Abstract

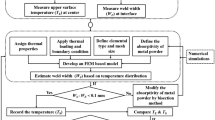

In this work, a heuristic inverse method for simultaneous estimation of thermal conductivity, specific heat, density and absorptivity in a laser-irradiated sheet is proposed. A fast forward model, which can predict the temperature evolution during laser heating is built as the foundation of the inverse model. The forward model comprises of a proper analytical modelling considering three-dimensional heat conduction equation with coupled conduction–convection boundary conditions. The proposed inverse method tries to change the unknown parameters in each step till the predicted temperature close to the recorded temperature. Two different examples of a heating process on aluminium alloy (Al 6061-T6) are considered to demonstrate the efficacy of the inverse method. The accuracy of the inverse method is assessed by simulated experimental temperatures considering temperature-dependent properties in the forward model. The results show that the inversely recovered parameters are sufficiently accurate in calculating the surface temperature at different process conditions. The suggested heuristic inverse method has the potential for the fast computation of parameters for a desired laser heating temperature without needing arduous experiments and unproductive finite element method (FEM) analysis.

Similar content being viewed by others

Data Availability

Data will be made available on reasonable request.

References

Dubey, A.K., Yadava, V.: Laser beam machining—A review. Int. J. Mach. Tools Manuf. 48(6), 609–628 (2008)

Dixit, U.S., Joshi, S.N., Kant, R.: Laser forming systems: a review. Int. J. Mechatronics Manuf. Syst. 8(3–4), 160–205 (2015)

Kennedy, E., Byrne, G., Collins, D.N.: A review of the use of high power diode lasers in surface hardening. J. Mater. Process. Technol. 155, 1855–1860 (2004)

Cao, X.J., Jahazi, M., Immarigeon, J.P., Wallace, W.: A review of laser welding techniques for magnesium alloys. J. Mater. Process. Technol. 171(2), 188–204 (2006)

Draper, C.W., Poate, J.M.: Laser surface alloying. Int. Met. Rev. 30(1), 85–108 (1985)

Chen, G.: Analytical solutions for temperature and thermal-stress modeling of solid material induced by repetitive pulse laser irradiation. Optik 135, 16–26 (2017)

Kant, R., Joshi, S.N.: Thermo-mechanical studies on bending mechanism, bend angle and edge effect during multi-scan laser bending of magnesium M1A alloy sheets. J. Manuf. Process. 23, 135–148 (2016)

Fetene, B.N., Kumar, V., Dixit, U.S., Echempati, R.: Numerical and experimental study on multi-pass laser bending of AH36 steel strips. Opt. Laser Technol. 99, 291–300 (2018)

Nath, U., Yadav, V., Purohit, R.: Finite element analysis of AM30 magnesium alloy sheet in the laser bending process. Adv. Mater. Process. Technol. 8(2), 1803–1815 (2022)

Cheng, P.J., Lin, S.C.: An analytical model for the temperature field in the laser forming of sheet metal. J. Mater. Process. Technol. 101(1–3), 260–267 (2000)

Kyrsanidi, A.K., Kermanidis, T.B., Pantelakis, S.G.: An analytical model for the prediction of distortions caused by the laser forming process. J. Mater. Process. Technol. 104(1–2), 94–102 (2000)

Peng, Q.: An analytical solution for a transient temperature field during laser heating a finite slab. Appl. Math. Model. 40(5–6), 4129–4135 (2016)

Nath, U., Yadav, V.: Analytical modeling of temperature evolution and bend angle in laser forming of Al 6061–T6 sheets and its experimental analysis. Opt. Laser Technol. 154, 108307 (2022)

Roder, H.M.: A transient hot wire thermal conductivity apparatus for fluids. J. Res. Natl. Bur. Stand. 86(5), 457 (1981)

Gustafsson, S.E.: Transient plane source techniques for thermal conductivity and thermal diffusivity measurements of solid materials. Rev. Sci. Instrum. 62(3), 797–804 (1991)

Cahill, D.G.: Thermal conductivity measurement from 30 to 750 K: the 3ω method. Rev. Sci. Instrum. 61(2), 802–808 (1990)

Lian, T.W., Kondo, A., Akoshima, M., Abe, H., Ohmura, T., Tuan, W.H., Naito, M.: Rapid thermal conductivity measurement of porous thermal insulation material by laser flash method. Adv. Powder Technol. 27(3), 882–885 (2016)

Ozisik, M.N.: Inverse Heat Transfer: Fundamentals and Applications. CRC Press, New York (2000)

Colaço, M.J., Orlande, H.R., Dulikravich, G.S.: Inverse and optimization problems in heat transfer. J. Braz. Soc. Mech. Sci. Eng. 28, 1–24 (2006)

Zhang, J., Bi, J., Chen, G.: Inverse estimation of the material parameters at metal surface irradiated by laser pulse. Optik 129, 108–117 (2017)

Mishra, A., Dixit, U.S.: Determination of thermal diffusivity of the material, absorptivity of the material and laser beam radius during laser forming by inverse heat transfer. J. Mach. Forming Technol. 5(3/4), 207 (2013)

Sun, S.: Simultaneous reconstruction of thermal boundary condition and physical properties of participating medium. Int. J. Therm. Sci. 163, 106853 (2021)

Cui, M., Li, N., Liu, Y., Gao, X.: Robust inverse approach for two-dimensional transient nonlinear heat conduction problems. J. Thermophys. Heat Transfer 29(2), 253–262 (2015)

Sun, S.C., Qi, H., Yu, X.Y., Ren, Y.T., Ruan, L.M.: Inverse identification of temperature-dependent thermal properties using improved Krill Herd algorithm. Int. J. Thermophys. 39, 1–21 (2018)

Kant, R., Joshi, S.N., Dixit, U.S.: An integrated FEM-ANN model for laser bending process with inverse estimation of absorptivity. Mech. Adv. Mater. Mod. Process. 1(1), 1–12 (2015)

Kumar, V., Dixit, U.S., Zhang, J.: Determination of thermal conductivity, absorptivity and heat transfer coefficient during laser-based manufacturing. Measurement 131, 319–328 (2019)

Kumar, V., Dixit, U.S., Zhang, J.: Determining thermal conductivity, specific heat capacity and absorptivity during laser based materials processing. Measurement 139, 213–225 (2019)

Özisik, M.N.: Boundary value problems of heat conduction, Courier Corporation, New-York. 64–79 (2002)

Mirkoohi, E., Ning, J., Bocchini, P., Fergani, O., Chiang, K.N., Liang, S.Y.: Thermal modeling of temperature distribution in metal additive manufacturing considering effects of build layers, latent heat, and temperature-sensitivity of material properties. J. Manuf. Mater. Process. 2(3), 63 (2018)

Valencia, J.J., Quested, P.N.: Thermophysical Properties; ASM Handbook, Volume 15, Casting. 468–481 (2008)

Yadav, V., Singh, A.K., Dixit, U.S.: Inverse estimation of thermal parameters and friction coefficient during warm flat rolling process. Int. J. Mech. Sci. 96, 182–198 (2015)

Zhu, Z., Wang, M., Zhang, H., Zhang, X., Yu, T., Wu, Z.: A finite element model to simulate defect formation during friction stir welding. Metals 7(7), 256 (2017)

Nath, U., Yadav, V.: Analytical modelling of 3D temperature evolution of Al 6061-T6 irradiated by a moving laser heat source considering intensive convective boundary conditions. J. Mech. Sci. Technol. 36(12), 6247–6260 (2022)

Acknowledgements

The support provided by the IIT Ropar for the laser machine established through the DST India (Project No. DST/TDT/AMT/2017/026) is gratefully acknowledged.

Author information

Authors and Affiliations

Contributions

Utpal Nath: Investigation, Methodology, Formal analysis, Writing—original draft. Vinod Yadav: Supervision, Methodology, Writing—review & editing.

Corresponding author

Ethics declarations

Ethical Approval

Not applicable.

Competing Interests

The authors have no relevant financial or non-financial interests to disclose.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

Following expressions are used in solution:

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Nath, U., Yadav, V. Inverse Model for Simultaneously Estimating Material Parameters and Absorption Coefficient in a Laser-Irradiated Sheet. Lasers Manuf. Mater. Process. 10, 606–625 (2023). https://doi.org/10.1007/s40516-023-00224-7

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40516-023-00224-7