Abstract

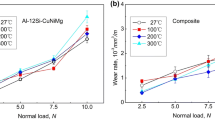

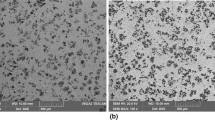

Carbon fibers reinforced lithium aluminosilicate matrix composites (Cf/LAS) were prepared by slurry infiltration combined with a hot press procedure. The friction, wear behavior, and wear mechanisms of Cf/LAS composites under dry sliding conditions were investigated. The results show that the coefficient of friction (COF) initially increased with the increase in carbon fiber content, and reached the maximum value of 0.20 for the 33%Cf/LAS composite. The COF increased sharply with increasing sample temperature from RT to 300 °C. The COF remained stable in the temperature range of 300–500 °C. The two wear mechanisms of LAS glassceramics are fatigue wear and abrasive wear. The Cf/LAS composites demonstrate slight spalling and shallow scratches. These results show that carbon fibers improve the mechanical properties and wear resistance of Cf/LAS composites.

Article PDF

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Abbreviations

- f(N):

-

$$V = \frac{1}{{2\pi Rn}} \times \frac{1}{f} \times \frac{w}{\rho }$$

- f(N):

-

Normal load

- V(mm3⊙N−1⊙m−1):

-

Wear rate

- R :

-

Distance between the specimen center and rotating disc center (namely friction radius 3 mm)

- n :

-

Number of rotations of the disc

- w :

-

Weight loss of specimens during friction process

- π:

-

Density of the tested specimens

$${\sigma _H} = \sqrt {\frac{{{F_n}\left( {\frac{1}{{{\rho _1}}} \times \frac{1}{{{\rho _2}}}} \right)}}{{\pi L\left( {\frac{{1 - \mu _1^2}}{{{E_1}}} + \frac{{1 - \mu _2^2}}{{{E_2}}}} \right)}}}$$ - ∂H :

-

(MPa) Contact stress

- Fn(N):

-

Normal stress

- L(mm):

-

Contact line length

- π1,π2 (mm):

-

Radius of curvature of the two contact materials at the contact point

- ±:

-

+ is used for external contact, - for internal contact

- gM1,gM2 :

-

Poisson’s ratio of the two contact materials

- E1, E2(MPa):

-

Elastic modulus of the two contact materials

References

Wright N A, Kukureka S N. Wear testing and measurement techniques for polymer composite gears. Wear251(1-12): 1567–1578 (2001)

Mao K. A new approach for polymer composite gear design. Wear262(3-4): 432–441 (2007)

Tunalioglu M S, Tuç B. Theoretical and experimental investigation of wear in internal gears. Wear309(1-2): 208–215 (2014)

Fang Y, Fan H Z, Song J J, Zhang Y S, Hu L T. Surface engineering design of Al2O3/Mo self-lubricating structural ceramics-Part II: Continuous lubrication effects of a threedimensional lubricating layer at temperatures from 25 to 800 °C. Wear360-361: 97–103 (2016)

Tatarko P, Kašiarová M, Chlup Z, Dusza J, Šajgalík P, Vávra I. Influence of rare-earth oxide additives and SiC nanoparticles on the wear behaviour of Si3N4-based composites at temperatures up to 900 °C. Wear300(1-2): 155–162 (2013)

Kim J H, Venkata M K B, Hong S H, Kim H D. Fabrication of silicon nitride nanoceramics and their tribological properties. J Am Ceram Soc93(5): 1461–1466 (2010)

Wang C, Li K N, Chen H, Ma X M. Research progress of processing technology for fiber reinforced ceramic matrix composites. Aeronaut Manuf Technol (3): 55–60 (2016)

Hu A M, Li M, Mao D L. Growth behavior, morphology and properties of lithium aluminosilicate glass ceramics with different amount of CaO, MgO and TiO2 additive. Ceram Int34(6): 1393–1397 (2008)

Zocca A, Gomes C M, Bernardo E, Müller R, Günster J, Colombo P. LAS glass-ceramic scaffolds by three-dimensional printing. J Eur Ceram Soc33(9): 1525–1533 (2013)

Soares V O, Peitl O, Zanotto E D. New sintered Li2OAl2O3-SiO2 ultra-low expansion glass-ceramic. J Am Ceram Soc96(4): 1143–1149 (2013)

Dai N L, Luan H X, Liu Z J, Sheng Y B, Peng J G, Jiang Z W, Li H Q, Yang L Y, Li J Y. Broadband NIR luminescence of Bi-doped Li2O-Al2O3-SiO2 glass-ceramics. J Non-Cryst Solids358(22): 2970–2973 (2012)

Beall G H, Pinckney L R. Nanophase glass-ceramics. J Am Ceram Soc82(1): 5–16 (1999)

Pelletant A, Reveron H, Chêvalier J, Fantozzi G, Blanchard L, Guinot F, Falzon F. Grain size dependence of pure ß-eucryptite thermal expansion coefficient. Mater Lett66(1): 68–71 (2012)

García-Moreno O, Kriven W M, Moya J S, Torrecillas R. Alumina region of the lithium aluminosilicate system: a new window for temperature ultrastable materials design. J Am Ceram Soc96(7): 2039–2041 (2013)

Chen J C, Huang G C, Hu C, Weng J P. Synthesis of negative-thermal-expansion ZrW2O8 substrates. Scr Mater49(3): 261–266 (2003)

Benavente R, Salvador M D, García-Moreno O, Peñaranda-Foix F L, Catalá-Civera J M, Borrel l A. Microwave, spark plasma and conventional sintering to obtain controlled thermal expansion ß-eucryptite materials. Int J Appl Ceram Tec12(S2): E187–E193 (2015)

Villalobos G R, Speyer R F. Electrical resistance as a tool in determining the failure of fibres in a nicalon-reinforced LAS glass-ceramic with Ta2O5 additions. J Mater Sci32(21): 5577–5581(1997)

Fox A G, Hunt R K, Maldia L C, Wang S W. Hot sodium sulphate corrosion of a Nicalon silicon carbide fibre-reinforced lithium aluminosilicate glass-ceramic matrix composite. J Mater Sci30(24): 6161–6170 (1995)

Drissi-Habti M. Assessment of the mechanical behaviour of SiC fibre reinforced magnesium lithium aluminosilicate glassceramic matrix composite tested under uniaxial tensile loading. J Eur Ceram Soc17(1): 33–39 (1997)

Kim K S, Jang H M, Baik Y K. SiC fibre-reinforced lithium aluminosilicate matrix composites fabricated by the Sol-Gel process. J Mater Sci30(4): 1009–1017 (1995)

Hasselman D P H, Donaldson K Y, Thomas JR J R, Brennan J J. Thermal conductivity of vapor-liquid-solid and vapor-solid silicon carbide whisker-reinforced lithium aluminosilicate glass-ceramic composites. J Am Ceram Soc79(3): 742–748 (1996)

Prewo K M, Brennan J J, Layden G K. Fiber reinforced glasses and glass-ceramics for high-performance applications. Am Ceram Soc Bull65(2): 305–322 (1986)

Phillips D C, Sambell R A J, Bowen D H. The mechanical properties of carbon fibre reinforced Pyrex glass. J Mater Sci7(12): 1454–1464 (1972)

Sambell R A J, Bowen D H, Phillips D C. Carbon fibre composites with ceramic and glass matrices. J Mater Sci7(6): 663–675 (1972)

Phillips D C. Interfacial bonding and the toughness of carbon fibre reinforced glass and glass-ceramics. J Mater Sci9(11): 1847–1854 (1974)

Seghi S, Fabio B, Economy J. Carbon/carbon-boron nitride composites with improved wear resistance compared to carbon/carbon. Carbon42(15): 3043–3048 (2004)

Zhou X, Zhu D M, Xie Q, Luo F, Zhou W C. Friction and wear properties of C/C-SiC braking composites. Ceram Int38(3): 2467–2473 (2012)

Hyuga H, Jones M I, Hirao K, Yamauchi Y. Influence of carbon fibre content on the processing and tribological properties of silicon nitride/carbon fibre composites. J Eur Ceram Soc24(5): 877–885 (2004)

Xia L, Zhao G L, Huang X X, Wen G W, Dai J Q, Zhao Z H. Effect of graphite intercalation compounds in the interfacial zone on the mechanical and thermal properties of unidirectional carbon fiber reinforced spodumene composite. Acta Mater61(9): 3522–3532 (2013)

Xia L, Wang X Y, Wen G W, Li X, Qin C L, Song L. Influence of brick pattern interface structure on mechanical properties of continuous carbon fiber reinforced lithium aluminosilicate glass-ceramics matrix composites. J Eur Ceram Soc32(2): 409–418 (2012)

Mazo M A, Tamayo A, Rubio J. Advanced silicon oxycarbidecarbon composites for high temperature resistant friction systems. J Eur Ceram Soc36(10): 2443–2452 (2016)

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Grant Nos. 51621091, 51872058, 51772060, and 51972078) and Key Laboratory of Advanced Structural-Functional Integration Materials & Green Manufacturing Technology, Harbin Institute of Technology, China.

Author information

Authors and Affiliations

Corresponding author

Additional information

Long XIA. He received his M.S. degree in materials physics and chemistry from Lanzhou University in 2004 and Ph.D. degree in materials science from Harbin Institute of Technology in 2013. He joined the Department of Materials Science at Harbin Institute of Technology at Weihai from 2004. His current position is an associate professor and the deputy director of the Department of Materials Science. His research areas cover the tribology of ceramics matrix composites, interfacial phenomena and control of ceramics matrix composites.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made.

The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder.

To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Ma, H., Wu, X., Xia, L. et al. Friction and wear behavior of carbon fiber reinforced lithium aluminosilicate composites sliding against GCr15 steel. Friction 8, 1063–1072 (2020). https://doi.org/10.1007/s40544-019-0322-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40544-019-0322-2