Abstract

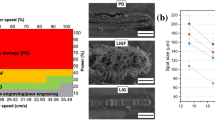

Fabrication of conductive patterns for flexible and printed electronic devices is one of the most challenging steps in the whole process. Conductive patterns in electronic devices are used as electrodes, transducers, connecting links, and sometimes, also as the active sensing elements. Since the introduction of laser induced graphene (LIG), it has been explored to print electrodes and connecting patterns for various electronic devices and systems. This work focuses on an in-house developed laser printing system and the comparison of various electrical, chemical, and morphological properties of the resulting LIG patterns using CO2 and diode lasers. The system parameters including the laser power, relative printing speed, and the printing resolution were explored and optimized to achieve conductive patterns with varying properties suitable for various targeted applications. The fabricated patterns were characterized for their sheet resistance, surface morphology, chemical properties, and physical size and resolution. Continuous conductive patterns with sheet resistance in range of 11.5 Ω/□ to 43 Ω/□ were achieved using CO2 laser with a minimum achievable pattern width of ~ 180 μm while patterns with sheet resistance in range of 19 Ω/□ to 105 Ω/□ were achieved using diode laser with a minimum pattern width of ~ 190 μm. The chemical and morphological properties of CO2 laser-based patterns indicate the formation of 2D graphite sheets with high porosity and low O2 concentration while the diode laser-based patterns have a lower porosity and higher percentage of O2 indicating burning and formation of oxides. Various applications of both types have also been discussed based on their respective properties.

Similar content being viewed by others

Data Availability

There are no datasets involved. Any other data will be made available on request.

References

Alsaid, D.A., Rebrosova, E., Joyce, M., Rebros, M., Atashbar, M., Member, S.: Gravure printing of ITO transparent electrodes for applications in flexible electronics. J. Disp. Technol. 8, 391–396 (2012)

Lathi M.: Gravure offset printing for fabrication of electronic devices and integrated components in LTCC modules. Faculty of Technology, University of Oulu, Finland (2008). http://herkules.oulu.fi/isbn9789514288944/

Fariza Dian, P., Hadi Teguh, Y., Vu Dat, N., Doyoung, B.: Ag dot morphologies printed using electrohydrodynamic (EHD) jet printing based on a drop-on-demand (DOD) operation. J. Micromech. Microeng. 23, 95028 (2013). https://doi.org/10.1088/0960-1317/23/9/095028

Khan, S., Doh, Y.H., Khan, A., Rahman, A., Choi, K.H., Kim, D.S.: Direct patterning and electrospray deposition through EHD for fabrication of printed thin film transistors. Curr. Appl. Phys 11, S271–S279 (2011). https://doi.org/10.1016/j.cap.2010.11.044

Han, Y., Wei, C., Dong, J.: ScienceDirect Super-resolution electrohydrodynamic (EHD) 3D printing of micro-structures using phase-change inks. Manuf. Lett 2, 96–99 (2014). https://doi.org/10.1016/j.mfglet.2014.07.005

Virtanen, J., Member, S., Ukkonen, L., Björninen, T., Elsherbeni, A.Z., Sydänheimo, L.: Inkjet-printed humidity sensor for passive UHF RFID systems. IEEE Trans. Instrum. Meas. 60, 2768–2777 (2011)

Barnes, D.: B.: Towards a better forecast for printed electronics. In: LOPEC 2014 The 6th International Exhibition and Conference for Printed Electronics (2014)

Daniel, J.: Printed electronics: technologies, challenges and applications. Palo Alto Research Center, pp. 1–73. International Workshop on Flexible and Printed Electronics (IWFPE 10), Muju Resort, Korea (2011).

Wu, S.-Y., Yang, C., Hsu, W., Lin, L.: 3D-printed microelectronics for integrated circuitry and passive wireless sensors. Microsyst. Nanoeng. 1, 15013 (2015). https://doi.org/10.1038/micronano.2015.13

Lee, D.Y., Shin, Y.S., Park, S.E., Yu, T.U., Hwang, J.: Electrohydrodynamic printing of silver nanoparticles by using a focused nanocolloid jet. Appl. Phys. Lett 90, 1–4 (2007). https://doi.org/10.1063/1.2645078

Rahman, K., Khan, A., Muhammad, N.M., Jo, J., Choi, K.-H.: Fine-resolution patterning of copper nanoparticles through electrohydrodynamic jet printing. J. Micromech. Microeng. 22, 65012 (2012). https://doi.org/10.1088/0960-1317/22/6/065012

Skrzetuska, E., Puchalski, M., Krucińska, I.: Chemically driven printed textile sensors based on graphene and carbon nanotubes. Sensors (Basel) 14, 16816–16828 (2014). https://doi.org/10.3390/s140916816

Gul, J.Z., Sajid, M., Choi, K.H.: 3D printed highly flexible strain sensor based on TPU-graphene composite for feedback from high speed robotic applications. J. Mater. Chem. C 7, 4692–4701 (2019). https://doi.org/10.1039/c8tc03423k

Tang, Y., He, W., Zhou, G., Wang, S., Yang, X., Tao, Z., Zhou, J.: A new approach causing the patterns fabricated by silver nanoparticles to be conductive without sintering. Nanotechnology 23, 355304 (2012). https://doi.org/10.1088/0957-4484/23/35/355304

Weise, D., Mitra, K.Y., Sowade, E., Baumann, R.R.: Intense pulsed light sintering of inkjet printed silver nanoparticle ink: Influence of flashing parameters and substrate. In: Materials Research Society Symposium Proceedings. pp. 30–35 (2015)

Ali, A., Jo, J., Yang, Y.J., Choi, K.H.: Direct fabrication of graphene/zinc oxide composite film and its characterizations. Appl. Phys. A 114, 323–330 (2014). https://doi.org/10.1007/s00339-013-8136-y

Żymełka, D., Saadaoui, M.: Selective sintering of inkjet-printed metal nanoparticles onto polyethylene terephthalate (PET) substrate. In: LOPEC 2014 The 6th International Exhibition and Conference for Printed Electronics (2014)

Sajid, M., Gul, J.Z., Kim, S.W., Kim, H.B., Na, K.H., Choi, K.H.: Development of 3D-Printed embedded temperature sensor for both terrestrial and aquatic environmental monitoring robots. 3D print. Addit. Manuf 5, 160–169 (2018). https://doi.org/10.1089/3dp.2017.0092

Davaji, B., Cho, H.D., Malakoutian, M., Lee, J.K., Panin, G., Kang, T.W., Lee, C.H.: A patterned single layer graphene resistance temperature sensor. Sci. Rep. 7 (2017). https://doi.org/10.1038/s41598-017-08967-y

Li, J., Chen, X.Y., Lei, R.B., Lai, J.F., Ma, T.M., Li, Y.: Highly thermally conductive graphene film produced using glucose under low-temperature thermal annealing. J. Mater. Sci 54, 7553–7562 (2019). https://doi.org/10.1007/s10853-019-03406-x

Gan, T., Hu, S.: Electrochemical sensors based on graphene materials. Microchim. Acta 175, 1–19 (2011). https://doi.org/10.1007/s00604-011-0639-7

Miller, J.R., Outlaw, R.A., Holloway, B.C.: Graphene double-layer capacitor with ac line-filtering performance. Science (80-) 329, 1637–1639 (2010). https://doi.org/10.1126/science.1194372

El-Kady, M.F., Strong, V., Dubin, S., Kaner, R.B.: Laser scribing of high-performance and flexible graphene-based electrochemical capacitors. Science 335, 1326–1330 (2012). https://doi.org/10.1126/science.1216744

Yang, X., Cheng, C., Wang, Y., Qiu, L., Li, D.: Liquid-mediated dense integration of graphene materials for compact capacitive energy storage. Science (80-) 341, 534–537 (2013). https://doi.org/10.1126/science.1239089

Lin, J., Peng, Z., Liu, Y., Ruiz-Zepeda, F., Ye, R., Samuel, E.L.G., Yacaman, M.J., Yakobson, B.I., Tour, J.M.: Laser-induced porous graphene films from commercial polymers. Nat. Commun. 5 (2014). https://doi.org/10.1038/ncomms6714

Xu, Y., Fei, Q., Page, M., Zhao, G., Ling, Y., Chen, D., Yan, Z.: Laser-induced graphene for bioelectronics and soft actuators. Nano Res 14, 3033–3050 (2021). https://doi.org/10.1007/s12274-021-3441-9

Ye, R., James, D.K., Tour, J.M.: Laser-induced graphene. Acc. Chem. Res 51, 1609–1620 (2018). https://doi.org/10.1021/acs.accounts.8b00084

Zergioti, I.: Laser printing of organic electronics and sensors. J. Laser Micro Nanoeng. 8, 30–34 (2013). https://doi.org/10.2961/jlmn.2013.01.0007

Parmeggiani, M., Zaccagnini, P., Stassi, S., Fontana, M., Bianco, S., Nicosia, C., Pirri, C.F., Lamberti, A.: PDMS/Polyimide composite as an elastomeric substrate for multifunctional laser-induced graphene electrodes. ACS Appl. Mater. Interfaces 11, 33221–33230 (2019). https://doi.org/10.1021/acsami.9b10408

Zhu, C., Tao, L.Q., Wang, Y., Zheng, K., Yu, J., Chen, L.X., Huang, X.: Graphene oxide humidity sensor with laser-induced graphene porous electrodes. Sens. Actuators B Chem. 325 (2020). https://doi.org/10.1016/j.snb.2020.128790

Jayapiriya, U.S., Rewatkar, P., Goel, S.: Direct Electron transfer based microfluidic glucose biofuel cell with CO2 laser ablated bioelectrodes and microchannel. IEEE Trans. Nanobiosci. 1241 (2021). https://doi.org/10.1109/TNB.2021.3079238

Li, L., Zhang, J., Peng, Z., Li, Y., Gao, C., Ji, Y., Ye, R., Kim, N.D., Zhong, Q., Yang, Y., Fei, H., Ruan, G., Tour, J.M.: High-performance pseudocapacitive microsupercapacitors from laser-induced graphene. Adv. Mater 28, 838–845 (2016). https://doi.org/10.1002/adma.201503333

Rathinam, K., Singh, S.P., Li, Y., Kasher, R., Tour, J.M., Arnusch, C.J.: Polyimide derived laser-induced graphene as adsorbent for cationic and anionic dyes. Carbon N. Y 124, 515–524 (2017). https://doi.org/10.1016/j.carbon.2017.08.079

Khattak, Z.J., Sajid, M., Javed, M., Rizvi, Z., Awan, H.M.: Mass-Producible 2D nanocomposite-based temperature-independent all-printed relative humidity sensor. ACS Omega (2022). https://doi.org/10.1021/acsomega.2c00850

Lee, J.-U., Shin, Y.-J., Yang, H.-J., Shin, B.-S.: A study on the fabrication of laser-induced graphene humidity sensor for mounting on a disposable mask. J. Korean Soc. Ind. Converg 23, 693–699 (2020). https://doi.org/10.21289/KSIC.2020.23.4.693

Zanoni, J., Moura, J.P., Santos, N.F., Carvalho, A.F., Fernandes, A.J.S., Monteiro, T., Costa, F.M., Pereira, S.O., Rodrigues, J.: Dual transduction of h2o2 detection using zno/laser-induced graphene composites. Chemosensors. 9 (2021). https://doi.org/10.3390/chemosensors9050102

Choi, J., Baek, S., Jeon, S., Yim, C.: Laser-induced graphene on a quartz crystal microbalance for humidity sensing. Crystals 11, 289 (2021). https://doi.org/10.3390/cryst11030289

Stanford, M.G., Yang, K., Chyan, Y., Kittrell, C., Tour, J.M.: Laser-induced graphene for flexible and embeddable gas sensors. ACS Nano 13, 3474–3482 (2019). https://doi.org/10.1021/acsnano.8b09622

Han, T., Nag, A., Simorangkir, R.B.V.B., Afsarimanesh, N., Liu, H., Mukhopadhyay, S.C., Xu, Y., Zhadobov, M., Sauleau, R.: Multifunctional flexible sensor based on laser-induced graphene. Sensors (Switzerland) 19, 13–22 (2019). https://doi.org/10.3390/s19163477

He, M., Wang, Y., Wang, S., Luo, S.: Laser-induced graphene enabled 1D fiber electronics. Carbon N. Y 168, 308–318 (2020). https://doi.org/10.1016/j.carbon.2020.06.084

Chhetry, A., Sharifuzzaman, M., Yoon, H., Sharma, S., Xuan, X., Park, J.Y.: MoS2-decorated laser-induced graphene for a highly sensitive, hysteresis-free, and reliable piezoresistive strain sensor. ACS Appl. Mater. Interfaces 11, 22531–22542 (2019). https://doi.org/10.1021/acsami.9b04915

Carvalho, A.F., Fernandes, A.J.S., Leitão, C., Deuermeier, J., Marques, A.C., Martins, R., Fortunato, E., Costa, F.M.: Laser-induced graphene strain sensors produced by ultraviolet irradiation of polyimide. Adv. Funct. Mater 28, 1–8 (2018). https://doi.org/10.1002/adfm.201805271

Dallinger, A., Kindlhofer, P., Greco, F., Coclite, A.M.: Multiresponsive soft actuators based on a thermoresponsive hydrogel and embedded laser-induced graphene. ACS Appl. Polym. Mater 3, 1809–1818 (2021). https://doi.org/10.1021/acsapm.0c01385

Ling, Y., Pang, W., Li, X., Goswami, S., Xu, Z., Stroman, D., Liu, Y., Fei, Q., Xu, Y., Zhao, G., Sun, B., Xie, J., Huang, G., Zhang, Y., Yan, Z.: Laser-induced graphene for electrothermally controlled, mechanically guided, 3D assembly and human–soft actuators interaction. Adv. Mater 32, 1–9 (2020). https://doi.org/10.1002/adma.201908475

Grossman, J.C., Getachew, B.A., Bergsman, D.S.: Laser-induced graphene from polyimide and polyethersulfone precursors as a sensing electrode in anodic stripping voltammetry. ACS Appl. Mater. Interfaces 12, 48511–48517 (2020). https://doi.org/10.1021/acsami.0c11725

Nayak, P., Kurra, N., Xia, C., Alshareef, H.N.: Highly efficient laser scribed graphene electrodes for on-chip electrochemical sensing applications. Adv. Electron. Mater. 2 (2016). https://doi.org/10.1002/aelm.201600185

Lan, L., Le, X., Dong, H., Xie, J., Ying, Y., Ping, J.: One-step and large-scale fabrication of flexible and wearable humidity sensor based on laser-induced graphene for real-time tracking of plant transpiration at bio-interface. Biosens. Bioelectron 165, 112360 (2020). https://doi.org/10.1016/j.bios.2020.112360

Boutry, C.M., Beker, L., Kaizawa, Y., Vassos, C., Tran, H., Hinckley, A.C., Pfattner, R., Niu, S., Li, J., Claverie, J., Wang, Z., Chang, J., Fox, P.M., Bao, Z.: Biodegradable and flexible arterial-pulse sensor for the wireless monitoring of blood flow. Nat. Biomed. Eng 3, 47–57 (2019). https://doi.org/10.1038/s41551-018-0336-5

Bobinger, M.R., Romero, F.J., Salinas-Castillo, A., Becherer, M., Lugli, P., Morales, D.P., Rodríguez, N., Rivadeneyra, A.: Flexible and robust laser-induced graphene heaters photothermally scribed on bare polyimide substrates. Carbon N. Y 144, 116–126 (2019). https://doi.org/10.1016/j.carbon.2018.12.010

Shaikh, S.F., Hussain, M.M.: Multisensory graphene-skin for harsh-environment applications. Appl. Phys. Lett. 117 (2020). https://doi.org/10.1063/5.0017769

Zang, X., Shen, C., Chu, Y., Li, B., Wei, M., Zhong, J., Sanghadasa, M., Lin, L.: Laser-induced molybdenum carbide–graphene composites for 3D foldable paper electronics. Adv. Mater 30, 1–8 (2018). https://doi.org/10.1002/adma.201800062

Jeon, S., Park, R., Jeong, J., Hong, S.W.: Laser fabrication of graphene-based materials and their application in electronic devices. J. Microelectron. Packag. Soc. 28, 1–12 (2021)

Huang, L., Su, J., Song, Y., Ye, R.: Laser-induced graphene: en route to smart sensing. Nano-Micro Lett 12, 1–17 (2020). https://doi.org/10.1007/s40820-020-00496-0

Zang, X., Shen, C., Chu, Y., Li, B., Wei, M., Zhong, J., Sanghadasa, M., Lin, L.: Laser-induced molybdenum carbide–graphene composites for 3D foldable paper electronics. Adv. Mater. 30 (2018). https://doi.org/10.1002/adma.201800062

Ye, R., Chyan, Y., Zhang, J., Li, Y., Han, X., Kittrell, C., Tour, J.M.: Laser-induced graphene formation on wood. Adv. Mater 29, 1–7 (2017). https://doi.org/10.1002/adma.201702211

Park, S.Y., Kim, Y.H., Lee, S.Y., Sohn, W., Lee, J.E., Kim, D.H., Shim, Y.S., Kwon, K.C., Choi, K.S., Yoo, H.J., Suh, J.M., Ko, M., Lee, J.H., Lee, M.J., Kim, S.Y., Lee, M.H., Jang, H.W.: Highly selective and sensitive chemoresistive humidity sensors based on rGO/MoS2 van der Waals composites. J. Mater. Chem. A 6, 5016–5024 (2018). https://doi.org/10.1039/c7ta11375g

Lin, J., Peng, Z., Liu, Y., Ruiz-Zepeda, F., Ye, R., Samuel, E.L.G., Yacaman, M.J., Yakobson, B.I., Tour, J.M.: Laser-induced porous graphene films from commercial polymers. Nat. Commun 5, 1–8 (2014). https://doi.org/10.1038/ncomms6714

Author information

Authors and Affiliations

Contributions

Dr. Memoon Sajid supervised the work and contributed in results compilation and manuscript writing. Faisal Saaed, Gohar Hussain, and Farhad performed the experimentation, Mazhar Javed and Zarak Jamal Compiled the results, Mohsin Saleem did the characterizations, and Dr. Khalid Rehman helped in assessment of results and manuscript preparation.

Corresponding author

Ethics declarations

Ethical Approval

There were no animal or human studies involved in this work.

Competing Interests

It is declared that the authors have no competing interests as defined by Springer, or other interests that might be perceived to influence the results and/or discussion reported in this paper.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

ESM 1

(DOCX 1.07 MB)

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sajid, M., Awan, F.S., Javed, M. et al. Fabrication, Comparison, Optimization, and Applications of Conductive Graphene Patterns Induced via CO2 and Diode Lasers. Lasers Manuf. Mater. Process. 10, 276–295 (2023). https://doi.org/10.1007/s40516-023-00209-6

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40516-023-00209-6