Abstract

In this paper, the material response of expanded glass granules at different scales and under different boundary conditions is investigated. At grain scale, single particle tests can be used to determine properties like Young’s modulus or crushing strength. With experiments like triaxial and oedometer tests, it is possible to examine the bulk mechanical behaviour of the granular material. Our experimental investigation is complemented by a numerical simulation where the discrete element method is used to compute the mechanical behaviour of such materials. In order to improve the simulation quality, effects such as rolling resistance, inelastic behaviour, damage, and crushing are also included in the discrete element method. Furthermore, the variation of the material properties of granules is modelled by a statistical distribution and included in our numerical simulation.

Similar content being viewed by others

References

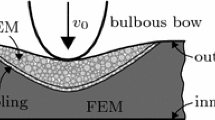

Schöttelndreyer M (2015) Füllstoffe in der Konstruktion: Ein Konzept zur Verstärkung von Schiffsseitenhüllen, Ph.D. thesis, Institut für Konstruktion und Festigkeit von Schiffen, Technische Universität Hamburg-Harburg. doi:10.15480/882.1258

Woitzik C, Chaudry M, Wriggers P, Düster A (2016) Experimental and numerical investigation of granular materials for an increase of the collision safety of double-hull vessels. Proc Appl Math Mech 16:409–410. doi:10.1002/pamm.201610193

Lehmann E, Peschmann J (2002) Energy absorption by the steel structure of ships in the event of collisions. Mar Struct 15:429–441

Cundall PA (1971) A computer model for simulating progressive, large-scale movements in blocky rock systems. In: Proceedings of the international symposium of rock fracture, Nancy, France, Paper No. II.8

Wellmann C (2011) A two-scale model of granular materials using a coupled DE-FE approach, no. 11/1 in Leibniz Universität Hannover, Institut für Kontinuumsmechanik B, University Institute für Kontinuumsmechanik

Wellmann C, Lillie C, Wriggers P (2008) Comparison of the macroscopic behavior of granular materials modeled by different constitutive equations on the microscale. Finite Elem Anal Des 44(5):259–271

Cundall PA, Strack OD (1979) A discrete numerical model for granular assemblies. Geotechnique 29(1):47–65

Gladwell GM (1980) Contact problems in the classical theory of elasticity. Springer, Berlin

Johnson KL (1985) Contact mechanics. Cambridge University Press, Cambridge

Mindlin RD (1949) Compliance of elastic bodies in contact. J Appl Mech 16:259–268

Thornton C (1997) Coefficient of restitution for collinear collisions of elastic–perfectly plastic spheres. J Appl Mech 64(2):383–386

Rathbone D, Marigo M, Dini D, van Wachem B (2015) An accurate force–displacement law for the modelling of elastic–plastic contacts in discrete element simulations. Powder Technol 282:2–9

Iwashita K, Oda M (1998) Rolling resistance at contacts in simulation of shear band development by dem. J Eng Mech 124(3):285–292

Ai J, Chen J-F, Rotter JM, Ooi JY (2011) Assessment of rolling resistance models in discrete element simulations. Powder Technol 206(3):269–282

Chaudry MA, Woitzik C, Weißenfels C, Düster A, Wriggers P (2016) Dem–fem coupled numerical investigation of granular materials to increase crashworthiness of double-hull vessels. PAMM 16(1):311–312

Cil M, Alshibli K (2012) 3d assessment of fracture of sand particles using discrete element method. Géotech Lett 2:161–166

McDowell G, Bolton M (1998) On the micromechanics of crushable aggregates. Géotechnique 48(5):667–679

Hiramatsu Y, Oka Y (1966) Determination of the tensile strength of rock by a compression test of an irregular test piece. Int J Rock Mech Min Sci Geomech Abstr 3(2):89–99

Chaudry MA, Wriggers P (2017) On the computational aspects of comminution in discrete element method. Comput Part Mech. doi:10.1007/s40571-017-0161-8

Sukumaran B, Einav I, Dyskin A (2006) Qualitative assessment of the influence of coordination number on crushing strength using dem. In: AIChE annual meeting, conference proceedings

Ben-Nun O, Einav I (2010) The role of self-organization during confined comminution of granular materials. Philos Trans R Soc Lond A Math Phys Eng Sci 368(1910):231–247

Lobo-Guerrero S, Ballejo L (2005) Crushing a weak granular material: experimental numerical analyses. Géotechnique 55(3):245–249

Salami Y, Dano C, Hicher P, Colombo G, Denain P (2015) The effects of the coordination on the fragmentation of a single grain. IOP Conf Ser Earth Environ Sci 26(1):12–15

Wang P, Arson C (2016) Discrete element modeling of shielding and size effects during single particle crushing. Comput Geotech 78:227–236

Schöttelndreyer M, Tautz I (2014) Validierung von Kollisionsberechnungen durch Großversuche an Konstruktionsvarianten von Seitenhüllen, Abschlussbericht des BMWi Verbundprojekts ELKOS, Institut für Konstruktion und Festigkeit von Schiffen. Technische Universität Hamburg-Harburg

OSTHOFF OMEGA GROUP, Omega C-XL expanded glass. http://osthoffomegagroup.com/cms/front_content.php?idcat=58&lang=2

Rozenblat Y, Portnikov D, Levy A, Kalman H, Aman S, Tomas J (2011) Strength distribution of particles under compression. Powder Technol 208(1):215–224. doi:10.1016/j.powtec.2010.12.023

Portnikov HKD (2014) Determination of elastic properties of particles using single particle compression test. Powder Technol 268(1):244–252. doi:10.1016/j.powtec.2014.08.011

Kolymbas D, Bauer E (1993) Soft oedometer-a new testing device and its application for the calibration of hypoplastic constitutive laws. Geotech Test J 16(2):263–270

Kolymbas D (2007) Geotechnik: Bodenmechanik, Grundbau und Tunnelbau, 2nd edn. Springer, Berlin

Woitzik C, Düster A (2017) Modelling the material parameter distribution of expanded granules. Granul Matter 19(3):52. doi:10.1007/s10035-017-0735-4

Müller P, Seeger M, Tomas J (2014) Druck- und Bruchverhalten von \(\gamma \)-Al\(_2\)O\(_3\)-granulaten. Chemie Ingenieur Technik 86(8):1284–1293. doi:10.1002/cite.201300021

Das BM (2010) Principles of foundation engineering, 7th edn. Thomson-Brooks/Cole, Pacific Grove

Subero-Couroyer C, Ghadiri M, Brunard N, Kolenda F (2003) Weibull analysis of quasi-static crushing strength of catalyst particles. Chem Eng Res Des 81(8):953–962. doi:10.1205/026387603322482194

Petukhov Y, Kalman H (2004) Empirical breakage ratio of particles due to impact. Powder Technol 143–144:160–169. doi:10.1016/j.powtec.2004.04.009

MATLAB, version 8.5.0 (R2015a), The MathWorks Inc., Natick, Massachusetts, 2015

Gruttmann F, Taylor R (1992) Theory and finite element formulation of rubberlike membrane shells using principal stretches. Int J Numer Methods Eng 35(5):1111–1126

Wellmann C, Wriggers P (2008) A coupled 3d discrete-finite element method for the simulation of granular materials and their interaction with solid structures. PAMM 8(1):10353–10354

Acknowledgements

The support of the DFG (Deutsche Forschungsgemeinschaft) under Grant Nos. DU 405/9-1 and WR 19/55-1 is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have no conflict of interest to declare.

Rights and permissions

About this article

Cite this article

Chaudry, M.A., Woitzik, C., Düster, A. et al. Experimental and numerical characterization of expanded glass granules. Comp. Part. Mech. 5, 297–312 (2018). https://doi.org/10.1007/s40571-017-0169-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40571-017-0169-0