, Wang L-P, Maxey MR, Grabowski WW (2011) An accurate and efficient method for treating aerodynamic interactions of cloud droplets. J Comput Phys 230(22):8109–8133

Casas G, Mukherjee D, Celigueta MA, Zohdi TI, Onate E (2017) A modular, partitioned, discrete element framework for industrial grain distribution systems with rotating machinery. Comput Part Mech 4(2):181–198

Thornton C, Cummins SJ, Cleary PW (2013) An investigation of the comparative behaviour of alternative contact force models during inelastic collisions. Powder Technol 233:30–46

Ramírez R, Pöschel T, Brilliantov NV, Schwager T (1999) Coefficient of restitution of colliding viscoelastic spheres. Phys Rev E 60(4):4465–4472

Lifshitz JM, Kolsky H (1964) Some experiments on anelastic rebound. J Mech Phys Solids 12(1):35–43

Aguilar-Corona A, Zenit R, Masbernat O (2011) Collisions in a liquid fluidized bed. Int J Multiph Flow 37(7):695–705

Padding JT, Louis AA (2006) Hydrodynamic interactions and Brownian forces in colloidal suspensions: coarse-graining over time and length scales. Phys Rev E - Stat, Nonlinear, Soft Matter Phys 74(3):1–31

Wasfy TM, Noor AK (2003) Computational strategies for flexible multibody systems. Appl Mech Rev 56(6):553–613

O’Sullivan C, Bray JD (2004) Selecting a suitable time step for discrete element simulations that use the central difference time integration scheme. Eng Comput

Harald Kruggel-Emden M, Sturm SW, Scherer V (2008) Selection of an appropriate time integration scheme for the discrete element method (dem). Comput Chem Eng 32(10):2263–2279

Antypov D, Elliott JA (2011) On an analytical solution for the damped Hertzian spring. EPL (Europhys Lett) 94(5):50004

Coussot P, Bertrand F, Herzhaft B (2004) Rheological behavior of drilling muds, characterization using MRI visualization. Oil Gas Sci Technol 59(1):23–29

Löhner R (2008) Applied computational fluid dynamics techniques. John Wiley & Sons Ltd, Chichester

Druzhinin OA, Elghobashi S (1998) Direct numerical simulations of bubble-laden turbulent flows using the two-fluid formulation. Phys Fluids 10(3):685–697

Casas González Guillermo (2018) Numerical analysis of particle-laden flows with the finite element method. PhD thesis, Universitat Politècnica de Catalunya

Loth E, Dorgan AJ (2009) An equation of motion for particles of finite Reynolds number and size. Environ Fluid Mech 9(2):187–206

Coimbra CFM, Rangel RH (2001) Spherical particle motion in harmonic stokes flows. AIAA J 39(9):1673–1682

Winkler CM, Rani SL (2009) Relative importance of the lift force on heavy particles due to turbulence driven secondary flows. Powder Technol 190(3):310–318

Marchioli C, Picciotto M, Soldati A (2007) Influence of gravity and lift on particle velocity statistics and transfer rates in turbulent vertical channel flow. Int J Multiph Flow 33(3):227–251

Lataste J, Huilier D, Burnage H, Bednář J (2000) On the shear lift force acting on heavy particles in a turbulent boundary layer. Atmos Environ 34(23):3963–3971

Auton TR, Hunt JCR, Prud’Homme M (1988) The force exerted on a body in inviscid unsteady non-uniform rotational flow. J Fluid Mech 197(1):241

Loth E (2008) Lift of a spherical particle subject to vorticity and/or spin. AIAA J 46(4):801–809

Wakaba L, Balachandar S (2007) On the added mass force at finite Reynolds and acceleration numbers. Theor Comput Fluid Dyn 21(2):147–153

Kendoush AA, Sulaymon AH, Mohammed SAM (2007) Experimental evaluation of the virtual mass of two solid spheres accelerating in fluids. Exp Thermal Fluid Sci 31(7):813–823

Maxey MR (1983) Equation of motion for a small rigid sphere in a nonuniform flow. Phys Fluids 26(4):883–889

Loth E (2008) Drag of non-spherical solid particles of regular and irregular shape. Powder Technol 182(3):342–353

Beetstra R, van der Hoef MA, Kuipers JAM (2007) Drag force of intermediate Reynolds number flow past mono- and bidisperse arrays of spheres. AIChE J 53(2):489–501

Azaiez J (2008) Bubbles, drops and particles in non-Newtonian fluids. R. P. Chhabra. Can J Chem Eng 85(2):251–252

Shah SN, El Fadili Y, Chhabra RP (2007) New model for single spherical particle settling velocity in power law (visco-inelastic) fluids. Int J Multiph Flow 33(1):51–66

Metzner AB, Reed JC (1955) Flow of non-Newtonian fluids–correlation of the laminar, transition, and turbulent-flow regions. AIChE J 1(4):434–440

Trinh KT (2010) On the critical Reynolds number for transition from laminar to turbulent flow. p. 39

Balachandar S (2009) A scaling analysis for point–particle approaches to turbulent multiphase flows. Int J Multiph Flow 35(9):801–810

Crowe C, Schwarzkopf J, Sommerfeld M, Tsuji Y (2012) Multiphase flows with droplets and particles. CRC Press, Boca Raton

Dadvand P, Rossi R, Oñate E (2010) An object-oriented environment for developing finite element codes for multi-disciplinary applications. Arch Comput Methods Eng 17(3):253–297

Coll J, Ribó AR, Pasenau M, Escolano E, Perez JSuit, Melendo A, Monros A, Gárate (2016) GiD v.13 Reference Manual. CIMNE

Thornton C (2009) A note on the effect of initial particle spin on the rebound behaviour of oblique particle impacts. Powder Technol 192(2):152–156

Sagaut P (2006) Large eddy simulation for incompressible flows: an introduction. Springer Science & Business Media, Berlin

Gupta P, Sun J, Ooi JY (2016) Dem-CFD simulation of a dense fluidized bed: wall boundary and particle size effects. Powder Technol 293:37–47

Boffi D, Brezzi F, Fortin M et al (2013) Mixed finite element methods and applications, vol 44. Springer, Berlin

Ern A, Guermond J-L (2004) Theory and practice of finite elements, applied mathematical sciences, vol 159. Springer, New York

Hughes Thomas JR (1995) Multiscale phenomena: green’s functions, the Dirichlet-to-Neumann formulation, subgrid scale models, bubbles and the origins of stabilized methods. Comput Methods Appl Mech Eng 127(1–4):387–401

Codina R (2001) A stabilized finite element method for generalized stationary incompressible flows. Comput Methods Appl Mech Eng 190(20–21):2681–2706

Codina R, Badia S, Baiges J, Principe J (2018) Variational multiscale methods in computational fluid dynamics. In: Stein E, de Borst R, Hughes TJR (eds) Encyclopedia of computational mechanics, 2nd edn. John Wiley, Hoboken, pp 1–28

Dalmau JC (2016) Applications of turbulence modelling in civil engineerng. PhD thesis, Universitat Politècnica de Catalunya

Wood WL, Bossak M, Zienkiewicz OC (1980) An alpha modification of Newmark’s method. Int J Numer Methods Eng 15(10):1562–1566

Funding

We acknowledge the financial support to CIMNE via the CERCA Programme/Generalitat de Catalunya, and also that provided by the Spanish Ministry of Economy and Competitiveness, through the “Severo Ochoa Programme for Centres of Excellence in R&D” (CEX2018-000797-S).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors certify that they have NO affiliations with or involvement in any organization or entity with any financial interest (such as honoraria; educational grants; participation in speakers’ bureaus; membership, employment, consultancies, stock ownership, or other equity interest; and expert testimony or patent-licensing arrangements), or non-financial interest (such as personal or professional relationships, affiliations, knowledge, or beliefs) in the subject matter or materials discussed in this manuscript.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix

A Details of the numerical method for the fluid equations

1.1 A.1 Finite element discretization

The FEM is based on the weak version of the problem formed by Eqs. (5) and (6), which is to find \((\varvec{u}; p) \in \varvec{\mathcal {X}} :=\varvec{\mathcal {V}}_D \times \mathcal {Q}\), where \(\mathcal {V}_D\) and \(\mathcal {Q}\) are appropriate function spaces for the velocity (vectors already fulfilling the Dirichlet boundary conditions) and the pressure fields.

for all \((\varvec{v}; q)\) in \(\varvec{\mathcal {Y}} :=\varvec{\mathcal {V}_0} \times \mathcal {Q}\), where \(\varvec{\mathcal {V}_0}\) is the space of velocity-like fields that vanish on the Dirichlet boundary.

The basic strategy in the FEM is to replace the relevant (infinite-dimensional) spaces of functions above with finite dimensional counterparts in the variational version of the problem which leads to the algebraic system of equations that must be solved computationally.

Let us consider a conforming finite element partition \(\mathcal {T}_h\) of the domain \(\Omega \). For each element in the domain \(\Omega _e \in \mathcal {T}_h\), we denote its diameter as \(h_e\) and we define \(h = \max {\left\{ h_e | \Omega _e \in \mathcal {T}_h \right\} }\). With these tools, it is possible to construct the finite element spaces in the usual way, as \(\varvec{\mathcal {X}}_h = \varvec{\mathcal {V}}_{D,h} \times \mathcal {Q}_h\), with \(\mathcal {V}_{D,h} \subset \mathcal {V}_{D}\), \(\mathcal {Q}_h \subset \mathcal {Q}\). The finite element solution will be a function \(\varvec{U}_h = [\varvec{u}_h, p_h] \in \varvec{\mathcal {X}}_h\), and since we will be using equal-order spaces for the velocity and the pressure, the solution can be expressed as (summation is assumed for repeated indices)

for \(j = 1, ..., n_{\text {dim}}\) and \(b = 1, ..., n_{\text {nodes}}\); where the \(N^b\) are the shape functions, \(n_{\text {dim}}\) is the number of space dimensions (2 or 3), and \(n_{\text {nodes}}\) is the total number of mesh nodes.

Once the finite element discretization is defined, the problem presented in Eq. (30) can be expressed using a compact notation as find \(\varvec{U}_h\in \varvec{\mathcal {X}}_h\) such that

with

and

where we have divided through by the (constant) density of the fluid, \(\rho _f\).

1.1.1 Stabilization

In the present work, we want to make use of the simplest linear simplex elements, for both the pressure and velocity approximations. However, for problems of the form of Eq. (32) (i.e., saddle-point problem, see [61]) not all velocity–pressure element pairs lead to viable numerical methods. A necessary condition to guarantee the stability of a particular combination is that the finite element spaces must fulfil the inf-sup or Ladyzhenskaya–Babusška–Brezzi (LBB) condition [61], and, in particular, the equal-order, piecewise linear spaces for the velocity and for the pressure (\(\mathcal {P}_1/\mathcal {P}_1\) element) do not fulfil this condition [62]. Nonetheless, one can resort to stabilization methods to fix the numerical method resulting from the use of element pairs not fulfilling the LBB condition by modifying the weak form of the problem.

The variational multiscale method (VMS) [63, 64] method provides a theoretical framework for the development of stabilized finite element formulations. These are based on the explicit consideration of the decomposition of the continuous solution into a part belonging to the finite element space \(\varvec{\mathcal {X}}_h\) and its complement in the continuous solution space \(\tilde{\varvec{\mathcal {X}}}\), or subscale.

In this work, we consider the algebraic sub-grid scales (ASGS) variant of VMS [65], which leads to rewriting the problem Eq. (32) as find \(\varvec{U}_h\in \varvec{\mathcal {X}}_h\) such that

where \(B_{ASGS}(\varvec{U}_h,\varvec{V}_h)\) and \(L_{ASGS}(\varvec{V}_h)\) are computed by adding a number of stabilization terms to the analogous terms in Eqs. (33) and (34), respectively. The resulting discrete problem does not suffer from the numerical instabilities that affect the Galerkin problem and allows us to work with the simplest finite element pair. A detailed derivation of the stabilized equations can be found in [37, 66].

1.2 Time integration and linearized system of equations

After assembling all the elemental contributions and imposing the boundary conditions, Eq. (36) leads to a system of equations of the form

where \({\mathbb {U}}\) and \({\mathbb {P}}\) stand for the nodal unknowns of the velocity and pressure, respectively. For the time discretization, we use a second-order Bossak time integration scheme [67], which defines the velocities as

The Bossak method introduces a relaxation factor in the acceleration of the system in Eq. (37)

where n is the time-step index. Combining Eqs. (38) and (39) and rearranging terms, one can rewrite Eq. (39) in residual form as

where we choose \(\alpha = -0.3\) and \(\gamma _N = 1/2 - \alpha _B\), as this combination of parameters provides maximal damping of the highest frequencies and a robust behavior overall [67]. The nonlinearities present in Eq. (5) are linearized using a first-order Taylor expansion. That is, at each nonlinear iteration i one solves

Then, the solution and the residual are iteratively updated with Picard’s method as

where, in evaluating the derivative of the residual, we use the following approximation

where the indices are applied only to matrix \({\mathbb {C}}\), as \({\mathbb {M}}\) does not depend on the solution. Note that this approximation assumes that the variation of \({\mathbb {C}}\) is moderate compared to that of the solution vector itself; otherwise, convergence problems can appear. Consequently, the final system to be solved reads

Rights and permissions

About this article

Cite this article

Casas, G., de-Pouplana, I., Gandikota, R. et al. Numerical simulation of particle impact drilling (PID) systems: a one-way coupled approach. Comp. Part. Mech. 9, 735–757 (2022). https://doi.org/10.1007/s40571-021-00440-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40571-021-00440-y