Abstract

In stress-augmented thermal activation, the activation energy barrier that controls the rate of atomic and molecular processes is reduced by the application of stress, with the result that the rate of these processes increases exponentially with applied stress. This concept has particular relevance to Tribology, and since its development in the early twentieth century, it has been applied to develop important models of plastic flow, sliding friction, rheology, wear, and tribochemistry. This paper reviews the development of stress-augmented thermal activation and its application to all of these areas of Tribology. The strengths and limitations of the approach are then discussed and future directions considered. From the scientific point of view, the concept of stress-augmented thermal activation is important since it enables the development of models that describe macroscale tribological performance, such as friction coefficient or tribofilm formation, in terms of the structure and behaviour of individual atoms and molecules. This both helps us understand these processes at a fundamental level and also provides tools for the informed design of lubricants and surfaces.

Article PDF

Similar content being viewed by others

Avoid common mistakes on your manuscript.

References

Karman T V. Physikalische Grundlagen der Festigkeitslehre, Section 24 67–770, Sept. 1914. Art 31, of Mechanics of deformable bodies in Enzyklopädie der mathematischen Wissenschaften mit Einschluss ihrer Anwendungen, Vol. IV, Part 4, C, eds. Felix Klein and Conrad Muller, Leipzig, 1907–1914.

Prandtl L. Ein Gedankenmodell zur kinetischen Theorie der festen Körper. Z Angew Math Mech 8(2): 85–106 (1928)

Eyring H. Viscosity, plasticity, and diffusion as examples of absolute reaction rates. J Chem Phys 4(4): 283–291 (1936)

Moore W J. Physical Chemistry. 4th ed. London (UK): Longman Green & Co., 1963.

Ewell R H. The reaction rate theory of viscosity and some of its applications. J Appl Phys 9(4): 252–269 (1938)

Becker R. Über die plastizität amorpher und kristalliner fester körper. Phys Z 26: 919–925 (1925)

Kincaid J F, Eyring H, Stearn A E. The theory of absolute reaction rates and its application to viscosity and diffusion in the liquid state. Chem Rev 28(2): 301–365 (1941)

Glasstone S, Laidler K J, Eyring H. Theory of Rate Processes. New York (USA): McGraw-Hill Inc., 1941.

Ewell R H, Eyring H. Theory of the viscosity of liquids as a function of temperature and pressure. J Chem Phys 5(9): 726–736 (1937)

Powell R E, Eyring H. Mechanisms for the relaxation theory of viscosity. Nature 154(3909): 427–428 (1944)

Eyring H, Ree T, Hirai N. The viscosity of high polymers— The random walk of a group of connected segments. Proc Nat Acad Sci USA 44(12): 1213–1217 (1958)

Moore Jr W J, Eyring H. Theory of the viscosity of unimolecular films. J Chem Phys 6(7): 391–394 (1938)

Kauzmann W. Flow of solid metals from the standpoint of the chemical-rate theory. Trans Am Inst Min Metall Eng 143: 57–83 (1941)

Kauzmann W, Eyring H. The viscous flow of large molecules. J Amer Chem Soc 62(11): 3113–3125 (1940)

Tobolsky A, Eyring H. Mechanical properties of polymeric materials. J Chem Phys 11(3): 125–134 (1943)

Spikes H A, Tysoe W. On the commonality between theoretical models for fluid and solid friction, wear and tribochemistry. Tribol Lett 59(1): 21 (2015)

Schallamach A. The velocity and temperature dependence of rubber friction. Proc Phys Soc B 66(5): 386–392 (1953)

Schallamach A. Friction and abrasion of rubber. Wear 1(5): 384–417 (1958)

Bueche F. Tensile strength of plastics above the glass temperature. J Appl Phys 26(9): 1133–1140 (1955)

Bueche F. Tensile strength of plastics below the glass temperature. J Appl Phys 28(7): 784–787 (1957)

Bueche F. Mechanical degradation of high polymers. J Appl Polym Sci 4(10): 101–106 (1960)

Zhurkov S N, Narzullaev B N. Time dependence of the strength of solids. Zh Tekh Fiz 23(10): 1677–1689 (1953)

Zhurkov S N, Tomashevsky É E. Investigation of the strength of solids. Zh Tekh Fiz 25(1): 66–73 (1955)

Zhurkov S N. Kinetic concept of the strength of solids. Int J Fract Mech 1(4): 311–322 (1965)

Zhurkov S N, Korsukov V E. Atomic mechanism of fracture of solid polymers. J Polym Sci Part B Polym Phys 12(2): 385–398 (1974)

Andrade E N D C, Roscoe R. Glide in metal single crystals. Proc Phys Soc 49(2): 152–177 (1937)

Orowan E. Zur TemperaturabhÄngigkeit der Kristallplastizität. Zeitschr Phys 102(1–2): 112–118 (1936)

Orowan E. Problems of plastic gliding. Proc Phys Soc 52(1): 8–22 (1940)

De Bruyne N A. Note on viscous and plastic flow. Proc Phys Soc 53(3): 251–257 (1941)

Seitz F, Read T A. Theory of the plastic properties of solids. III. J Appl Phys 12(6): 470–486 (1941)

Gemant A. Frictional phenomena. XI: C-solids. J Appl Phys 13(11): 688–696 (1942)

Feltham P. Influence of structure on the plastic flow of steel above the A3-point. Nature 169(4310): 976(1952)

Mott N F. Dislocations, work-hardening and creep. Nature 175(4452): 365–367 (1955)

Seeger A. CXXXII. The generation of lattice defects by moving dislocations, and its application to the temperature dependence of the flow-stress of F.C.C. crystals. London Edinburgh Dublin Philos Mag J Sci 46(382): 1194–1217 (1955)

Schoeck G. The activation energy of dislocation movement. Phys Status Solidi (b) 8(2): 499–507 (1965)

Gibbs G B. The thermodynamics of thermally-activated dislocation glide. Phys Status Solidi (b) 10(2): 507–512 (1965)

Cottrell A H. The time laws of creep. J Mech Phys Solids 1(1): 53–63 (1952)

Kocks U F, Argon A S, Ashby M F. Thermodynamics and Kinetics of Slip. Oxford, New York (USA): Pergamon Press, 1975.

Antolovich S D, Armstrong R W. Plastic strain localization in metals: origins and consequences. Prog Mater Sci 59: 1–160 (2014)

Pollet J C, Burns S J. Thermally activated crack propagation—Theory. Int J Fract 13(5): 667–679 (1977)

Zerilli F J, Armstrong R W. The effect of dislocation drag on the stress-strain behavior of F.C.C. metals. Acta Metall Mater 40(8): 1803–1808 (1992)

Haward R N, Thackray G. The use of a mathematical model to describe isothermal stress-strain curves in glassy thermoplastics. Proc Roy Soc A Math Phys Eng Sci 302(1471): 453–472 (1968)

Ward I M. Review: The yield behaviour of polymers. J Mater Sci 6(11): 1397–1417 (1971)

Frisch D, Eyring H, Kincaid J F. Pressure and temperature effects on the viscosity of liquids. J Appl Phys 11(1): 75–80 (1940)

Spikes H A, Zhang J. History, origins and prediction of elastohydrodynamic friction. Tribol Lett 56(1): 1–25 (2014)

Ree T, Eyring H. Theory of non-Newtonian flow. I.Solid plastic system. J Appl Phys 26(7): 793–800 (1955)

Ree F, Ree T, Eyring H. Relaxation theory of transport problems in condensed systems. Ind Eng Chem 50(7): 1036–1040 (1958)

Maron S H, Pierce P E. Application of Ree-Eyring generalized flow theory to suspensions of spherical particles. J Colloid Sci 11(1): 80–95 (1956)

Kumar P, Khonsari M M, Bair S. Full EHL simulations using the actual Ree–Eyring model for shear-thinning lubricants. J Tribol 131(1): 011802 (2009)

Smith F W. The effect of temperature in concentrated contact lubrication. ASLE Trans 5(1): 142–148 (1962)

Plint M A. Traction in elastohydrodynamic contacts. Proc Inst Mech Eng 182(1): 300–306 (1967)

Hirst W, Moore A J. Non-Newtonian behaviour in elastohydrodynamic lubrication. Proc Roy Soc A Math Phys Eng Sci 337(1608): 101–121 (1974)

Hirst W, Moore A J. Elastohydrodynamic lubrication at high pressures. Proc Roy Soc A Math Phys Eng Sci 360(1702): 403–425 (1978)

Hirst W, Moore A J. Elastohydrodynamic lubrication at high pressures II. Non-Newtonian behaviour. Proc Roy Soc A Math Phys Eng Sci 365(1723): 537–565 (1979)

Hirst W, Moore A J. The effect of temperature on traction in elastohydrodynamic lubrication. Philos Trans Roy Soc A Math Phys Eng Sci 298(1438): 183–208 (1980)

Tevaarwerk J, Johnson K L. A simple non-linear constitutive equation for elastohydrodynamic oil films. Wear 35(2): 345–356 (1975)

Johnson K L, Tevaarwerk J L. Shear behaviour of elastohydrodynamic oil films. Proc Roy A Math Phys Eng Sci 356(1685): 215–236 (1977)

Hirst W, Richmond J W. Traction in elastohydrodynamic contacts. Proc Inst Mech Eng Part C J Mech Eng Sci 202(2): 129–144 (1988)

Evans C R, Johnson K L. The rheological properties of elastohydrodynamic lubricants. Proc Inst Mech Eng Part C J Mech Eng Sci 200(2): 303–312 (1986)

Conry T F. Thermal effects on traction in EHD lubrication. J Lubr Technol 103(4): 533–538 (1981)

Muraki M. Molecular structure of synthetic hydrocarbon oils and their rheological properties governing traction characteristics. Tribol Int 20(6): 347–354 (1987)

Sui P C, Sadeghi F. Non-Newtonian thermal elastohydrodynamic lubrication. J Tribol 113(2): 390–396 (1991)

Muraki M, Dong D. Derivation of basic rheological parameters from experimental elastohydrodynamic lubrication traction curves of low-viscosity lubricants. Proc Inst Mech Eng Part J J Eng Sci 213(1): 53–61 (1999)

Sharif K J, Morris S J, Evans H P, Snidle R W. Comparison of non-Newtonian EHL models in high sliding applications. Tribol Ser 39: 787–796 (2001)

Sharif K J, Evans H P, Snidle R W, Newall J P. Modeling of film thickness and traction in a variable ratio traction drive rig. Trans J Tribol 126(1): 92–104 (2004)

Bou-Chakra E, Cayer-Barrioz J, Mazuyer D, Jarnias F, Bouffet A. A non-Newtonian model based on Ree–Eyring theory and surface effect to predict friction in elastohydrodynamic lubrication. Tribol Int 43(9): 1674–1682 (2010)

Gutzow I, Dobreva A, Schmelzer J. Rheology of non- Newtonian glass-forming melts: Part I Flow-stress relations. J Mater Sci 28(4): 890–900 (1993)

Spikes H A. Comment on: Rheology of an ionic liquid with variable carreau exponent: A full picture by molecular simulation with experimental contribution, by Nicolas Voeltzel, Philippe Vergne, Nicolas Fillot, Nathalie Bouscharain, Laurent Joly, Tribology Letters (2016) 64: 25. Tribol Lett 65(2): 72 (2017)

Ewen J P, Gattinoni G, Zhang J, Heyes D M, Spikes H A, Dini D. On the effect of confined fluid molecular structure on nonequilibrium phase behaviour and friction. Phys Chem Chem Phys 19(27): 17883–17894 (2017)

Jadhao V, Robbins M O. Probing large viscosities in glassformers with nonequilibrium simulations. Proc Natl Acad Sci USA 114(30): 7952–7957 (2017)

Voeltzel N, Vergne P, Fillot N, Bouscharain N, Joly L. Rheology of an ionic liquid with variable Carreau exponent: A full picture by molecular simulation with experimental contribution. Tribol Lett 64(2): 25 (2016)

Voeltzel N, Vergne P, Fillot N, Bouscharain N, Joly L. Reply to the Comment on ‘Rheology of an ionic liquid with variable Carreau exponent: A full picture by molecular simulation with experimental contribution’. Tribol Lett 65(2): 73 (2017)

Miller R, Wüstneck R, Krägel J, Kretzschmar G. Dilational and shear rheology of adsorption layers at liquid interfaces. Colloid Surf A 111(1–2): 75–118 (1996)

Bartenev G M. On the theory of dry friction of rubber. Dokl Akad Nauk SSSR 96(6): 1161–1164 (1954)

Bartenev G M, El’kin A I. Friction properties of high elastic materials. Wear 8(1): 8–21 (1965)

Schallamach A. A theory of dynamic rubber friction. Wear 6(5): 375–382 (1963)

Bartenev G M, Lavrentjev V V, Konstantinova N A. The actual contact area and friction properties of elastomers under frictional contact with solid surfaces. Wear 18(6): 439–448 (1971)

Schallamach A. How does rubber slide? Wear 17(4): 301–312 (1971)

Steijn R P. Sliding experiments with polytetrafluoroethylene. ASLE Trans 11(3): 235–247 (1968)

Chernyak Y B, Leonov A I. On the theory of the adhesive friction of elastomers. Wear 108(2): 105–138 (1986)

Amuzu J K A, Briscoe B J, Tabor D. The shear properties of poly (N-alkyl methacrylates) in concentrated contacts. ASLE Trans 20(2): 152–160 (1977)

Briscoe B J, Tabor D. Shear properties of thin polymeric films. J Adhes 9(2): 145–155 (1978)

Bouhacina T, Aimé J, Gauthier S, Michel D, Heroguez V. Tribological behavior of a polymer grafted on silanized silica probed with a nanotip. Phys Rev B 56(12): 7694–7703 (1997)

Briscoe B J, Evans D C B. The shear properties of Langmuir-Blodgett layers. Proc Roy Soc A Math Phys Eng Sci 380(1779): 389–407 (1982)

Chugg K J, Chaudhri M M. Boundary lubrication and shear properties of thin solid films of dioctadecyl dimethyl ammonium chloride (TA 100). J Phys D Appl Phys 26(11): 1993–2000 (1993)

Ingram M, Noles J, Watts R, Harris S, Spikes H A. Frictional properties of automatic transmission fluids: Part I-measurement of friction-sliding speed behaviour. Tribol Trans 54(1): 145–153 (2011)

Campen S, Green J H, Lamb G D, Atkinson D, Spikes H. On the increase in boundary friction with sliding speed. Tribol Lett 48(2): 237–248 (2012)

Drummond C, Israelachvili J, Richetti P. Friction between two weakly adhering boundary lubricated surfaces in water. Phys Rev E 67(6): 066110 (2003)

Mazuyer D, Cayer-Barrioz J, Tonck A, Jarnias F. Friction dynamics of confined weakly adhering boundary layers. Langmuir 24(8): 3857–3866 (2008)

Tománek D, Zhong W, Thomas H. Calculation of an atomically modulated friction force in atomic-force microscopy. Europhys Lett 15(8): 887–892 (1991)

Gnecco E, Bennewitz R, Gyalog T, Loppacher C, Bammerlin M, Meyer E, Güntherodt H J. Velocity dependence of atomic friction. Phys Rev Lett 84(6): 1172–1175 (2000)

Müser M H. Nature of mechanical instabilities and their effect on kinetic friction. Phys Rev Lett 89(22): 224301 (2002)

Riedo E, Gnecco E, Bennewitz R, Meyer E, Brune H. Interaction potential and hopping dynamics governing sliding friction. Phys Rev Lett 91(8): 084502 (2003)

Glosli J N, McClelland G M. Molecular dynamics study of sliding friction of ordered organic monolayers. Phys Rev Lett 70(13): 1960–1963 (1993)

Kong Y C, Tildesley D J, Alejandre J. The molecular dynamics simulation of boundary-layer lubrication. Mol Phys 92(1): 7–18 (1997)

Chandross M, Grest G S, Stevens M J. Friction between alkylsilane monolayers: Molecular simulation of ordered monolayers. Langmuir 18(22): 8392–8399 (2002)

Zhang L Z, Leng Y S, Jiang S Y. Tip-based hybrid simulation study of frictional properties of self-assembled monolayers: effects of chain length, terminal group, scan direction, and scan velocity. Langmuir 19(23): 9742–9747 (2003)

Chen J Y, Ratera I, Park J Y, Salmeron M. Velocity dependence of friction and hydrogen bonding effects. Phys Rev Lett 96(23): 236102 (2006)

Kapila V, Deymier P A, Raghavan S. Molecular dynamics simulations of friction between alkylsilane monolayers. Modell Simul Mater Sci Eng 14(2): 283–297 (2006)

Ewen J P, Gattinoni C, Morgan N, Spikes H A, Dini D. Non-equilibrium molecular dynamics simulations of organic friction modifiers adsorbed on iron-oxide surfaces. iLangmuir 32(18): 4450–4463 (2016)

Müser M. Velocity dependence of kinetic friction in the Prandtl–Tomlinson model. Phys Rev B 84(12): 125419 (2011)

Faraday M. The decomposition of chloride of silver by hydrogen and by zinc. Quart J Liter Sci Arts 8: 374–376 (1820)

Ostwald W. The Fundamental Principles of Chemistry. Morse H W, trans. New York (USA): Longman Green, 1909.

Bell G. Models for the specific adhesion of cells to cells. Science 200(4342): 618–627 (1978)

Beyer M K, Clausen-Schaumann H. Mechanochemistry: the mechanical activation of covalent bonds. Chem Rev 105(8): 2921–2948 (2005)

Boldyrev V V. Mechanochemistry and mechanical activation of solids. Russ Chem Rev 75(3): 177–189 (2006)

Kaupp G. Mechanochemistry: The varied applications of mechanical bond-breaking. Cryst Eng Comm 11(3): 388–403 (2009)

James S L Adams C J, Bolm C, Braga D, Collier P, Friščić T, Grepioni F, Harris K D M, Hyett G, Jones W, et al. Mechanochemistry: Opportunities for new and cleaner synthesis. Chem Soc Rev 41(1): 413–447 (2012)

Ribas-Arino J, Marx D. Covalent mechanochemistry: theoretical concepts and computational tools with applications to molecular nanomechanics. Chem Rev 112(10): 5412–5487 (2012)

Takacs L. The historical development of mechanochemistry. Chem Soc Rev 42(18): 7649–7659 (2013)

Beldon P J, Fábián L, Stein R S, Thirumurugan A, Cheetham A K, Friščić T. Rapid room-temperature synthesis of zeolitic imidazolate frameworks by using mechanochemistry. Angew Chem Int Ed Engl 49(50): 9640–9643 (2010)

Keller D, Bustamante C. The mechanochemistry of molecular motors. Biophys J 78(2): 541–556 (2000)

Greenberg M J, Moore J R. The molecular basis of frictional loads in the in vitro motility assay with applications to the study of the loaded mechanochemistry of molecular motors. Cytoskeleton 67(5): 273–285 (2010)

Lenhardt J M, Ogle J W, Ong M T, Choe R, Martinez T J, Craig S L. Reactive cross-talk between adjacent tensiontrapped transition states. J Am Chem Soc 133(10): 3222–3225 (2011)

Craig S L. Mechanochemistry: A tour of force. Nature 487(7406): 176–177 (2012)

Knothe Tate M L, Gunning P W, Sansalone V. Emergence of form from function—Mechanical engineering approaches to probe the role of stem cell mechanoadaptation in sealing cell fate. BioArchitecture 6(5): 85–103 (2016)

Zhu C. Mechanochemitry: a molecular biomechanics view of mechanosensing. Ann Biomed Eng 42(2): 388–404 (2014)

Black A L, Lenhardt J M, Craig S L. From molecular mechanochemistry to stress-responsive materials. J Mater Chem 21(6): 1655–1663 (2011)

Brantley J N, Wiggins K M, Bielawski C W. Polymer mechanochemistry: the design and study of mechanophores. Polym Int 62(1): 2–12 (2013)

De Simo M, Hilmer F B. Process for stabilizing polymers. U.S. Patent 2085525, Jun. 1937.

Morris W J, Schnurmann R. Mechanical degradation of large molecules. Nature 16(4072): 674 (1947)

Marx N, Ponjavic A, Taylor R I, Spikes H A. Study of permanent shear thinning of VM polymer solutions. Tribol Lett 65(3): 106 (2017)

Sohma J. Mechanochemistry of polymers. Prog Polym Sci 14(4): 451–596 (1989)

De Gennes P G. Coil-stretch transition of dilute flexible polymers under ultrahigh velocity gradients. J Chem Phys 60(12): 5030–5042 (1974)

Odell J A, Keller A, Rabin Y. Flow-induced scission of isolated macromolecules. J Chem Phys 88(6): 4022–4028 (1988)

Odell J A, Muller A J, Narh K A, Keller A. Degradation of polymer solutions in extensional flows. Macromolecules 23(12): 3092–3103 (1990)

Gosvami N N, Bares J A, Mangolini F, Konicek A R, Yablon D G, Carpick R W. Mechanisms of antiwear tribofilm growth revealed in situ by single-asperity sliding contacts. Science 348(6230): 102–106 (2015)

Adams H L, Garvey M T, Ramasamy U S, Ye Z J, Martini A, Tysoe W T. Shear-induced mechanochemistry: pushing molecules around. J Phys Chem C 119(13): 7115–7123 (2015)

Adams H, Miller B P, Kotvis P V, Furlong O J, Martini A, Tysoe W T. In situ measurements of boundary film formation pathways and kinetics: dimethyl and diethyl disulfide on copper. Tribol Lett 62(1): 12 (2016)

Felts J R, Oyer A J, Hernández S C, Whitener Jr K E, Robinson J T, Walton S G, Sheehan P E. Direct mechanochemical cleavage of functional groups from graphene. Nat Commun 6: 6467 (2015)

Yeon J, He X, Martini A, Kim S H. Mechanochemistry at solid surfaces: polymerization of adsorbed molecules by mechanical shear at tribological interfaces. ACS Appl Mater Interfaces 9(3): 3142–3148 (2017)

He X, Kim S H. Mechanochemistry of physisorbed molecules at tribological interfaces: molecular structure dependence of tribochemical polymerization. Langmuir 33(11): 2717–2724 (2017)

Brizmer V, Matta C, Nedelcu I, Morales-Espejel G E. The influence of tribolayer formation on tribological performance of rolling/sliding contacts. Tribol Lett 65(2): 57 (2017)

Akchurin A, Bosman R. A deterministic stress-activated model for tribo-film growth and wear simulation. Tribol Lett 65(2): 59 (2017)

Zhang J, Spikes H. On the mechanism of ZDDP antiwear film formation. Tribol Lett 63(2): 24 (2016)

Dickinson J T, Park N S, Kim M W, Langford S C. A scanning force microscope study of a tribochemical system: stress-enhanced dissolution. Tribol Lett 3(1): 69–80 (1997)

Kopta S, Salmeron M. The atomic scale origin of wear on mica and its contribution to friction. J Chem Phys 113(18): 8249–8252 (2000)

Gotsmann B, Lantz M A. Atomistic wear in a single asperity sliding contact. Phys Rev Lett 101(12): 125501 (2008)

Jacobs T D B, Carpick R W. Nanoscale wear as a stressassisted chemical reaction. Nat Nanotechnol 8(2): 108–112 (2013)

Ewen J P, Gattinoni C, Morgan N, Spikes H A, Dini D. Nonequilibrium molecular dynamics simulations of organic friction modifiers adsorbed on iron oxide surfaces. Langmuir 32(18): 4450–4463 (2016)

Mott N F. Slip at grain boundaries and grain growth in metals. Proc Phys Soc 60(4): 391–394 (1948)

Gnecco E, Bennewitz R, Socoliuc A, Meyer E. Friction and wear on the atomic scale. Wear 254(9): 859–862 (2003)

Konda S S M, Brantley J N, Bielawski C W, Makarov D E. Chemical reactions modulated by mechanical stress: extended Bell theory. J Chem Phys 135(16): 164103 (2011)

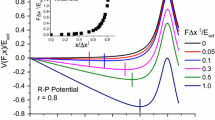

Furlong O J, Manzi S J, Martini A, Tysoe W T. Influence of potential shape on constant-force atomic-scale sliding friction models. Tribol Lett 60(2): 21 (2015)

Tysoe W. On stress-induced tribochemical reaction rates. Tribol Lett 65(2): 48 (2017)

Zhang J, Tan A, Spikes H. Effect of base oil structure on elastohydrodynamic friction. Tribol Lett 65(1): 13 (2017)

Galmiche B, Ponjavic A, Wong J S S. Flow measurements of a polyphenyl ether oil in an elastohydrodynamic contact. J Phys Condens Matter 28(13): 134005 (2016)

Wool R S, Bretzlaff R Y, Li B H, Wang C H, Boyd R H. Infrared and Raman spectroscopy of stressed polyethylene. J Polym Sci Part B Polym Phys 24(5): 1039–1066 (1986)

Author information

Authors and Affiliations

Corresponding author

Additional information

This article is published with open access at Springerlink.com

Hugh SPIKES. He graduated in natural sciences from the University of Cambridge in 1968 and received his PhD degree in mechanical engineering from the University of London in 1972. He joined the staff of the Mechanical Engineering Department at Imperial College in 1978, where in 1996 he became professor and head of the Tribology Group. He is currently a senior research fellow at Imperial College. His research areas cover all aspects of liquid lubrication, from hydrodynamic to boundary, with a particular interest in the influence of lubricant molecular composition on performance. He is a recipient of the ASME Mayo D Hersey Award, STLE International Award, and the Tribology Gold Medal.

Rights and permissions

Open Access: The articles published in this journal are distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Spikes, H. Stress-augmented thermal activation: Tribology feels the force. Friction 6, 1–31 (2018). https://doi.org/10.1007/s40544-018-0201-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40544-018-0201-2