Abstract

A modular discrete element framework is presented for large-scale simulations of industrial grain-handling systems. Our framework enables us to simulate a markedly larger number of particles than previous studies, thereby allowing for efficient and more realistic process simulations. This is achieved by partitioning the particle dynamics into distinct regimes based on their contact interactions, and integrating them using different time-steps, while exchanging phase-space data between them. The framework is illustrated using numerical experiments based on fertilizer spreader applications. The model predictions show very good qualitative and quantitative agreement with available experimental data. Valuable insights are developed regarding the role of lift vs drag forces on the particle trajectories in-flight, and on the role of geometric discretization errors for surface meshing in governing the emergent behavior of a system of particles.

Similar content being viewed by others

References

Adam S, Suzzi D, Radeke C, Khinast JG (2011) An integrated quality by design (qbd) approach towards design space definition of a blending unit operation by discrete element method (dem) simulation. Eur J Pharm Sci 42(1):106–115

Antypov D, Elliott JA (2011) On an analytical solution for the damped hertzian spring. EPL (Europhys Lett) 94(5):50004

Aphale A, Bolander N, Park J, Shaw L, Svec J, Wassgren C (2003) Granular fertiliser particle dynamics on and off a spinner spreader. Biosyst Eng 85(3):319–329

Cleary PW (1998) Predicting charge motion, power draw, segregation and wear in ball mills using discrete element methods. Miner Eng 11(11):1061–1080

Cleary PW (2001) Recent advances in dem modelling of tumbling mills. Miner Eng 14(10):1295–1319

Coetzee CJ, Lombard SG (2011) Discrete element method modelling of a centrifugal fertiliser spreader. Biosyst Eng 109(4):308–325

Cool S, Pieters J, Mertens KC, Hijazi B, Vangeyte J (2014) A simulation of the influence of spinning on the ballistic flight of spherical fertiliser grains. Comput Electron Agric 105:121–131

Crowe CT, Schwarzkopf JD, Sommerfeld M, Tsuji Y (2011) Multiphase flows with droplets and particles. CRC press, Boca Raton

Dadvand P, Rossi R, Oñate E (2010) An object-oriented environment for developing finite element codes for multi-disciplinary applications. Arch Comput Methods Eng 17(3):253–297

Das S (2003) Physical aspects of process control in selective laser sintering of metals. Adv Eng Mater 5(10):701–711

Dennis SCR, Singh SN, Ingham DB (1980) The steady flow due to a rotating sphere at low and moderate reynolds numbers. J Fluid Mech 101(02):257–279

Dintwa E, Van Liedekerke P, Olieslagers R, Tijskens E, Ramon H (2004) Model for simulation of particle flow on a centrifugal fertiliser spreader. Biosyst Eng 87(4):407–415

Duran J (2012) Sands, powders, and grains: an introduction to the physics of granular materials. Springer, New York

Farazmand M, Haller G (2015) The maxey-riley equation: existence, uniqueness and regularity of solutions. Nonlinear Anal: Real World Appl 22:98–106

Feuillebois F, Lasek A (1978) On the rotational historic term in non-stationary stokes flow. Q J Mech Appl Math 31(4):435–443

Gouesbet G, Berlemont A (1999) Eulerian and lagrangian approaches for predicting the behaviour of discrete particles in turbulent flows. Prog Energ Combust Sci 25(2):133–159

Haider A, Levenspiel O (1989) Drag coefficient and terminal velocity of spherical and nonspherical particles. Powder Technol 58(1):63–70

Hofstee JW (1995) Handling and spreading of fertilizers: part 5, the spinning disc type fertilizer spreader. J Agric Eng Res 62(3):143–162

Höhner D, Wirtz S, Kruggel-Emden H, Scherer V (2011) Comparison of the multi-sphere and polyhedral approach to simulate non-spherical particles within the discrete element method: Influence on temporal force evolution for multiple contacts. Powder Technol 208(3):643–656

Horner DA, Peters JF, Carrillo A (2001) Large scale discrete element modeling of vehicle-soil interaction. J Eng Mech 127(10):1027–1032

Irazabal J (2015) Masters thesis: Numerical modelling of railway ballast using the discrete element method

Johnson KL (1987) Contact mechanics. Cambridge university press, Cambridge

Ketterhagen WR, am Ende MT, Hancock BC (2009) Process modeling in the pharmaceutical industry using the discrete element method. J Pharm Sci 98(2):442–470

Kim I, Elghobashi S, Sirignano WA (1998) On the equation for spherical-particle motion: effect of reynolds and acceleration numbers. J Fluid Mech 367:221–253

Kloss C, Goniva C, Hager A, Amberger S, Pirker S (2012) Models, algorithms and validation for opensource dem and cfd-dem. Prog Comput Fluid Dyn Int J 12(2–3):140–152

Kodam M, Curtis J, Hancock B, Wassgren C (2012) Discrete element method modeling of bi-convex pharmaceutical tablets: contact detection algorithms and validation. Chem Eng Sci 69(1):587–601

Landau LD, Pitaevskii LP, Kosevich AM, Lifshitz M (1986) Theory of elasticity, 3rd edn., vol 7 (Course of theoretical physics), vol 1, 3rd edn. Butterworth-Heinemann,

Maxey MR, Riley JJ (1983) Equation of motion for a small rigid sphere in a nonuniform flow. Phys Fluids (1958–1988) 26(4):883–889

Mishra BK (2003) A review of computer simulation of tumbling mills by the discrete element method: Part II—practical applications. Int J Miner Proc 71(1):95–112

Mishra BK (2003) A review of computer simulation of tumbling mills by the discrete element method: part I—contact mechanics. Int J Miner Proc 71(1):73–93

Morrison RD, Cleary PW (2004) Using dem to model ore breakage within a pilot scale sag mill. Miner Eng 17(11):1117–1124

Mukherjee D, Zohdi TI (2015) A discrete element based simulation framework to investigate particulate spray deposition processes. J Comput Phys 290:298–317

Muzzio FJ, Shinbrot T, Glasser BJ (2002) Powder technology in the pharmaceutical industry: the need to catch up fast. Powder Technol 124(1):1–7

Oesterle B, Bui Dinh T (1998) Experiments on the lift of a spinning sphere in a range of intermediate reynolds numbers. Exp Fluids 25(1):16–22

O’Sullivan C, Bray JD (2004) Selecting a suitable time step for discrete element simulations that use the central difference time integration scheme. Eng Comput 21(2/3/4):278–303

Patterson DE, Reece AR (1962) The theory of the centrifugal distributor. I: motion on the disc, near-centre feed. J Agric Eng Res 7(3):232–240

Perret-Liaudet J, Rigaud E (2006) Response of an impacting hertzian contact to an order-2 subharmonic excitation: theory and experiments. J Sound Vib 296(1):319–333

Pöschel T, Schwager T (2005) Computational granular dynamics: models and algorithms. Springer, Berlin

Schwartz SR, Richardson DC, Michel P (2012) An implementation of the soft-sphere discrete element method in a high-performance parallel gravity tree-code. Granul Matter 14(3):363–380

Stronge WJ (2004) Impact mechanics. Cambridge university press, Cambridge

Thornton C, Cummins SJ, Cleary PW (2013) An investigation of the comparative behaviour of alternative contact force models during inelastic collisions. Powder Technol 233:30–46

Tijskens E, Ramon H, De Baerdemaeker J (2003) Discrete element modelling for process simulation in agriculture. J Sound Vib 266(3):493–514

Van Hinsberg M, ten Thije J, ten Thije Boonkkamp J, Clercx H (2011) An efficient, second order method for the approximation of the basset history force. J Comput Phys 230(4):1465–1478

Van Liedekerke P, Tijskens E, Dintwa E, Anthonis J, Ramon H (2006) A discrete element model for simulation of a spinning disc fertilizer spreader I. Single particle simulations. Powder Technol 170(2):71–85

Van Liedekerke P, Tijskens E, Dintwa E, Rioual F, Vangeyte J, Ramon H (2009) DEM simulations of the particle flow on a centrifugal fertilizer spreader. Powder Technol 190(3):348–360

Van Liedekerke P, Tijskens E, Ramon H (2009) Discrete element simulations of the influence of fertiliser physical properties on the spread pattern from spinning disc spreaders. Biosyst Eng 102(4):392–405

Van Liedekerke P, Piron E, Vangeyte J, Villette S, Ramon H, Tijskens E (2008) Recent results of experimentation and DEM modeling of centrifugal fertilizer spreading. Granul Matter 10(4):247–255

Villette S, Cointault F, Piron E, Chopinet B (2005) Centrifugal spreading: an analytical model for the motion of fertiliser particles on a spinning disc. Biosyst Eng 92(2):157–164

Yan X, Gu P (1996) A review of rapid prototyping technologies and systems. Computer-Aided Des 28(4):307–318

Ye H, Liu XY, Hong H (2008) Fabrication of metal matrix composites by metal injection moldinga review. J Mater Proc Technol 200(1):12–24

Zhu HP, Zhou ZY, Yang RY, Yu AB (2008) Discrete particle simulation of particulate systems: a review of major applications and findings. Chem Eng Sci 63(23):5728–5770

Zohdi TI (2007) An introduction to modeling and simulation of particulate flows, vol 4. Siam, Philadelphia

Acknowledgments

We would like to acknowledge the kindness of Dr. Van Liedekerke from the Ecole Normale Superieure and Dr. Coetzee from University of Stellenbosch, who responded promptly to all our enquiries regarding their work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Guillermo Casas and Debanjan Mukherjee have contributed equally to this work.

Appendices

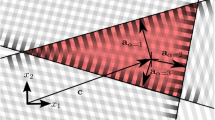

Appendix 1: The case of a conical disk with no vanes

Let us consider a conical disk of radius R spinning around its vertical axis with angular velocity \(\omega \). Let the Cartesian coordinate system \(\left\{ \mathbf {O},\mathbf {i},\mathbf {j},\mathbf {k} \right\} \) be centered at the cone’s vertex. The forces acting on the particle are

The three forces above correspond to the weight, \(\mathbf {f}_g\), the reaction against the cone, \(\mathbf {f}_R\), and the friction resistance, \(\mathbf {f}_f\). Furthermore, \(\mathbf {n}\) is the inner normal to the cone at the particle’s position, \(\mathbf {n}_{\mathbf {v}}\) the normalized (when non-zero) relative velocity of the cone with respect to the particle and \(f_R\) is the magnitude of the normal reaction to the particle’s forces against the cone. Note that \(f_R\) is a priori unknown but must be positive (no attractive forces). Consequently, the Second Law of Newton applied to the particle yields the following system:

where \(\theta \) is the standard polar angular coordinate and \(\alpha \) the cone angle (\(\alpha = 0\) for a flat disk). Since the particle is forced to move on the surface of the cone, the three coordinates x, y and z are linked by

which can readily be derived yielding

In order to be solved, this system of equations must be provided with initial conditions. Let us consider the following:

where \(r_0 \in (0, R)\), with R the radius of the disk.

Let us normalize this system of ODE’s to obtain a non-dimensional analog of it . By repeated application of direct substitution and the chain rule to the derivatives, one may obtain the following equivalent non-dimensional system:

with

and

where the dot notation has been abused to refer to the derivatives with respect to the non-dimensional time

or the units of time needed to complete a 1 radian turn by the spinning disk. The rest of the new non-dimensional parameters are

Thus distances have been normalized by the disk’s radius and the forces by the modulus of the centripetal force felt by a particle stuck to the disk’s rim edge. The variable \(\gamma \) can be interpreted as a Froude’s number for the system. From this form of the system it becomes apparent, for example, that the solution does not depend on the mass of the particle, since none of the known variables are defined in terms of it.

The system above can be solved numerically. In this work a simple forward Euler scheme has been employed, in which \(\phi _R\) is taken from the old time-step in Eqs. 58 and subsequently updated using 59. The rest of the parameter values are fixed to the quantities given in Table 3.

Appendix 2: Derivation of Eq. 19

The incremental expression provided by Thornton reads:

where the super-index n indicates the nth time-step and the operator \({\Delta }\) denotes the forward finite difference operator in time. It is direct to see that the first branch of 63 leads to the first branch of Eq. 19 by taking the limit when the time increments tend to 0. Similarly, the second branch becomes, after dividing it through by \(k_t^n\)

which yields the expression of the second branch in 19 after dividing both sides by the time increment and taking the limit when it tends to 0.

Rights and permissions

About this article

Cite this article

Casas, G., Mukherjee, D., Celigueta, M.A. et al. A modular, partitioned, discrete element framework for industrial grain distribution systems with rotating machinery. Comp. Part. Mech. 4, 181–198 (2017). https://doi.org/10.1007/s40571-015-0089-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40571-015-0089-9