Abstract

The magnetocaloric effect has seen a resurgence in interest over the last 20 years as a means towards an alternative energy efficient cooling method. This has resulted in a concerted effort to develop the so-called “giant” magnetocaloric materials with large entropy changes that often come at the expense of hysteretic behavior. But do the gains offset the disadvantages? In this paper, we review the relationship between the latent heat of several giant magnetocaloric systems and the associated magnetic field hysteresis. We quantify this relationship by the parameter Δμ 0 H/ΔS L, which describes the linear relationship between field hysteresis, Δμ 0 H, and entropy change due to latent heat, ΔS L. The general trends observed in these systems suggest that itinerant magnets appear to consistently show large ΔS L accompanied by small Δμ 0 H (Δμ 0 H/ΔS L = 0.02 ± 0.01 T/(J K−1 kg−1)), compared to local moment systems, which show significantly larger Δμ 0 H as ΔS L increases (Δμ 0 H/ΔS L = 0.14 ± 0.06 T/(J K−1 kg−1)).

Similar content being viewed by others

Introduction

In magnetic materials the application of a magnetic field under adiabatic conditions can result in heating due to the magnetocaloric effect, where a reduction in magnetic entropy results in an increase of lattice entropy. This suggests the possibility of a cyclic process to achieve cooling, a technology that has the advantages of an absence of greenhouse gases and a potential increase in engine system efficiency compared to conventional vapour compression systems.[1] While utilisation of the magnetocaloric effect was proposed by Debye[2] and Giauque and MacDougall[3] for cooling below 1 K (−272 °C) in the early twentieth century, it was not until the seminal papers by Brown,[4] and Pecharsky and Gschneidner[5] that room temperature magnetic refrigeration started to be considered a viable application.

Almost two decades on, there are now a handful of materials that have been identified as suitable candidates for solid-state refrigeration. For the most part these material systems are described as exhibiting a giant magnetocaloric effect (GMCE); typically defined as an entropy change that exceeds that of the standard benchmark material, Gd. A common feature of such GMCE materials is magneto-volume or magneto-structural coupling that results in field and thermal hysteresis, an example of which can be found in Gd5(Ge1−x Si x )4. In this material system, an appropriate choice of Si content (x = 0.5) produces an orthorhombic to monoclinic structural transition that coincides with a ferromagnetic (FM) to paramagnetic (PM) transition.[6] While the entropy change at this field driven phase transition is promising (ΔS ~ 15 J K−1 kg−1), this magnitude of entropy change requires large operating fields (~2 to 5 T) and the system shows significant field hysteresis (Δμ 0 H ~ 1 T). In order to develop future attractive materials for use in a commercial solid-state refrigeration device, a compromise needs to be reached between the magnitude of ΔS, the required magnetic field, material fatigue and hysteretic losses.

In this paper, the general characteristics of the phase transition in a collection of material systems considered interesting with regards to applications of the magnetocaloric effect will be discussed. The magneto-volume, structural and elastic coupling in these material systems that leads to a moderate or giant magnetocaloric effect will also be considered in light of the associated detrimental hysteresis and its relationship with the development of latent heat.

Experimental

The full details of preparation routes for each of the samples discussed in this paper are reported elsewhere. Single crystal Gd5Ge2Si2 was prepared by the Bridgman method;[7] DyCo2 was prepared by arc melting;[8] the La(Fe,Si)13 bulk ingots were prepared by arc melting followed by annealing at 1323 K (1596 °C) for 7 days; the Co(Mn1−x Fe x )(Si1−y Ge y ) alloys were prepared by induction melting followed by annealing at 1223 K (1496 °C);[9] Mn1.95SbCr0.05 was prepared by arc melting;[10] La0.67Ca0.33MnO3 and RMnO3 were prepared by standard solid-state methods.[11,12]

Magnetization measurements were carried out using a Quantum Design vibrating sample magnetometer (VSM) for temperatures ranging from 77 K to 300 K (−196 °C to 27 °C) and at a field sweep rate of 0.5 T/min.

Microcalorimetry measurements were obtained for 100 μm fragments using a commercial Xensor (TCG-3880) SiN membrane gauge that has been adapted to work as an ac calorimeter[13] or an adiabatic temperature probe[14] in a cryostat capable of 0 to 8 T and 4.2 K to 295 K (−268.9 °C to 22 °C). (The sample size is typically limited to the size of the heater on the SiN chip: 50 × 100 μm.) As an ac calorimeter the heat capacity, C p, is measured by the application of an ac temperature modulation to the sample while held in He exchange gas. The solution to the heat transfer equation yields C p of the sample as a function of the phase and amplitude of the resultant thermal modulation (with respect to the source signal). Due to the nature of the ac technique, it measures C p alone, and not the latent heat, ΔQ L. While any latent heat that occurs on first driving the phase transition may be registered, as it is neither reversible nor necessarily in phase with the temperature modulation, it will not yield a repeatable measurement.[15] In order to fully sample the latent heat, a separate measurement is required: the adiabatic temperature probe.[14] When operated in this mode, the helium exchange gas is evacuated and the temperature change due to a change in applied magnetic field is registered. The noise floor of this measurement is of the order of 1 μV, which is equivalent to 1 nJ.

Characteristics of the Continuous Phase Transition

The Ehrenfest classification of phase transitions defines the ‘order’ of a phase transition by the order of the derivative after which the Gibbs function exhibits a discontinuity.[16] In a simple magnetic system the Gibbs function can be written as:

where U is the internal energy, T the temperature, S the entropy, H the applied magnetic field and M the magnetization.

When Eq. [1] is differentiated with respect to temperature (at constant field) we obtain

where the second term is equivalent to heat capacity and the third term is equivalent to the derivative of the magnetization with respect to temperature. Thus, a discontinuity in the measurement of heat capacity (i.e., latent heat) is expected at a first-order phase transition. In a similar way, the magnetization as a function of temperature will present a discontinuity at a first-order phase transition when differentiated with respect to temperature (or indeed field at fixed temperature). Higher order phase transitions would exhibit a discontinuity only when further differentiating with respect to field or temperature and are referred to here as ‘continuous’, the aim being to distinguish between systems with and without latent heat.

Gd was chosen to demonstrate the characteristics of a magnetocaloric (MC) material which exhibits a continuous phase transition. Due to an ordering temperature close to room temperature (T c = 294 K (21 °C)), and a large magnetic moment (M sat = 7.43 μ B/Gd), this material is often used as a benchmark to compare other MC materials against.[17] Figure 1 shows some of the characteristic features of the phase transition, which includes:

-

(a)

A continuous change in magnetic moment,

-

(b)

Good agreement with the Curie–Weiss relationship for inverse susceptibility,

-

(c)

Continuous changes in the heat capacity as a function of field.

It should be noted that while heat capacity measurements are often presented as a function of temperature, we instead display them here with respect to field. This is in order to complement the latent heat data presented later. Also, for measurements close to room temperature, small changes in the heat capacity might be observed due to sample movement (Figure 1(b) at 296 K (23 °C)) as the adhesion of the thermal grease used to fix the sample onto the membrane starts to decrease. This results in the small hysteresis observed in Figure 1(b) where it would otherwise not be expected.

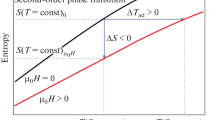

Mechanisms for the Onset of the First-Order Phase Transition

For the majority of MC materials studied (normal magnetocaloric effect), the magnetic transition involves a paramagnetic (PM) to ferromagnetic (FM) change of state, which results in a change of magnetic entropy (−|ΔS M|). Due to conservation of entropy, under adiabatic conditions this decrease in magnetic entropy gives rise to a change of temperature (+|ΔT ad|). In the absence of volume effects and structural phase transitions, the PM–FM phase transition is expected to be continuous;[18] however, this would limit the maximum achievable entropy change, and thus the operating power of the ‘refrigerant’. In order to maximise the achievable entropy change, efforts have been focussed on seeking a material that has one or more of the following:

-

(a)

A coupled structural transition (e.g., Gd5Ge2Si2 changes from an orthorhombic FM to monoclinic PM,[6])

-

(b)

Strong magneto-elastic coupling (e.g., competing exchange interactions in CoMnSi,[19] or the Jahn–Teller distortion in manganites[20]),

-

(c)

An associated change in volume, i.e., magneto-volume coupling (e.g., La(Fe,Si)13 exhibits a volume change, ΔV/V, of ~1 pct[21]).

In each case, the energy barrier that results in a first-order phase transition is due to some change in the crystal lattice that occurs alongside a magnetic change of state.[18]

The major advantage of the microcalorimetry technique presented here is that the first order characteristics of the phase transition (i.e., latent heat, ΔQ L) can be separated from continuous changes in heat capacity. While other techniques such as differential scanning calorimetry can be used to estimate ΔQ L, this often also includes disorder broadening of the phase transition that makes it difficult to distinguish between the actual latent heat and gradual changes in the heat capacity for complex phase transitions. The size of the sample measured using this technique is one factor that limits the averaging effect of disorder broadening, another is the thermal modulation technique itself. Overall, this results in an independent measure of how much the total entropy change, ΔS tot, increases as latent heat is introduced, while enabling correlation of ΔQ L, with the observed hysteresis of the phase transition, Δμ 0 H. When studying the material system in this way it will generally fall under one of two cases (or a combination of the two), as outlined in the following sections.

Case 1: Step-Like Changes in Heat Capacity

For strong magneto-structural coupling, the change in magnetic moment is often sharp with respect to field or temperature. An example of such a first-order phase transition is given in Figure 2. Here, the sample is single crystal Gd5Ge2Si2, which exhibits a co-incident magnetic (FM–PM) and structural (orthorhombic–monoclinic) change of state in response to magnetic field or temperature. Although the bulk M(H) loop shown in Figure 2(a) is broad with respect to field, Hall probe imaging of the surface confirmed that locally, the magnetic moment switches sharply.[22] This local change in moment is reflected in the latent heat data, ΔQ L, of Figure 2(d), which indicates multiple nucleation(s) of FM phase over a range of critical fields. The corresponding change in heat capacity shown in Figure 2(c) exhibits a step-like change that occurs over the same field window as the latent heat, ΔQ L. As a check of this measurement, we have compared measured values against independent data.

(a) Typical M(H) loop for the Gd5Ge2Si2 single crystal with (b) the corresponding Curie–Weiss plot as a function of temperature. (c), (d) Microcalorimetry data taken for the Gd5Si2Ge2 single crystal with the b-axis aligned with the magnetic field. The arrows here indicate the direction of field sweep for each measurement. (c) Change in heat capacity as a function of field, where the dotted circles highlight small (irreproducible) artefacts due to latent heat. (d) Corresponding latent heat of the field-driven phase transition

The latent heat contribution to the total entropy change at a given temperature, ΔS L(T), can be obtained by finding the sum of ΔQ L and dividing by temperature, T:

For the Gd5Ge2Si2 single crystal this results in a value of ΔS L = 6.39 ± 0.3 J K−1 kg−1 at 285 K (12 °C), compared to the total entropy change at this temperature of ΔS tot = 12.5 ± 0.6 J K−1 kg−1.[23] This value agrees well with the structural contribution determined by Liu et al.[24] and Pecharsky et al.[25] to be between 40 and 60 pct of ΔS tot.

In contrast to the example of a continuous phase transition, this first-order phase transition shows:

-

(a)

A continuous change in bulk magnetic moment that is comprised of multiple sharp changes in the local magnetic moment (nucleation), with slightly different critical fields (Figure 2(a)).

-

(b)

A linear trend in the Curie–Weiss plot (inverse susceptibility) away from T c, and then a departure from linearity with a sharp drop to zero at T c (Figure 2(b)),

-

(c)

A step-like change in the heat capacity accompanied by latent heat.

Typically, with Case 1 phase transitions, the latent heat and change in heat capacity are only weakly dependant on temperature and where there are changes in the magnitude of the latent heat it is not directly reflected in the heat capacity.

Case 2: Coupled Heat Capacity and Latent Heat Behavior

Case 2 behavior is typically observed in itinerant metamagnets where the first-order phase transition is often signalled by S-shaped M(H) loops, as can be seen in Figure 3(a). One example of an itinerant metamagnet is the LaFe13−x Si x material system, which exhibits volume changes of the order of 1 pct at T c; it is this large volume change that leads to the energy barrier required for a first-order phase transition.[18] As the silicon content (x) is decreased, the volume change increases and the phase transition becomes more first order. The result is an increase of the Curie temperature, T c, with respect to the transition temperature in the absence of a volume change, T 0. (This corresponds to a divergence of the Curie–Weiss plot due to the volume change at the phase transition, as seen in Figure 3(b); a property that was highlighted by Bean and Rodbell[18] in their work on magneto-volume-driven first-order phase transitions.)

(a) M(H) loops for LaFe11.44Si1.56 at increments of 2.5 K (−270.5 °C) (where the S-shaped curve moves to higher fields as the temperature is increased, as indicated by the arrow), and (b) the corresponding Curie–Weiss plots for LaFe11.44Si1.56 and LaFe11.8Si1.2. Dashed lines indicate linear behavior of the Curie–Weiss plot at temperatures far above T c that were used to estimate T o. The dotted line for x = 1.2 indicates the linear behavior of the Curie–Weiss plot close to T c. (See text for details.) (c) Change in heat capacity and (d) latent heat measurements for LaFe11.44Si1.56, where the general trend(s) with regards to the magnitude of these measurements are indicated by arrows

As with the previous examples, the characteristic features of this type of phase transition include:

-

(a)

A continuous change in magnetic moment (Figure 3(a)),

-

(b)

Divergence of the inverse susceptibility from the linear behavior expected by the Curie–Weiss law (Figure 3(b)), indicating two different Curie temperatures: T o (in the absence of a volume change) and T c (the observed Curie temperature),

-

(c)

A large change in the heat capacity (ΔC > 100 pct) accompanied by latent heat, both of which change dramatically with the increasing temperature (Figure 3(c) and (d)).

Typically with Case 2 phase transitions the field-driven latent heat is sensitive to increasing temperature, and this is also reflected in the change in heat capacity. Another example of this type of phase transition is the RCo2 material system (where R is a rare earth);[26] similar features were observed for R = Dy.[8] In each case, as the temperature is increased, the phase transition is driven towards continuous behavior, where:

-

(a)

The hysteresis decreases,

-

(b)

The magnitude of the latent heat decreases (see arrow indicator in Figure 3(d)),

-

(c)

The amplitude of the heat capacity at the phase transition changes non-monotonically (see arrow indicators in Figure 3(c)).

The shape of the heat capacity curve is also significantly different to both continuous and Case 1 phase transitions. For example, in Figure 3(c) a peak in C p can be observed (that in a measurement that does not separate the contributions might be mistakenly attributed to latent heat) that moves to higher magnetic fields as the temperature is increased. Another important point to note is that the magnitude of the change in heat capacity is significantly larger for Case 2 phase transitions. In addition, these changes can exceed observations for continuous phase transitions (such as Gd in Figure 1(b)).

Exceptions

While the characteristics of the Case 1 and Case 2 first-order phase transitions discussed in Sections IV–A and IV–B were fairly straightforward, it is possible that other material systems may exhibit a combination of the two (characteristics). An example of this is the antiferromagnetic (AFM)-FM phase transition of CoMnSi (Figure 4), which exhibits an inverse magnetocaloric effect[27] (cooling on field increase). Here, while the phase transition largely exhibits Case 1 characteristics, there are indicators of a precursor increase in the heat capacity, similar to that seen in Case 2. The phase transition is also particularly sensitive to changing temperature.

(a) Change in heat capacity for CoMnSi0.92Ge0.08, which indicates both a step-like change in C p (Case 1) as well as the signature (gradual) increase in C p as the transition is approached (Case 2). The arrows on the data for 190 K (−83 °C) indicate the direction of magnetic field sweep. (b) Corresponding latent heat data for CoMnSi0.92Ge0.08, where the arrows indicate the direction of field sweep. Notice that here the latent heat is negative on increasing magnetic field, unlike in Figs. 2 and 3 where it was positive

Disorder broadening[28] (of the phase transition) may also make it difficult to identify whether it is first order (or not). While it is common to use the Banerjee criterion to determine whether a phase transition is first order, as this criterion is based on the mean field approximation it is likely to break down in the case of itinerant magnets where spin fluctuations may play a larger role.[8,12]

Hysteresis as a Function of Entropy Gain

The relationship between Δμ 0 H and ΔS L in different systems provides insight into the relationship between energy barriers and latent heat. Uniquely, the separation of entropy change due to latent heat, ΔS L and heat capacity, ΔS HC (where ΔS tot = ΔS L + ΔS HC), in fragments approaching the nucleation size of the phase transition enables determination of the parameter Δμ 0H/ΔS L, as shown in Figure 5. In this case, the hysteresis, Δμ 0 H, was determined as the difference in applied magnetic field of features observed in latent heat measurements and ΔS L was determined using Eq. [3] (or where the latent heat was distributed with respect to field, such as in Figure 3(d), the method outlined in References 8 and 12 was used). While the effect of extrinsic hysteresis (due to temperature change or strain) has been mentioned elsewhere,[29] due to the limited size of the microcalorimetry samples this is often not a consideration. In either case, latent heat measurements were obtained for field sweep rates of 0.5 and 0.1 T/min, which exhibited no significant difference in Δμ 0 H (therefore, it can be assumed that the extrinsic hysteresis was negligible). Before discussing the general features of Figure 5 further, however, the potential impact of additional factors on the intrinsic hysteresis will be discussed.

Relationship between entropy change due to latent heat, ΔS L, and hysteresis, Δμ 0 H. (a) Impact of strain, fragmentation and anisotropy on the observed Δμ 0 H(ΔS L) relationship for the Co(Mn1−x Fe x )(Si1−y Ge y ) material system. (b) General trend(s) observed for the material systems presented here, where magneto-structural coupling (Case 1) leads to Δμ 0 H/ΔS L = 0.14 ± 0.06 T/(J K−1 kg−1) and magneto-elastic coupling in La(Fe,Si)13 and RMnO3 (Case 2) leads to Δμ 0 H/ΔS L = 0.02 ± 0.01 T/(J K−1 kg−1)

In Figure 5(a), some results for the CoMn1−x Fe x Si1−y Ge y alloy (which is sensitive to strain and has strong magnetocrystalline anisotropy), are shown. In this case, while each individual measurement followed a linear trend (aside from the Fe doped sample, which will be discussed later), it appears that the gradient of this line, Δμ 0 H/ΔS L, was also sensitive to strain and field orientation. For example, by quenching the CoMnSi ingot after melting, strain is introduced that inhibits the phase transition. This results in an increase in Δμ 0 H/ΔS L of the quenched CoMnSi (quenched).[30] Additionally, as the size of the fragment measured in microcalorimetry is of the order of a single crystallite it is possible that this could be aligned according to the easy axis of magnetization resulting in a decrease of Δμ 0 H/ΔS L (Ge doped).[31] Lastly, it was also shown that for the Fe doped CoMnSi at low temperatures the structural contribution to entropy change continues to increase, while the magnetic entropy change has saturated. As these two contributions compete in this material system, this results in a decrease of the total entropy change, and indeed the latent heat, thus Δμ 0 H/ΔS L is no longer constant (Fe doped).[32] Overall, while these additional factors can influence the absolute value of Δμ 0 H/ΔS L, each of these examples still followed a general linear trend.

In Figure 5(b), the Δμ 0 H(ΔS L) for a larger set of samples that exhibit Case 1 and Case 2 characteristics is shown. Notice that this data exhibits two (general) linear trends

-

Case 1—Where magneto-structural or magneto-exchange effects typically dominate, Δμ 0 H/ΔS L = 0.14 ± 0.06 T K kg J−1.

-

Case 2—Where magneto-volume or magneto-elastic effects typically dominate, Δμ 0 H/ΔS L = 0.02 ± 0.01 T K kg J−1.

Note that the large error on the value of Δμ 0 H/ΔS L here is to encompass the selection of materials shown. This result suggests that although magneto-structural coupling could, in principle, lead to larger entropy changes, the associated hysteresis is significantly large. In particular, magneto-structural coupling appears to be less attractive in comparison to other routes of introducing first-order behavior, such as magneto-volume or magneto-elastic coupling: there is a fivefold increase of the value of Δμ 0 H/ΔS L for Case 1 phase transitions compared to Case 2 phase transitions.

Conclusions

We have shown that for first-order magnetic phase transitions the general characteristics can fall into one of two categories: Case 1, where magneto-structural coupling probably plays a large role and the latent heat is largely independent of temperature; and Case 2 where an itinerant metamagnetic phase transition occurs and the heat capacity and latent heat both change dramatically with temperature. Once identified, it appears that Case 1 phase transitions exhibit larger increases of Δμ 0 H with respect to ΔS L, compared to Case 2 phase transitions (Δμ 0 H/ΔS L = 0.14 ± 0.06 and 0.02 ± 0.01 T K kg J−1, respectively).

The results of this work indicate that the largest gain is to be had in itinerant magnets (that typically exhibit Case 2 characteristics), where spin fluctuations may play a role in lowering the energy barrier to the phase transition. An additional benefit is the ease with which they can be tuned with respect to field, temperature, or composition in order to approach the tri-critical point.[1] Overall, this suggests that material systems which exhibit an easily tunable critical point (i.e., where the phase transition moves from continuous to first order) are desirable not only because they enable better control of the desired properties (ΔS, ΔT ad, and T c), but also because of the lower hysteresis (Δμ 0 H) associated with them.

While the last 20 years have seen an increase in known material systems that exhibit favourable MC properties, the detrimental impact of hysteresis, durability and poor thermal conductivity are starting to become apparent.[33–36] This has resulted in a shift of focus towards material systems that lie closer to the critical point: on the cusp of first-order and continuous phase transitions. As this technology approaches maturity, it is reasonable to speculate that focus will continue to shift towards tri-critical magnets that can be easily shaped, react well with thermal engineering, and respond rapidly to changing magnetic field.

References

K.G. Sandeman, Scripta Mater. 67, 566–71 (2012)

P. Debye, Ann. Phys. 81, 1154–60 (1926)

W.F. Giauque, D.P. MacDougall, Phys. Rev. 43, 768–768 (1933)

G.V. Brown, J. Appl. Phys. 47, 3673–80 (1976)

V.K. Pecharsky, K.A. Gschneidner Jr., Phys. Rev. Lett. 78, 4494–97 (1997)

V.K. Pecharsky, K.A. Gschneidner Jr., Adv. Mater. 13, 683–86 (2001)

H. Tang, A.O. Pecharsky, D.L. Schlagel, T.A. Lograsso, V.K. Pecharsky, and K.A. Gschneidner, Jr.: J. Appl. Phys., 2003, vol. 93, pp. 8298–300.

K. Morrison, A. Dupas, A.D. Caplin, L.F. Cohen, Y. Mudryk, V.K. Pecharsky, and K.A. Gschneidner: Phys. Rev. B, 2013, vol. 87, pp. 134421-1–134421-6.

K.G. Sandeman, R. Daou, S. Özcan, J.H. Durrell, N.D. Mathur, and D.J. Fray: Phys. Rev. B, 2006, vol. 74, pp. 224436-1–224436-6.

L. Caron, X.F. Miao, J.C.P. Klaasse, S. Gama, and E. Brück: arXiv: 1307.3194 [cond-mat.mtrl-sci]

K. Morrison, L.F. Cohen, A. Berenov, Mater. Res. Soc. Symp. Proc. 1310, 31–40 (2011)

K. Morrison, M. Bratko, J. Turcaud, A.D. Caplin, L.F. Cohen, and A. Berenov: Rev. Sci. Instrum., 2012, vol. 83, pp. 033901-1–033901-6.

A.A. Minkaov, S.B. Roy, Y.V. Bugoslavsky, and L.F. Cohen: Rev. Sci. Instrum., 2005, vol. 76, pp. 043906-1–043906-9.

Y. Miyoshi, K. Morrison, J.D. Moore, A.D. Caplin, and L.F. Cohen: Rev. Sci. Instrum., 2008, vol. 79, pp. 074901-1–074901-3.

K. Morrison, J. Lyubina, K.G. Sandeman, L.F. Cohen, A.D. Caplin, J.D. Moore, O. Gutfleisch, Phil. Mag. 92, 292–303 (2012)

C.J. Adkins, Equilibrium Thermodynamics, 3rd edn. (Cambridge University Press, Cambridge, 1983), pp. 180–205

K.A. Gschneidner, Jr., V.K. Pecharsky, and A.O. Tsokol: Rep. Prog. Phys., 2005, vol. 68, pp. 1479–539.

C.P. Bean, D.S. Rodbell, Phys. Rev. 126, 104–15 (1962)

A. Barcza, Z. Gercsi, K.S. Knight, and K.G. Sandeman: Phys. Rev. B, 2010, vol. 104, pp. 247202-1–247202-4.

H.A. Jahn, E. Teller, Proc. R. Soc. Lond. A 161, 220–35 (1937)

A. Fujita, Y. Akamatsu, K. Fukamichi, J. Appl. Phys. 86, 4766–68 (1999)

J.D. Moore, K. Morrison, G.K. Perkins, L.F. Cohen, D.L. Schlagel, T.A. Lograsso, K.A. Gschneidner Jr., V.K. Pecharsky, Adv. Mater. 21, 3780–83 (2009)

K. Morrison, L.F. Cohen, V.K. Pecharsky, K.A. Gschneidner Jr., Mater. Res. Soc. Symp. Proc. 1310, 47–53 (2011)

G.J. Liu, J.R. Sun, J. Lin, Y.W. Xie, T.Y. Zhao, H.W. Zhang, and B.G. Shen: Appl. Phys. Lett., 2006, vol. 88, pp. 212505-1–212505-3.

V.K. Pecharsky, K.A. Gschneidner Jr., Y. Mudryk, D. Paudyal, J. Magn. Magn. Mater. 321, 3541–47 (2009)

E. Gratz, A.S. Markosyan, J. Phys. Condens. Matter 13, R385–R413 (2001)

T. Krenke, E. Duman, M. Acet, E.F. Wassermann, X. Moya, L. Mañosa, A. Planes, Nat. Mater. 4, 450–54 (2005)

Y. Imry and M. Wortis: Phys. Rev. B, 1979, vol. 19, pp. 3580–85.

J.D. Moore, K. Morrison, K.G. Sandeman, M. Katter, and L.F. Cohen: Appl. Phys. Lett., 2009, vol. 95, pp. 252504-1–252504-3.

K. Morrison, J.D. Moore, K.G. Sandeman, A.D. Caplin, L.F. Cohen, A. Barcza, M.K. Chattopadhyay, and S.B. Roy: J. Phys. D Appl. Phys., 2010, vol. 43, art. id 195001, pp. 1–8.

K.Morrison, J.D. Moore, K.G. Sandeman, A.D. Caplin, and L.F. Cohen: Phys. Rev. B, 2009, vol. 79, pp. 134408-1–134408-5.

K. Morrison, Y. Miyoshi, J.D. Moore, A.D. Caplin, L.F. Cohen, A. Barcza, and K.G. Sandeman: Phys. Rev. B, 2008, vol. 78, pp. 134418-1–134418-6.

J. Lyubina, R. Schäfer, N. Martin, L. Schultz, O. Gutfleisch, Adv. Mater. 22, 3735–39 (2010)

A. Smith, C.R.H. Bahl, R. Bjørk, K. Engelbrecht, K.K. Nielsen, N. Pryds, Adv. Energy Mater. 2, 1288–1318 (2012)

J.A. Turcaud, K. Morrison, A. Berenov, N.Mc.N. Alford, K.G. Sandeman, L.F. Cohen, Scripta Mater. 68, 510–13 (2013)

H. Zhang, Y.J. Sun, E. Niu, F.X. Hu, J.R. Sun, and B.G. Shen: Appl. Phys. Lett., 2014, vol. 104, pp. 062407-1–062407-4.

Acknowledgments

The authors would like to express their gratitude to the various individuals who provided us with good quality samples, without which this paper would not have been possible. In particular: T. A. Lograsso and Y. Mudryk of Ames Laboratory (Gd5Ge2Si2, DyCo2), K. G. Sandeman (CoMnSi based alloys), J. Lyubina and O. Gutfleisch (La(Fe,Si)13), L. Caron (Mn1.95SbCr0.05), J. Turcaud (La0.67Ca0.33MnO3) and A. Berenov (RMnO3). L. F. C. acknowledges funding for this work from EPSRC EP/G060940/1.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted January 29, 2014.

Rights and permissions

About this article

Cite this article

Morrison, K., Cohen, L.F. Overview of the Characteristic Features of the Magnetic Phase Transition with Regards to the Magnetocaloric Effect: the Hidden Relationship Between Hysteresis and Latent Heat. Metallurgical and Materials Transactions E 1, 153–159 (2014). https://doi.org/10.1007/s40553-014-0015-8

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40553-014-0015-8