Abstract

By integrating literature reviews, site observation, field monitoring, theoretical analysis, summarization, etc., a construction strategy was proposed and verified for tunneling with big deformation in this paper. The tunnel was in phyllite, shotcrete cracks and steel arch distortion were observed, and a big deformation with a maximum of 2.0 m was monitored during the initial stage of the construction. Through carefully examining the site observation and laboratory test results, a construction principle was established for the tunneling on the basic concept of maintaining the rock strength/stiffness and keeping the rock dry, by providing confinement pressure to the rock, reducing the rock exposure time, keeping water out of the tunnel, etc. To achieve the construction principle, a set of specific construction measures with 11 items was further proposed and applied to the construction. To check the effectiveness of the construction measures, field monitoring was carried out, which showed that the rock deformation was well controlled and the tunnel became stable. An allowable deformation was then determined using the Fenner formulae and the monitored data in order to guide further construction, which received a good result. From this study, it can be concluded that providing quick strong initial support and reserving core soil at the working face are extremely important to control the rock deformation and keep the tunnel stable.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

The occurrence of big deformation in tunneling had become a serious problem since 1906 when an extremely big deformation was found in the Simplon Tunnel that is located between Italy and Switzerland [1, 2]. Big deformation could cause a lot of difficulty in several aspects [3–5]: (1) rock support failure, which induces tunnel instability such as working face collapsing and roof fall; (2) tunnel section reduction, in which initial support invades the tunnel and occupies the space of concrete lining, and an expansion excavation has to be done again; (3) lining crack, which causes the tunnel’s instability and water leakage during the operation.

Based on relevant studies worldwide, big deformation in tunneling can be classified into four categories [6–8]: (1) squeezing deformation; (2) swelling deformation; (3) loosing deformation; and (4) soft rock deformation under high in situ stress, which frequently causes big deformation. There could be many factors influencing rock deformation [9–11]. Firstly, the in situ stress and rock strength would be the most important factors. Obviously, a higher in situ stress generates a higher stress in the rock and a bigger load onto the tunnel structure. Under a high in situ stress, tunneling in soft rock is prone to induce big deformation. In other words, big deformation is believed to easily occur when tunneling in a soft rock with a high in situ stress [12]. Secondly, the ground water would be another factor as it could significantly reduce the strength and stiffness of the soft rock. Laboratory tests show that the water existence can reduce the rock strength up to 90 % depending on the water flow rate [13]. Thirdly, the construction method, especially the support time, would be another key factor as it may boost rock overrelaxation and strength reduction if the support was delayed [14]. In addition, the intersection angle between the tunnel axis and the rock structures may affect the rock failure mode and the rock deformation [15].

The construction experience confirmed the effectiveness of some measures in avoiding big deformation [16, 17]. The most effective measure would be to strengthen the working face by applying rock blots and shotcrete, or reserving core soil at the working face. Once the working face becomes stable, big deformation can be minimized. Controlling floor heave and strengthening sidewall base are other effective measures, and an invert arch could be considered if required [18]. Providing stronger initial support and earlier lining can effectively control the rock deformation. Furthermore, rock deformation monitoring and advanced geological prediction during the tunneling are necessary to provide adequate informational data to the measure decision [19, 20].

However, more and more big deformation cases in tunneling are still occurring [21]. The problem is that in most cases, no attention was paid at the beginning and no effective measures were adopted before the big deformation was found, which missed the best time to control rock deformation [4]. In addition, there is a lack of a comprehensive summary from previous similar projects in providing references to guide further construction [22].

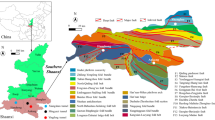

The Dongsong Hydropower Station is located on the Shuoqu River in Nishi Town and Dongsong Town of Xiangcheng County, Sichuan Province, China [23]. It is the fourth cascade hydropower station with a capacity of 150 MW. The diversion tunnel of the station was laid at the right side of the river with a total length of 17.862 km and an overburden of 150–500 m. The tunnel section is in a horseshoe shape with a width of 7.88 m and a height of 7.96 m.

The major rock encountered is phyllite with a uniaxial compressive strength (UCS) of less than 4.0 MPa, which belongs to extremely soft rock according to the Chinese specifications. The water flow rate of the tunnel is about 103.5 m3/s. A big deformation was observed during the tunneling with a maximum deformation of 2.0 m, causing great difficulty and severe delay.

This paper is to investigate the strategy for the tunnel construction. The site observation was firstly briefed. A tunneling strategy and a set of measures were then proposed and applied to the construction. Then, an allowable deformation was determined to guide further construction of the tunnel.

2 Site observation

As the tunnel is very long, the construction was divided in nine segments. Eight horizontal branch tunnels were used in between for achieving earlier completion of the project. In other words, the tunnel has 18 working faces in order to speed up the advance. The construction was started in February 2009, but a big deformation was observed in branch tunnels 2, 4, and 6. The construction became very difficult and the advance was much delayed. As of May 2010, only a total excavation length of 6.8 km was completed in 16 months.

2.1 Site observation from branch tunnel 2

Branch tunnel 2 is 357 m long toward the intersection with the diversion tunnel. The excavation of the tunnel was started in May 2008 and completed in September 2009. A big deformation occurred and the advance was very slow with an average monthly advance of 21 m.

The excavation of the diversion tunnel through the branch tunnel 2 was then started from two working faces, one going upstream and the other downstream. As of October 2010, the excavation of only 106 m was completed within 14 months, equivalent to an average monthly advance of <8.0 m. During that period, the tunneling was extremely difficult due to big deformation occurrence at the crown and sidewall. Generally, the deformation ranged from 10–50 cm, while the mountain side deformed more than the river side. A deformation of 2.0 m occurred at the intersection of the branch tunnel and the diversion tunnel. Due to the big deformation, the shotcrete cracked and steel arch distorted as shown in Figs. 1 and 2. The initial support invaded the tunnel and occupied the lining space, and a second expansion excavation had to be done. Site observation showed that the rock was wet, very soft, and extremely fractured; once water was present, the rock could not be stabilized and advanced support had to be done.

2.2 Site observation from the downstream of branch tunnel 4

Branch tunnel 4 is 436 m long. Excavation of the tunnel was started in June 2008 and completed in March 2009 with an average monthly advance of about 44 m.

The excavation of the diversion tunnel through branch tunnel 4 was then started from two working faces, one going upstream and the other downstream. As of April 2011, the excavation of 156 m downstream was completed, equivalent to an average monthly advance of only 6.0 m, which was the worst case in the tunneling.

During the tunneling, a big deformation occurred downstream (S8 + 267.92–S8 + 409.46) as well as at the intersection of the branch tunnel and the diversion tunnel (K8 + 237.92–K8 + 267.92). The deformation ranged from 6–10 cm at the crown and 10–30 cm at the sidewalls, and the second expansion excavation had to be carried out. The maximum deformation velocity was 5.5 cm/day. The shotcrete cracked and the steel support distorted very severely (Fig. 3). In particular, the working face at the downstream area collapsed in April 2010 (Fig. 4), and its treatment was not completed until April 2011, taking more than 1 year. Some water was found in the site, which made the rock wet, soft, and extremely fractured. The in situ stress is high as the overburden is around 440 m.

2.3 Site observation from the upstream of branch tunnel 6

Branch tunnel 6 is 360 m long. The excavation of the tunnel was started in July 2008 and completed in July 2009, taking 13 months with an average monthly advance of about 33 m.

The excavation of the diversion tunnel from branch tunnel 6 was then started from two working faces: one going upstream and the other downstream. As of March 2011, an excavation of only 281 m in the upstream direction was completed, equivalent to an average monthly advance of only 13.0 m.

During the construction, a big deformation occurred at the upstream area (S13 + 493.0–S13 + 630.0). The deformation ranged from 9–22 cm at the crown and 10–25 cm at the sidewalls. A second expansion excavation had to be carried out. The maximum deformation was 37 cm. The shotcrete bulged and the steel support distorted very severely. To control the big deformation, steel support was applied as shown in Fig. 5. The steel support was then cast into the lining as a permanent support (Fig. 6). The reinforcement anchor was also applied. Fortunately, no water was observed, but the in situ stress was very unfavorable with an overburden of 550 m and big eccentric compression from the mountain side.

In summary, the big deformation occurred in the tunneling because of three reasons. Firstly, the rock is phyllite, which is very soft with a low strength. Particularly when water is present, the rock will lose its strength and the tunnel becomes unstable. Secondly, the in situ stress is very high with a serious eccentric compression. The rock bedding is oblique to the tunneling direction with a small angle. The excavation released the normal stress on the bedding, which caused a big deformation. Finally, the initial support (shotcrete and rock bolt) was not strong enough and could not provide enough normal stress to the bedding. In addition, the lining was installed too late to allow more stress release.

The site observation also indicated that the rock weathered very fast after the excavation, and a quicker application of shotcrete was effective to prevent the rock from weathering. Laboratory tests found that the rock properties were closely related to the confinement pressure. With the decrease of confinement pressure, both rock strength and Young’s modulus decrease sharply. Particularly when the rock contained water, the rock loses a lot of strength.

3 Tunneling strategy

Among the reasons causing big deformation, compared with high in situ stress and soft rock that cannot be changed during the construction, the rock strength loss and rock stiffness decrease can be improved by providing quick and strong support pressure to the rock and keeping the rock dry. Based on the site observation and laboratory test results, a set of tunneling strategies was proposed to overcome the big deformation problem.

3.1 Construction principle

To avoid big deformation, a construction principle was established for the tunneling including the following:

-

(1)

Effort should be made to provide confinement pressure to the rock.

-

(2)

Exposure time of rock at/near the working face should be shortened to avoid rock weathering and loosing.

-

(3)

The water should be kept out of the tunnel by reducing the water stay time and strengthening water drainage.

-

(4)

The working face would be kept stable to avoid it collapsing, which will seriously delay the tunnel advancing and increase treatment cost.

-

(5)

Field data and information should be collected, back analyzed, and returned to guide the construction and rock support design.

-

(6)

The tunnel advance should be improved if the safety can be assured.

-

(7)

An allowable rock deformation should be given in the design to prevent the second expansion excavation.

3.2 Specific measures for the construction

Based on the construction principle above, a set of specific construction measures including 11 items was proposed:

-

An advanced geological prediction needs to be done. The geology in front of the working face needs to be explored before the excavation to predict water condition, fractured zone, etc.

-

The rock deformation monitoring needs to be done during the construction. Information such as crown subsidence and convergence needs to be collected and back analyzed to judge the tunnel stability, optimize the rock support parameters and construction scheme, and determine the allowable deformation, initial support parameters, and lining installation time.

-

An allowable rock deformation is needed to avoid second expansion excavation. The determination of the allowable deformation would be based on the achievement from the advanced geological prediction and rock deformation monitoring results. A method to predict the rock deformation would be established to support the determination of allowable rock deformation.

-

After the excavation, shotcrete would be applied immediately to the exposed rock at/near the working face in order to reduce the rock exposing time, avoid rock weathering, and prevent rock strength and stiffness from decreasing.

-

Water would be drained out of the tunnel to avoid water pond in the tunnel to prevent the rock from soaking and softening.

-

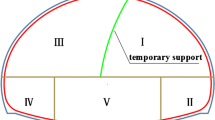

If the rock is heavily fractured, keeping the working face stable is most important. This can be assured by controlling the step advance, strengthening support, reserving core soil to support the working face, and preventing the working face from collapsing.

-

Integrated support of the steel arch, rock bolt, reinforcement mesh, and shotcrete would be applied immediately after the excavation. Keeping the support as a whole with a strong connection and improving the support stiffness are very important.

-

The steel arch is a major load-bearing support. Except the steel arch stiffness itself, the longitudinal steel arch stiffness is also very effective to resist the big deformation. This can be achieved by connecting steel arches using longitudinal steel beams. In addition, keeping the steel arch close at bottom as a loop is also effective.

-

Although it is verified that long rock bolts (9 m or longer) are workable to resist big deformation, long rock bolts are not applicable in this tunnel as the tunnel diameter is small. Short rock bolts (4.5 m) are suggested to connect the steel arches to the rock.

-

Shotcrete is useful to prevent the rock from weathering and to provide an integrated support pressure to the rock. Shotcrete would be applied again in time if it was cracked.

-

Lining can provide a strong support; earlier application of the lining can effectively resist big deformation. It is suggested to apply lining within a distance of twice the tunnel diameter from the working face.

3.3 Measures to speed up the tunneling

The specific measures above were preliminarily applied to the tunneling in the branch tunnel 2 and a good result was obtained, but with a very slow advance. The main reason causing slow advance is that the lining is applied using a full frame that takes a long time (9–12 m per half a month) and the working face must be stopped during the lining installation. To solve this problem, the following measures were taken:

-

(1)

Instead of the full frame, a formwork jumbo was used to allow the transportation passing through.

-

(2)

The upper part of the lining was applied first to provide fast support to the rock, and the invert part of the lining was then followed.

-

(3)

A good road condition was kept to allow easy entrance of transportation and manpower to improve the construction effectiveness.

-

(4)

The ventilation is strengthened to improve the air condition to enhance the construction effectiveness.

-

(5)

The full face excavation was suggested, but core soil must be reserved to assure the working face stability. After adopting the measures above, the tunneling was speeded up with an average advance of more than 60 m/month.

4 Field monitoring

In order to check the effectiveness of the tunneling strategy above, a series of field monitoring procedures was carried out during the construction at branch tunnel 2. A total of 18 monitoring sections was carried out, 5 of them being at the upstream area and the others at the downstream. The monitoring items include (1) convergence, (2) rock support (rock bolt, steel arch, and lining) stress, and (3) contact pressure between rock and lining.

4.1 Convergence

The convergence was conducted at three sections, and monitored data are listed in Table 1 (the third column). In fact, the monitored data are not the total convergence, but are only partial as the monitoring started at a distance behind the working face. To evaluate the convergence developing with the advancing, numerical modeling was carried out and a relation of displacement percentage versus distance coefficient was obtained as shown in Fig. 7. From the relation, the prior convergence occurring before the monitoring as listed in Table 1 (the fifth column) could be calculated according to the distance behind the face (the forth column) when the first monitoring data were read. The total deformation was then calculated from the sum of the monitored convergence and the prior one as listed in Table 1(the last column).

As an example, Fig. 8 shows the convergence monitoring data at Section S3 + 770.0. It can be seen that the monitored convergence is small with a maximum of only 18 mm. More importantly, the convergence initially increases with the tunnel advancing, but gradually tends to be a certain value, indicating that the tunnel is stable.

4.2 Contact pressure between rock and shotcrete

Figure 9 shows the monitoring data of the contact pressure between the rock and shotcrete at Section S3 + 762.8. As shown in the figure, the contact pressure is very small with a maximum value of 0.47 MPa, and the contact pressure tends to be stable.

4.3 Steel arch stress

Figure 10 shows the monitoring data of steel arch stress at D of Section S3 + 766.8. As shown in the figure, the steel arch stress with tunneling converges very fast, and the stress is small with a maximum stress of less than 100 MPa.

4.4 Lining strain

Figure 11 shows the monitoring data of lining strain at Point A of Section S3 + 657.6. As shown in the figure, the concrete strain is small with a maximum of <180 με, and the strain tends to be stable.

The monitoring results above indicate that the rock deformation is effectively controlled by applying the proposed tunneling strategy. The stress on the support is small and the contact pressure between the rock and shotcrete is within the allowable value, which suggests that the tunnel is stable and the tunneling strategy is applicable.

4.5 Site observation

From the site observation, no shotcrete failure was found near Sections S3 + 762.8 and S3 + 770.0, but shotcrete cracking and steel arch distortion were observed near Section S3 + 634.4. This agrees well with the monitored deformation. However, the support failed though the tunnel became stable, which indicates that an allowable deformation would be given to the support design to prevent the support from failing.

5 Determination of allowable deformation

To determine the allowable deformation, a maximum deformation would be obtained. According to the Fenner formulae, the yielding radium, normal stress at the border between the elastic zone and the yielding zone, and tunnel deformation are related to rock properties, overburden, tunnel radium, and support pressure as

where

c is cohesion, ϕ is the friction angle, a is the tunnel radium, r0 is the yielding radium, σr0 is the normal stress at the border between the elastic zone and the yielding zone, ua is the tunnel deformation, K is the bulk modulus of rock, Pa is the support pressure, and\( \sigma_{\text{y}} \) is the vertical in situ stress

Figures 12, 13 show the yielding radium and tunnel deformation versus support pressure for overburden of different depths. From the figures, it can be found that a higher overburden causes a bigger yielding radium and tunnel deformation, while a bigger support pressure could decrease the yielding radium and tunnel deformation.

Based on Eq. (1) and taking account of the respective installation time of the initial support and lining, the tunnel deformation was estimated as 10–30 cm for evaluated cohesion of 0.05–0.20 MPa. Compared to the monitoring results as listed in Table 1, it can be seen that the deformation estimation agrees well with the monitored result. Therefore, the allowable deformation for this project was determined as 30 cm, which was verified by the further construction.

6 Conclusions

Big deformation with a maximum up to 2.0 m was observed in the tunneling of the diversion tunnel of Dongsong Hydropower Station. The shotcrete was cracked and the steel arch was distorted due to the big deformation. In order to solve this problem, a construction strategy was proposed and an allowable deformation was determined for further construction of the tunnel.

-

A construction principle was established based on a concept of mainly maintaining the rock strength/stiffness and keeping the rock dry, by providing a confinement pressure to the rock, reducing the rock exposure time, keeping water out of the tunnel, etc. A set of construction measures with 11 items was then proposed and applied to the construction, and a good result was achieved. It was found that among them, reserving core soil at the working face and applying immediate initial support to the rock after excavation were most effective to control the rock deformation.

-

Presetting a bigger allowable deformation in the support design is necessary as the soft rock needs an obvious deformation before becoming stable; otherwise, the support may fail. The allowable deformation can be determined through an integrated manner of theoretical prediction and monitoring verification. In this study, an allowable deformation of 30 cm was obtained and applied to the support design, which had a good achievement in further construction of the tunnel.

References

Guan BS (2008) Key issues on tunnel construction. People’s Transportation Publisher, Beijing

Chapman D, Metje N, Staark A (2010) Tunnel construction. Spon Press, London

Guan BS, Zhao Y (2011) The construction technology of soft rock tunnels. People’s Transportation Publisher, Beijing

Brady BHG, Brown ET (1993) Rock mechanics for underground mining. Chapman & Hall, London

Zhang Z, Guan BS (2000) A study on deformation patterns of soft rock tunnels under high in situ stress. Chin J Geotech Eng 22(6):696–700

Cheng F, Chen SG, Tan X et al. (2009) Wang, Deformation control for tunneling with a small separation in soft strata. Paper presented at the ISRM regional symposium Eurock 2009, Cavtat, Dubrovnik, 29–31 Oct 2009

Chen SG, Zhao YB, Zhang H (2009) Analysis of large rock deformation under high in situ stress. Paper presented at the 9th international conference on analysis of discontinuous deformation, Singapore, 25–27 Nov 2009

Bieniawski ZT (1984) Rock mechanics design in mining and tunneling. A. A. Balkema, Boston

Kolymbas D (2005) Tunneling and tunnel mechanics. Springer, Berlin

Singh B, Goel RK (1999) Rock mass classification. Elsevier, Amsterdam

Wang M, Zhang J (1998) A study on the mechanical effect of measures to control tunnel deformation. Chin J Geotech Eng 20(5):27–30

Chen SG, Zhang H, Tan X et al (2011) Key technologies for construction of Jinping traffic tunnel with an extremely deep overburden and a high water pressure. J Mod Transp 19(2):94–103

Zhang L, Zhou X, Zhao C (2006) The design and construction technologies of soft rock tunnel. China Water Power Press, Beijing

Chen SG, Hu W (2009) A comprehensive study on subsidence control using COSFLOW. Int J Geotech Geolog Eng 27(3):305–314

Ma H, Chen SG, Hu C, et al. (2011) A study on the stability of a big-section tunnel in karst area. Paper presented at the 10th international conference of discontinous deformation, Hawaii, USA, 6–9 Dec 2011

Gui R, Liu Y (2011) An analysis on time and space effect during tunneling in soft rock. J Nanhua Univ 25(1):28–32

Haruyama K, Teramoto S, Taira K (2005) Construction of large cross-section double-tier metropolitan inter-city highway tunnel by NATM. Tunn Undergr Space Technol 20:111–119

Chou WI, Bovet A (2002) Predictions of ground deformations in shallow tunnels in clay. Tunn Undergr Space Technol 17(1):3–19

Peck RB (1969) Advantages and limitations of the observational method in applied soil mechanics. Geotechniques 19:171–187

Ma H, Chen SG, Tan X et al. (2012) Advanced geological detection for tunneling in karst area, ASCE Geotechnical Engineering State of the Art and Practice, San Francisco, 25–29 March 2012

Li R (2005) The processing for large-scale deformation of early support in road tunnel. J West Mine Explor 7:118–119

Li YL, Feng XG, Jiang Y et al (2005) Large deformations encountered in the surrounding rocks of tunnels and their prediction. Mod Tunn Technol 42(5):46–51

Chen SG (2011) A development on technologies of tunnel construction with big deformation. A research report, Southwest Jiaotong University

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

This article is published under license to BioMed Central Ltd. Open Access This article is distributed under the terms of the Creative Commons Attribution License which permits any use, distribution, and reproduction in any medium, provided the original author(s) and the source are credited.

About this article

Cite this article

Chen, L., Chen, S. & Tan, X. A construction strategy for a tunnel with big deformation. J. Mod. Transport. 21, 86–94 (2013). https://doi.org/10.1007/s40534-013-0014-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40534-013-0014-y