Abstract

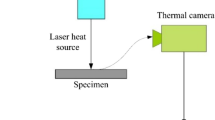

This study reports a new hybrid integrated technique to predict the absorptivity of absorber and the interface temperature of the joint in laser transmission welding. The new approach is more robust as the numerical model is confirmed through experimental observations initially with weld width and further with surface temperature. Experiments are performed on polycarbonate sheets with electrolytic iron powder (EIP) as an absorber. The surface temperature and weld width are measured from the experiments. A transient 3-D finite element-based numerical model is developed for heat transfer analysis. The variation of heat flux with stand-off distance is also considered to enhance the accuracy of the computed results. The absorptivity is tuned in the numerical model by inverse analysis so that the numerical weld width is in close conjunction with the experimental weld width. After inverse estimation, the numerical model is validated with the experimental results of surface temperature using infrared thermography. The results indicate that the upper surface temperatures at the center in the numerical model are found to be in good agreement with experimental observations, and the average error is obtained to be less than 6%. Then, the interface temperatures are estimated after the validation of the numerical model.

Similar content being viewed by others

Availability of data and material

The authors confirm that the data and material supporting the findings of this study are available within the article. Raw data are available from the corresponding author upon reasonable request.

Code availability

DFLUX subroutine is written in Fortran to incorporate the moving heat flux. The subroutine code can be provided by the corresponding author upon reasonable request.

References

Liu M, Ouyang D, Zhao J, Li C, Sun H, Ruan S (2018) Clear plastic transmission laser welding using a metal absorber. Opt Laser Technol 105:242–248. https://doi.org/10.1108/13552540010337029

Liu MQ, Ouyang DQ, Li CB, Sun HB, Ruan SC (2018) Effects of metal absorber thermal conductivity on clear plastic laser transmission welding. Chin Phys Lett 35(10):104205. https://doi.org/10.1088/0256-307X/35/10/104205

Wu J, Lu S, Wang HJ, Wang Y, Xia FB, Jin-Wang (2021) A review on laser transmission welding of thermoplastics. Int J Adv Manuf Technol 116(7–8):2093–2109. https://doi.org/10.1007/s00170-021-07519-z

Pereira AB, Fernandes FAO, de Morais AB, Quintão J (2019) Mechanical Strength of Thermoplastic Polyamide Welded by Nd: YAG Laser. Polymers 11(9):1381. https://doi.org/10.3390/polym11091381

Acherjee B (2021) Laser transmission welding of polymers – a review on welding parameters, quality attributes, process monitoring, and applications. J Manuf Process 64:421–443. https://doi.org/10.1016/j.jmapro.2021.01.022

Mehrpouya M, Gisario A, Rahimzadeh A, Barletta M (2019) An artificial neural network model for laser transmission welding of biodegradable polyethylene terephthalate/polyethylene vinyl acetate (PET/PEVA) blends. Int J Adv Manuf Technol 102(5–8):1497–1507. https://doi.org/10.1007/s00170-018-03259-9

Villar M, Garnier C, Chabert F, Nassiet V, Samélor D, Diez JC, Sotelo A, Madre MA (2018) In-situ infrared thermography measurements to master transmission laser welding process parameters of PEKK. Opt Lasers Eng 106(February):94–104. https://doi.org/10.1016/j.optlaseng.2018.02.016

Becker F, Potente H (2002) A step towards understanding the heating phase of laser transmission welding in polymers. Polym Eng Sci 42(2):365–374. https://doi.org/10.1002/pen.10954

Horn W (2009) A progressive laser joining method: online process control with pyrometer and galvo scanner. Laser Tech J 6(1):42–43. https://doi.org/10.1002/latj.200990008

Ilie M, Kneip JC, Matteï S, Nichici A, Roze C, Girasole T (2007) Through-transmission laser welding of polymers - temperature field modeling and infrared investigation. Infrared Phys Technol 51(1):73–79. https://doi.org/10.1016/j.infrared.2007.02.003

Speka M, Matteı S, Pilloz M, Ilie M (2008) The infrared thermography control of the laser welding of amorphous polymers. Ndt E Int 41:178–183. https://doi.org/10.1016/j.ndteint.2007.10.005

Van De Ven JD, Erdman AG (2007) Laser transmission welding of thermoplastics – part I : temperature and pressure modeling. J Manuf Sci Eng 129:849–858. https://doi.org/10.1115/1.2752527

Mahmood T, Mian A, Amin MR, Auner G, Witte R, Herfurth H, Newaz G (2007) Finite element modeling of transmission laser microjoining process. J Mater Process Technol 186:37–44. https://doi.org/10.1016/j.jmatprotec.2006.11.225

Mayboudi LS, Birk AM, Zak G, Bates PJ (2009) A three-dimensional thermal finite element model of laser transmission welding for lap-joint. Int J Model Simul 29(2):149–155. https://doi.org/10.1080/02286203.2009.11442520

Acherjee B, Kuar AS, Mitra S, Misra D (2012) Modeling of laser transmission contour welding process using FEA and DoE. Opt Laser Technol 44:1281–1289. https://doi.org/10.1016/j.optlastec.2011.12.049

Sooriyapiragasam SK, Hopmann C (2016) Modeling of the heating process during the laser transmission welding of thermoplastics and calculation of the resulting stress distribution. Welding in the World 60(4):777–791. https://doi.org/10.1007/s40194-016-0330-z

Wang C, Liu H, Chen Z, Zhao D, Wang C (2021) A new finite element model accounting for thermal contact conductance in laser transmission welding of thermoplastics. Infrared Phys Technol 112:103598. https://doi.org/10.1016/j.infrared.2020.103598

Acherjee B (2021) Laser transmission welding of dissimilar plastics: 3-D FE modeling and experimental validation. Weld World. https://doi.org/10.1007/s40194-021-01079-2

Lambiase F, Genna S (2020) Homogenization of temperature distribution at metal-polymer interface during laser direct joining. Opt Laser Technol 128:106226. https://doi.org/10.1016/j.optlastec.2020.106226

Wei LC, Ehrlich LE, Powell-Palm MJ, Montgomery C, Beuth J, Malen JA (2018) Thermal conductivity of metal powders for powder bed additive manufacturing. Addit Manuf 21:201–208. https://doi.org/10.1016/j.addma.2018.02.002

Kant R, Joshi SN (2016) Numerical and experimental studies on the laser bending of magnesium M1A alloy. Lasers Eng 35(1–4):39–62

Wahba M, Kawahito Y, Katayama S (2011) Laser direct joining of AZ91D thixomolded Mg alloy and amorphous polyethylene terephthalate. J Mater Process Technol 211(6):1166–1174. https://doi.org/10.1016/j.jmatprotec.2011.01.021

Tolochko NK, Khlopkov YV, Mozzharov SE, Ignatiev MB, Laoui T, Titov VI (2000) Absorptance of powder materials suitable for laser sintering. Rapid Prototyp J 6(3):155–160. https://doi.org/10.1108/13552540010337029

Goyal D.K, Yadav R, Kant R (2022) Study of Temperature Field Considering Gradient Volumetric Heat Absorption in Transparent Sheet During Laser Transmission Welding (LTW). Lasers Eng 53(3–4):215–229

Acknowledgements

The laser system used for this study was established through grant received from the Department of Science and Technology (DST), India, under project number DST/TDT/AMT/2017/026.

Author information

Authors and Affiliations

Contributions

Dhruva Kumar Goyal has proposed the methodology and performed the numerical simulations and experiments, including data analysis, and drafted the original manuscript. Ramsingh Yadav coordinated and helped in the development of experimental setup, conducting the experiments, and editing the original manuscript. Ravi Kant has supervised the overall project from conceptualization to methodology. He has reviewed and edited the primary manuscript. He also led the project and overall collaborative effort of all entities.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Goyal, D.K., Yadav, R. & Kant, R. An integrated hybrid methodology for estimation of absorptivity and interface temperature in laser transmission welding. Int J Adv Manuf Technol 121, 3771–3786 (2022). https://doi.org/10.1007/s00170-022-09536-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-09536-y